Kevin McNulty

Former Editor, Mud Life

Kevin McNulty

Former Editor, Mud Life

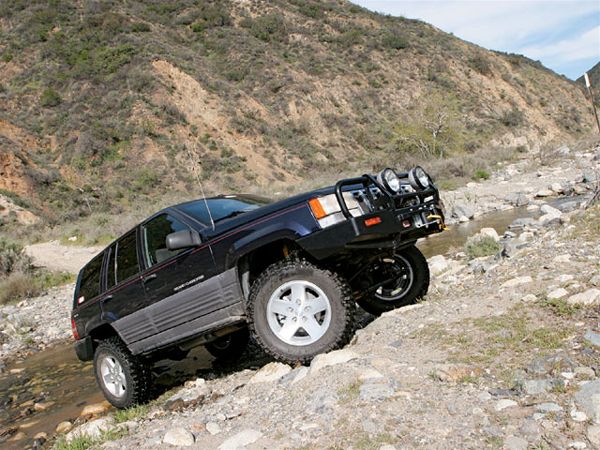

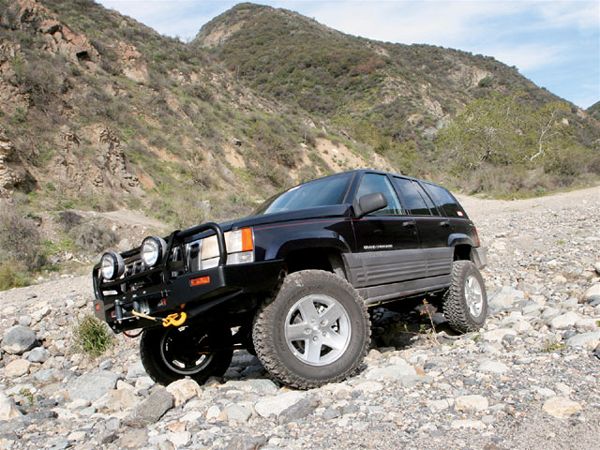

The '93-'98 Grand Cherokee is a great building block for a trail rig. And if you can get past a couple minor problems such as the undesirable unibody, the ZJ has lots of interior room for stashing all kinds of adventure gear. Also some versions of the Grand came with the powerful 5.2L or (only for '98) the 5.9L V-8 engine, and even better, the aging Jeep can be purchased today for a song.

I've had a '97 Grand for a few years now, but it had just been taking up a parking space at the office. I hadn't driven it more than 500 miles in the last two years because I was unhappy with the aftermarket suspension and axle conversion that had been installed on it. The Jeep had a full locker in the rear, which made the rear tires chirp and squeal every time it turned a corner. The locker also clicked and ratcheted, and when it unloaded it caused the vehicle to violently jerk. The factory suspension didn't ride too badly and was comfortable, but the installed aftermarket suspension was obnoxious and squeaked like a horse-drawn buckboard.

Other issues I had with my ZJ were the Dana 30 axle up front and the weak Chrysler rear axle with aluminum center-section in the rear. These axles are great for everyday street driving and mild four-wheeling, but anything beyond that and the dependability becomes questionable, especially with a V-8. There is a plethora of upgrades available for the Dana 30 axle, but it's still a Dana 30, and there aren't many parts available for the aluminum rear axle. It's best just left alone or swapped out.

I knew that if I let the Grand sit long enough a solution for the vehicle's problems would appear, and in the Apr. '08 issue of 4-Wheel & Off-Road, I reviewed the new Dana 44 Rubicon (JK) axles available from Jeep. As soon as the boys from Mopar told me they were going to start selling these crate axles, I immediately thought of my abandoned ZJ. What else could I ask for? The axles are far stronger and have 4.10 gears with selectable electric lockers.

I needed a well-mannered suspension so I called JKS Manufacturing. I have been reviewing the JKS suspension components for a while now and I really like how the control arms are fit with rubber bushings rather than Delrin or polyurethane, and the rubber bushings dramatically help reduce the transfer of road noise into the vehicle. The bushings don't squeak or require any maintenance, and they help absorb torsional force while four-wheeling. The control arms and rubber bushings also offer a smoother, softer, and quieter ride. JKS didn't have a complete bolt-in kit for my Jeep, since this is a custom axle swap and build, so I ordered adjustable control arms, track bars, sway-bar disconnects, and super-cool ACOS Pro adjustable coil spacers with bumpstops for the front.

The key was to build a daily driver/adventure Jeep with a suspension that was safe, comfortable, reliable, and controllable at high speed. I didn't want or need a super-slinky rig with 20 inches of articulation capable of crawling over small mountains. I ordered ARB Old Man Emu Nitrocharger gas shocks, coil springs, and steering stabilizer. The OME components are designed and tested in Australia's harsh outback conditions. I have had good experience with OME suspensions in the past.

This was a comprehensive axle and suspension conversion, which required lots of fabrication and suspension geometry know-how. The front swap was almost a direct bolt-in, however the rear axle required the most fabrication. After the swap, the ZJ rode comfortably, was quiet, and is now far more capable than factory.

PhotosView Slideshow

PhotosView Slideshow