Verne Simons

Senior Editor, Jp

Verne Simons

Senior Editor, Jp

Clunk…Clunk

My 23-year-old daughter has a ’00 TJ that we bought about 21⁄2 years ago. It has the 4.0L, five-speed, and Dana 44 rearend that is supposed to have a Trac-Loc, but I’ve never cracked it open to confirm. I drive the Jeep when she is in town visiting, and last Christmas I noticed that when you run through the gears, unless you are shifting very slowly and carefully, you get a clunk from the rear end that you feel and hear as the drivetrain delivers the torque. I know you love those technical terms, but clunk is a very accurate description! It happens in all gears, so it is not the tranny—it definitely is coming from the rear. You also get it when you have to let off the gas in traffic and then accelerate, no shifting of gears required.

I took a cursory look at the U-joints and they seemed fine. The Jeep has 82K on it now, and I know there are clutch-packs in a limited slip that can need replacing. Your thoughts are appreciated, thanks!

Brett Siegrist

Denver, CO

Hmm, Well I doubt that it is the Trac-Loc needing a rebuild. While it may be worn out, the differential should not make a noise unless something is broken internally (how hard is your daughter on this Jeep?). The first thing I would do is check the Jeep’s transmission/T-case mount (which can cause a clunk if worn out or broken). You can do this by sticking your head up under the Jeep and having a look at the mount. Worst-case scenario is that you may have to pull the belly pan/center skid plate to inspect the T-case mount. From there I’d move on to checking the control arm bushings in the rear control arms. Just have a look at them and yank on the control arms a time or two to make sure everything is tight.

After that I’d check the rear driveshaft U-joints. I’d do this by raising the rear axle off the ground (chock the front tires and put the rear axle securely on jack stands) and then climb under there and try turning the rear driveshaft when the transmission is in neutral. It can be hard to see this when the Jeep is on its tires and the drivetrain can’t turn. If one or more of the U-joints is worn out, you’ll know when you turn the driveshaft.

If the U-joints are fine, then you should notice the noise is coming from inside the rear differential. You can kind of isolate where the noise is coming from by turning the pinion backwards and forwards and by pushing up and pulling down on the pinion. There should be a small amount of play when you turn the pinion (it’s called backlash and is measured with a dial indicator and should be less than .01 of an inch). If there is more play than that, or the pinion moves up or down, then the pinion bearings in the rear axle need to be replaced. If the side gears of the limited slip are worn or broken they can make a noise such as you describe. Visual inspection is the only way to confirm this, and that may mean pulling the differential from the axle.

Clunk…Clunk Part Deux

Verne, thanks so much for the detailed info and directions. Before I launch on that journey, I have a follow-up question. I dropped the driveshaft off the pinion last night. The pinion had virtually no play in any direction, nice and tight, and the wheels were on the ground. On the T-case side (NP231, 2.72:1), there was enough rotational play that I could feel/hear contact as I twisted it back and forth. It was a small amount, but enough that again I could feel contact on both sides of the rotation. Normal? Bad news?

Brett Siegrist

Denver, CO

Brett, I think the T-case is probably okay, but it’s always a little hard when describing rotational movement via email because a little turn to you might be a huge turn to me. A little turn before engaging gears is normal.

Still, I’d check the fluid in the T-case and make sure it is full (it uses ATF). NP231s like the one in your daughter’s Jeep are pretty darn tough and can last well over 200k miles, let alone 82k miles—unless they are run without fluid or in reverse for a long long time. Interestingly, the oil pump in those T-cases only pumps while the Jeep is going forward. That’s all right, because most people only ever reverse for a few hundred feet at most at a time.

The source of the clunk could be in the axle, but with the link-style suspension, it also could be in the control arms, T-case bushings, U-joints, or any of several places.

