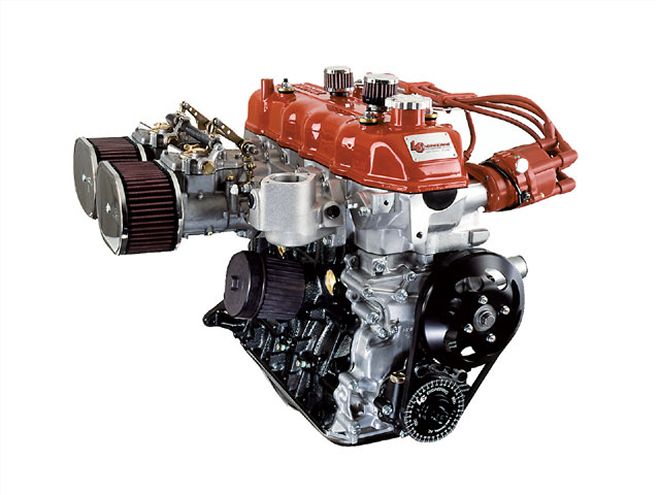

This Toyota 22R engine is one of many long-block combinations offered by LC Engineering. The sidedraft Weber carburetor version features the more desirable cylinder head from the earlier 20R engine.

This Toyota 22R engine is one of many long-block combinations offered by LC Engineering. The sidedraft Weber carburetor version features the more desirable cylinder head from the earlier 20R engine.

You read that title right. We're talking about Toyota four-cylinders as an alternative powerplant for your next hot rod project. You've seen these cars out on the street and in parking lots around town. Maybe you've even got one in the driveway as your daily here-to-there car. Did you ever notice that those tough little four-cylinder engines under the hood are virtually indestructible?

The off-road crowd figured it out years ago and has been running various Toyotas in the sand and on the rocks. Drag racing fans have been watching Toyotas run for a few years already, not just on the import circuit but also in NHRA Funny Car. American-built Tundras have been competing in NASCAR's Craftsman Truck Series since 2004 and, as this is being written, Toyota is on the verge of announcing its likely entry into the Busch Series and Nextel Cup next year.

Before you start complaining about R&C merging with Compact Import Car Tuner magazine, that's not where this is going. We're just poking our nose into a world we're not very familiar with, in the hopes of turning up some interesting options for hot rodders willing to think differently. It's the same philosophy we used 40 years ago when we promoted the Volksrod T-roadster with an air-cooled VW engine. VWs never edged traditional mills out of the hobby, but some cool hot rods were built along the way. The same thing is happening with Toyotas, and we're kind of curious about it. Maybe you are too.

We talked about this topic at length with several builders at Toyota and Toyota Motorsports, as well as aftermarket folks at LC Engineering and Toysport, and a few hot rod builders who have already taken this route. Jim Shelton, who owns the Chevy-powered '32 roadster that won the Asphalt Ego-Rama in 2005 (and who managed a Toyota dealership for many years) pointed out the potential of these alternative powerplants, which are easy to find at the local salvage yard (where complete drivetrains can be pulled fresh from donor vehicles) and are supported by both the performance aftermarket and the corner auto parts chain store.

The more we scratched the surface, the more we discovered that there were numerous engine choices that would be great, but for basic, keep-it-simple swaps, most people we talked to recommended two basic engine types: the 2T and 3T series, and the 20R and 22R series. Since those engines are a good way to get into this whole thing, that's where we focused our attention.

