Perhaps the most susceptible parts of any car to road damage are the frame and suspension components. Besides the normal rain, dirt, and other road debris, there are the usual oils, grease, and road-repair tars coming from the road, our own tires, and some of it coming from the minivan in front of us. It's fairly easy to keep the top of your car clean and shiny, but not so much the bottom.

Muscle Car Restoration, located in Chippewa Falls, Wisconsin, has a solution for the owner who really wants to drive his car and isn't looking for an exact Concours-type resto: powdercoating the frame and all of the suspension components. Powdercoating is not new, but not just anyone knows how to properly coat something as large as a fullsized car frame. Very much like paint, the trick to the perfect powdercoat is in the preparation.

MCR's preferred powdercoater is Premier Powdercoating, Inc. in Ettrick, Wisconsin. Owner Kevin Guenther has extensive experience with automotive applications and has tweaked his processes to specifically deal with the special requirements of classic-car restos.

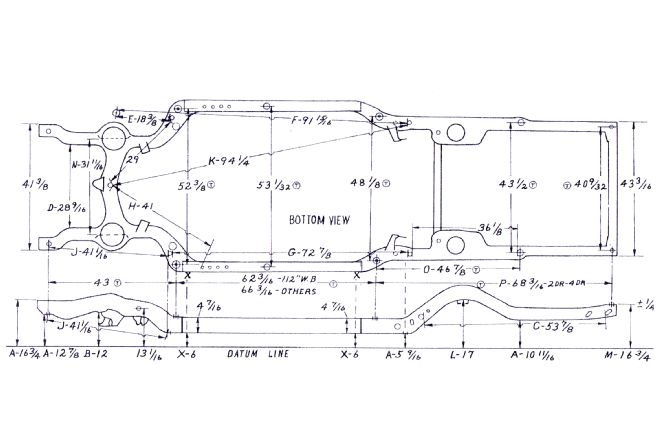

Before anyone at Muscle Car Restoration works on a frame, they check to see if it is straight, square, and within factory specs. Frames specs came from ChevelleStuff.com.

Premier has tried various chemical dips to cleam frames, but none of them was totally effective in removing residual oils from inside the frame and from the weld seams. Any oil left behind can weep out when the frame goes into the curing oven and ruin the powdercoat in those areas. Burning out the inside of the frame is the only way to be dure the frame is completely grease-free.

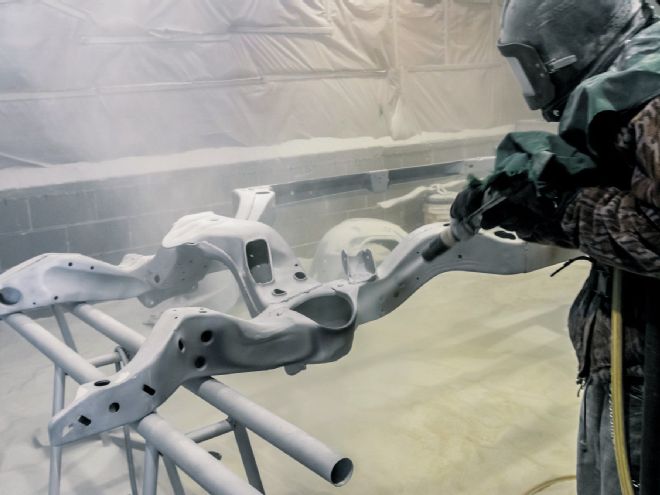

Next, Premier Powdercoating blasts the entire frame with the aluminum-oxide equivalent of 120-grit sandpaper to achieve a uniform finish with the right amount of "tooth" for the powdercoat to hang onto.

Once the frame has been thoroughly cleaned of all blasting material and hung on a rack, it gets one final blast with the torch to remove any fingerprints, fuzz from clothing contact, or anything else that would interfere with the finish.

While most frames will likely be finished in some form of black, there are thousands of colors, textures, and finishes to choose from, including candy and transparent, colors, hammertone finishes, various levels of gloss, and even glow-in-the-dark colors. Custom color-matching is also available, so you can have nearly any color you want. Glossy powdercoats can be wet-sanded and polished to a high-gloss finish similar to liquid paints.