The suspension lift without an slip-yoke eliminator makes me immediately suspect the U-joints because generally any TJ with a lift is exceeding the angularity of the U-joints in the rear driveshaft—although if you have the driveshaft out, you would know if the U-joints are worn or not. Also, it is possible that the factory slip yoke at the back of the T-case is worn and could be the source of the clunk, but it’s unlikely (you would notice wear on the splines of the yoke). I’m sure you’ll find the source and hopefully this helps you look in the right places.

Clunk…Clunk III (We’ve Identified the Problem)

Verne, since you’ve basically become a member of the family now, I thought I’d show you what I found! The attached pics are the passenger side lower control arm mount. The bolt hole has elongated and the axle is sliding back and forth about a 1⁄2-inch—bizzare! Seems like an easy fix. I figure I’ll weld some small circular pieces of plate steel on the outsides of the bracket. The bracket itself is in good shape.

One last question since I’m a leaf-spring guy. There is no load on the control arm, is there? As long as I stabilize everything, I can just drop the control arm down and repair?

Brett Siegrist

Denver, CO

Cool, I knew you’d find it. Somehow that bolt loosened and was able to move back and forth. Your plan to fix it is right on, but still, I don’t think I’d pull the control arm with the suspension loaded. While you might be able to do it safely, if for some reason something bumps the axle, it could cause a disaster. This is especially true if you’re gonna be welding under there.

I’d put the Jeep on jackstands (to the frame), pull the wheels, and let the rear suspension droop out. You may have to pull the lower end of the rear shocks and then pull the rear coils out (it sounds horrible, but really just a few nuts other than the lug nuts). Now you can cycle the suspension to about ride height and pull the lower control arm without worrying about something popping out violently. Just loosen both ends and then take the bolt loose from that one end (as a rule only pull one control arm at a time on these linked suspensions or getting the control arms back in is gonna take some work). You could also eyeball the bushings in the control arm to make sure they are in good shape.

I’d also bet that bolt is no good, so be ready to replace it with a high-grade bolt (like Grade-8 if standard or 10.9 if metric) and locking nut (or put some thread-locking compound on the bolt to keep it from loosening again).

Das German Transmission und Road Stance

I own a ’12 Jeep Wrangler Unlimited Arctic and I am having a Magnuson Supercharger installed. Do you know of any company that offers suspension modifications to help my non-lifted Wrangler handle (corners) better? All my inquires go nowhere because I don’t want to lift my Jeep. I am using Method MR305 Matte Black NV Wheels 17x8.5, and P265/70R-17 Michelin LTX A/T2 tires. My Jeep sits about a 1⁄2-inch lower than stock due to the tire height, which is fine with me. I seldom go off-road and when I do, it is only on gravel or dirt for a very short distance. Do you have any suggestions?

Also do you know of a company offering a kit to modify (strengthen) the automatic transmission in a ’12 Jeep Wrangler Unlimited? I am having a Magnuson Supercharger installed and would like to beef up the transmission to handle the extra power.

