The Combo

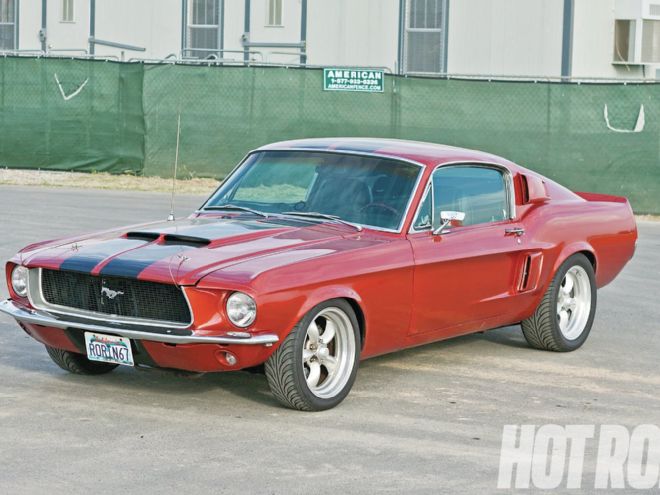

Ryan Nowicki bought his ’67 Ford Mustang fastback eight years ago. In place of the car’s original 289, the previous owner had swapped in a ’69 351 Windsor, mildly warmed over with Edelbrock Performer components--a hydraulic flat-tappet cam, an RPM intake, and a 600-cfm carb. An MSD standalone distributor and ignition coil lights the spark; Hedman headers dumping into 2½-inch dual pipes with an H-crossover and Flowmaster 40-series mufflers handle exhaust duties. As purchased, the car still had the original Ford four-speed Top Loader trans and bellhousing. Out back was an 8-inch Ford rearend with a limited-slip diff and 3.55:1 gears.

The Problem

“Ever since I bought it,” Nowicki relates, “The car has had an intermittent vibration turning right from speeds as low as 5 mph in parking garages to high-speed, long, sweeping rights on the freeway. It only happens once the car is warmed up a bit and driven 15–20 miles, and not necessarily all the time. The problem is not sensitive to outside air temperature. It’s not like a whole-car violent shake, but it’s intense enough of a vibration that I would never take the car to an autocross event. I do feel safe enough to drive it daily back-and-forth from my Hermosa Beach, California, home to work in Westwood. The car has never been in an accident since I’ve owned it, but evidence of body-panel repairs indicate it may have been in an accident prior to my ownership.”

The Owner’s Attempted Fixes

When Nowicki bought the car it still had the original Ford-style front-suspension, albeit completely rebuilt by the previous owner. Faced with the vibration, Nowicki says initially he “replaced all of the wheel bearings, checked for tire rub on the inner fenders and quarters, and added friction modifier to the limited-slip rear--all to no avail.”

Nowicki performed numerous enhancements over the years to increase performance and try and cure the strange vibration. A big one was axing the stock Top Loader for a ’93 Mustang T5 trans and bellhousing that bolted up to the existing trans support and mount. This didn’t cure the bad vibes, but in hindsight was a major clue: Ultimately, AEW would trace the problem to the mount/crossmember interface.

Nowicki performed numerous enhancements over the years to increase performance and try and cure the strange vibration. A big one was axing the stock Top Loader for a ’93 Mustang T5 trans and bellhousing that bolted up to the existing trans support and mount. This didn’t cure the bad vibes, but in hindsight was a major clue: Ultimately, AEW would trace the problem to the mount/crossmember interface.

Over the years, Nowicki installed manual rack-and-pinion (R&P) steering, upgraded that to power R&P, and replaced the front drum brakes with discs. The stock Top Loader four-speed trans was swapped-out for a ’93 Mustang T5 and bellhousing, which, Nowicki says, “bolted right up to the existing trans crossmember and mount.” Inside the bellhousing, a Centerforce dual-friction diaphragm clutch bolts to a 157-tooth flywheel with 28oz unbalance (correct for a 351W).

The front suspension and brakes also went through several rebuilds and enhancements, ultimately evolving into the present power rack-and-pinion setup with front disc brakes. None of these changes had any affect on the vibration, either.

The front suspension and brakes also went through several rebuilds and enhancements, ultimately evolving into the present power rack-and-pinion setup with front disc brakes. None of these changes had any affect on the vibration, either.

