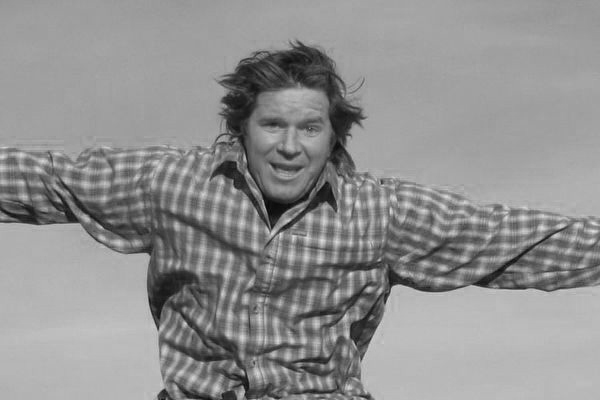

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

BluFerd, our ’79 Ranch Raptor (aka F-150) is a good truck, but even though it’s shod with the tough General Grabbers we’d hate to walk home from the back forty if we ever encounter a flat tire. We mounted up a fifth 35-inch Grabber on a 15x8 Mickey Thompson Sidebiter as a spare tire and in an afternoon wrangled a homebrew bedside mount for the big rubber.

Our goal was simple: Head to the local farm supply hardware store and come home with parts to build a simple yet tough mount for the spare, all while keeping bed space open for hauling lumber, logs, bales, and hogs. Mounting the spare underneath is a good option, but many larger tires don’t fit in the stock location. As a challenge we wanted to see if we could do it without the welder or tube bender, as many readers don’t have those higher-dollar tools. Here’s what we came up with for under $50. You could probably do it even cheaper.

PhotosView Slideshow