Ronald Corte

Via email

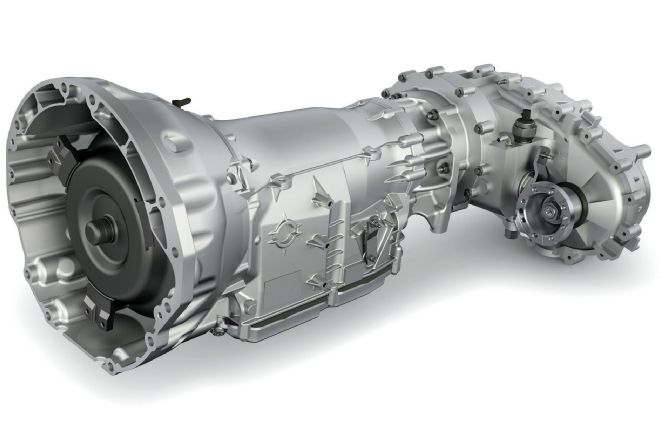

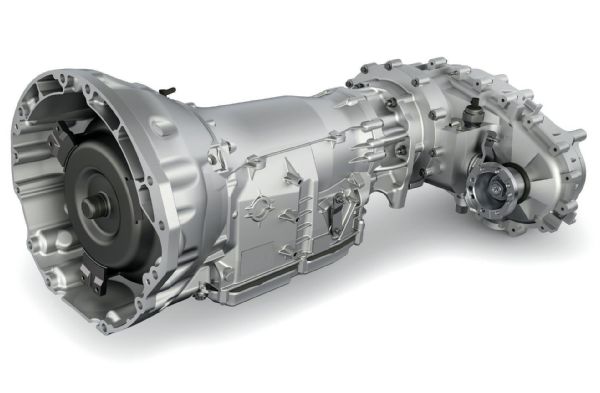

Wunderbar! First off, the auto tranny of which you speak is called the W5A580 or NAG1 five-speed transmission. This tranny has a beefy heritage spending time in SRT8 Grands up to 2012 behind healthy Hemis (amongst other powerful vehicles from Chrysler Company and Mercedes). This tranny seems to be pretty robust and, according to allpar.com, up to about 700 hp is where the tranny’s clutches can’t handle the Fourth to Fifth shift under full load—wow. Let us know if you plan on running 700 hp through yours and then shifting from Fourth to Fifth at full throttle. Otherwise we have heard that they can be susceptible to failure after water intrusion (don’t think that’s gonna be a problem for you). I suppose if you really wanted to take care of your transmission, you could run a tuner that gives real-time transmission temp info and keep an eye on that. Heat is generally the main enemy of all auto transmissions.

Also, I think I know what you are going for with your Wrangler: maybe more of an on-road sports vehicle than an off-road trail rig. I get it, I think. I like the idea if it’s done well. Just be sure to do it with taste, and no big heavy wheels or obnoxious paint schemes please. Check out the Eibach Pro Coil Spring Kit by Quadratec with Bilstein HD Shocks. This suspension offers a slightly lower than stock stance and improved handling. I think it’s right up your alley. If you like the sound of that, but want to retain the stock height, you could probably combine the Eibach springs with budget boost spacers like those from Daystar.

It’s an NP249

I recently picked up a low-mileage (135,000 miles) ’94 ZJ Limited for $4,000. It has the V-8 and auto with a transfer case that has 4-Hi, Neutral, and 4-Lo. I have flushed all the fluids, cleaned it, gave it a tune up, and now almost everything works. The info center keeps telling me to service the 4WD switch. Any idea what that is? My local Chrysler dealer said their best guess was to start throwing parts at it. I also would like to fit some 31s on it. What would you recommend for a high quality lift? It is mainly a daily driver with a little weekend trail driving. I mainly need the tires and clearance for the snow drifts in the Wyoming winter. Is there anything I should keep my eye on mechanically? And what T-case is this? Thanks and love the mag.

Cfrider69

Via email

I’m gonna start by answering your last question first. Your Jeep has the NP249 transfer case. Unfortunately, that T-case lacks a low range center differential lock. Many have swapped to either NP231s or NP242s, both of which have a true part-time 4-wheel drive in both 4-Hi and 4-Lo. As for a suspension lift, we have had pretty good luck with Rubicon Express suspension systems in ZJs (and XJs) in a 31⁄2-inch flavor. I personally prefer the adjustable control arms with rubber bushings on at least one end to help soak up any vibrations. Otherwise, I’d keep my eyes peeled on the CV boots on the front axle shafts, and rear drive shaft U-joints unless you also add a slip-yoke eliminator at some point. If something fails, it will let you know when it quits working. As far as the info center, I am not sure what to tell you. It seems like those early ZJs with the info centers frequently have issues with that switch or message. I’d start by checking all the connections and possibly replacing the switch on the T-case. If that does not work, you can either replace the info center or ignore the message and Jeep on.