The mods continued with thicker front and rear antisway bars, all-new suspension bushings, new rear leaf springs, and new 1-inch-shorter front coil springs. Nowicki dropped the front upper control-arm pivot points 1 inch for better camber geometry when the front suspension loads (aka “the Shelby drop”). He installed fatter tires and wheels (205/50 tires on 17x7 wheels up front, 255/40 tires on 17x8s out back). To eliminate any interference possibilities, Nowicki “rolled the front fenders, and cut out part of the rear lip on the rear quarters.”

Nowicki may have had the makings of a good autocrosser, but none of these changes had any affect on the vibration.

The Initial Diagnosis

Eight years in, Nowicki had inspected, upgraded, or replaced just about everything but the exhaust clearances, mounts, internal rearend parts, and driveshaft. That’s when he contacted us. We sent the car to Mark Sanchez’s Advanced Engineering West (AEW) in Mira Loma, California. Sanchez is practically dyed Ford Blue. Although best known as an ace tuner for late-model Fords and as a Ford retrofit engine expert, he can diagnose and fix just about any Ford service issue.

Finally honing-in on the trans/mount/crossmember/driveshaft area, Sanchez discovered a scored, worn transmission yoke. Nowicki said he’d never had the driveshaft checked for straightness and balance, so AEW sent the ’shaft over to nearby Inland Empire Driveline.

Finally honing-in on the trans/mount/crossmember/driveshaft area, Sanchez discovered a scored, worn transmission yoke. Nowicki said he’d never had the driveshaft checked for straightness and balance, so AEW sent the ’shaft over to nearby Inland Empire Driveline.

“Start with the basics before you go off the deep end and start replacing everything.” - Mark Sanchez, AEW

Sanchez took the car for a test drive to replicate the owner’s complaint. In right-hand turns, he experienced a vibration through the floorboard and tunnel. “It was apparent through the soles of my feet.” Sanchez also could feel an irritating rattle through the T5 transmission’s Hurst shifter-handle. The vibration was full-time (not just occurring in right-hand turns), so Sanchez believed it was a separate problem unrelated to the vibration transmitted through the floor. Still, it made isolating the underlying vibration problem difficult. And the trans wouldn’t shift cleanly, making it hard to drive the car consistently.

After the initial test-drive, Sanchez performed a complete static inspection both with the wheels and tires loaded as well as with the car up in the air. There was some play in the steering rack’s inner tie-rod ends, as well as from the front wheel bearings that eventually will require attention. But because no vibrations were transmitted through the steering wheel during the test drive, Sanchez concluded the suspension wasn’t the miscreant, either.

The exhaust headers, pipes, and mufflers weren’t loose, and there were no visible markings, dents, or abrasions indicating contact between any of these components and the body. The bushings, shackles, and U-bolts attaching the rear leaf springs to the rearend checked out OK, too.

Inspecting the car’s still-original factory driveshaft, Sanchez detected excessive up-and-down play at the trans slip-yoke end. “This indicates the possibility of a worn yoke or transmission extension housing bushing, or both,” points out Sanchez. Pulling the ’shaft assembly, he found excessive radial scoring on the yoke, so he sent the unit to Inland Empire Driveline for a thorough checkup.

The Fix: Driveshaft

Inland reported the driveshaft 0.020-inch out-of-straight and slightly unbalanced. Both U-joints were worn, with the front U-joint that joins the ’shaft to the trans yoke showing the most distress. This dovetailed with the yoke sealing surface wear observed during Sanchez’s inspection. Inland straightened and rebalanced the driveshaft, changed the U-joints, and installed a new yoke. It’s unknown whether the driveshaft issues and general vibration problems are related, but at least one possible wildcard had been eliminated. At some point Nowicki should replace the T5’s extension-housing bushing, as the yoke’s excessive endplay probably has caused corresponding damage to it as well.

To straighten the driveshaft, the area with the most runout is first heated with a torch, which relieves the stress.

To straighten the driveshaft, the area with the most runout is first heated with a torch, which relieves the stress.

The Fix: Shifter

While the driveshaft was at Inline, Sanchez applied an expedient fix to the T5’s seven-year-old Hurst shifter-handle to get rid of its distracting rattle. The baseplate’s receiver slots for the lower shifter handle’s cross-shaft were worn, causing the handle’s tensioning springs to lose preload. Sanchez shimmed the springs to restore downward pressure. This is only a temporary fix, because the groove will eventually wear even deeper. “A new shifter will eventually be needed,” warns Sanchez.

The Primary Diagnosis

Steelman’s Wireless ChassisEAR remote audible listening device helped Sanchez isolate the primary vibration’s exact location. It’s like your Doc’s stethoscope, only wireless and for a car.

