Hardly anything can make a car more miserable to drive than a persistent shake. And it's not just annoying; over time the oscillations generated by imbalanced or worn parts can literally tear a car apart.

It's easy to exorcise demons for most cars with the obvious remedies but others shake despite seemingly all attempts to cure them. But that doesn't make them incurable. Vehicles are nothing but a collection of parts, each of which can run true on its own. Often an incurable shimmy boils down to an easily overlooked thing, like the way those parts meet or the condition or tune of the parts they bolt to.

What follows are some familiar and uncommon things that can make the best car develop the worst shake. Most are universal but a few apply specifically to our cars, at least to the combinations of parts that we use to build them. We won't address every potential shake source in a car, but if your car still shakes despite these solutions it might need a minister more than a mechanic.

Wheel Balancing

With few exceptions every shimmy diagnosis should start with a good wheel balance. There are two methods: Static and dynamic.

Static balancing equalizes the wheel's mass parallel to its axis (the point around which the wheel spins, say an axle). A classic example of an extreme static imbalance is a bucket swung on a rope. Even if you stop swinging the bucket its stored energy will drag your hand in a circle until it stops. Now think of your car's suspension as your hand and you'll see why that energy causes the car to shake.

An equal amount of weight (a counterweight) applied at the inverse angle of the imbalance will statically balance a wheel. In fact it will achieve static balance whether the weight mounts to the wheel's face or backside. For reasons explained later, narrow wheels and tires respond best to static balancing.

Now to dynamic balancing. Increasing a wheel's width creates a balancing conundrum. It potentially moves the imbalance and counterbalance points further away from the wheel's centerline. A counterbalance added to the wheel's backside to counter an imbalance at the wheel's face would statically balance the wheel; however, that likely won't prevent a shake at high speeds. In fact, doing that might actually make the wheel wobble as if it were mounted to a bent shaft.

Imagine a driveshaft to understand why. If the tailshaft end were imbalanced at 12 o'clock then a counterweight added to the yoke end at 6 o'clock would statically balance it. However, as momentum increased each end would follow its respective imbalance point. In fact that's how the earth spins: it wobbles. Now imagine if your wheels spun that way.

Summary: Static balances almost always work adequately for narrow wheels; wider wheels almost always need a dynamic balance.

Alternative Balancing Methods

On-car balancing addresses imbalances throughout the entire rotating assembly, tire, wheel, brake, hub, and all. In fact, it'll eliminate the imbalance created by removing a counterweight from a Buick drum.

This type of balancing has shortcomings: it balances only statically so it's most suitable for narrow wheels. And it requires that all parts index so they go back together the exact way every time. But the worst shortcoming is availability; the machines and their operators got rare a long time ago.

But balancing beads eliminate all but one of those shortcomings. They're just tiny balls (usually ceramic) that freely roll around inside the tire or, if equipped, tube. As the tire spins it generates centripetal force that holds the beads along the inside of the tire or tube. Ultimately the beads gather at the point opposite the imbalance until they amass enough weight to offset it. At that point the wheel rolls true and the spare beads just distribute themselves equally along the inside of the tire. When the vehicle comes to a stop they all come crashing back down to the bottom.

Like on-car balancers they affect only a static balance; however, they're available everywhere (mail order), don't cost much, transfer to new tires, and constantly correct imbalances over the life of the tire.

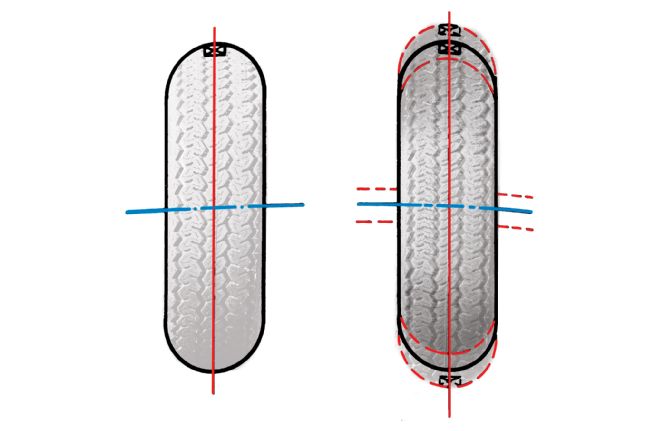

1. Imbalance that can be cured by static balancing. Vibration of the wheel while driving is shown at the right. At low speeds a wheel rotates around its principle axis of inertia, its axle (blue line). But at speed a static imbalance can force the suspension to deflect so the wheel can follow another axis called the axis of rotation (red line). Swing a bucket to experience the force a static imbalance can generate.

2. Imbalance that can be cured only by dynamic balancing. Vibration of the spinning wheel shown at the right. Imbalances away from the wheel centerline can generate an axis of rotation (red) irrespective to the axle itself (blue). When the axis of rotation is close to a wheel's centerline (left) the wheel won't wobble. But moving the imbalances apart (right) moves the axis of rotation further away from the centerline and a wobble is likely to follow.