Have You Been to the Torque Down Under?

Hello great magazine I must say. I live in Australia and I’ve just brought a brand new 2-door JK with what they call a “Special Ops Package,” which is an AEV front bumper and winch, rock rails and mag wheels. I changed the tires from 245/75R17 to 265/75R17, not a big jump as I just wanted wider feet and not longer legs. This one is a 3.6L V-6 with the 6-speed manual. My problem with this Jeep is the torque of the engine or more to the point, the lack of it low down in the low rev’s, let’s say from 1,000-3,000 rpm range. What can I do, if anything, to get more torque without supercharging the engine as it is still under warranty and I’d like to keep it that way? Your thoughts would be greatly appreciated.

Regards Steve

Australia WA

G’day Steve, thanks for the compliments and the JK sounds cool. I don’t think we get that package on this side of the Earth. Assuming you need the torque for rock work, I’d say the best option for you might be to look for a NP241 Rock-Trac transfer case out of a Rubicon. Also, we are currently testing a heavier Centerforce Clutch/Jp magazine flywheel for JKs. The theory being that a heavy flywheel will help build torque down low like on the old odd-fire Buick 225ci V-6s. Editor Trasborg reports that so far he can lug our ’07 JK equipped with the prototype flywheel down below 500 rpm in 4-Hi without stalling. Also, you could maybe up the torque a little bit with a tuner, air intake system, and exhaust, but it’s not gonna make much of a difference in torque. Alternatively you could look for a Rubicon or a JK like yours with the automatic transmission. That will give you the feel of a little bit more torque from the automatic torque converter slip. Oh, by the way please say hello to the brumby or the roo under the gum tree for us.

Rusty…

I am curious about one aspect of my Jeep Wrangler. I found a great dealership in Henderson, Nevada, and purchased a new ’10 Jeep Wrangler Unlimited Sport in December 2009. I live in Ely, Nevada, which is at 6,500 feet with plenty of mountain wheeling and lots of snow and cold temps in the winter. Anyway, I always look my vehicles over carefully to see where everything is and what makes it tick. Without being in the snow or rain yet, I noticed a great deal of rust underneath the Jeep. Axles, driveshafts, frame and so forth, were all looking pretty rusty. That didn’t seem right to me. Later, I was shopping north of here in Elko and stopped at their Jeep dealership. I looked at all of their new Wranglers on the lot. They had not moved except for maybe a test drive or two. They were also rusty. Being naturally curious, I started asking Jeep dealers about it. They were clueless. One said they just missed painting some of the areas black. Haha! There was a memo from Jeep that severe snow might cause corrosion and should be checked at the dealership. Nevada was not on that list. I am interested in what your take on the matter might be? Oh, by the way, I am loving Jpmagazine on my Kindle.

Bob Moreland

Ely, Nevada

Good to hear about the Jp magazine on Kindle. That’s awesome! I’m sure many of our readers don’t know that Jp is available on Kindle. As far as the rusty Jeeps I think you’ve hit on something that most would not notice until it’s too late. I had a look under my own Arizona-based ’13 JK with about 5,000 miles to see what was painted and what was not. A brief look reveals that the driveshafts and yokes are bare steel and have a little light rust that I would call “surface rust.” That is rust that is basically just coating the metal and not forming flakes—man this sounds like some kind of dubious non-science. Also, there is a touch of surface rust on the exhaust system, but not much. Otherwise, everything looks good, and I haven’t heard about any rusting memos from Jeep. Maybe mine got the proper paint coating under there and I am under-informed? Maybe it’s just because my JK is a (very young) Southwestern car. I don’t know. Maybe this is an issue relating to ’10-’12 JKs? Maybe Nevada uses that nasty liquid snow melt stuff that seems to be popular in some municipalities. Jp readers with newer JKs, let us know if your Jeeps are all rusty on the belly or not, especially those of you in the Midwest rust belt.

