Go Green

A. Kotecki, via CarCraft.com: Will the E85 "green" carb you used awhile back have any benefit on the 6.0L engine you just built with L92 heads?

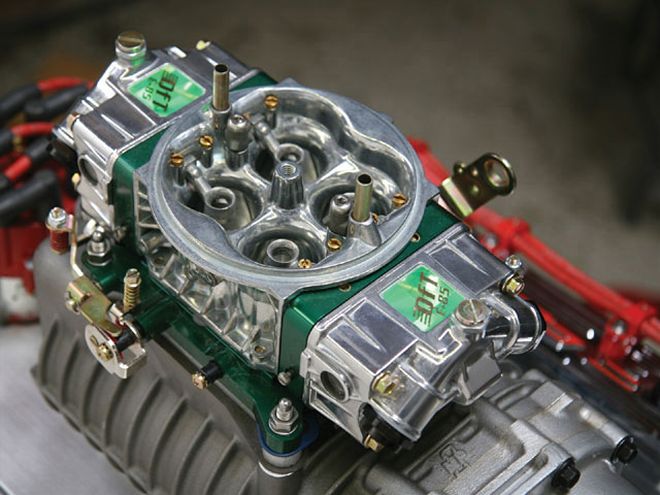

This is the E85 carburetor we used on the Magnuson-supercharged 355ci small-block on E85 fuel that made 601 hp. It is a 750-cfm carb and is available right now from Quick Fuel (PN Q750-E85, $625.00)

This is the E85 carburetor we used on the Magnuson-supercharged 355ci small-block on E85 fuel that made 601 hp. It is a 750-cfm carb and is available right now from Quick Fuel (PN Q750-E85, $625.00)

Jeff Smith: We just love getting questions about our E85 stories because it tells us that you guys are really paying attention. The E85 green carb in question here is the Quick Fuel carburetor specifically designed to meter E85 fuel. We used E85 on the Magnuson supercharged 355ci small-block Chevy in the February issue ("E85 Solution"), where our little Mouse motor made 601 hp at 10 psi with a 9.4:1 compression ratio. To bring everybody up to speed, E85 is 85 percent grain alcohol mixed with 15 percent gasoline and offers an excellent 105 octane rating. The trick to using E85 is a carburetor modified to handle an increase of roughly 25 to 30 percent more fuel. This is why Quick Fuel decided to build a special E85 carburetor-many standard carbs are not designed to handle this great an increase in fuel volume.

So now we can jump over to the LQ4 6.0L (364ci) engine we tested in the May issue, where we bolted on a set of L92 aluminum factory heads and a carbureted intake manifold along with an aggressive Comp Cams XR281HR hydraulic roller camshaft. This amazing 364ci Gen III engine cranked out 551 hp at 6,800 rpm in this configuration at around 9.4:1 compression, which is on the low side, especially for a cam this size. The advantage of using the Quick Fuel carb and E85 on this engine is not so much what the fuel would do with the engine in its current configuration as much as what the fuel offers in terms of potential. As we stated earlier, E85 is a 105-octane fuel that can be purchased in most places for equal to or less than the price of 87-octane pump gas. If we wanted to configure this 6.0L to run exclusively on E85, then the first step would be to get rid of the stock pistons and jump into a set of forged aftermarket pistons to raise the static compression ratio. It's possible to bump the compression to 10.0:1 with a flat-top piston with a 4.030-inch bore and stock 3.62-inch stroke, but this really doesn't take advantage of the E85 octane. Domed pistons will certainly do the job, and most piston companies like Diamond, JE, and others make a domed version for this configuration. We researched the Diamond piston catalog and found a 10cc domed piston for a 4.030-inch-bore Gen III package that would be worth 11.6:1 compression, and if we mill the heads down from 70cc to 62cc, it would bump the compression to 12.9:1. Don't let that scare you, because with 105 octane and the cooling effect of the alcohol-based fuel this motor would make some serious power.

Please stop mounting phony brake rotors behind your wheels. We'd rather see real drum brakes than fake rotors."> CC Quickies<br>Please stop mounting phony brake rotors behind your wheels. We'd rather see real drum brakes than fake rotors.

CC Quickies<br>Please stop mounting phony brake rotors behind your wheels. We'd rather see real drum brakes than fake rotors.

