Tire treatment, often referred to as soaking, is becoming a popular way to enhance performance while saving money, which is truly a racing oxymoron. We will explore the secretive world of race tire soaking and try to come to some intelligent conclusions about this underground movement.

Tire treatment, often referred to as soaking, is becoming a popular way to enhance performance while saving money, which is truly a racing oxymoron. We will explore the secretive world of race tire soaking and try to come to some intelligent conclusions about this underground movement.

The treatment of racing tires with various solutions has been a hotly debated topic for a number of years. During the last ten years or so, the art has become a science of sorts. Teams have become more know-ledgeable, dedicated companies have emerged and are prospering, and a whole culture of soakers has emerged. This secret group is much like the early moonshiners who plied their trade right under the noses of the authorities. The flip side of this coin is that the practice is opposed by the "soak police" who promote, operate, and sanction the various racetracks across the country.

Let's take a look at the evolution of this phenomenon, the specifics of the treatments and why they might be effective, and where we stand today on all sides of this issue.

How It All Began Soon after the development of dedicated racing tires, teams quickly discovered that the sooner a tire was raced after leaving the mold, the better it gripped the track and the faster the car could go through the turns. The longer a tire sat on the shelf, the harder it got and the less grip it had. That basic principle is still true of today's racing tires. Many manufacturers will advise you to store your tires in a dark, cool place and wrap them to help prevent deterioration due to the evaporation of certain chemicals that help maintain the elasticity of race tires.

Dirt teams find tire soaking to be especially useful. A glaze will often appear on the surface of a dirt tire after a heat cycle, and the team must remove this hard crust before the next use. It is suggested that when using the treatments, the tire will not glaze over as easily, saving a ton of work. For that reason alone, tire soaking is well worth the effort. If the series uses only one design and hardness of tire, a team can adjust the tire characteristics by using the treatments.

Dirt teams find tire soaking to be especially useful. A glaze will often appear on the surface of a dirt tire after a heat cycle, and the team must remove this hard crust before the next use. It is suggested that when using the treatments, the tire will not glaze over as easily, saving a ton of work. For that reason alone, tire soaking is well worth the effort. If the series uses only one design and hardness of tire, a team can adjust the tire characteristics by using the treatments.

As racers became aware of the shortfalls of advanced age in a race tire, they began to search for ways to introduce various ingredients into the tire so that it could live a longer life. In the mid-'90s, a few enterprising teams took advantage of the use of tire treatments to freshen up their tires. Most teams were not aware of the process. This left a select few winners who cleaned up each weekend. The soakers' world came crashing down when some of the sanctioning bodies declared that all teams were to purchase and use their race day tires on the day of the race. That ended the reign of many soak champions.

Almost overnight, teams that were considered unbeatable could not keep up and were struggling to finish in the Top 5 each race night. So, as it always happens in racing, everyone had to get smarter in order to circumvent the rules, and that they eventually did.

How Big Is It? In today's racing world, it is important for us to understand the magnitude of the "problem" in terms of the following: 1. In which classes does soaking exist? 2. What percentage of racers are in a particular type of racing soak? 3. Are the numbers growing? The answers to these questions will astound most outsiders and many who think they are in the know. The only people who know beyond a shadow of a doubt are the users themselves, who stay very quiet on the subject, and the actual manufacturers of the products, where discretion is mandatory. We talked with a number of people from both groups and discovered the real truth. We promised not to reveal their names, series, or any other information about them. We can say that the teams who use treatments are not who you would call outlaws or devout cheaters, but in most cases ordinary teams that are well-respected and only do what many others are doing.

A certain percentage of racers in virtually every segment of the circle track industry use tire treatments to enhance the grip properties and longevity of their tires. The companies who manufacture, market, and sell race tire treatments in various forms tell us that the number of users of their products is much greater than anyone would ever imagine. More and more, teams are discovering the advantages of soaking. They feel it is no different from seeking out the best engine or chassis builder in order to keep up with the competition.

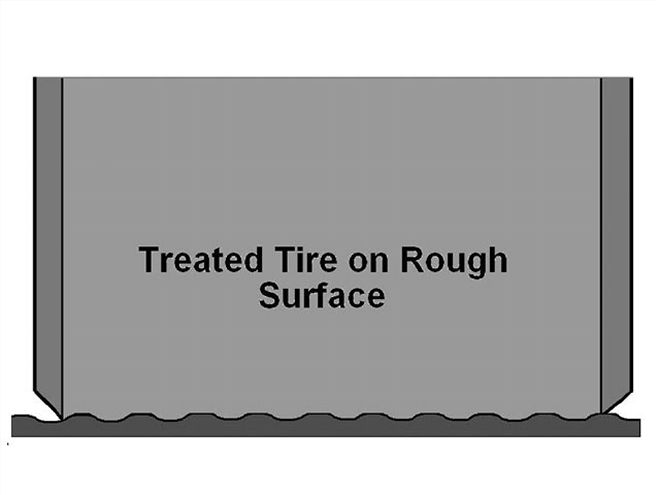

A hard tire does not adhere well to a rough surface because the contact patch does not conform to all of the surface area. The total square inches of rubber that meets the track is reduced when the tire is harder. By treating the tires, the surface is changed chemically so that it is more compliant and "fills" the areas around the high spots in the track surface. A treated tire would not benefit performance nearly as much if the track were smooth.

