Around three years ago Doc Hammett, of Totally Stainless, called STREET RODDER Editor Brian Brennan because of a recommendation in a tech article not to reuse Nylock nuts. Doc had remembered a tech release by the Nylock corporation that stated their nylon insert lock nuts can be reused over 100 times (because nylon has memory it will gradually return to its original shape when deformed). Since Totally Stainless stocks a full range of nylon insert lock nuts and had destroyed a common myth, Brian suggested Doc write an article about locking fasteners and address pros and cons of their uses and, better late than never, here it is. -Senior Editor Ron Ceridono

Did you ever notice that highly stressed fasteners like rod, main, and head bolts don't use any locking devices? These critical fasteners stay tight by being stretched-they work like clamps. If a fastener can't be stretched enough to create adequate clamping force, then a locking device may be needed. But it's not always practical or even desirable to use a properly torqued high strength bolt for many automotive applications, such as fenders or hood hinges, but there are other means of securing fasteners.

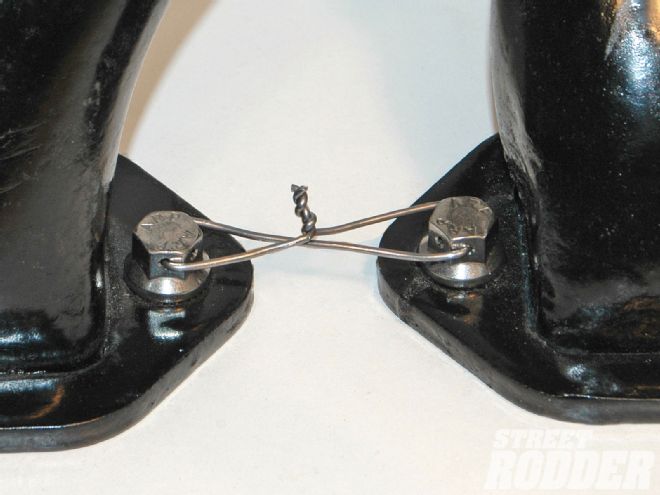

Safety wire is an effective means of locking fasteners when installed correctly. Note how one bolt trying to come loose will tighten the other.

Safety wire is an effective means of locking fasteners when installed correctly. Note how one bolt trying to come loose will tighten the other.

There are a wide variety of locking bolts, nuts, and washers on the market. These can be divided into three types: externally applied devices, prevailing torque, and free spinning.

Externally applied devices include safety wire, locking tabs, pins, and clips. These are often used on critical components (like suspensions) because it is easy to verify that the fastener is locked into place. These devices provide very positive locking but may be difficult to install and remove. Safety wire can be a real pain but it does have that nostalgic racer look! These devices need either a stationary object to work against or another fastener to be paired with.

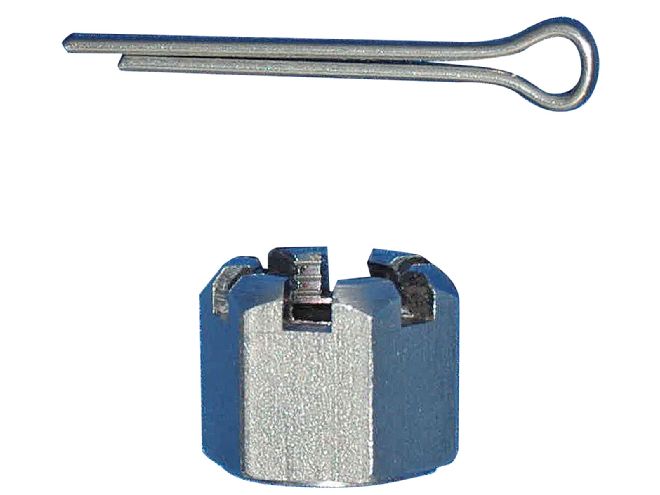

Slotted nuts (often referred to as castle nuts) and cotter keys are used on many suspension parts; we are often asked if we stock them. We don't because standard industrial stainless castle nuts should not be used on suspensions because they have yield strength of only half of what is used originally. Castle nuts have prongs that are smaller than the full hex of the nut; slotted tall nuts are normally used on automotive suspensions. We can make the proper strength slotted nuts from high-strength stainless stock-but the height of the nuts and the location of the slots do not follow any fastener standard. Slotted nuts are provided with the part when purchased and the nut height is determined by where the hole is located in the threaded shaft of the part!

