Most off-roaders realize how vital wheels are. Choosing a wheel based primarily on styling might be tempting, but doing some homework can reveal the best supporting cast for your vehicle.

Terminology

Wheelspeak is popular among four-wheelers. Whether reminiscing about old favorites like'80s Western turbine-style wheels or gawking at (mocking?) the latest creations from the dub world, offsets and bolt patterns are part of normal 4x4 conversation. Here is a quick review of standard wheel terms.

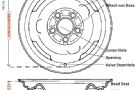

Diameter: The straight-across bead-seat-to-bead-seat distance-not the outer-edge distance.

Width: The distance from the front bead seat to the rear bead seat-not the outer-edge distance.

Bolt pattern: The number of bolt holes in addition to the distance from the centerline of one hole to the center line of the one farthest from it.

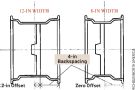

Backspacing: The distance from the wheel's outer edge to its mounting pad.

Offset: The relationship of the wheel's mounting pad to its centerline. Zero offset is when the pad is centered on the wheel. Positive offset is when the pad is outboard of the centerline (narrower track width). Negative offset is when the mounting pad is inboard of the centerline (wider track).

Load rating: The maximum weight a wheel can safely support. The sum of all four wheels' load ratings should exceed the vehicle's gross vehicle weight rating (GVWR) with some cushion to spare.

Construction

4x4s and steel wheels have a long, glorious history together. Although steel doesn't win many style points, it is generally strong, durable, and repairable. On the trail a deformed steel wheel that loses bead contact can often be hammered back into air-holding position. Rust can be the main drawback to steel wheels, which are normally two pieces: a rim that's welded to a centersection.

Alloy wheels are more upscale than steel, and many wheelers like the unsprung-weight advantage of alloy. According to Center Line, a 1-pound reduction in rotating mass equals an 8-pound static-weight savings. Lighter wheels also improve braking, acceleration, and fuel economy.

Materials and construction methods vary. "Aircraft-quality" A356-T6 aluminum is generally the primary metal, often combined with other nonferrous (nonsteel) metals to create a balance between lightness and load capacity. Exotic metals like ultralight titanium and even composites such as carbon-fiber are used for some racing and high-end sports car wheels. (Magnesium is the origin of mag wheel, a term that has become generic for stylish alloy [aluminum] wheels. True magnesium wheels are big-dollar racing equipment.

Alloy wheels are cast, forged, or CNC-machined from an aluminum billet. Low-pressure casting involves pouring molten metal into a mold. This is the most cost-effective method, but it also introduces pores and impurities into the finished product. Counterpressure casting uses vacuum to minimize the pores, creating a stronger wheel.

Cast wheels are identifiable by the rough finish of their unmachined areas. They're generally the most affordable alloy wheels. However, casting makes the wheels more brittle than other manufacturing processes do. Also, some manufacturers "test" their cast wheels by computer simulation only, passing the R&D savings onto the customer. If an alloy wheel price sounds too good to be true, check to see if it's actually DOT-certified and covered by a warranty, and read the online enthusiast bulletin boards to see how the manufacturer stands behind the product.

Forging uses high pressure to form solid alloy. The results can be three times as strong and 20 percent lighter than comparable-sized cast-aluminum wheels. Hot forging keeps the metal at a specific temperature while a press shapes it, sometimes realigning the aluminum molecules in a circular pattern to add strength. Cold forging retains more of the alloy's original grain, using only enough heat to make the metal malleable for forming.

Billet wheels generally have two pieces, with only the centersection actually CNC-machined from a single chunk of alloy. Alloy wheels can be one, two, or three pieces. One-piece wheels can be created by casting or forging. Two-piece wheels use bolts, rivets, or welds to join the centersection to the rim. Three-piece "modular" wheels consist of outer and inner rims that are bolted to a center. This often allows greater offset flexibility.

Three-piece wheels typically have rubber sealing gaskets that sometimes get damaged during impact or tire mounting. These wheels can be serviced, and the individual pieces can often be repaired or replaced as opposed to having to buy a whole new wheel.

The Hollander Wheel Interchange Manual is valuable for used-wheel shoppers. It isn't cheap but could be a worthy investment for a 4x4 club whose members wheel-shop at junkyards or on eBay and Craigslist.

