E-mail: HOTROD@primedia.com

* Mail: HOT ROD PIT STOP, 6420 Wilshire Blvd., Los Angeles, CA 90048

* Fax: 323/782-2223

* Message Board: HOTROD.com

Got a tech question? Send them to me and I'll answer select questions within the magazine or on our Web site. I cannot respond to every question personally. When e-mailing, include Pit Stop in the subject line, and don't forget to include your real first and last name (not screen name), and hometown or military unit, base, or ship. This month online, Bill Heller wants to know if it's really necessary to run a water-pump bypass hose on a big-block Chevy. To learn the answer, go to HOTROD.com and click This Month.-Marlan Davis

Q-Jet Leakage

I am having problems with the Quadrajet carb on my '72 Cutlass. The engine cranks fine, drives fine, and idles fine. The problem comes when I shut it off: After about five minutes,fuel seeps from the top of the carb. It also smells of unburned gas every time I crank it. I have rebuilt and taken it apart about four times to fix it with no success. Please help.

Tony Bell

Memphis, TN

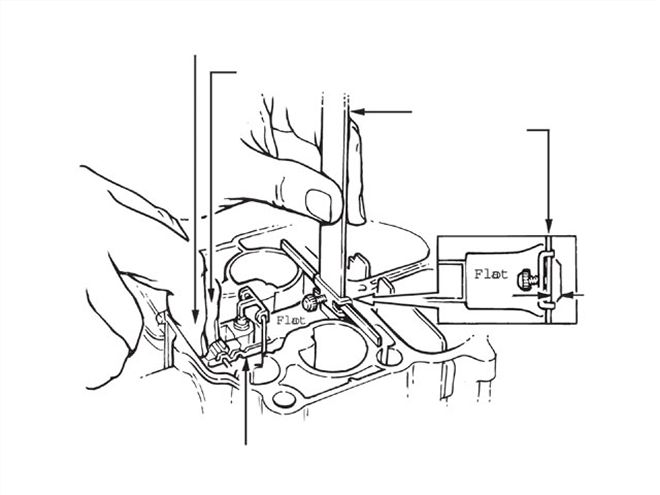

The culprit may be in the carburetor itself, in the fuel-supply system to the carburetor, or a combination of both. For example, if the fuel tank is improperly vented, pressure can remain in the line even after engine shut-down, resulting in fuel seepage into the carburetor, especially if the inlet valve (needle-and-seat assembly) is stuck open, unseated due to excessively high fuel pressure (don't go over 511/42 psi on a Q-Jet), or installed improperly (see the photo on page 141).

Also look at the float or float adjustment. Floats can get heavy (fuel saturated), but usually a carb with this problem floods out all the time, not just under certain circumstances as related in your letter. Brass floats are more likely to leak than the more common Nitrophyl float (the latter, if normal, weighs about 7-9 grams).

Check the float level following the procedures in the diagram. For the '72 Olds Q-Jet specifically, the official float setting is 11/44 inch as measured from the top of the main-body casting to the top of the float. This is higher than the 31/48 to 151/432 inch usually specified for Q-Jets. If you do not have the original carburetor (GM PN 7042250 for a 350ci engine; PN 7042953 for a 455), try setting the float to 151/432 and see if the problem diminishes.

Finally, check the air horn (top lid) for warpage. Over-tightening can cause the horn to warp low on the perimeter and higher toward the center. Lay the lid on a flat surface, douse the room lights, and backlight the lid using a small flashlight. If light seeps under the lid, it's warped. Unfortunately, the intricate lid is virtually impossible to hand-file flat, and-because some metering takes place in the air horn-doubled-up gaskets may squish-in and interfere with proper metering. You might be able to save the lid by temporarily installing thin, 0.032-inch-thick washers between the air horn and the main-body attaching bolt holes then carefully tightening the perimeter bolts to unbend the lid and remove the warpage. Otherwise, you're looking at a new carburetor.

Hybrid Speedo Drive

I have a '92 Camaro with a 350 and a replacement 700-R4 transmission. The tranny has a mechanical cable-driven speedo output and the car has the wires for an electric speedo. I've seen electrical-to-mechanical converters, but with the way they are designed you cannot install them backward. Is there a way of getting my trans to work with the stock electric speedo without swapping out the trans for a 4L60?

