One of the most intimidating aspects of building a classic truck is doing the bodywork that's more often than not necessary. The choices for addressing that chore are often reduced to tackling the job yourself or coming up with the budget to pay someone else to do it. Around our garage if we don't do what needs to be done it doesn't get done.

Attempting bodywork for the first time is downright intimidating, especially when see something like a pickup bed that looks like a gunnysack full of walnuts. A less frightening approach is to start with something simple like a dented fender. In most cases sheetmetal repairs are done in the reverse order of the way the damage was done. As an example, if you ran into a fence post and the damage started at the front of the fender and continued for 18-inches or so to the rear, the repair process would start at the end of the dent and move forward. If the damaged panel has some crown to it, a hammer alone can often be used to bring the metal back to shape. But more than likely a hammer and dolly will be used together.

There are two techniques for using hammers and dollies — hammering on dolly and hammering off dolly. Hammering on dolly is like using a hammer on an anvil. To repair the damaged area a dolly that is similar in shape to the panel is used. Using a low crown hammer, start the hammering around the edge of the damage, overlapping the hammer blows by half the diameter of the hammer's head as you work toward the center. As hammering on dolly means the metal is squeezed between the two, being too aggressive with the hammer blows will result in the metal becoming thinner, which means it stretches. That material has to go somewhere so it will often "grow" in the direction of the pre-existing high (or low) spot. When hammering off dolly pressure is applied to the low spot with the dolly from the backside of a panel and the high spot is hammered from the front, this will simultaneously raise the low spot and lower the high spot with little or no stretching.

The truth is explaining how to do bodywork is like trying to tell someone how to play a piano, the best way to do either is to gain hands-on experience. To learn bodywork the first step is to equip your shop with a few basic body tools, then try some minor repairs. Here are a few tools that should be in your garage:

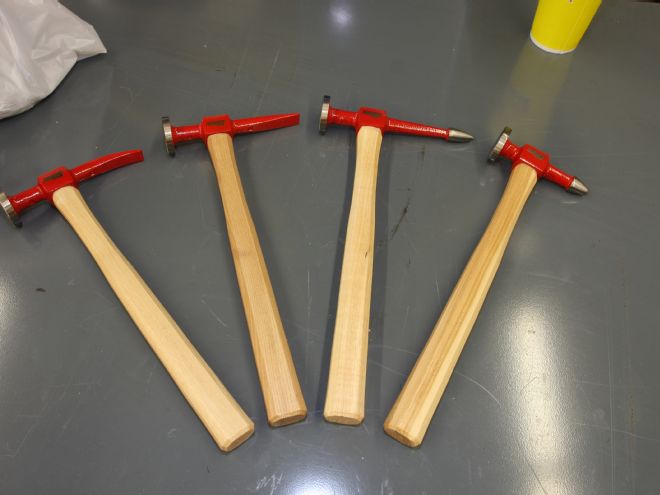

Hammers

These come in a variety of sizes, shapes, and weights. The heads are usually round or square and the faces will have a slight convex shape in the case of a low-crown hammer, slightly more with a medium-crown hammer, and still more curvature with a high-crown hammer. The difference between them is in the contact the hammer has with the metal being worked. The higher the crown, the smaller the contact area will be. In most cases a low-crown hammer will be used, as it will spread its impact over a larger area than its high-crown counterpart. That means there's less of a chance the metal will be stretched.

However, the shape of the panel must be considered when choosing a hammer. The curvature of the hammer's face should be greater than the panel being repaired to prevent the edges of the hammer from contacting the metal. In any case a flat-face hammer should never be used for bodywork as more often than not the edge of the face will put a "smile" shaped impression in the surface if a blow lands other than square. Along with the square or round head on one side, many hammers will have a "pick" on the other. Used to raise low spots, these picks may be pointed or chisel-shaped.

Another common type of hammer face is the shrinker. These can be found with a simple crosshatch pattern or more aggressive "meat tenderizer" face. In either case the effect is to displace metal and tighten, or shrink the surface. While they can be effective, the end result is a rough surface that must be sanded smooth or covered with a thin coat of filler

While hammers are similar in design, one obvious difference will be found in the types of handles used; they may be wood or fiberglass. Some bodymen claim the wood handles provide better "feel," while others claim the fiberglass handle absorb more shock and are less likely to break. Basically it comes down to personal preference.

Dollies

There are dollies available in every conceivable shape and size, and generally weigh 2 pounds or more. Good dollies are made from forged steel, the cheaper variety are cast iron.

For versatility each dolly usually has a variety of contours, so matching the shape of its surface to that of the panel being repaired shouldn't be too difficult

Spoons

These can be used like a dolly in situations where space is restricted. They can also be used to pry, and in some cases even used as a "slap" hammer. Like hammers and dollies, spoons come in a variety of sizes and shapes.

Grinders and Sanders

Bodywork requires the use of a variety of abrasives ranging roughly from 24-grit to around 320. Coarse abrasives are used to quickly remove old filler and paint in damaged areas and that is generally done most effectively with an air-driven grinder.