Stubborn Rear Main

I purchased an ’04 LJ, bone stock with the inline-six, auto tranny and about 56,000 on the odometer 21⁄2 years ago. It now has 80,000 on it. I knew the rear main seal had a small leak, a small drip every few days when I purchased it. Knowing it’s not “if” but “when” the rear main is going to leak, I didn’t think it was a big deal.

I had the seal replaced by a local mechanic and thought I was good to go. One year to the day later, I started noticing significant drips on the garage floor after driving. I took it back to the mechanic and he said that something must of gotten “banged and bent” at the mating surfaces at some point in the Jeep’s life. This thing never saw dirt until I got it. When I told them everything underneath was pristine and I never saw any sign of damage to the factory skid plates and no signs of damage to the mating surfaces. Their reply was that maybe it was due to the modifications I now had on the Jeep.

I am running a 4-inch TeraFlex longarm, a 1-inch body lift, and a 1-inch engine lift, with a lot of other goodies, but I have never heard of any this causing a rear main leak. I believe they were referring to the engine lift in particular. Have you ever heard of this? Makes no sense to me since the leak was there before the mods.

I went to a second mechanic in my area that is highly recommended. They replaced the rear main and I was good for about two weeks, then it started leaking again. They immediately took it back in and looked at it. They agreed it was leaking and not just residual oil on the skid plates and so forth from the original fix. They replaced the seal again, no questions asked. For the record I had them check for “damage” while doing the work—none found.

It has been about 8 months since the last fix and I am leaking again! You can clearly see the drips forming from the bottom of the rear main seal. The real head scratcher is they are inconsistent. It will drip then seems to stop or not drip nearly as much. Then drip really good, leaving a 2-inch or so diameter puddle overnight. This doesn’t include what has collected on the inside of the skid plates.

I have tried Bar’s rear main seal leak additive, to no luck. I have recently read to switch to “dino” oil, instead of synthetic. The theory being that the molecules are larger than synthetic and should not work through the gaps around the seal. Internet mumbo jumbo, or worth trying? I am just about willing to try anything at this point. I don’t mind spending money on my Jeep for good mods/fixes, but tossing $500 at my fourth rear main seal in 21⁄2 years is ridiculous! Is this normal and just something I am going to have to live with?

You guys have always given great advice. I find something every month in your magazine that I can use. I hope you can help me out here, or give me some suggestions to point me in the right direction. I am at a total loss!

Chris Jackson

Via email

Man that is a tough one. Out of four Jeeps with 4.0Ls that I personally have owned with mileage ranging from 60,000 to 120,000, I have never had to replace a rear main seal on one. Maybe that’s just dumb luck. Editor Trasborg reports that every 4.0L he has met leaks from the rear main. He says “I’ve never replaced one. If it’s leaking badly, I park with the nose downhill.” Either way, and even though rear main seals can be a stubborn fix, one shot out of five really should have been good—or at least slowed the flow. That is assuming the mechanics were using good replacement parts and were doing the job properly.

It also seems the multiple attempts at fixing the rear main by multiple shops on your Jeep indicates that something else could be at fault. I am wondering if there is somehow some imperfection in your block. Hypothetically, there could be some unusual porosity or crack in the in the area of the rear main seal. Otherwise there could be a similar unusual flaw in the rear bearing cap or oil pan that is somehow eluding the mechanics inspections. Is it possible that the leak is actually originating higher on the back of the engine? Maybe even a leaky valve cover that is dripping down the back of the block? It’s just a thought that might help. Lastly, it could be that you keep getting bad rear main seal replacements and your LJ is destined to leak. Good luck and let us know what you find.

Write Us!

Got a tech question you’re just itching to get answered? Send it on in to Jp Magazine, Your Jeep, 831 S. Douglas St., El Segundo, CA 90245, or e-mail it to verne.simons@jpmagazine.com.