The rule of thumb for compression is roughly 3 percent gain in power for every 1 point of increase in compression. Moving from 9.4:1 to 12.9:1 would be an increase of 3.5 points, which equals roughly 10.5 percent. Round that down to 10 percent and we're talking about 600 hp with an equal or greater increase in torque throughout the entire power curve, because compression adds power everywhere. Another good reason to swap the pistons, even if you only pump the compression to 11.0:1, is that these power and rpm levels are pushing the limit of stock cast pistons. Our ex-GM engineer pal Mark McPhail tells us that the early LQ4 pressed wristpin pistons could fail at these engine speeds. Later LQ4 and LQ9 engines after roughly 2002 come with floating pins and are of a stronger design, though still cast.

The downside to building a 12.5:1-compression engine is that it's destined to always run on E85 or race gas. But it appears that E85 availability is on the rise across the U.S. Right now it is still most easily found in the corn-producing midwestern states, but with all of E85's green advantages-especially as a renewable resource of fuel-expect that you will be able to find E85 in an increasing number of places all over this great country of ours.

Hot Rat Monte

Roman Rzasa, Ortonville, MI: I am the second owner of a '75 Chevy Monte Carlo with a 454 and a Turbo 400 trans. When I bought this car in March 2004 it was all original with approximately 85,000 miles and all the original emissions equipment including the catalytic converter. I drove it as it was for about three months with no problems, and since it came with factory gauges, all the readings including the temperature always looked good.

The first thing I changed was the 2.73 open rearend to a 3.42 limited slip. The next day I had the converter removed, and a dual-hump crossmember and true dual 211/42 exhaust with DynoMax mufflers installed from the original exhaust manifolds back. About a week later I noticed the radiator leaking, so I replaced it with a larger one, a new fan clutch, and a 180-degree thermostat.

After these changes I noticed that the car seemed to run hotter than before, sometimes too hot. And I could never figure out why, since all I had was a new cooling system, 8.1:1 compression, no cam, and a no-power 454. Recently I decided to remove all the emissions equipment and I replaced the original exhaust manifolds with Hedman Elite shorty headers. I decided then to get serious about finding out why it runs hot. I started looking up all of what I thought would be the pertinent information regarding Chevy big-blocks.

The one thing that seemed to stand out was ignition timing, considering the big jump in initial timing from 10 to 16 degrees BTDC. Looking at the timing information, it seems to indicate that initial timing increased as emission controls increased and power decreased, and a large jump from 10 to 16 degrees in 1975 could only have been due to the addition of the catalytic converter. This information came mostly from Haynes and Chilton manuals and some from other GM books. My first question is, could the removal of the converter with no other accompanying adjustments in timing or carburetor be the cause of my running-hot problem?

My second question is, where do all the magazine and Web writers get their timing information? From all the magazine articles I've read and hours I've spent on the Web, the majority opinion on big-block Chevys seems to be to have the initial timing as high as possible, up to 14 or even 16 degrees BTDC, and to have the total timing from 34 to 36 degrees and all in by 2,800 rpm (including your answer to "Stumble In" in the Apr. '07 issue). Yet looking at all the data I've collected, it appears from past and current GM recommendations, including those on the latest 454 and 502 crate engines, that initial timing should be from 4 to 8 degrees BTDC and total timing should be between 26 and 30 degrees.

The reason for tuning with different total ignition timing numbers is to determine what timing the engine wants to make best power. While 36 degrees is a popular number with most current performance engines, each engine is different and may need more or less timing to make best overall power.

The reason for tuning with different total ignition timing numbers is to determine what timing the engine wants to make best power. While 36 degrees is a popular number with most current performance engines, each engine is different and may need more or less timing to make best overall power.

Jeff Smith: The first thing to do in this situation, Roman, is to look at the temperature itself. Unfortunately, you did not mention what "too hot" is exactly. Many enthusiasts get nervous with an engine above 200 degrees F when that's not really hot at all. Most factory engines run at that temperature normally. Consider that water boils at 212 degrees at sea level, but 15 psi of pressure raises the boiling point of straight water by 30-plus degrees. This means the coolant won't boil until around 245 degrees! When the coolant begins to boil, it creates steam pockets that prevent the transfer of heat away from the cylinders, especially the combustion chamber. That's when your problems begin. A good indication that the engine is in trouble is when it starts detonating at part-throttle. When that happens, shut the engine off immediately before this causes more damage. Our point here is that an engine running at 200 to 210 degrees is not in trouble, and as long as it's not pushing coolant out of the radiator, it's not hurting the engine to run if it's not detonating. The other side of this is that running an engine at 165 degrees all the time is not good for it either, since the oil temperature may not achieve at least 212 degrees so that the water in the oil can evaporate out. If this does not happen (such as in winter climates), acids begin to form in the water remaining in the oil, damaging engine bearings if allowed to sit for long periods of time.