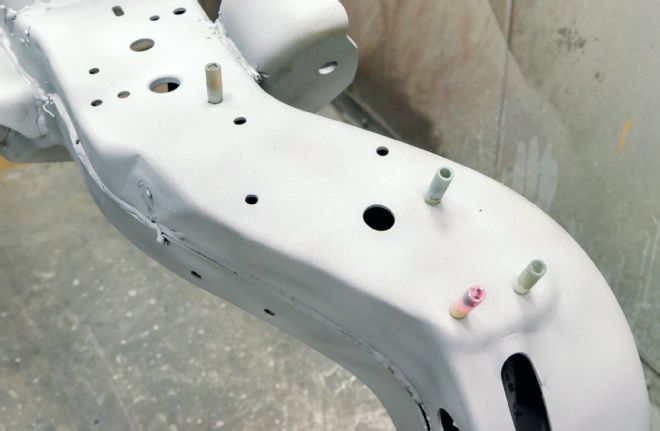

Premier will routinely plug any threaded holes to protect them from being coated, though a tap can easily be run through the hole after the fact, if necessary.

Bearing surfaces can be protected from being coated with a simple plug that's removed before the part goes into the oven.

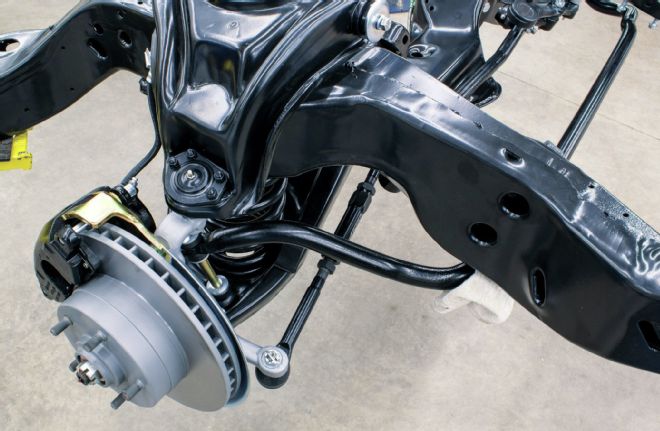

Rather than trying to mask the friction surfaces of brake drums and rotors, Premier will coat the entire part because MCR routinely does a very light cut to dress these parts to ensure they're perfectly flat and round. Note that the rotors are coated gray rather than black.

In case you're unfamiliar with powdercoating, let's cover a few of the major differences between it and conventional paint. First, it's in powder form instead of a liquid, which means is doesn't require a solvent to keep the various chemical components (binder, filler, pigment, etc.) in a liquid suspension form. Instead, all of the chemical components are melted, mixed, cooled, and then ground into a uniform powder that looks and feels a lot like colored baking flour. No solvents means it emits few, if any, VOCs and makes it very safe to handle and apply. It's applied with a spray gun that applies an electrostatic charge to the powder particles, which are then attracted to the electrically grounded part. Once coated, the part goes into an oven, where it's heated to and held at 400 degrees Fahrenheit for 10 minutes.

Heat causes chemical reactions within the product that produce long molecular chains with high cross-link density. That's science speak for something that has very strong adhesion properties and is very tough and highly resistant to breakdown. At the same time, it is also much more flexible (and chip-resistant) than regular paint, so it can be reliably applied to flexible parts like springs and sway bars. It can also be applied 4 to 10 times thicker than traditional sprayed paint, which adds to its durability without increasing the risk of cracking. Powdercoats are not totally immune to chips and scratches, but if they do occur, the surrounding finish usually won't allow any rust that forms to undermine and spread to the surrounding area. Generally, failures are the result of improper surface preparation, inadequate cure temp and/or time, or using cheap powder—mostly in that order.

The "spray" gun for powder application is nothing like a conventional spray gun. Yes, air pressure is used to propel the powder from the gun, but a powdercoating gun works by applying the proper electrical charge to the powder as it leaves the gun; positively charged powder clings to the grounded part. Though not without its nuances, the application process is more forgiving than spraying liquid paint, but using a high-quality, professional gun is essential.

With liquid paint, it's impossible to coat the inside of the frame, but with powder, you can puff it into the cavities and allow the electrical charge to draw it to the interior metal surfaces.

After the powder has been applied, the frame goes into a curing oven, where it's heated to 400 degrees for 10 minutes. Heat causes the chemicals to react and bond to the metal surface. It's at this point that we can start to see that shiny black finish we're all familiar with. Parts can be handled as soon as their temperature cools to the point that they can be safely touched with bare hands, but a full cure takes a few days.

Powdercoating will make parts grow by several thousandths of an inch, so let your coater know if there are any areas that need to be plugged or masked to prevent clearances from getting tight. Factory-style rubber bushings generally install normally, but stiff aftermarket ones might not like the smaller dimension.

In addition to being extremely tough, powdercoats are also very flexible. They hold up very well on parts that bend, such as springs and sway bars. End

Coated inside and out, this restored chassis will look good and clean up well when needed for a very long time.