Six years ago, designer Eric Black pitched the idea to Rod & Custom magazine of pairing artists with builders to design the dream cars they'd love to build for themselves. The article that came from Black's idea can be found online here. It includes Black's design drawings of a 1932 Ford three-window coupe that he and Troy Ladd of Hollywood Hot Rods dreamed up. They imagined a traditional hot rod with styling borrowed from coachbuilt European sports cars (think Bugatti, Ferrari, Delahaye).

Now Hollywood Hot Rods is building a real-life version of that concept coupe for a customer. The car will feature a '49 Caddy engine, Borg-Warner five-speed, quick-change rearend, and Sprint Car–style cowl steering—plus some brilliant body modifications (we'll tell you more about that in the future). The unusual suspension will be based on quarter-elliptical springs as a rear lower link with upper control links; in the front, dual quarter-ellipticals in the style of the early Miller race cars (more on that in the future too).

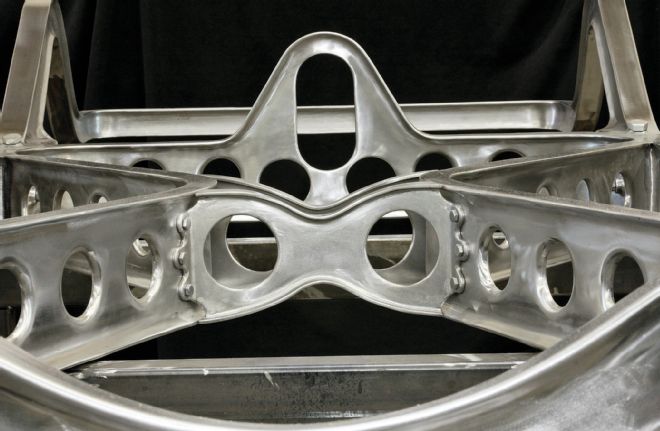

"The idea is to build a Deuce coupe with a European Bugatti-style performance car feel," Ladd told us. "We needed to come up with a chassis that was traditional but creative and different. Typically chassis are all rectangles and squares. We like to add radiuses and swoops and third dimensions and all these shapes to throw a new dynamic into the chassis. It's very difficult to do but that's what makes it cool."

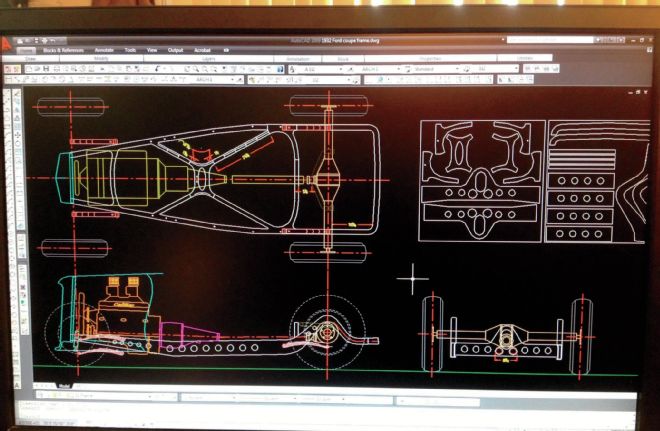

HHR fabricator Paul Bosserman created computer drawings showing how the frame would look, then took a couple sheets of 1/8-inch steel plate and built what he'd drawn. The frame starts with a stock Deuce 'rail design, but departs from that pretty quickly. The 'rails are boxed, but the inside plates are radiused and dimpled. "The idea was to give it the look of an aircraft," Paul explained. "The dimples strengthen the structure and prevent it from buckling. And welding the cups into the boxing plates makes it a completely sealed frame."

What you're about to see is a virtually handmade chassis. Aside from the computer, CNC plasma cutter to precisely create plates, and Miller welders, the only large metalworking tools used were a Pullmax machine, slip roll, drill, and bandsaw. The vast majority of the shaping was done with hammers and dollies.

1. Since originally drawing this '32 Ford coupe six years ago, Eric Black has done dozens of illustrations for Hollywood Hot Rods, where this hot rod is being built.

2. The foundation for the coupe was designed on the computer. The plan view in the upper left shows the hourglass-shaped crossmembers. The side and end elevation views include the wheels and tires to set ride height.

3. Fabricator Paul Bosserman at HHR started with aftermarket Deuce 'rails, cutting them off just in front of the rear wheel location and rebuilding the rear portion. The rear kick-ups measure 15 inches.

4. The scratch-built rear section includes a crossbar radiused to match the shape of the body. When the body is added, the reveals will match.

5. The boxing plates were radiused at the top and bottom on the Pullmax. It looks great and provides increased strength.

6. The framehorns were cut off at the center line of the front axle, and the 'rails pinched approximately 5 inches and raised 2 inches. A 4-inch dropped I-beam axle will be used.

7-8. The only open portions of the frame are where it was boxed at the rear kick-up to mount the rear quarter-elliptical springs. The front quarter-ellipticals will be mounted on a bracket on the outside of the frame.

9. The crossmembers were constructed from four pieces of 1/8-inch steel to form an I-beam shape. A dimple die was used to cut 2-1/2-inch holes, which were welded around the circumference.

10-11. The rear crossmember includes four of the dimples plus a sleeved oval hole for the driveshaft loop and a pair of sleeved round holes for the exhaust pipes.

12-13. The dimples on the inside plates of the frame sides are sealed with cups built from 2-1/2-inch schedule 40 steel pipe caps.

14. The cups were welded into place, and ground and polished to create a factory-prepped look.

15. The X-member pieces have the same dimpled I-beam structure as the rear crossmember. At the inside corner creases where the diagonal crossmembers meet, the boxing plates are especially tight and hard to weld.

16. Curved plates connect the front and rear sections of the X-member.

17. Bosserman used the slip roll to give those plates the correct arc.

18. He added the upper and lower radiuses with help from a Pullmax.

19. The bowtie-shaped pieces that make up the transmission mount are single-walled plates with curved tops and bottoms, cut on the CNC cutter and located at the center of the X-member. The exhaust pipes will run through the sleeved holes.

20. The mounting flanges for the transmission mounts were hand-shaped and ground to give them some three-dimensional shape. It's more decorative than a rectangular flange and was done strictly for style.

21. This bracket on the forward plate of the trans mount is drilled for two pins that will hold the transmission housing. Additional side pins will be accessible through sleeved holes that will be drilled into the curved plates in the X-member. The transmission can then be dropped without having to pull the engine.

22-23. The front crossmember matches the I-beam style of the other crossmembers. The difference is that there is not a straight inch on this entire front piece—it's all complex curves and it's all custom handwork.

24. Fabricating the front crossmember provided a chance to use a variety of hammers and dollies, including this dolly built from about 6 inches of railroad track rail.

25. Grinding and polishing finishes the front crossmember and gives it the look of a single piece of forged steel.

26. It's such a piece of art that we're almost sorry that the frame will be covered by the Deuce coupe body. But the body's incredible too. Wait until you see it.