A hard tire does not adhere well to a rough surface because the contact patch does not conform to all of the surface area. The total square inches of rubber that meets the track is reduced when the tire is harder. By treating the tires, the surface is changed chemically so that it is more compliant and "fills" the areas around the high spots in the track surface. A treated tire would not benefit performance nearly as much if the track were smooth.

Is Soaking That Effective?

There are various claims made by those who use and sell tire treatments about how effective the treatments are. The real numbers depend a lot on the driver's experience level, the setup in the car, and the racetrack itself. Claims of lap times two- to five-tenths lower may be valid for a worn-out track, whereas you might not need to soak the tires at all on a newly paved track. True average lap time gains are in the two- to three-tenth range. That could be the difference between starting and running in the Top 5 or the middle of the pack.

Many companies claim the tires will run cooler and last up to 50 percent longer by using tire treatment. The lower temperatures, they say, are due to the fact that a tire that grips the track better will slide around less, causing less heat and generating friction. More grip also reduces the amount of wear because the tire is not scuffing off little pieces lap after lap.

Tire treatments generally do not make the tire sticky. Chemicals that would do that would also cause the tire to wear excessively and not last but a few laps. The modern blends will make the tire surface more flexible so that the face of the tire can conform to the track surface. The rougher the track surface, the more difference the treated tires will make. It's all about helping the tire make complete contact with the entire surface of the track instead of sitting atop the peaks and missing the valleys like a hard tire will do.

Used tires can be brought up to near-new grip capability simply by applying treatments to them. This allows a team to run the same tire for several weeks if the races aren't too long. For a track that runs feature races of 35-50 laps, a team might expect to use a set of tires for several weeks before needing to buy new tires and still be competitive.

Many teams on the low end of the budget scale will buy low-lap-count used tires from the teams who can afford new tires every week. They treat them, and then, with the right setup, are able to compete on a fairly even basis with the high-dollar programs.

Is This Good or Bad for the Sport? Depending on your conversation, racers who use tire-enhancing compounds are either ruining the sport or causing it to grow. Most racetracks forbid the use of tire treatments. Some are aggressive in enforcing the rules while others tend to look the other way, or worse, practice selective enforcement for whatever reason.

An indentation-hardness durometer reading can be inaccurate. We read a used tire in three different places and got three different readings. The primary causes of these differences were the residue rubber that was stuck to the tire as well as the pitting that naturally occurs with race tires. Small pieces of rubber attaching themselves to a hot tire surface is a common occurrence when exiting the racetrack after qualifying or practicing. This can play havoc with durometer readings.

An indentation-hardness durometer reading can be inaccurate. We read a used tire in three different places and got three different readings. The primary causes of these differences were the residue rubber that was stuck to the tire as well as the pitting that naturally occurs with race tires. Small pieces of rubber attaching themselves to a hot tire surface is a common occurrence when exiting the racetrack after qualifying or practicing. This can play havoc with durometer readings.

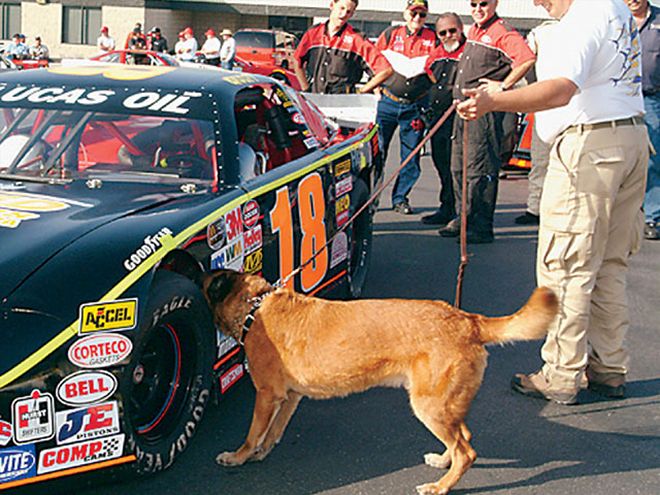

Irwindale Speedway in California went so far as to bring in a tire "dope"-sniffing dog that had been trained to sniff select chemicals that are used in most tire treatments. It worked; the first night, several hits were recorded and those teams were told to not come back with treated tires. (See sidebar)

Many tracks rely on tire durometers that are used to measure the indentation hardness of the tire. The use of these instruments is subjective and inaccurate at times. The tire must have been run and heated in order for most of the soaks to work. Therefore, on a cold tire, or one that has been allowed to cool sufficiently, the reading will be fairly normal.