Steelman’s Wireless ChassisEAR remote audible listening device helped Sanchez isolate the primary vibration’s exact location. It’s like your Doc’s stethoscope, only wireless and for a car.

With distractions removed, Sanchez honed-in on the vibration’s location using Steelman’s Wireless ChassisEAR remote wireless audible listening device with its clamp-on magnetic sensors. “We clamped on two sensors: one onto the body close to the trans, and one on the trans itself; then we put one on the transmission crossmember, and one on the trans. This let us isolate and confirm where the vibration was coming from.” Meanwhile, G-tech’s RR Fanatic real-time performance meter allowed Sanchez to consistently replicate the same conditions over the same route during each test drive.

Correlating the G-tech readouts over the same course with the ChassisEAR’s audible cues showed that the vibration always started at 0.2 g and went away at 0.4 g. Sanchez explains, “When the car turns right, the inertia of the engine and trans loads the car to the left. If the car wasn’t leaning enough or going fast enough, it wouldn’t touch. On the other hand, if it was going much faster and harder, it would make 100 percent contact and not develop a vibration. It was just a certain window, just enough to ‘bounce’ metal-to-metal.” There was insufficient clearance between the ’member and the trans mount on the left-hand side.

The Final Fix

Visual inspection at the affected location--the trans mount and left-hand (driver-side) trans support kick-up interface--revealed insufficient clearance in that area. Sanchez confirmed this by temporarily shimming the mount with ¼-inch steel plate that provided enough clearance to eliminate the vibration.

Visual inspection at the affected location--the trans mount and left-hand (driver-side) trans support kick-up interface--revealed insufficient clearance in that area. Sanchez confirmed this by temporarily shimming the mount with ¼-inch steel plate that provided enough clearance to eliminate the vibration.

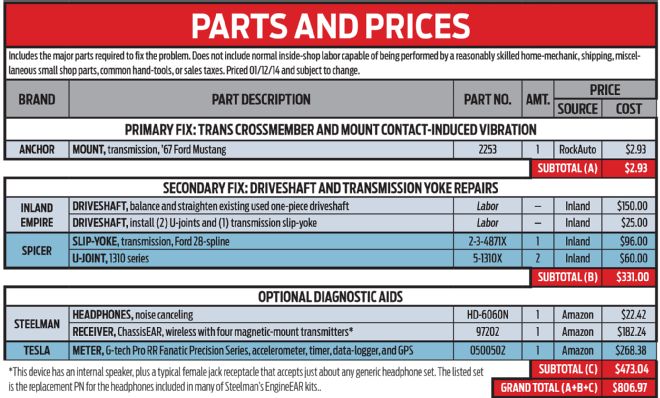

Once the problem was isolated, the fix was easy. First, to ensure the existing trans mount was correct for the application, AEW got a new ’67 Mustang mount. Both old and new checked identical. That left the support; for whatever reason, it was slightly off. Sanchez carefully clearance-ground the edge of the new mount and the crossmember at the observed contact points. Problem solved.

Results

<strong>BEFORE</strong>

<strong>BEFORE</strong>

These views clearly show the mount and crossmember before and after modification. Sanchez says, “You want to see at least 0.200-inch (slightly under ¼-inch) clearance. We ended up with about 0.300, which should compensate for any future wear.”

AFTER"> <strong>AFTER</strong>

<strong>AFTER</strong>

Sanchez drove the car around the prescribed route repeatedly and the vibration was gone for good. “We even took the car into a corner at 0.7 g to make sure we couldn’t force the trans up against the chassis--no problems!” Nowicki exalts, “I’ve been throwing the car into right-hand turns. It’s so nice, the vibration hasn’t come back. Having this problem, and having done so much to try to fix it, left me with a lack of confidence in the car. I have to say ‘thank you’!”

No more bad vibes: Plenty of clearance now!

No more bad vibes: Plenty of clearance now!

Lessons Learned

In retrospect, the fact that the same vibration was present with both the original Top Loader trans and the T5 retrofit should have been a key clue: Both trannies used the same mount and crossmember, one of the few major chassis parts that remained unaltered. On the other hand, Sanchez says the car’s poorly formed crossmember was not the original stocker; the previous owner must have replaced it sometime in the past. Although the problem could have been identified without Sanchez’s trick diagnostic aids, they sped up the process while ensuring test repeatability.

Fixed at last,the Mustang can finally be driven like it was meant to be driven. Nowicki says “it’s like being in a new car!”

Fixed at last,the Mustang can finally be driven like it was meant to be driven. Nowicki says “it’s like being in a new car!”

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at pitstop@HotRod.com and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.