The Hollander Wheel Interchange Manual is valuable for used-wheel shoppers. It isn't cheap but could be a worthy investment for a 4x4 club whose members wheel-shop at junkyards or on eBay and Craigslist.Fitment

In recent years, wheel diameters have grown proportionately to baseball players' biceps. The hardcore trail crowd used to balk at anything larger than 15 inches, claiming that "plus-sizing" yielded lower-profile tires lacking the necessary sidewall flex for optimal off-road performance. But as OE wheels have grown and tire technology progresses, larger diameter wheels are becoming more accepted for trail and competition. Their primary functional advantages are caliper clearance for high-performance disc brakes and additional room for knuckle bosses/tie-rod ends.

Spyderlock beadlocks president Clifton Slay elaborates on the big-wheel trend: "I first ran 18s and 20s in 2003 as part of Nitto's push to be the first to market in this trend that was trickling up from the street and show truck market. Beyond the cool Hot Wheels look, there was never a performance gain realized until you surpassed a 38-inch tire for most off-road situations. Wheelers are starting to discover that an 18 or 20 can be an excellent balance of sidewall flex control and ride qualities for 40-inch-plus tire applications. These wheel sizes will continue to gain commonality as people and tire manufactures understand their advantages."

Slay also says that 16-inch wheels are becoming an endangered species. "Tire companies are not building progressive 16-inch tire designs anymore, at least that a wheeler who requires beadlocks would look for," he says. "17 and 15 inches are my most-requested wheel sizes. 17 inches has the most choices in off-road tire styles, as this size is viewed as the most commonly desired for dirt enthusiast and competitors."

Competent tire stores and the mail-order retailers who advertise here are good sources for hits/fits information. When buying used, however, you might have to rely on word of mouth and your own trial fitment. While bolt patterns might be the same, bore centers and backspacings might not make wheels a direct interchange. For more information, refer to the Hollander Wheel Interchange Manual.

Some wheel spacers, such as these Trail Sport 1/2-inchers, simply slip over the existing studs. Other spacers and bolt-pattern-changing adapters bolt to the existing studs, using their own preinstalled studs for wheel-mounting duties.

Some wheel spacers, such as these Trail Sport 1/2-inchers, simply slip over the existing studs. Other spacers and bolt-pattern-changing adapters bolt to the existing studs, using their own preinstalled studs for wheel-mounting duties.

Wheel Spacers

Spacers used to be considered a Band-Aid fix for people who couldn't afford to buy the correct wheels for their vehicle or wanted an affordable dualie conversion. These days, however, quality billet spacers from companies such as Performance Wheel, Spider Trax, and Trail Sport provide 4x4 owners a reliable and cost-effective alternative to replacing their existing wheels. Spacers decrease effective backspacing, creating a wider track and increasing tire clearance between chassis components. Many aftermarket aluminum wheels have 4 1/4 to 5 or more inches of backspacing, which tucks in the tires under the wheelwells. Unfortunately, this often creates clearance issues when you're adding wider-than-stock tires and aftermarket axles, calipers, brake hoses, and lift kits.

Aftermarket spacers are available in most popular bolt patterns in thicknesses ranging from 1/2 to 4 inches. In some cases they require longer axle wheel studs for proper thread engagement. Additionally, most spacer manufacturers also offer adapters for changing bolt patterns. This can be a convenient solution when swapping in an axle that has a different pattern than the one it replaces.

Hutchinson's Rock Monster is among the few beadlocks that are DOT-approved. It uses a multipiece centersection and an inner liner.

Hutchinson's Rock Monster is among the few beadlocks that are DOT-approved. It uses a multipiece centersection and an inner liner.