The durometer reading itself is indicative of the age of a new tire. For a new batch of tires that may have just arrived from the tire manufacturer, the reading might just be near the softness limit, while a few months later with the vendor selling from the same batch, the reading might be much higher. Suppose I purchase a set from a newly "hatched" batch, wrap them in cellophane, and store them in a cool, dark place. When I go to use them later on, they will read a lot softer than other tires from the same batch that have hardened after being stored in a trailer, enduring high heat day in and day out. The difference can be substantial and I have not cheated by soaking the tires, but I may well be a target of suspicion and disqualified nonetheless.

Some tracks will penalize a team with tires that measure significantly softer than the majority of other teams' tires. The above example shows why this may not be the right thing to do. What is best for the sport is having close competition in which everyone is on the same page and all racers are doing the same thing-not something in between. Since some racers will always soak, that leaves little choice for the tracks.

Is Tire Soaking Dangerous? Just about all tire companies warn racers against the use of chemical treatment of their tires. The two largest manufacturers of racing tires in the U.S. include the following warnings on their Web sites:

After a tire has been run, the surface begins to pit and a hot tire will pick up rubber pieces off the track as the car is coming in after a hard run. Compare the used tire on the top with the new tire on the bottom. The irregular surface on a used tire makes accurate durometer readings almost impossible.

After a tire has been run, the surface begins to pit and a hot tire will pick up rubber pieces off the track as the car is coming in after a hard run. Compare the used tire on the top with the new tire on the bottom. The irregular surface on a used tire makes accurate durometer readings almost impossible.

Goodyear: Never attempt to treat or alter the tire carcass and/or tread compound of any Goodyear Racing Tire; such as tire "soaking" or use of tread "softener." This practice could result in premature or catastrophic tire failure with resulting serious injury or death.

Hoosier: Chemical Treatment of Tires-Hoosier Racing Tire Corporation strictly forbids any chemical alteration of the tire carcass and/or tread compound such as tire "soaking" or use of tread "softener."

These warnings carry a degree of validity for those who choose to mix up their own batch of tire brew in the backyard barn. Some types of chemicals will deteriorate the tire compound as well as the core structure and possibly cause the tire to fail with obviously dangerous results. The companies who publicly sell tire treatments all have a highly refined knowledge of the chemicals they use and exactly how those affect the tire in all areas.

Many of the early concoctions were made using, among other things, turpentine, kerosene, and creosote. Modern commercial race tire treatments do not use these chemicals. In fact, the argument that modern tire treatments use so-called dangerous chemicals that can cause health problems is absolutely true. The problem with that presentation is that these same chemicals are found in products we all use on a day-to-day basis such as gasoline, paint, and paint thinners and solvents.

Tuluene, Xylene, and Acetone may be used in some or all of the modern tire treatments. When asked if tire treatments may contain those chemicals, an expert in the industry confirmed it. At first glance, these sound like chemicals we should avoid, but do we really come in contact with these in our everyday lives? Let's see what the government has to say about their availability and uses.

Many racers utilize a rotisserie machine that is used to rotate the tire through a solution for a predetermined period of time. In this way, a precise measure of soak can be applied to the tire. The amount of time the tire soaks determines its ultimate softness when the tire is hot. Soak times vary depending upon the original tire hardness and the type of application (class of car and racetrack conditions).

Many racers utilize a rotisserie machine that is used to rotate the tire through a solution for a predetermined period of time. In this way, a precise measure of soak can be applied to the tire. The amount of time the tire soaks determines its ultimate softness when the tire is hot. Soak times vary depending upon the original tire hardness and the type of application (class of car and racetrack conditions).

Tuluene: The EPA states on its Web site that "the largest chemical use for tuluene is to make benzene and urethane. It is released into the atmosphere principally from the volatilization (vaporization) of petroleum fuels and tuluene-based solvents and thinners and from motor vehicle exhaust."

Xlyene: OSHA says, "Xylene is used as a solvent in paint, printing, rubber, and leather industries; as a solvent for gums and resins, rubber, castor and linseed oils and dibenzylcellulose; as a constituent of paints, lacquers, varnishes, inks, dyes, adhesives, and cleaning fluids; as a carrier in production of epoxy resins; as a degreaser and cleaning agent; as a constituent of motor and aviation fuels; in chemical synthesis; and in the manufacture of quartz crystal oscillators, perfumes, and insect repellents."