For feather-edging paint, preparing for the application of body filler or refinishing materials, finer grits are used on a DA, or a dual-action sander. Air driven, these sanders have two modes: circular or oscillating, or random orbit. In the oscillating mode, which is used more often, material is removed faster and with less likelihood of abrupt edges.

Getting Started

To get started doing bodywork doing bodywork a basic assortment of hammers and dollies will be necessary. Keep in mind as your confidence grows there will certainly be additional tools and equipment to consider. But in the beginning, start slow and with time, practice, and patience your skills will improve and the best part will be when someone asks who did the bodywork on your truck? You can say, "I did." CT

01 Hammers and dollies are the basic tools for bodywork, and they come in all sizes and shapes. This set of four Fairmount hammers from Eastwood feature wood handles.

02 Another set of hammers from Eastwood, these are also from Fairmount, but have fiberglass handles.

03 Body hammers are crowned to keep the edges from striking the surface being repaired. This is a low-crown hammer. When used on a flat surface the contact point of a higher crown hammer is smaller and more concentrated.

04 This an Eastwood shrinking hammers. The texture of the face compacts the surface of the metal, effectively shrinking it; however, a rough surface is left behind.

05 Dollies come in a variety of configurations and each will normally have a variety of contours to meet most needs. This set of four Fairmount dollies is from Eastwood.

06 To make it easier to access difficult-to-reach areas Fairmount offers anvil dollies. They can also be clamped in a vise for bench work.

07 This is a unique dolly from Eastwood — the "meat tenderizer" face can be used for shrinking.

08 This is an example of hammering on the dolly. A common practice; use care when hammering to prevent compacting the surface, which stretches it.

09 Hammering off the dolly is an effective method to knock down high spots and raise low spots simultaneously without stretching. The dolly must be held tightly against the surface.

10 Spoons come in a wide range of sizes and shapes, A true multi-purpose tool, spoons can be used as a dolly, pry bar, and even as a slap hammer.

11 The venerable DA sander can be used to remove paint, feather-edge layers of finish materials, smooth filler, and remove surface rust. This example is from Harbor Freight.

12 This small air-powered grinder has a variety of uses; it makes quick work of removing paint from damaged areas and flattening welds around patch panels.

13 An air-powered long board, such as this example from Harbor Freight, makes quick work of sanding large surfaces to make them flat.

14 Handy for getting into confined areas, this Harbor Freight angle grinder/sander uses stick-on sandpaper pads.

15 An inherent part of bodywork is sanding, and the proper way to do that is with blocks. It can be a small hand block or a long board, but they are the key to making a repaired and primered surface flat.

16 This selection of Dura Blocks sanding blocks comes from Eastwood. Made of closed-cell EVA rubber, they can be used on flat and contoured surfaces.

17 Some tools are simple. A wood dowel wrapped with sandpaper works great for smoothing concave surfaces.

18 Electric shears make quick work of cutting and trimming sheetmetal.

19 This is a panel flanger from Eastwood (it also punches holes). After cutting out a damaged or rusted section, the flanger can be used around the edges of the hole.

20 By stepping the opening, the patch panel can be welded in place and the edges will be flush with the outer surface.

21 Another item from Eastwood to make body repair easier are panel clamps. They hold a patch panel in place and provide the proper gap for welding.

22 More cool tools to have, especially when installing patch panels are clecos. The style on the left can be put through holes in the replacement panel and the body to hold the two together. In the middle is the clamp style that holds two panels together, and on the right is the installation tool for both. These are also from Eastwood.

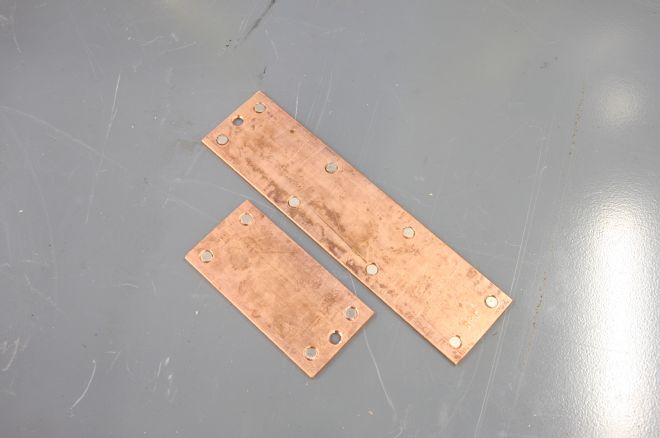

23 For welding holes in sheetmetal these interchangeable copper backup plates on a handle are handy as the welding wire won't stick to them.

24 Other options are these copper backup plates with captured magnets to hold them in place. These are from Eastwood.

25 When installing patch panels this magnetic plug weld tool is like having an extra set of hands.

26 For most of us even after we've done our best some body filler will be required to make repaired surfaces perfect. You'll need a variety of spreaders to apply it.

27 Commonly called a cheese grater, this file is used to shape body filler before it hardens completely.

28 This is a body file typically used on lead; however, it has a number of other uses as well.

29 Body files are normally attached to handles. They can be used to file lead, but they can also be used to identify high and low spots.

30 This adjustable handle is used to flex a body file to match the contour of the metal. Filing on bare metal should be kept to minimum to avoid removing too much material.