Muscle cars might have been quick in the 0-60 department, but the 60-0 department was a whole other story. What was considered pretty cutting edge on the best performance muscle cars in the 1960s (Shelby, Z/28, Boss, etc.) would be bottom of the barrel today. In stock form, most can't even touch the numbers of a modern generic four-door sedan with all-season tires. Even worse, the four-wheel drums in most run-of-the-mill muscle cars will get you in serious trouble in an emergency braking situation surrounded by newer cars. Of course, none of them would be considered acceptable for any serious hard driving with lots of repeated heavy braking, especially with higher-powered engines or stickier tires.

For a dose of reality, we took our stone-stock, four-wheel manual drum-equipped '68 Mustang shod with 17x8 and 17x9.5 Vintage Wheel Works V50 wheels and Nitto NT05 tires out for a few 60-0 deceleration tests. Our very best result was 210.4 feet. Read that number again slower. That's over two thirds of a football field. Most modern 1-ton pickups can stop faster than that, and every single car built in the last 20-plus years can as well. If the tires on your vintage car are harder, or your drums haven't been checked lately, your stopping distance could be even worse.

So how much brake do you need? For bare minimum safety in today's traffic, all of which can stop much faster than any 1970s or older car, we'd recommend at least 11-inch discs up front with modern calipers. Like to drive fast or through the curves? It's time to look at better calipers and pads and get some discs on the rear too. Really enjoy pushing your car or getting it out on the autocross or track? Now it's time for some 13- or 14-inch rotors and big calipers, at least on the front.

For decades there were no real upgrade options available that didn't involve custom machining to adapt stock late-model or race car parts. Those days are long gone and most popular muscle cars have brake upgrade kits ready to purchase. But there's more than bolting on a set of calipers and rotors to creating a truly effective braking system; it takes a complete rethinking of the whole system to create something that works like a new OEM system. Thankfully, companies like Wilwood have stepped up and created exactly that: full proper disc conversions with just a few part numbers.

We've got a rearend swap planned for our pony, so for now we're just starting with the front brake conversion with a new master cylinder to get it safe. Slight spoiler alert: You're going to be blown away by how much improvement it netted us. We're not quite hanging with brand-new Mustangs yet, but it's close, and we will be soon!

Included in the SL6 Mustang front brake conversion kit is Wilwood's forged narrow Superlite 6R (FNSL6R) caliper. This is their newest version in the Superlite caliper series that adds versatile radial mounting to provide two planes of adjustment for accurate alignment over the disc. The kit is actually quite simple, and the swap can easily be done in a day at home.

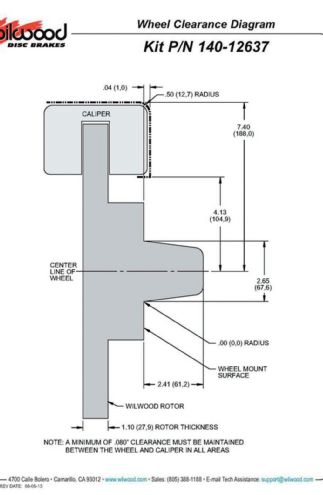

Not only will your wheel choice determine the diameter of rotor usable on your swap, it may also determine the caliper that will be required for adequate clearance. Wilwood always recommends using the proper sizing chart (this one is for our 13-inch, six-piston kit) to check your wheels before ordering.

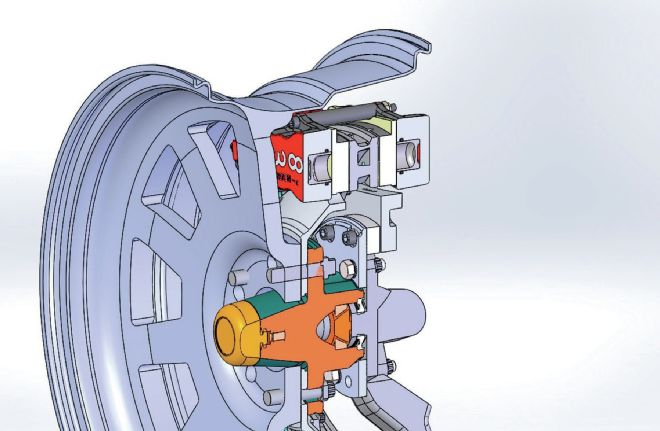

Those fitment diagrams are simple, but there's nothing low-tech at Wilwood. While the front 17x8 Vintage Wheel Works V50s were off, Wilwood scanned them to create this CAD image to show exactly how much space was available. As you can see, there is tons of clearance for huge calipers.

This is where we are starting, the same stock manual drum package that the vast majority of Mustangs were equipped with from the factory. Not only do drums stop slower and fade much more quickly after repeated hard use, they can become completely unusable if you happen to hit a big enough puddle in the rain, sometimes only on one side. Ask us how we know.

To give them a fair shake for testing, we made sure our drums were in good shape prior to testing. The shoes had plenty of good material and were in proper adjustment, and the wheel cylinders were new. Removing the drum is as simple as four bolts on the spindle. The hydraulic hose was left connected temporarily to prevent a mess.

The drums had never been removed from the spindle, but we thankfully had little rust to deal with. A wire brush was used to clean up the scale and make sure the bearing surface was free of corrosion.