To get back to your temperature question, let's first address the accuracy of your gauge. It's possible that the gauge may not be indicating the actual temperature of the engine. Or the sending unit could have gone bad, or perhaps a weak ground between your sending unit and the gauge itself could be affecting the temperature reading. The best way to check would be to calibrate your factory gauge with a separate thermometer or gauge that you trust to get an actual temperature reading, as opposed to using only the classic factory gauge that just indicates a range between hot and cold. Assuming everything is functioning normally, it's possible, although unlikely, that your new fan clutch may not be working properly. We've had experience with budget fan clutches that only work correctly for a short time and then get weaker as the miles pile up. A quick check for fan clutch operation is to allow the engine to achieve a minimum of 200 degrees F of coolant temperature (by placing a piece of cardboard in front of the radiator) and then listening for the fan clutch to engage, which will make more noise when it attempts to pull more air through the radiator. If there is no noticeable change in airflow, the fan clutch would be our top suspect. Another possibility is that the radiator you purchased has a low-density core while the original radiator used a high-density core. As we mentioned in our cooling system story in the July issue, budget radiators are still being made with low-density cores where the space between the cooling tubes is wider, generally around 11/42 inch, while high-density cores place more cooling tubes within the same area so that the width between tubes is reduced to around 31/48 inch or less. If you purchased a low-density radiator, that could contribute to the higher engine-operating temperatures.

As for ignition timing, the typical base ignition setting of 10 to as much as 16 degrees is established to generate the best overall power, especially at lower engine speeds. Most enthusiasts know that when an engine gets hot, the chance for engine detonation is more likely, and thus you don't want to lean on your engine hard when the coolant temperature is higher than 210 degrees F. Unfortunately, the new-car companies have to assume that the engine may be asked to perform these kinds of high-load duties while operating at high engine temperatures, so they purposefully reduce maximum ignition timing to minimize the chance for detonation-induced engine damage. They pull back the initial timing to a more conservative 5 to 8 degrees and also are very conservative with a total ignition timing of around 32 degrees.

We were checking out this ornate hood ornament from a barn-find Plymouth at the Mopars at the Strip show. Plymouth used sailing ships as mascots to represent the Mayflower, the ship that carried the Pilgrims to Plymouth Rock-get it?"> CC Quickies<br>We were checking out this ornate hood ornament from a barn-find Plymouth at the Mopars at the Strip show. Plymouth used sailing ships as mascots to represent the Mayflower, the ship that carried the Pilgrims to Plymouth Rock-get it?

CC Quickies<br>We were checking out this ornate hood ornament from a barn-find Plymouth at the Mopars at the Strip show. Plymouth used sailing ships as mascots to represent the Mayflower, the ship that carried the Pilgrims to Plymouth Rock-get it?

Because we are car crafters, we want to make the most power possible from our engines, so we optimize the ignition timing for every rpm point since this is an area that helps make power and also costs nothing. Generally, increasing base ignition timing will improve a potential overheating problem because starting the combustion process sooner means the engine will be closer to oxidizing most of the fuel by the time the exhaust valve opens. The exhaust gas temperature is reduced if most of that heat energy was expended pushing the piston down. If the onset of ignition occurs later, the engine can run warmer since the tail end of the combustion process could still be occurring when the exhaust valve opens, causing the exhaust valve and port to be subjected to a dramatic increase in temperature. This places a greater burden on the cooling system.

Most street engines these days seem to prefer a total ignition timing of around 32 to 36 degrees for best power, but each engine is different. Some may need more, some less. For example, the GM Gen III engines are often tuned from the factory with less than 30 degrees of total ignition lead because that's all those engines need to create maximum cylinder pressure. This is a strong indication of a well-designed combustion chamber.

A lower total ignition-timing requirement indicates that the combustion chamber is designed as a fast burn that does not require as much time (as measured in ignition timing) to complete the combustion process. So if the engine makes the same or more power with 32 degrees instead of 40 degrees of timing, that's a good thing.