Brock Barlow

New Palestine, IN

Absolutely-GM faced the very same problem on most '85-'92 F-cars. The 700-R4 and T5 transmissions used originally in those models still had mechanical speedo drive gears, even though the speedometer was electric. GM installed a special speedo driven gear that interfaced with a pulse generator that accepts the wires going to the speedometer. The table lists the GM gear combos for 700-R4 transmissions; T5 part numbers are different. You won't have to change the existing drive gear provided the available driven gears bring the unit into calibration. The calibration procedure is the same as with any traditional set of mechanical speedometer gears (see Car Craft, April '00, "How to Correct Your Speedometer," ; or browse to www.carcraft.com/techarticles/113_0004_gear). If your local GM dealer feigns ignorance, contact Mike English at Rotolo Chevrolet or Lance at Lance Martin Automotive.

Big Brakes for the Monza

I've had a '77 Monza for the last 15 years and each year I start a project or two on it, trying to save money by using junkyard parts if possible. This year, I want to change my front spindles so that I might have a Chevy five-bolt pattern and be able to buy rotors at the local parts store as I wear them out. It is a lot of work going through junkyards pulling spindles out for comparison. Will an '83 S-10 two-wheel-drive spindle transplant? If not, is there anything else out there that fits? I already have a Chevy five-bolt-pattern on the rear.

Bob McCormick

Detroit, MI

There is no direct bolt-in, but spindles from an '83-and-later 2WD S-10/S-15/Blazer/Jimmy or '79-'88 GM G-body (Monte Carlo and related rear-drive intermediate-chassis clones, Hollander interchange No. 1025) can be made to work by using adapter sleeves available from v8monza.com. The sleeves permit retaining the stock GM H-body (Monza, Vega, and clones) upper ball joints and '74-and-later GM H-body lower ball joints. Alternatively, the H-body upper and lower control arms can be reworked to accept the G-body ball joints (welding and fabrication skills required). Reportedly the S-truck spindle works better because its lug nuts/studs are larger (stronger) and the integral steering arm is only 11/42 inch longer than the stock Monza spindle (the G-body arm is a full inch longer).

From the wrecking yard, grab the tie-rod ends, spindles, calipers, rotors, dust shields, and wheel bearings. The correct-length brake hoses are from a '76 Chevy Nova. A NAPA TruStop hose (PN UTS4136845) is the best choice; other aftermarket hoses may require modifying the keyways in the stock H-body brake-hose/brake-line brackets.

If your H-body was factory-equipped with vented front brake rotors, the existing master cylinder and proportioning valve should suffice. Otherwise, install an '82-'88 S-10/S-15 manual-brake master cylinder and reservoir (Hollander 737). Do not use the G-body master cylinder; when installed in an H-body, its reservoir ends up tilted forward, resulting in fluid spillage when the cover is removed. If proportioning requires adjustment, I recommend gutting the metering functions out of the factory prop valve (retaining it for brake-failure warning and distribution purposes only), then installing an aftermarket adjustable prop valve inline to the rear brakes.

Complete step-by-step instructions and photos, a parts list, and sleeve purchase information are available from v8monza.com. This company also offers complete H-body V-8 engine and drivetrain conversion solutions.

C10 Spark-Knock

I have an '85 Chevy C10 truck with a 350/700-R4 combo from an '87 Suburban. It has been converted to a conventional carburetor and ignition system using an Edelbrock 1406 on a Holley Street Dominator intake and an HEI ignition with a Hypertech Power Coil, MSD module, and a new stock pickup that fires the plugs through MSD Super Conductor plug wires. The motor has a Comp Cams XE262 K-kit. It has a set of stock-type headers from an '85 1-ton.

I have spark-knock at wide-open throttle so bad that I have to set my timing at TDC. I recurved the distributor and tried everything else I could think of. I even removed the heads to make sure there are no excess deposits on the pistons or heads. It doesn't run hot or even overheat. I have richened up the carb on the primaries and secondaries and replaced the harmonic balancer, thinking that it may have slipped; nothing helped. The EGR is blocked right now but will be hooked back up for emissions purposes.

