When last we worked on our 1969 Dodge Charger (code name Project 50), we had completed an installation of Reilly Motorsports' Alterktion suspension. It was time to test-fit the engine and the transmission. Astute readers will recall that this project was going to feature late-model technology sheathed in one of the most iconic muscle cars of all time.

With the car in full roller trim, we had now come to the point of the project where we had to make a decision on who was going to be the shop of record to do huge amounts of bodywork, prep, and painting of our B-Body. It didn't take long to figure out who we wanted to do the work. Ken Mosier and his Danville, Indiana-based shop, The Finer Details, should be a name you're already familiar with, and if you're not, you need to be. Mosier has been in the collector car business for more than 20 years and has been operating his own restoration shop since 2002. His cars have won more awards than we can count and from our vantage point, the quality of his shop's work is second to none.

This Charger started out life as a 318 automatic car. When we got it there was really not much left but the shell, a rotted-out dashboard, and the big bulky A/C box. Since there was nothing overly rare about this car and we had neither original engine, trans, or most anything else for that matter, we took the opportunity to dial up the good folks at Roseville Moparts and order a brand-new Gen III 6.4 Hemi. That was followed by a call to American Powertrain to get our hands on a T56 Magnum six-speed. That's right, we were in essence putting a late-model Challenger drivetrain in our '69 Charger. There was, however, one small problem.

That small problem turned into a bit of major surgery. You see, a T56 Magnum is a fairly tall transmission while the trans tunnel on an automatic Charger of this era isn't very big at all. To fit that transmission in our Charger we were going to have to modify the tunnel, and there was no way around it. We mocked up the transmission and located it exactly where it needed to be. After marking general cutting areas with a Sharpie, we broke out the body saw and cutoff wheel and proceeded to cut. A nip here and a tuck there, and we were able to pull the tunnel apart far enough to get the transmission in the proper spot. Then we tack-welded a patch panel so the guys at The Finer Details knew where the shifter hole needed to be.

In the process of doing all of that we unfortunately had to cut out bracing that spans the car's width about 20 inches behind the firewall, which you can see in the images. Cutting bracing in any car is never something you want to do and that's especially true in a unibody car, but we had no choice. So in order to properly support the car we highjacked some .095 DOM tubing from an old oval-track race car project and welded supports front to back. These, coupled with the new extra-beefy crossmember from American Powertrain should more than make up for our brace-cutting expedition.

Now our plan in doing all of that was to save Ken and his team some time and headache of dealing with the drivetrain, but when he saw our handiwork we learned why they call the company The Finer Details. Ken said it would be best to just send the transmission and engine to him so that they could ensure that everything fit correctly when they were done. Hours of work could have been wasted if Ken's team didn't have a way to double-check fitment. It's somewhat like the old measure twice, cut once mantra.

They say that pictures are worth a thousand words, so we'll let the images of the process shine through.

01. Project 50, our 1969 Charger, sits in The Finer Details, the Danville, Indiana, restoration shop of Ken Mosier. Take a good look because this car isn't going to look like this much longer.

02. Before the car ever made it to The Finer Details, we did some preliminary cutting and locating so that we had an idea of how the whole thing was going to fit together.

03. Using a cutoff wheel, the old tunnel was shaped to accommodate the Tremec shifter. You can see just how far up the trans tunnel we had to slice in order to fit the very tall T56 Magnum six-speed.

04. Unfortunately, we had to cut the center brace out of the car, which you can partially see sitting behind the new and very beefy trans crossmember. The heft of the crossmember coupled with the some added bracing that you'll see later should be more than enough to keep the Charger nice and stiff.

05. We used a block of wood to get the driveline angle close to ideal so that we could order the correct trans mount. How the whole driveline would sit in this car would pose another problem with the firewall, but you'll get to see how we handled that at a later date.

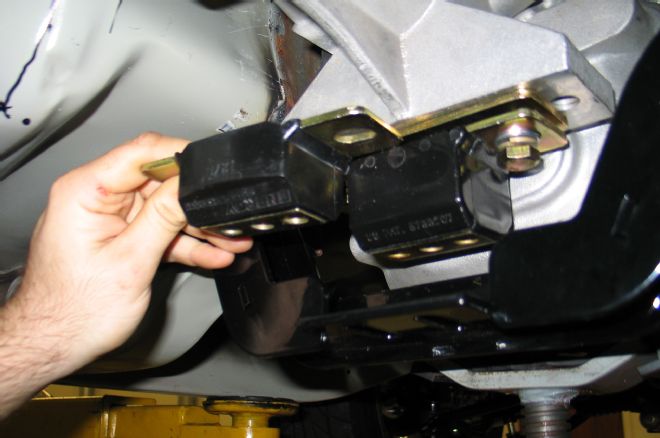

06. Energy Suspension sent two different sizes of transmission mounts to ensure that we had options since our little project wasn't the most common swap.

07. With the preferred mount chosen, we slid it into place and then tightened it down.

08. With the trans mount tightened down we could finalize the placement of the shifter hole, but first a strap was tack welded in place to help hold the floor pan in place. You can also see temporary bracing that we welded in to help keep everything square for the thousand-mile journey north.

09. We then tacked a sheet over the hole basically showing how we wanted the finished product to look. This was to be the road map for The Finer Details team.

10. Early on in this project we noticed a problem in a lot of the bracing on this car. Yes, we love Swiss cheese as much as the next guy, but not in this spot. This is the "before" shot.

11. Here's the "after" photo. Scott Dowdy of The Finer Details got hold of our car and grafted a good frame rail into the place of our holey one. He literally sectioned out the bad and replaced it with the good. When it's painted we'll never be able to tell the difference.

12. To fit the T56 in place we unfortunately had to cut out the torsion bar crossmember that spans the car's width about 20 inches behind the firewall, which you can see here. In order to properly support the car, we highjacked some .095-DOM tubing and welded supports front to back. These, coupled with the new extra beefy crossmember from American Powertrain should more than make up for the cut. Dowdy then covered our rollbar tubing with frame connectors from U.S. Car Tool.

13. Dowdy ended up cutting out a large rectangle to give the tunnel more continuity front to back. Once complete it will be impossible to tell that the tunnel was ever modified. Here, you can make out the original shifter hole for the automatic trans and how Scott plated over the open hole that was left when we cut into the torsion bar crossmember.

14. Here you can see the trans tunnel has been smoothed, the metal worked, and the hole for the shifter cut. The next step is to test fit the final product.

15. That's a brand-new drivetrain that normally can be found in a late-model SRT8 Challenger, but it's going into our Charger thanks in part to The Finer Details team who are getting ready to roll the engine and transmission into place as the car sits elevated on multiple jackstands.

16. The motor and trans sit in the very spot they will when the car is done, on the Reilly Motorsports K-frame. The only thing left to do is lower the car into place.

17. The painstaking work is rewarded with a perfect fit, exactly what you can expect from the guys at The Finer Details.