500HP Small-Blocks

Ronald Brooks, via CarCraft.com: I find it interesting in your online article about 500hp engine combos that run on pump gas that there are no real small-block (5.7L or smaller engines) in it. Why is that? It can't be done? It should be easy to make 500 hp when you're toting 383 or more cubic inches. Why not ramp up the difficulty a little? What about 500-plus horsepower on pump gas with small-cubic-inch engines with no power adder at all?

Jeff Smith: Great question, Ronald. Making 500 hp has never been easier, even with a small-block. But there are compromises that must be made when you're talking about smaller-displacement engines that we'll assume are still going to be run on the street, since you mentioned that they should run on pump gas. The concepts are really easy, but there are some critical points that are often overlooked by enthusiasts who are interested only in peak horsepower numbers as opposed to the overall power curve. We chose the big-blocks at 500 hp because this is a relatively easy number to attain, which means you don't have to push an engine nearly as hard to achieve that number.

While making 500 hp is achievable with a small displacement, the smart street engine plan is to build it with as much displacement as possible. This is a Ken Crocie Pontiac 455 that made 516 hp at 5,300 rpm and 575 lb-ft of torque at 3,900. That's great grunt.

While making 500 hp is achievable with a small displacement, the smart street engine plan is to build it with as much displacement as possible. This is a Ken Crocie Pontiac 455 that made 516 hp at 5,300 rpm and 575 lb-ft of torque at 3,900. That's great grunt.

It's not difficult to achieve 500 hp with a smaller-cubic-inch, normally aspirated engine. Just for grins and giggles, let's simulate a 302ci, small-block Chevy. We'll start with a set of good 210cc intake port heads that flow 280 cfm on the intake side at 0.600-inch lift. Let's add a set of domed pistons (remember, we only have a 3.00-inch stroke) with an 11.5:1 static compression ratio, a huge 242/248-degree-at-0.050 mechanical roller camshaft with 0.600-inch valve lift, a large single-plane intake manifold, an 850-cfm carburetor, and large 1 71/48-inch headers with very low-restriction mufflers. We plugged all this data into our ProRacing Sim DeskTop Dyno engine simulator program and it spit out some interesting numbers. First of all, peak horsepower was an impressive 555 hp at 7,000 rpm. That seems a bit optimistic, because just last month we tested a 383ci small-block with a set of Dart 227 CNC ported heads, 10.5:1 compression, a 750-cfm carb, big single-plane intake, and a mechanical roller cam with 254/260 degrees at 0.050-inch lift, and that engine made an impressive 570 hp. That was 1.48 hp per cubic inch (hp/ci), but doing the math on the 302 comes to a far stronger 1.83 hp/ci. Granted, both engines have the same bore, and the 383's piston friction at 7,000 rpm will be much greater due to the 0.750-inch-longer stroke, but what we're getting at is that the 302 combo is probably optimistic by at least 30 hp. Still, 525 hp is certainly achievable.

While the peak horsepower was at 7,000 rpm with the 302 (and very close at 6,900 rpm with the 383), the 302 achieved a simulated peak torque of 450 lb-ft (again, perhaps optimistic by 30 lb-ft or more), but this came at 5,500 rpm. Here's where the reality of street engine operation begins to blend into the romance of 500hp engine combinations. That hopped-up 383 managed to pull around 350 lb-ft of torque at 3,000 rpm while the simulation reported almost the same torque, but a real dyno test on an engine like this would probably see closer to 300 lb-ft at 3,000 rpm. That's much less torque than a stock engine makes at this rpm, which means you'll need much more gear to make up for the lack of torque at lower engine speeds. For example, even with a lightweight Chevy II at 2,800 pounds, you're going to need a 3.73:1 or deeper gear. To optimize this motor at the dragstrip, something closer to a 4.56:1 gear with a 26-inch-tall tire will be necessary to pull 7,000 rpm at the end of the quarter-mile, assuming a trap speed of roughly 125 mph. Now what we have is much closer to a race car than a street car.

How's this for attention to detail? Harley Graves had most of the fasteners on his '69 Charger ceramic-coated. It wasn't cheap to have done, but it looks nice."> CC Quickies<br>How's this for attention to detail? Harley Graves had most of the fasteners on his '69 Charger ceramic-coated. It wasn't cheap to have done, but it looks nice.

CC Quickies<br>How's this for attention to detail? Harley Graves had most of the fasteners on his '69 Charger ceramic-coated. It wasn't cheap to have done, but it looks nice.