On the '85 stock headers, the two center ports are siamesed (not divided). Could this be disrupting the flow to the cylinder next to it and causing the detonation?

I have limited the timing with an MSD bushing kit, but I feel I am not getting all my timing. I want to be able to at least set it to 8 degrees BTDC; most other people say I should be able to set it at 12-14 degrees BTDC.

J. Dodson

Angleton, TX

The absence of an EGR valve may exacerbate tip-in pinging but shouldn't affect wide-open-throttle (WOT) performance. The siamesed headers are no big deal, either.

If 305 heads somehow ended up on this so-called 350, their tiny 58cc chambers would cause the engine to rattle its brains out. You could also have a jumped chain or bad oil rings. Was the cam itself installed correctly? Many shadetree hot rodders insist on plugging in the cam 4 degrees advanced right from the get-go-even though most street cams are already ground advanced.

A cylinder-compression check often provides clues for isolating the problem: For example, if cylinder-to-cylinder compression is all over the place, I'd bet on a jumped chain or improperly installed cam; if it's low on one cylinder, look for a ring or valveguide problem; if it's low on two adjacent cylinders, it may be a head gasket.

As for the timing itself, it's the total timing (initial plus centrifugal advance) that's important, not any particular static initial setting. Assuming no mismatched parts or mechanical gremlins, you should have around 9-9.5:1 static compression. With a mild street cam, the engine ought to like about 34-36 degrees of timing at WOT on 91-octane gas, or 28-30 degrees total with 87 octane. Beg or borrow an adjustable timing light, disconnect the vacuum advance, run the engine up to 3,000 rpm, and set the timing to 34 degrees and everything should be OK (unless the engine is really a 305 or 350 with 305 heads). If WOT spark-knock reappears after reconnecting the vacuum advance to spark-ported vacuum, the distributor has too much vacuum advance (not uncommon on a stock HEI).Try hooking the vacuum advance up to a manifold-vacuum port (a vacuum source below the carburetor throttle blades) instead of the more usual spark-ported vacuum port (a vacuum source above the carburetor throttle blades). Ultimately, install Crane's adjustable vacuum can (PN 99600-1 fits the GM HEI) and dial-back the vacuum advance to about 5-7 degrees.

Ford 460 Buildup

I'm putting a '79 Ford 460ci engine with production heads and a C6 trans into my '70 Ford F-250. What do I need to do to get 500 or so horsepower and 500 lb-ft of torque out of it? I had it bored 0.030 inch for flat-top Sealed Power hypereutectic pistons. I got a Comp Cams Xtreme 4x4 cam (PN 34-239-4) from Summit Racing. The 0.050 duration is 226 degrees on the intake and 234 degrees on the exhaust; the valve lift is 0.554/0.574 intake/exhaust. Summit said this is a good cam, but Comp said I needed a smaller cam for streetability because I only have an 8.0:1 compression ratio. Comp also said I would need a 2,200-stall converter to get the engine in the proper power range. I think I need 9.5-10.0:1 to make a killer engine on pump gas. I know I could get more of what I want just by bolting on some aftermarket heads, but I would like to see what I could do by shaving the block and heads, and maybe even porting the heads.

George Lewis

Orange, CA

Mismatched combo alert! Your selected cam is too big, the heads are too weak, and the compression ratio is too low. With 97cc combustion chambers, Speed-Pro H535P-30 flat-top pistons with two valve reliefs (-4.2cc effective dish volume), the Ford 460 "blueprint" piston deck height of 0.040-inch below the deck, and Fel-Pro PN 1018 heavy-duty head gaskets (11.2cc compressed volume), you're looking at about 8.8:1 compression max-insufficient for your chosen cam in a heavy 31/44-ton pickup truck. However, you need to retain at least this level cam to have any hope of closing in on the desired power and torque goals.

With the existing pistons, you can raise compression to 9.5:1 by zero-decking the block. Alternatively, every 0.003 inch removed from the deck on factory open-chamber 460 heads reduces combustion-chamber volume approximately 1 cc, so milling the heads about 0.030 inch to reduce chamber volume to 87 cc also yields around 9.5:1. A 9.5:1 compression ratio is OK for iron heads on 91-octane gas with this cam as long as you're not towing or carrying heavy loads (if you are, you shouldn't be using this cam). With aluminum heads you can go to 10.0:1 on the truck.