Part 1: The 2T and 3T

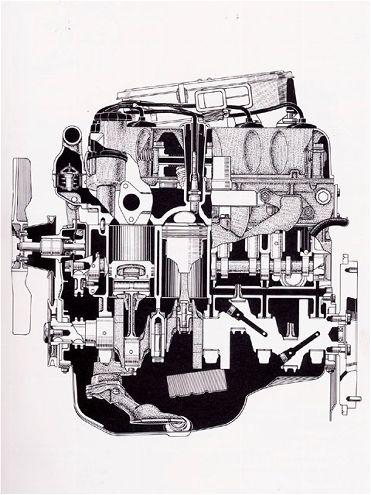

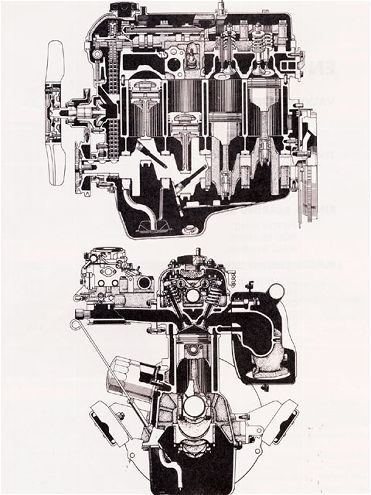

You know those old Toyota engines that look like half a Chrysler Hemi? Those are from the T series and can be found in old rear-wheel-drive Toyotas from the '70s and '80s. Toyota introduced the 2T-C engine in 1971 under the hood of the U.S. Corolla. The 1.6L, two-barrel carbureted, two-valve pushrod engine features hemispherical heads that can be bored quite a bit to boost displacement beyond the stock 97 ci. The 2T-C was produced until the 1980 model year, when Toyota introduced the 3T-C, a 1.8L increased-stroke version of the earlier engine. The 3T-C was produced through 1982.

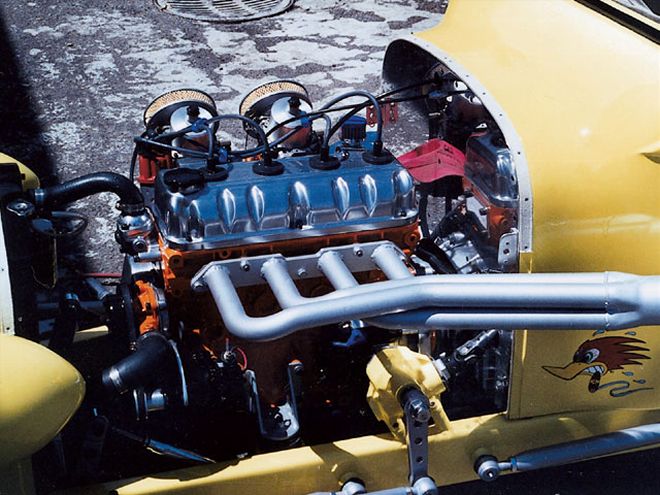

When it comes to Toyota-powered hot rods, it's hard to find anybody more knowledgeable than Jim Leininger. Jim has been racing at Bonneville since the '60s and is a field product engineer for Toyota. In 2004, Jim was the engineer on the hybrid Prius that set a land speed record on the salt at a speed of more than 130 mph. Jim loves the T series engines for hot rod applications because they are already rear-wheel drive, they're carbureted, and you don't have to be a Toyota engineer to get it to work in your hot rod.

Jim chose a 2T-G, fed by a pair of Mikuni-Solex sidedraft carbs, for his '27 Ford modified. The 2T-G is the more powerful twin-cam version of the hemispherical 2T-C with two sidedraft two-barrel carbs (there is also the 2T-B pushrod version with dual downdraft two-barrel carbs that looks like an old Ardun). Not all of these variations are easily available in the U.S., but the Internet is making it easier to find them.

The early ('71-74) carburetors found on these engines are simpler and predate emission-related functions, but have the disadvantage of possible burned-out choke stove heater pipes in the manifold.

According to Jim, the '76-79 carbs are recommended, although a little work is required to disconnect the emissions functions. As with all old carburetors, check for worn-out diaphragms, damaged needles, and worn bores. Weber two-barrels are one alternative to the Mikunis.

Jim is running the popular Toyota T-50 transmission from a Supra Turbo, which he likes because of the close-ratio gears and overdrive. Because of the miniscule amount of legroom, Jim needed a bellhousing that had the clutch release on the passenger side (the T-50's is located on the driver side). To have the best of both worlds, he mated the T-50 to an R150 bellhousing from a '93 V-6 truck, fabricating an aluminum adapter plate to accommodate the 1 1/8-inch-longer Supra input shaft. The rearend is from a '79 Toyota pickup. The 7 1/2-inch housing is found on early '70s to early '80s trucks. Jim used a 4.30:1 differential from a Previa van, combined with limited slip from an early '80s Supra, shortening each axle by about 1/8-inch.