Everyone's idea of what constitutes a "real" street car is different. Personally, my Olds with a 3.23:1 rear gear with a 28-inch-tall rear tire suffers from unacceptably high engine speed at 70 mph without an overdrive trans. A car with a high-strung small-block and a 4.56:1 rear gear isn't something I'd like to drive at 4,125 rpm on the freeway here in L.A. at 70 mph to keep from getting run over by everybody else driving 75 to 80 mph. But perhaps your tolerance for buzzing small-blocks on the freeway is greater than mine. That's fine as long as you're willing to put up with all that racket. As an alternative, let's look into a 550hp, big-block 496 (or better yet, a 540ci Rat) that will make that same 550hp number at a leisurely 5,800 rpm, as an example, with peak torque of roughly 630 lb-ft at 4,200 rpm. This motor would probably pull well in excess of 550 lb-ft at 3,000 rpm and as a result would not need much more than a 3.23:1 rear gear, most likely getting by just fine with a mild stall speed of 2,000 rpm with a 3.08:1 rear gear. This combination could easily run decent 11-second dragstrip times without pulling stratospheric engine speeds, which also means it would live a long time without breaking parts. This engine in a relatively heavy car would still be quick on the dragstrip and yet much more fun to drive on the street. The reason the big-block will run as quick or quicker than a tiny small-block with the same peak horsepower is because the big-block (by virtue of its large displacement) will make much more torque throughout the entire rpm band in which the engine runs down the track. If peak horsepower and vehicle weight are the same between two engines, the one with the stronger overall power curve within the rpm band where the engines run on the track will always be quicker (assuming decent traction). This is overlooked when you concentrate only on peak horsepower numbers. The Rat motor can give up a little peak horsepower if it has more torque in the middle. That extra torque in the middle will out-accelerate the smaller motor at midtrack every time. The only choice for the small-block is to run a much deeper gear to compensate for its lack of torque.

There's certainly nothing wrong with the 302 combination, and some guys prefer these little motors that spin to the moon. The problem is that high rpm requires excellent (that means expensive) valvetrain parts that tend to not be as durable, because you have to run high valvespring pressures to keep everything glued together. Then buzz the motor all the time and you can begin to see why these high-strung beasts don't make good street motors. On the other side of the coin are the big-blocks that just loaf along at low engine speeds while still offering tremendous torque. It's really not a matter of taking on a challenge, Ronald, to build a 550hp small-block as much as that a larger-displacement engine will make the power really easily and offer more streetable power at lower engine speeds so stuff doesn't break as often. And fewer broken parts is a concept everybody can agree on.

Nitrous Rats

Jay Jones, currently in Iraq: I own a '76 Nova. It has been gutted and treated to a set of CalTrac bars and adjustable shocks in the rear. My Nova is powered by a 468ci big-block Chevy that I have been more than happy with. I have two problems, though. About six months ago I put a Nitrous Express Hitman kit on the big-block and set it up to deliver a 150hp shot. I want to put more nitrous to the engine, but I am told that there are two things that will hold me back from doing that. First, I did not put a forged crank in the car. Although the Scat crank is stronger than production, I'm not sure if it will hold up to much more gas. The second thing is I am told that the ring seats on my pistons are too high (I don't know what that means) and that the pistons, even though they are a good forged set, cannot or should not have more than 175 hp of nitrous applied to them. Do you think that the bottom end will handle maybe 200 hp of nitrous? Also, I am running the Edelbrock Performer 454-0 heads on the engine along with a Team-G intake and a Race Demon carb. If you don't think the bottom end will hold up, what rotating assembly would you advise me to get? I do not want to get into another overly expensive build, but I know that you must pay to play. If I go with a new assembly I would like it to be a 496.

Measuring top ring endgap is important when building any engine, even if the rings are already clearanced for the bore diameter. Make sure to square the ring in the bore to ensure that measurement is accurate.

Measuring top ring endgap is important when building any engine, even if the rings are already clearanced for the bore diameter. Make sure to square the ring in the bore to ensure that measurement is accurate.