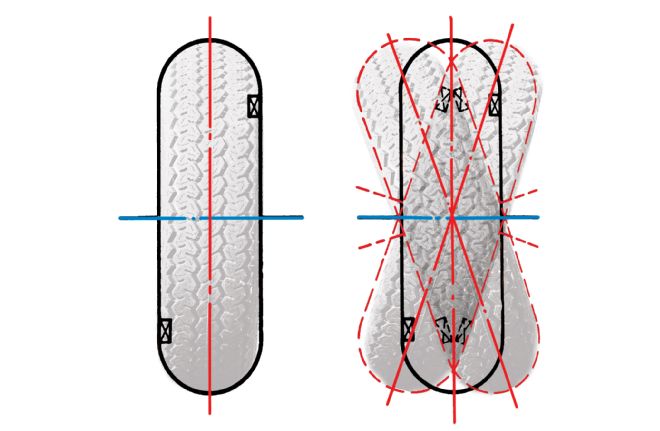

3. A narrow wheel balanced statically can have all of the counterweights on one side (usually backside). But a wide wheel balanced dynamically requires weights on each plane with an imbalance, the face if one exists there.

4. Imbalanced hubs, drums, and rotors nullify a wheel's balance. Buick drums' weights may not be handsome but they're not as ugly as the shake that results from removing them. Most Buick-style drum covers aren't balanced. Personal experience indicates that some aren't even round.

Straightness

No amount of balancing will matter if a wheel rolls like an egg. Chris Sage at The Wheelsmith noted a few things that prevent a wheel from rolling true. "It's a good idea to check all wheels, and especially old ones, for runout," he begins. "I like to build wheels with no more than 0.015-inch radial and lateral runout but that's so we know a wheel won't ever be the cause of any problems." He even noted that a wheel with 0.030-inch runout will likely work just fine. "Until the '70s or '80s the OEMs considered 0.055-inch runout acceptable."

Because most wheels center on the lug nuts on older cars he recommends seating nuts by hand before tightening them. "Tire stores have gotten really bad about this," he cautions. "A kid with an impact can jam the lug nut on before the lug seats have a chance to line up." The consequences should be obvious.

And some of us are responsible for a potentially ill fit. It's popular to mount Buick drums to old Fords. However, early Ford disc wheels with the 5.5-inch pattern (and some of their reproductions) mount over a larger diameter than the Buick drum offers. Because most of the Buick-style drum covers maintain the same external dimensions they too suffer the same problem as I discovered on my own car. If the wheel doesn't seat properly it possibly won't roll true. There's a fix for that, though.

Alignment

Sometimes an elusive shimmy or vibration stems from an improper wheel alignment. The two main culprits are toe and caster.

Toe

Toe describes the longitudinal relationship between two wheels on an axle. Toe-in: wheels point toward each other in the direction of travel; toe-out: wheels point away from each other in the direction of travel.

The front wheels on most rear-drive road cars benefit from a touch of toe-in. It compensates for the road force that can induce a toe-out condition. Toe-in also eliminates lash in the various components, which enhances straight-line stability.

Excessive toe-in can induce a bear of a shake. It causes the tires to fight each other for traction and the rapid release/traction cycle can cause a shake. It also wears tires unevenly, which causes its own problems.

Toe settings vary by suspension design so start with the specs that the original manufacturer determined for the suspension under your car. But don't treat these specs as if they're set in stone. Your vehicle's dimensions may differ considerably from what the manufacturer intended so you may have to slightly alter toe settings. Remember that bias-ply tires neither need nor tolerate as much toe as radial tires do.

Caster

Caster in a roundabout way generates tracking stability. It refers to the Steering Axis Inclination (SAI)—the line plotted through the kingpin or through both ball-joint centerlines—as viewed from the wheel face.

What actually generates the stability is the relationship between the point where the SAI intersects the ground and the tire's contact patch. Most vehicles feature negative caster, meaning the tire follows the point where the SAI intersects the ground. In fact, motorcyclists express this tracking-stability dimension by the distance that the tire "trails" the SAI where it intersects the ground. Increasing this distance increases the force by which the front wheels center themselves. That makes a car feel more stable at speed.

But that force sword has a second edge: excessive caster/trail can generate enough force to steer the wheel beyond center and slightly into the other direction. If conditions are just right the centering forces can volley the wheel rapidly left and right in a shimmy. Motorcyclists have a more descriptive term for this too: Death wobble or tank slapper. Anyone who's experienced it in a car or on a bike can testify that it's terrifyingly scary and it goes away only if you reduce speed dramatically.

Again, refer to the specifications for the suspension under your car and prepare to alter them if the suspension came from another vehicle. Most suspensions benefit from a touch more caster than stock but too much caster can induce a shimmy.

5. It sounds like magic but when a wheel rolls these beads orient themselves inside the tire to counter imbalance. Unseat the bead and drop the beads into a tubeless tire or use supplied bottles to feed them into a tube's valve-stem hole. Innovative Balancing's ceramic Dynabeads may outlast the car they're in.