Still, major porting is mandatory on the sucky Ford iron smog heads to attain your goal. By the time you're done porting the heads, installing new oversize valves with a good multiangle valve job, adding heavy-duty springs, and machining the heads for an adjustable valvetrain, figure on having $1,200-$1,500 into the stock heads; that's within striking distance of an $1,800 set of Edelbrock aluminum heads.

And even with ported stock heads, you're looking at around 475 hp with the chosen cam and 9.5:1 compression. If you really want to hit the 500hp/500-lb-ft mark in that big truck, zero-deck the block, step up to Edelbrock's 95cc-chamber Performer RPM 460 head (assembly PN 60669), and mill them to 90cc to get 10.06:1 compression (that's about a 0.027-inch cut; Edelbrock says every 0.0055 inch removed from its head reduces chamber volume about 1 cc). Finally, install that 2,200-stall converter and at least 3.55:1 rear gears.

Where do i get . . .

...parts and service for old four-speed Hydramatics in the Southern California area?

William Douglas

Hesperia, CA

For parts only, contact Ron Gaines at Trans-Matic Parts (Glendale, CA; 818/246-7788; www.transmaticparts.com). For rebuilding services, contact Joel at Glendale Trans Exchange (Glendale, CA; 818/243-0413) or Paul Riley at Performance Transmission (Palmdale, CA; 661/273-3010).

...a listing or archive of casting numbers for classic motors and trannies? I'm restoring a '67 Firebird and am having problems trying to ID the motor and trans.

Johnny Bostick

Dallas, TX

Year One Inc. (Tucker, GA; 800/YEAR-ONE or 770/493-6568) has a Web page chock-full of Pontiac casting codes and ID photos-surf to www.yearone.com/updatedsinglepages/Id_info/pontiacengineid/pontengid1.html. Other good sources for general Pontiac codes and casting numbers include www.pontiacpower.org and Fred's Pontiac Information (www.teufert.net). For the '67-'69 Firebird specifically, check out www.firstgenfirebird.org.

...someone to make a stainless steel 3-inch exhaust for my '67 Camaro with a 454 LS6? All the local shops say they can't get a stainless collector ring to weld to the pipes to bolt to my headers, and none of them do mandrel-bending anyway.

Kevin Baker

Clinton, AR

Burns Stainless (Costa Mesa, CA; 949/631-5120; www.burnsstainless.com) and Stainless Specialties (Sebastian, FL; 772/589-7750 [tech]; www.stainless-specialties.com) have everything you need to fabricate stainless steel exhaust systems. Burns has special welding rods for joining stainless to mild steel; Stainless Specialties can build the whole system if you send a dimensionally accurate drawing.

...performance parts for an Olds Aurora?

John McLoughlin

Danbury, CT

Contact RSM Racing USA (Morton, IL; 866/776-7224; www.rsmracing.com).

....302/351 Ford V-8 conversion brackets for my '87 Thunderbird?Donnis McDonaldJohnsonville, SC

Kaufmann Products (Garden Grove, CA; 714/903-9717; www.kaufmannproducts.com) or Total Performance (Clinton Township, MI; 586/468-FORD). Or go to the wrecking yard and find 302 mounts and brackets from a similar-vintage T-Bird.

...quality work installing turbos and superchargers in Southern California? I plan on buying a new '05 Mustang and would like to have a nice kit put onto it.Dallas WilliamsIrvine, CA

Ford Performance Solutions (Anaheim, CA; 714/773-9027; www.f-p-s.com) and Extreme Automotive (Canoga Park, CA; 818/883-8165; www.teamextreme.net) specialize in Ford supercharger installations. For custom turbo setups, try Innovative Turbo Systems (Simi Valley, CA; 805/526-5400; www.innovativeturbo.com) or Nelson Racing Engines (Chatsworth, CA; 818/998-5593; www.nelsonracingengines.com). A good Web reference for turbo Mustang freaks is www.turbomustangs.com.