Jeff Smith: Great question, Jay. As with some information you get from friends and Internet experts, there are a few grains of truth amid the chaff. Let's look at the crankshaft question first. Our experience with Scat cranks, even the cast units, has been universally good. The downside to a cast crankshaft is that castings tend to crack when hit with a bending moment, while forgings, generally speaking, are more flexible and resilient. While everyone thinks about horsepower with nitrous systems, it's actually torque that has a big impact on the crankshaft. Consider that a 200hp shot delivered to the engine at 3,500 rpm is the equivalent of an increase of 300 lb-ft of torque. That's roughly a 75 percent increase in torque at that rpm. That's why the nitrous companies tell you not to engage nitrous at engine speeds lower than 3,500 to 4,000 rpm. In your case, I think that your crankshaft is OK as long as you don't rev the engine much past 6,000 rpm. With cast cranks, engine speeds above 6,500 rpm are a common cause of crankshaft failures, especially when combined with heavy pistons. The g-force loads of heavy rods and pistons changing direction at higher engine speeds are what may eventually fail a crank, not necessarily the addition of another 200 hp.

As for the pistons, top ring position is very important to increasing piston and ring life when using nitrous. The closer the ring is to the top of the piston, the higher the temperature from the heat of combustion that transfers to the top ring. Nitrous increases cylinder temperature, which puts more heat into the top ring, causing it to expand. If the ring expands enough to push the ends of the ring together, the ring seizes in the groove and causes all kinds of ugliness to cylinder walls and pistons. In the worst cases, it will break the piston. We've seen a hypereutectic piston with the entire top half broken off from just above the wristpin as the result of a butted top ring. All good engine builders will automatically increase the top ring gap to accommodate mild nitrous use. One way to reduce the heat that hits the top ring is to move away from the piston deck surface, away from the heat. A less expensive step would be to increase the top and second ring endgaps to accommodate the additional heat. Since you've already successfully run your engine with a 150hp shot, the additional 50 hp may not do any damage, but short of tearing down your engine there's no way to be sure. Unfortunately, you did not include enough information to make an educated guess.

If you're traveling through Baker, California, and are craving protein, we recommend the beef jerky from this place. "Alien" is a reference to Area 51, near where the store was originally located. They don't sell jerky made from alien meat."> CC Quickies<br>If you're traveling through Baker, California, and are craving protein, we recommend the beef jerky from this place. "Alien" is a reference to Area 51, near where the store was originally located. They don't sell jerky made from alien meat.

CC Quickies<br>If you're traveling through Baker, California, and are craving protein, we recommend the beef jerky from this place. "Alien" is a reference to Area 51, near where the store was originally located. They don't sell jerky made from alien meat.

Here are some areas that need to be addressed: If you are running forged pistons, I would call the piston manufacturer and get its recommendation for nitrous use. If the pistons are hypereutectic, I would not recommend running any more than your current 150hp shot. While hypereutectic pistons are stronger than cast, they are more brittle and tend to break rather than bend when subjected to detonation. If you know what the top piston ring gaps were set at when the engine was built, this will also help determine your course of action. For example, if your ring endgaps were set tight, then that additional nitrous is asking for trouble. But if the ring endgaps were set loose, then the additional nitrous may be OK. If you don't know your ring endgaps, you'll be taking a certain amount of risk at levels around 200 hp. I've included a piston ring endgap chart courtesy of JE Pistons that makes recommendations for ring endgap based on normally aspirated and nitrous use. Note that the chart uses bore size times a given clearance that increases as horsepower and cylinder temperatures increase.

Other recommendations for more nitrous would include going one step colder on your spark plug heat range and changing (if you have not already done so) to nonprojected-nose spark plugs. Projected-nose spark plugs use a longer ground strap, which can turn into a glow plug that can preignite the incoming mixture and cause all sorts of engine damage. I'd also recommend using a copper-core-style spark plug since the center electrode does not tend to glow when subjected to higher cylinder temperatures. It's also advisable to reduce your total ignition timing by at least another 2 to 3 degrees to prevent detonation. Of course we probably don't need to tell you that you will need higher-octane fuel and sufficient fuel flow and fuel pressure to feed that additional 50 hp.

RING ENDGAPS DESCRIPTION TOP RING Normally aspirated street engine Bore x 0.0045 Moderate street turbo/nitrous use Bore x 0.0050 Nitrous race only Bore x 0.0070Example: Moderate street nitrous use for a top ring in a 4.250-inch bore is 4.25 x 0.0050 = 0.0212-inch top ring endgap.

You've Got Problems?We've Got Solutions!

CarCraft@primedia.com

CarCraft.com

Car Craft Mag

6420 Wilshire Blvd.

Los Angeles, CA 90048

'CC Quickies"Remember these people are not rational, they are yelling at you in their underwear at 7 in the morning on a Sunday; chances are they cannot be reasoned with."-San Fernando Valley Illegal Soap Box Derby Federation.