Part 2: The 20R and 22R

The 20R and 22R were Toyota's most popular U.S. engines, and are still in use in racing, as well as in plumbers' and gardeners' pickups across America. Toyota introduced the indestructible 2.2L two-valve, SOHC 20R in the compact pickup in 1972, and the engine found its way into Celicas and Coronas starting in 1975. The two-valve SOHC carbureted 22R, displacing 2.4 liters, appeared in compact pickups, Celicas, and Coronas in 1981, and lasted through the mid-'90s. The fuel-injected 22R-E came out in 1983, with a turbocharged version-the 22R-TE-appearing one year later.

In addition to displacement, there are a few other differences between the 20R and 22R engines, including the head ports, combustion chamber design, intake manifold design, and the chaindrives. People generally go for the larger-displacement 22R block, but prefer the earlier 20R head and intake, and will run that combination. Prior to '83, these engines used a double timing chain system. Switching later single-chain 22Rs to the earlier two-chain system is a common conversion, which requires not much more than some simple machining on the cover to make it fit.

According to Joel Luz, owner of Toysport, which specializes in high-performance Toyota engines for street and race applications, one of these normally aspirated engines can be easily modified to make upward of 200 hp, and makes a great setup for a lightweight rod.

There's a lot of aftermarket support for the 20Rs and 22Rs. LC Engineering is one of the biggest suppliers, and offers short-blocks and long-blocks in every conceivable configuration, as well as engine components, accessories, gaskets, induction packages, headers, brakes, and more.

According to John Kimes in LC Engineering's tech department, the ready availability of inexpensive parts and the ease of the swap are two of the biggest appeals of these engines. A builder could order everything he needed from Internet aftermarket companies, or freshen up a cheap salvage yard motor with a rebuild kit and save even more money. John says the procedure is simple: "Pick up a tranny and rearend, shorten the driveshaft, bolt it all in, and away you go."

Pairing the 20R or 22R with the stock Toyota five-speed transmission (W-50, W-55, W-56, W-57, W-58, W-59) is the easy approach, but for those who must have a GM TH350, TH400, Powerglide, or Ford C4, there are adapters available from the aftermarket for that as well.

Since the 20R and 22R are larger engines than the 2T and 3T, the rearend gear ratio doesn't need to be as high to get your hot rod moving. Depending on the weight and tire size, a gear ratio of 3.50, 3.73, or 4.10 would probably be sufficient. Once again, if you can use the entire drivetrain from the same donor car, you've made the job easy. The Toysport Web site has excellent charts listing the various engine models, transmission gear ratios, rearend ratios, and lots more.

Here's the bottom line: If your definition of hot rodding stops with the drivetrain combinations that we've been building for 60 or 70 years, that's great. Traditional American V-8 mills are going to be the number one choice in this hobby for quite a few more years. But if your definition of hot rodding includes taking something different and figuring out how to make it work in your ride, then here are some relatively cheap, relatively simple alternatives that could be relatively cool.

Controlling Vibration

As an engineer and land speed car builder, Jim had a lot of concerns about the vibration inherent in high-revving, 180-degree, four-cylinder engines. He went to great lengths to minimize the issue in his roadster. Some remedies include dampers in the crossmembers directly below the engine, heavy flywheels, low engine compression, hydraulic or cable clutch operation, and rubber-mounted radiators. The stock header pipe is rigidly anchored at the bellhousing and has a soft mount at the back. "Use as many stock parts as possible," is Jim's suggestion. "Many of these components have vibration dampers. They're made for small cars and fit well in a hot rod."

Class Project

Dick Walters teaches auto shop at the Washington State Penitentiary in Walla Walla, where his students built this traditional-looking '27 Ford, powered by a 3T-C out of an '82 Corolla. Dick raced these engines in his younger days, and has used them in several rod projects.

"All I did to the engine was freshen it up-new timing gears and chain, made the manifold, and ported the head." Instead of buying Webers, which would have worked well, he decided to use a pair of Nissan 240Z carburetors. The hardest part of the job, he says, was building the fabricated intake manifold and exhaust manifold; he machined his own baseplates from 3/8-inch plate. He mated a new VW points-type distributor to an electronic Toyota base, TIG welding the shaft together. "I wanted to keep it retro-looking to go along with the look of the hemi," he says.

Dick built his own motor mounts, using old-style Chevy pad motor mounts from Speedway. The engine has good mount bosses and it's a straightforward job, he says. The little hemi was hooked up to a three-speed automatic Corolla transmission, shifted with a motorhome shifter from a salvage yard. He combined Toyota and Chevy driveshafts to spin the Nissan pickup rearend, modified to look like a quick-change.