Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Imagine your 4x4 equipped with larger-than-stock tires ripping across the desert or mud bog when all of a sudden a hidden berm, log, or ditch sends you skyward. You land with a crash and likely do one of two things: get out and check for damage, or spin a U-turn and do it again because it was so much fun. Either way you may want to consider just how much abuse your axles are taking.

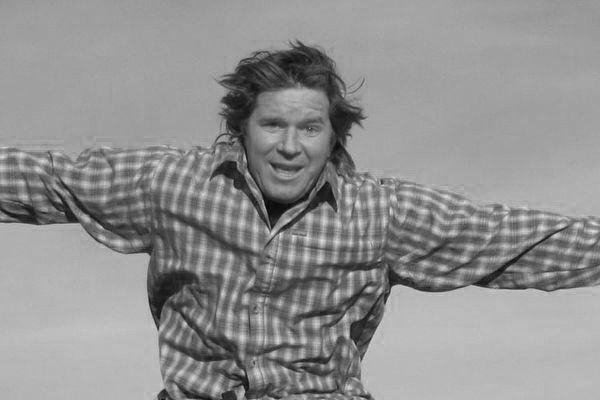

Yeehaw! It’s all fun and games until the landing. That is when the ground pushes up on your axletube via tires and wheels while your truck pushes down via body, frame, and suspension. Eventually something might give in.

Yeehaw! It’s all fun and games until the landing. That is when the ground pushes up on your axletube via tires and wheels while your truck pushes down via body, frame, and suspension. Eventually something might give in.

When OEMs source an axlehousing they have two priorities. Will it do the job required by the stock vehicle, and at what cost? When we four-wheelers get a hold of an axle we inevitably put greater stresses and abuse on it than the OEMs or axle manufacturers ever required.

Axlehousings often bend because of constant pounding from going fast, landing from big jumps, or hitting a trail obstacle (rock, tree, ditch) at speed. An axle truss must gusset the axletube against this by forming a long low triangle away from the axletubes such as this unit on the rear of the infamous Herbst Land Shark Class 1 Buggy.

Axlehousings often bend because of constant pounding from going fast, landing from big jumps, or hitting a trail obstacle (rock, tree, ditch) at speed. An axle truss must gusset the axletube against this by forming a long low triangle away from the axletubes such as this unit on the rear of the infamous Herbst Land Shark Class 1 Buggy.

One way to care for your gear-spinning, shaft-protecting axlehousing is to install a truss. A truss is a simple or elaborate steel structure that gussets and supports the axletubes in such a way as to deter bending from excessive use and abuse, something we wheelers call fun.

PhotosView Slideshow