We have a long-running relationship with Miller Electric, which, among other things, has provided us the opportunity to use several of its welders and plasma cutters over the last decade. This relationship also means we are privy to new products before they are released to the public, so a few months ago we were invited to test Miller's new Syncrowave 210 at its West Coast training center, located about 60 miles west of our office. Two things are immediately apparent: Miller's new Syncrowave 210 is a more powerful, refined, and sophisticated welding machine, and it's enclosed in a housing nearly half the size of its Syncrowave 200 predecessor. How does such a small machine pack such a big punch? It's all in the inverters, man.

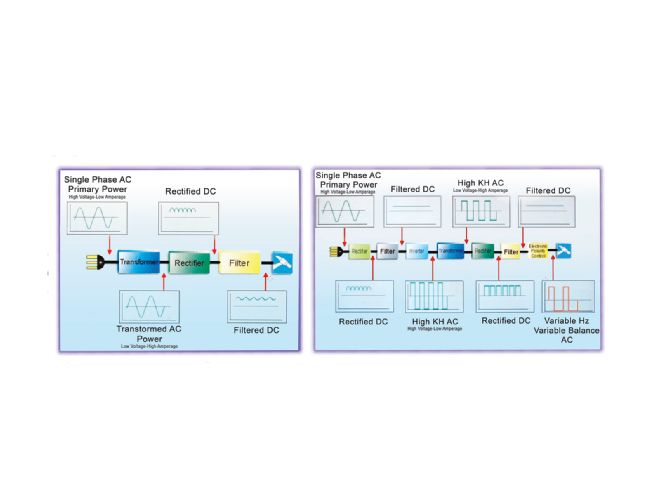

What’s an inverter? We couldn’t actually answer that until Miller provided us with these diagrams showing the differences between transformer-based (left) and newer, inverter-based TIG machines. At a basic level, think of it like the difference between a mechanical voltage regulator versus an internally regulated alternator. An inverter regulates the current from your wall outlet, taking a high-voltage low-current sine wave and changing it to a very precise digital signal that ultimately leads to a more stable weld arc and smoother starts. It can also adjust the frequency of the current, where transformer-based machines can only operate at 60hz output when welding in the AC setting.

What’s an inverter? We couldn’t actually answer that until Miller provided us with these diagrams showing the differences between transformer-based (left) and newer, inverter-based TIG machines. At a basic level, think of it like the difference between a mechanical voltage regulator versus an internally regulated alternator. An inverter regulates the current from your wall outlet, taking a high-voltage low-current sine wave and changing it to a very precise digital signal that ultimately leads to a more stable weld arc and smoother starts. It can also adjust the frequency of the current, where transformer-based machines can only operate at 60hz output when welding in the AC setting.

On the right is Miller’s Syncrowave 200, predecessor to the new 210, flanked on the left by our new (at the time) Diversion 165, Miller’s much smaller, entry-level TIG machine. Miller Diversion series are inverter-based welders.

On the right is Miller’s Syncrowave 200, predecessor to the new 210, flanked on the left by our new (at the time) Diversion 165, Miller’s much smaller, entry-level TIG machine. Miller Diversion series are inverter-based welders.

This is our current Diversion 180 TIG, which is more powerful than the 165 but retains the same external dimensions. Note the trend to simpler controls; Miller has taken great care to make TIG welding less confusing for the enthusiast.

This is our current Diversion 180 TIG, which is more powerful than the 165 but retains the same external dimensions. Note the trend to simpler controls; Miller has taken great care to make TIG welding less confusing for the enthusiast.

In person, the new Syncrowave 210 looks slightly smaller than the 200, but the real shock comes when you flip open the side panel to reveal a cavernous storage area for the machine’s cables and hoses.

In person, the new Syncrowave 210 looks slightly smaller than the 200, but the real shock comes when you flip open the side panel to reveal a cavernous storage area for the machine’s cables and hoses.

The Syncrowave 210 also has the simplest control panel we’ve ever seen: one knob for the process setting, one for amperage adjustment, and a menu button that allows the operator to toggle through all the features the 200 had separate knobs and buttons for. The 210’s software can also be updated via the SD card slot on the lower right of the control panel. As updates are available from Miller, they can be downloaded and plugged into the machine.

The Syncrowave 210 also has the simplest control panel we’ve ever seen: one knob for the process setting, one for amperage adjustment, and a menu button that allows the operator to toggle through all the features the 200 had separate knobs and buttons for. The 210’s software can also be updated via the SD card slot on the lower right of the control panel. As updates are available from Miller, they can be downloaded and plugged into the machine.

The actual welding unit is the size of our small plasma cutter, making this a very lightweight and portable machine.

The actual welding unit is the size of our small plasma cutter, making this a very lightweight and portable machine.

We weren’t able to spend very much time using the 210, but we were able to make a couple passes on mild steel and in the AC setting on aluminum, and we were impressed with the smooth, stable arc. The torch and cable are also much lighter than that of our Diversion 180, making it much easier and comfortable to hold steady while running a long bead. Will it automatically make you a better welder? No, it won’t cover up a lack of basic skill, but it does make welding easier and cleaner looking than when using a transformer-based machine. We look forward to hopefully having one on our own shop soon. End

We weren’t able to spend very much time using the 210, but we were able to make a couple passes on mild steel and in the AC setting on aluminum, and we were impressed with the smooth, stable arc. The torch and cable are also much lighter than that of our Diversion 180, making it much easier and comfortable to hold steady while running a long bead. Will it automatically make you a better welder? No, it won’t cover up a lack of basic skill, but it does make welding easier and cleaner looking than when using a transformer-based machine. We look forward to hopefully having one on our own shop soon. End