Acetone: From the CDC Web site: "Acetone is a manufactured chemical that is also found naturally in the environment. Acetone is used to make plastic, fibers, drugs, and other chemicals. It is also used to dissolve other substances. It occurs naturally in plants, trees, volcanic gases, forest fires, and as a product of the breakdown of body fat. It is present in vehicle exhaust, tobacco smoke, and landfill sites."

There are some very dangerous and sometimes illegal chemicals that some racers try to incorporate into their homemade treatments. Legitimate tire-treatment manufacturers do not use ingredients that either hurt the tire or are illegal or overly dangerous to the user. Several representatives of these companies told us their products are no more dangerous to handle than gasoline or motor oil. A certain degree of care must be taken when handling all chemicals, even everyday cleaning products.

The facts about the safety of legitimate commercial tire treatments speak for themselves. All of the companies we contacted told us they would not be in the business of selling race tire treatment if they thought it dangerous. With our litigious society as it is, they wouldn't have to make that decision-the public would make it for them.

What Does The Future Hold?

The fact is that most racers want to use tire treatments. A few don't want to use it but must because other top teams soak. Since tire soaking makes the tires perform better, the cars will handle better. When the cars handle better, we get better racing for the benefit of the spectators. Better racing means more attendance and more money to run the track, not to mention more profits for the track owners.

Racers are allowed to, within certain limitations, tune their carburetors, motors, setups, shocks, gearing, and so on, so why not the tires? Some have suggested that one reason tracks are adamant about stopping soaking is because they operate as the tire vendor, and that is a source of income for the track owners. If every team were able to use their tires longer through the use of soaking, then fewer tires would be sold.

Sinbad, the tire-sniffing dog, is a member of the Irwindale Speedway official crew in 2004. When he detects the odor of tire treatment, he will sit. Sinbad is at work in the inspection line. This car passed the smell test.

Sinbad, the tire-sniffing dog, is a member of the Irwindale Speedway official crew in 2004. When he detects the odor of tire treatment, he will sit. Sinbad is at work in the inspection line. This car passed the smell test.

If true, this mentality is directly contrary to what most promoters and sanctioning bodies say. Their stated goals supposedly include finding ways to save the racer money. Among the most expensive items a racer must continually buy are the tires. Many parts companies and race shops offer to treat a race team's tires for them at a cost of around $45 per set. You can do it yourself for less. Compare the low cost of soaking to that of a new set valued at between $400 and $600 per set.

Do the math: Example savings-for 30 weeks of racing, a team either buys new tires every week at $440 for a yearly total of $13,200, or soaks and uses the same tires for three weeks for a yearly total of $4,400 (10 sets at $440) plus $45 per week soaking costs, which totals $5,750 yearly. Soaking saves this team $7,450. That's enough to freshen most Late Model race engines or actually purchase a new Stock class motor.

There have been teams that could continue to race in part to the availability and use of tire treatments and the cost savings. So, does the future of racing really depend on the elimination or the allowance of soaking? The fact remains that you can only treat a tire to a certain level of durometer reading whether it is new or used. Soaking could possibly level the playing field in many cases.

Many racers feel it's time the promoters across the country were better educated and responsive to what the racers really want and need on all fronts. That means having the integrity to put the racer, who spends lots of money to show up and put on the show every week, at the top, instead of at the bottom, of the food chain. The more popular soaking becomes, the better the products will become. It is the opinion of many racers that when everyone is allowed by rule to treat their tires, no one will have an advantage in the area of tires. More teams will be able to afford to race more competitively, and then the sport will be better off.

The Nose Knows

It's against the rules to soak tires at California's Irwindale Speedway, and it has been a tech inspector's nightmare to find the culprits. Due to the complexity of the checking process, some tracks don't even test for soaking, turning a blind eye to the process. That's not the case at Irwindale.

In March 2004 Sinbad jumped out of the SUV of his handler, Scott Edmonds, and went to work. The 10-year-old Belgian Malinois is coming out of retirement from his work as a bomb-sniffing dog to help the track. He has an official "hard card" identification (No. K9-1) and is a fixture in the pit area.

The idea came from Ed Branch, who runs the tire program at the track. Branch contacted Interquest Detection Canines in Pasadena after theorizing that if dogs can sniff out bombs, drugs, and other illicit materials, they might also be able to detect illegal tires. Edmonds confirmed that it could be done, and Sinbad was selected for the task. The dog went through countless training sessions to differentiate between official and illegal tires. Tests were conducted on hot afternoons and cool nights. Sinbad's final exam grade was 100 percent.

On the night of his first visit to the track's inspection line, Sinbad sat at three cars and followed that with a post-race sitting. After track officials visited the teams, there were assorted confessions of illegal activity. Sinbad's record is intact.

Racers may not consider him man's best friend, but his nose knows when something is amiss. Like all tech officials, who usually work like a dog on race nights, he's just doing his job.-Larry Jewett