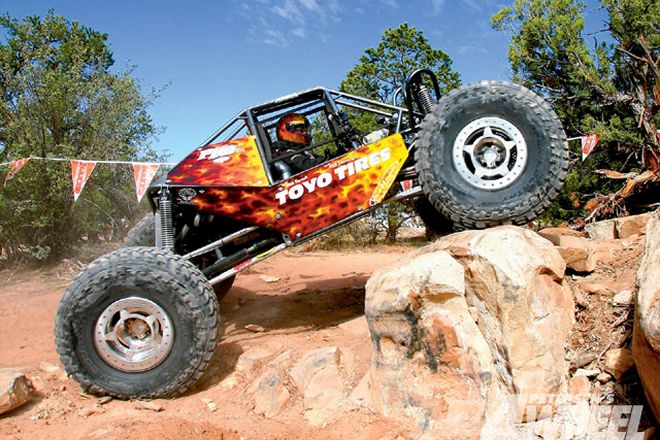

Beadlocks

Most extreme wheelers run beadlocks to keep their tires and wheels attached when running little to no air pressure. Like standard wheels, beadlocks are available in steel and aluminum. "Steel is everything anyone needs for rockcrawling," says High Impact president Greg Miller (who also sells alloy wheels and beadlocks for customers who want form and function). "Aluminum is prettier, but the weight savings is often canceled by the big tires. Racers like the small percentage savings in unsprung weight, but if weight is that important they should go to independent suspension."

The biggest beadlock news is the number of companies that are now casting aluminum one-piece wheels with an integral internal lock ring. These "born beadlocks" eliminate manufacturing variances. Spyderlock's Slay says, "Wheels with a weld-on application partially have their design element dictated by the structure of the host wheel. Wheels 'born' as beadlocks are not hindered in design in the same way. Weld-together beadlock are more likely to fail. However, this is very uncommon and is usually due to poor welding technique when the beadlock is first produced or when the end user overtightens the beadlock."

Slay continues to say that casting a beadlock creates an opportunity for optimal off-road backspacing. "I have traditionally built my Rock Rods and custom Jeeps around shallow backspacing-primarily for suspension clearances, maximum turning radius, and stability. Spyderlocks are molded at a 3 1/2-inch backspace; before the Spyderlock this was only accomplishable in steel. This offset also accommodates Jeep TJs and the new JKs, which normally require wheel spacers to realize full steering and prevent suspension rubbing with large tires."

Beadlocks also require routine maintenance. AEV recommends retorqueing the bolts at least once a month and replacing all bolts annually or sooner. The company also advocates a 50- to 100-mile seating period, after which the wheels should be balanced and retorqued.

Using beadlocks on road is a story in itself. DOT compliance involves manufacturers submitting their wheels to independent labs for construction and fatigue testing. Many companies' beadlocks are built to pass these tests, but smaller manufacturers find the testing too expensive. "The disadvantage of having this badge is it may open wheel companies to a larger liability," Slay says.

Rob Gillanders, an off-roader and industry lawyer practicing with the Gaitn Group in Seattle, elaborates: "Section 110 of the Federal Motor Vehicle Safety Standards (49 CFR 571, part 110) allows manufacturers to indicate wheels are DOT certified if they meet all requirements of the FMVSS. Those requirements are considered minimal safety standards and should not be treated as a safe harbor from either state law requirements or mean sheriffs restricting on-road use of beadlock rims. Best practice is to follow manufacturers' recommendations/warnings and consult state vehicle equipment regulations before taking your Moab-ready beadlocks out on the road. Also, choose a wheel manufacturer that follows SAE J2530 recommended guidelines for quality and durability." (These SAE guidelines are the wheel industry's current standard for policing itself.)

Beadlocks' outer rings are sacrificial, which is why many manufacturers offer them separately. The Spyderlock's impact-resistant features include a 3/4-inch-thick billet clamping ring and 3/8-inch Grade 8 bolts that are recessed into the ring for protection.

Beadlocks' outer rings are sacrificial, which is why many manufacturers offer them separately. The Spyderlock's impact-resistant features include a 3/4-inch-thick billet clamping ring and 3/8-inch Grade 8 bolts that are recessed into the ring for protection.

High Impact's Miller adds, "Most of the time when cops pull over someone with beadlocks it's to ask where they got them."

Basically, safety certification is becoming increasingly important. Slay says, "In the past most off-highway enthusiast were primarily focused on the performance of their vehicles in the dirt. However, with the new JK, FJ, and H3 crowd hitting the trails, stamp-of-compliance and questions surrounding it are much more common. If companies want to harness the demand from this new generation, it may be wise to seek DOT approval."

Currently, Hutchinson/Rock Monster (also sold through AEV and High Impact, among others) and Center Line are the two highest-profile companies to DOT-certify beadlocks. The inflatable Staun internal system is also DOT-compliant. (AEV has additional DOT beadlock-compliance information on its website.)

Wheel material, construction, style, and fitment are just a few of the factors in choosing the right rims for your rig. Hopefully this article helped narrow down the hundreds if not thousands of possibilities.