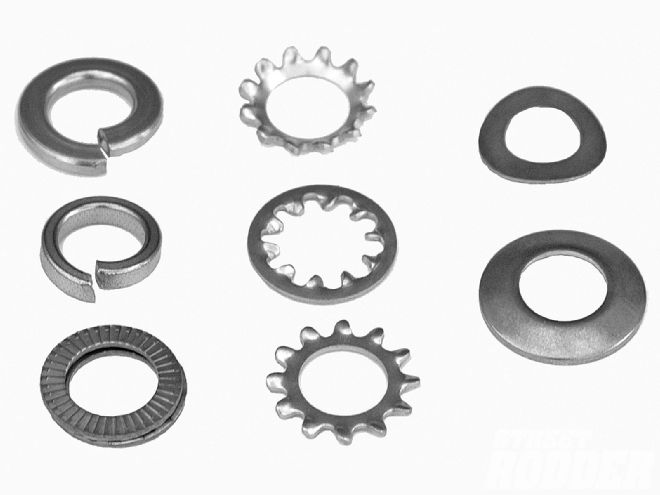

Lock washers also come in a variety of forms-split washers come in standard and high collar diameters (left middle and upper), toothed washers (middle) can have internal or external teeth and some are available for countersunk holes, and wave washers and Belleville washers are often found in light-duty applications (right). The unique wedge lock washers are relatively new and extremely effective (lower left).

Lock washers also come in a variety of forms-split washers come in standard and high collar diameters (left middle and upper), toothed washers (middle) can have internal or external teeth and some are available for countersunk holes, and wave washers and Belleville washers are often found in light-duty applications (right). The unique wedge lock washers are relatively new and extremely effective (lower left).

Prevailing torque fasteners use a thread interference type lock where there is resistance to removal even when the fastener isn't fully seated. Automakers often use these type of lock nuts on suspension parts to provide extra security for critical parts that may loosen due to long-term wear or other factors. Nylock nuts are one of the most familiar of this type. Caution must be used when using prevailing torque type fasteners in stainless. Stainless has a tendency to gall-the surface of the threads can tear and lock permanently to the mating surface. The friction produced by prevailing torque locking features increase galling problems. Appling a liberal coating of antiseize prevents galling under most conditions.

Free spinning locks include most types of locking washers and serrated flange nuts. Most lock washers work using spring action-they exert spring force between two objects. Split lock washers are the most commonly used spring type lock washers. There are several other types, including wave washers and Belleville washers. Note there are special high collar split lock washers for use under the heads of socket cap screws. The standard split locks are too large in outside diameter and can push out from under the head when tightened; high collar locks are the same diameter as the socket head. Heat takes the temper out of spring lock washers causing them to lose their locking ability, which is why they don't work on exhaust manifolds

Locking nuts come in a variety of forms, including jam nuts, captured serrated washers, nylon inserts, and serrated flanges.

Locking nuts come in a variety of forms, including jam nuts, captured serrated washers, nylon inserts, and serrated flanges.

Toothed lock washers and serrated flange nuts work by increasing the friction between the fastener and the mating surface. Automakers used toothed lock and flat washers during the late-'50s through the mid-'60s for many of the body fasteners. This practice was largely discontinued by the late-'60s. The big drawback to using toothed and serrated locks is they cut through painted surfaces. One of the best uses for toothed lock washers is for electrical grounds.

Another time-honored mechanical method of retention is the castellated nut and cotter pin. These are still common on critical suspension components.

Another time-honored mechanical method of retention is the castellated nut and cotter pin. These are still common on critical suspension components.

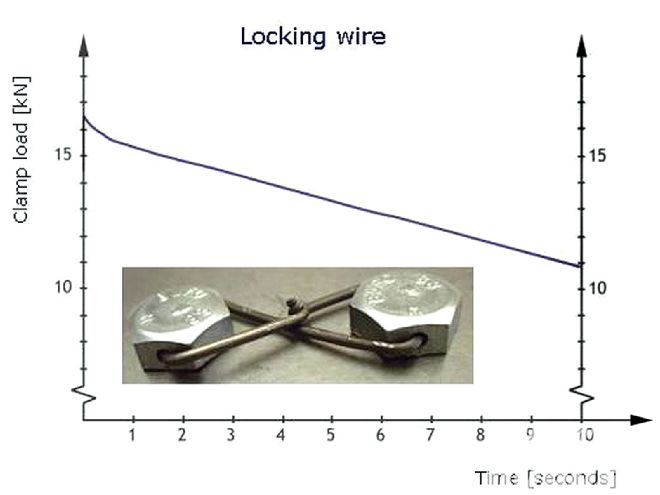

Fasteners with prevailing torque and free-spinning locking features are by far the most common because they are the relatively inexpensive and are easy to use. Most of these fasteners are not vibration proof and many will lose their spring force in high-heat applications. One notable exception are wedge lock washers. These are two-piece washers that have small ramps on the inside of each half of the pair. With this type of lock, the fastener is stretched as it tries to back out, making it tighter.

