Pete Trasborg

Brand Manager, Jp

Pete Trasborg

Brand Manager, Jp

We are all familiar with the benefits that the Unitbody Jeep wagons have over their short-wheelbase siblings: longer wheelbase, better ride, securely locking cargo area, and nearly-dry interiors-to name but a few.

BEFORE

BEFORE

We like the benefits so much we often ignore one of the big shortcomings: Small wheelwell openings require more lift to fit the same-size tire as the short wheelbase siblings. Up until now, we've just lived with it, or half-assed flares onto the Jeeps to keep mudslinging to a minimum.

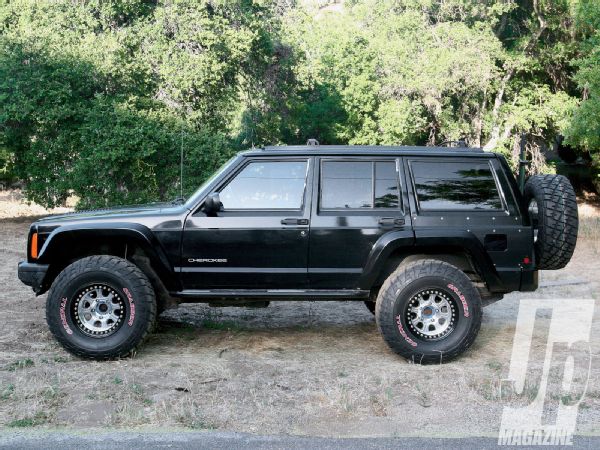

AFTER

AFTER

Enter Iceland Offroad: The company has been building fiberglass bumpers and cut-out fender flares for ZJs and WJs for the past 4 years. At the 2010 Easter Jeep Safari the company introduced its cut-out flares for the Jeep Cherokee, which the company claimed would allow a 35-inch tire on only 4.5 inches of lift (a 2-inch reduction from normal).

Not only do the flares allow the Cherokee owner to open up the fenderwells, they look better than any other cut-out fender flare on the market, and they look way better than hacked-in TJ flares (ours included). Like all of the Iceland Offroad products, these flares complement the design of the Jeep and look like they could have been a factory offering.

We started on the driver's side front, and since the washer fluid reservoir is located between the inner and outer fender, the first step was to remove it. We had already ditched the inner fender liner, so access was a no-brainer. While we didn't have to cut where the reservoir was located, we did have to drill holes for mounting bolts through the outer fender towards it. A couple of screws retain it to the inner fender; then the filler neck just pulls out.

We started on the driver's side front, and since the washer fluid reservoir is located between the inner and outer fender, the first step was to remove it. We had already ditched the inner fender liner, so access was a no-brainer. While we didn't have to cut where the reservoir was located, we did have to drill holes for mounting bolts through the outer fender towards it. A couple of screws retain it to the inner fender; then the filler neck just pulls out.

We have been doing everything we can to keep our '98 Cherokee low, and we were never really happy with the rear TJ flares we tacked onto it. We were running 30-inch tires with 2-inches of lift, and we had tried 31s, but they rubbed the pinch seam in the rear and inner fender in the front. Sure, we could have cut further, but we aren't huge fans of the no-flare look and a black XJ with no flares is going to look horrible all the time.

After contacting the company and asking if 33s would fit with 2-inches of lift-their response was "They should,"-we wasted no time in ordering a set for our four-door '98. We wanted to see how hard the install was and if it was really possible to fit 33s on an XJ with minimal lift and have it look good when it was all done. So without further ado, here's how the flares actually install and how they look with our chosen tire size.

PhotosView Slideshow