6. A dial indicator should be part of every enthusiast's toolbox. Run it against the side of the bead to measure lateral runout and against the inside diameter of the bead to measure radial runout.

7. Because it's so close to the centerline a hub or axle flange bent even a tiny bit will make a wheel wobble like mad. For this reason most vocational manuals recommend 0.005-inch maximum runout.

8. Early Ford 5½-inch-pattern disc wheels mount over an 8-inch diameter. The Buick drums and their reproduction counterparts offer only 7 inches of mounting diameter. Unable to mount properly, the wheel can wobble. The correction is simple: the plates that Buffalo Enterprises makes extend the surface-mounting pad to 8 inches. At 3⁄16-inch thick they won't deflect where unsupported by a small hub, drum, or rotor cover. Fingers point to where the edge of the mounting pads on Ford wheels dug in without them.

Suspension

Suspension components by themselves can't shake simply for the fact that they don't rotate. However, they can give the wheels the opportunity to wobble.

As a vehicle rolls down the highway its wheels—particularly the front on a rear-drive car—encounter an intense amount of resistance. Just one worn component can let the suspension deflect out of alignment. If the suspension deflects enough to let the geometry enter an unfavorable range then a wobble may follow.

Driveshafts

Last but far from least, driveshafts, since they spin several times faster than the drive wheels they're particularly capable of vibrating. We'll let Steve Raymond at Dynotech Engineering Services explain a few essential things. And he's well versed; when the Big Three encounter persistent vibration issues they hire Dynotech to find and solve them.

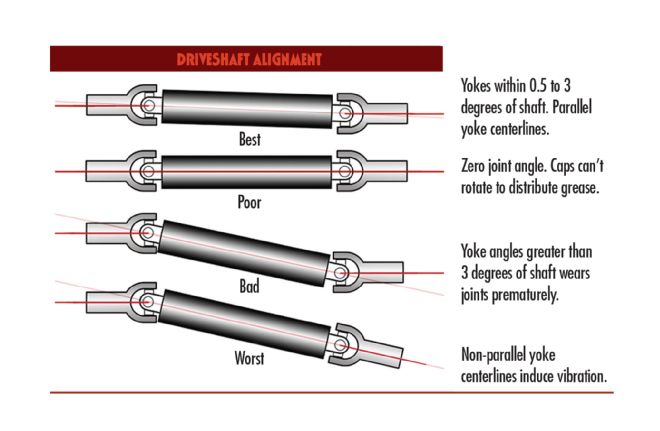

"You want equal and opposite," he instructs. "If your tailshaft points down 2 degrees then your pinion should point up 2 degrees so effectively they run parallel." Why? Universal joints at an angle don't spin in a circle; they follow an ellipse that makes them speed up and slow down at various points. "If the joints are phased correctly on the shaft then one joint will accelerate as the other joint decelerates and the two forces will cancel each other.

But don't confuse parallel with straight line. "Set your U-joint angles at a minimum of 0.5 degree to 3 degrees," he says. "If the joint is at 0 degrees then (it) won't articulate and the needle bearings won't roll. That will purge the grease out of the caps and wear the bearings. But when they roll they distribute grease through the cap. Without that little bit of movement the joints will run hot and wear out prematurely. A worn joint can introduce a vibration."

Here's a tip if your engine vibrates at certain speeds even when the car sits still: disassemble assemblies (like a torque converter from a flexplate), rotate one side (like the torque converter), and reassemble. You may do a reasonable job balancing each of the components but small imbalances always remain," he says. "So you have to prevent those small imbalances from adding up at one angle." By rotating one part 180 degrees the imbalances may cancel out each other.

9. Ideally, manufacturers replace square tires; however, some specialty tires are notorious for roundness issues. In those cases find someone like my pal Bill Ross who trues tires. It takes a bit of life off a tire but what good is a life spent wobbling?

10. This Hunter model illustrates toe-in. If your car shakes despite all other efforts then play with toe. Just don't go too far and remember that toe-out usually makes a car dart (it wants to turn in all the time).

11. Wheel Centerline Caster Angle Trail We amplified the dimensions but this illustrates how the tire centerline (yellow) actually "trails" the point where the steering axis (red) intersects the ground. Less trail makes a car feel lively but too little makes it wander. More trail makes it stable but too much makes the steering feel dead and can induce a wobble.

12. Consider every wear point a potential culprit in a persistent wobble issue. Worn kingpins, ball joints, bushings, tie-rod ends, idler arms, strut rods, and even steering gears can let the geometry slip into the wobble zone.

13. This is a steering damper. Though it can damp small oscillations that cause wobbles that is not its job. It exists to take the edge off of the small impacts amplified by the gear lash in older steering boxes before they reach your hands.

14. Joints work best with at least 0.5 degree but no more than 3 degrees misalignment. For a one-piece driveshaft on a road car set the pinion angle at the exact inverse angle of the tailshaft. So if the tailshaft points down 2 degrees then point the pinion up 2 degrees.