Finally, Something New

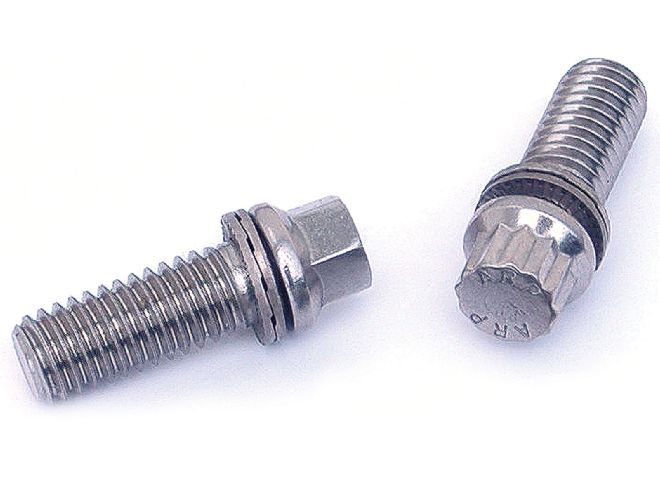

One of most common customer requests has always been for easy-to-use, low-cost locking header bolts. To answer that need we've added the Nord-Lock two-piece wedge lock washers line in No. 10 through 3/4-inch diameters to the Totally Stainless inventory and started to experiment with a package for header bolts. The most common header bolt has 3/8-16 threads with an extra-small diameter flange head. The small flange diameter is needed on many of the older non-metric engines because the bolt holes for the headers are very close to the header tubes. The standard 3/8-inch wedge lock washers have an outside diameter that is larger than the flange on the header bolts and can interfere with the header tubes so special washers with a small diameter are needed. After discussing the optimal dimensions for this application with Greg Bolduc at Nord-lock, the idea of using a fastener assembly with a captured washer developed and the result was the Total-Loc header bolt, which has captured wedge-lock washers that can't fall off. Total-Locs are vibration proof, heat-resistant, and have been tested over the last two years in the toughest racing conditions, such as off-road, off-shore, and hydroplane racing.

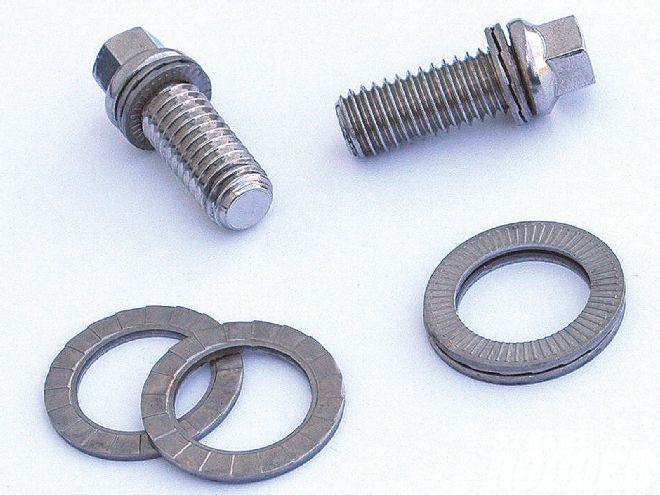

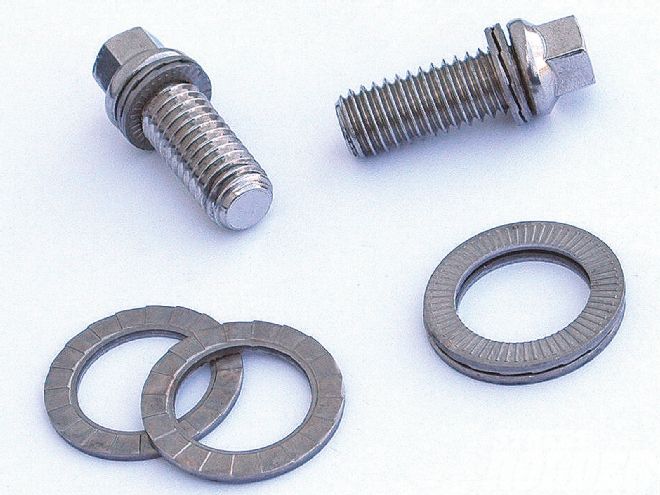

Something new from Totally Stainless are Total-Loc header bolts. Assembled by ARP, they are available in 12-point bolts with a 3/8-inch hex and six-point with a 5/16-inch hex.

Something new from Totally Stainless are Total-Loc header bolts. Assembled by ARP, they are available in 12-point bolts with a 3/8-inch hex and six-point with a 5/16-inch hex.