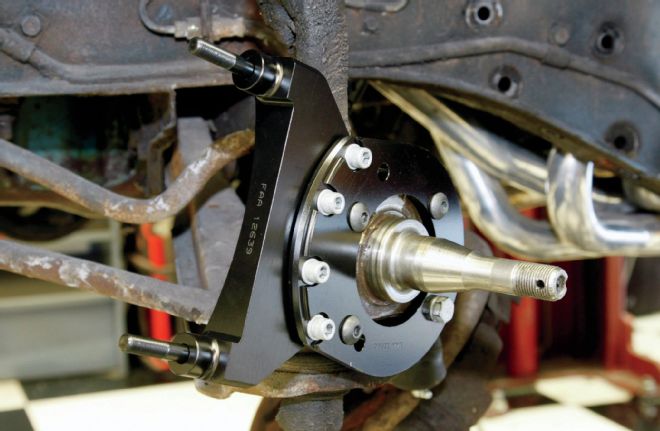

The caliper mounting bracket is designed so that it can be used on either Ford disc or drum brake spindles, so both bolt patterns are included. Our Mustang's spindles are drum, so the four appropriate holes were lined up and the button head Allen bolts were installed.

Multiple .015-inch shims are provided with the kit to allow for differing tolerances in the spindle and make it possible to have ideal alignment with the caliper on the rotor. We have to get it all assembled to know for sure, though. Once the number of shims is determined, red thread locker is recommended.

This is the radial mount bracket that will hold the six-piston caliper in place. Using this mounting solution allows for easy adaption of the caliper to multiple spindle designs.

To mount the rotor, Wilwood conversion kits for vintage spindle use a forged aluminum hub. The bearings are included, but will need to be packed with high-temperature disc brake bearing grease, and installed. They do not get pressed in, but we did use the press to make installing the seal a little easier. A mallet will also work just fine.

The hub then installs directly on the spindle and is lightly secured using a spindle washer and the OEM spindle nut. The nut should be tightened per OEM specifications, and secured with a new cotter pin.

Wilwood's lightweight two-piece rotors require assembling the outer discs to the rotor hat with an alternating sequence on the bolts. Red Loctite 271 is applied to the threads, and they are torqued to 155 in-lb. For added safety, especially in competition use, the bolts can be wired using standard 0.032-inch diameter stainless steel safety wire.

Wilwood's cool e-coat not only keeps the rotor from rusting before use, it keeps all the non-braking surfaces corrosion-free even after use! The hat/rotor assembly slides in only one way since the small countersunk holes in the hat must line up with the small threaded holes in the hub. Three flat-head screws install through the small holes in the hat, and get torqued to 85 in-lb.

Most Mustangs will use all three alignment shims to get the correct centering of the caliper, and our '68 was no exception. They may look the same, but there are distinct right- and left-hand calipers that must be mounted in a specific direction. The calipers must be mounted so the largest of the three pistons are at the rotor exit end of the caliper, in relation to the direction of rotor rotation.

They are technically an option, but we say always replace your flexible brake lines with new ones when upgrading a vintage car. The stock rubber ones are guaranteed to be dry and prone to cracking. These braided ones from Wilwood will not only last for many years, but the covering keeps them safe from abrasion.

We even threw on a new stock-style manual master cylinder when we first drug out our '68 Mustang for the 2013 paint and body special, so we had full pedal pressure for baseline testing. It's inappropriately sized for what we have in mind, so it'll be swapped as well.

In its place will be one of Wilwood's aluminum tandem master cylinders. These work great on manual or power brakes, and will fit just about any vintage car, though we have a Mustang-specific pedal rod kit. Bench bleeding is a necessity, and each master cylinder includes a pre-plumbed kit. We'll be using Wilwood's EXP 600 Plus high-temp racing brake fluid.

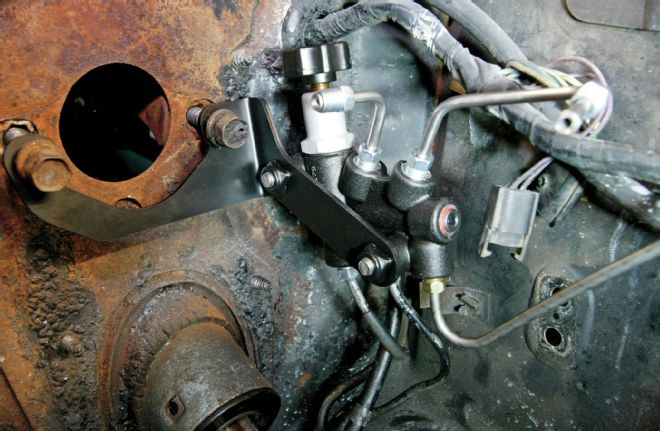

Our master cylinder kit included a new adjustable proportioning valve to replace the original distribution block. Controlling the front-to-rear pressure bias will be extra critical since we'll still have the factory drums on the rear for now. The brake pressure sensor on the end will be removed and plugged since Mustangs have one under the dash.

This mounting bracket makes life simple for getting the proportioning valve in place. The plumbing, however, will require a bit of reworking. Using a flaring tool, Wilwood was able to reuse most of the original lines since they were in good shape. Ideally, this would be a good time to replace all of them.

Besides getting the most out of our new brakes, the Wilwood master cylinder is just classy looking! The master is available in .875-, 1-, and 1.125-inch bores. Early Mustangs will likely use a .875-inch bore, but talk with a Wilwood tech expert about your parts and plans to be sure.

Now we still have the vintage Shelby look of our Vintage Wheels Works V50 wheels, but with modern stopping power. Paired with the 200 treadwear Nitto NT05, we should have a very potent braking package even with the stock rear drums.

The result? A 135.3-foot 60-0! That's 75 feet sooner than previous. We're pretty sure it can do better since the very worn-out suspension nose-dived so hard under threshold braking that it felt like we were doing a stoppie. With only the lap belts currently installed, we had to fight to keep ourselves off the steering wheel against the 1g peak and .9g average. These numbers will only improve as we upgrade our suspension and rear brakes.