It never fails, things tend to finally wear out, and ultimately break at the most inopportune moment. You could be ready to enter the final round of elimination at the track, or, 2,000 miles from home, but when a part's life-span has ended, you're going to find out.

Such was the case with my 2003 Ram part's hauler. I was on a multi-day road trip, stopping at shops in North Carolina, and Virginia, and somewhere in between the two, I started to hear a strange noise coming from the underside of my truck. I wasn't far from my final destination, so I took my time, and hoped I made it.

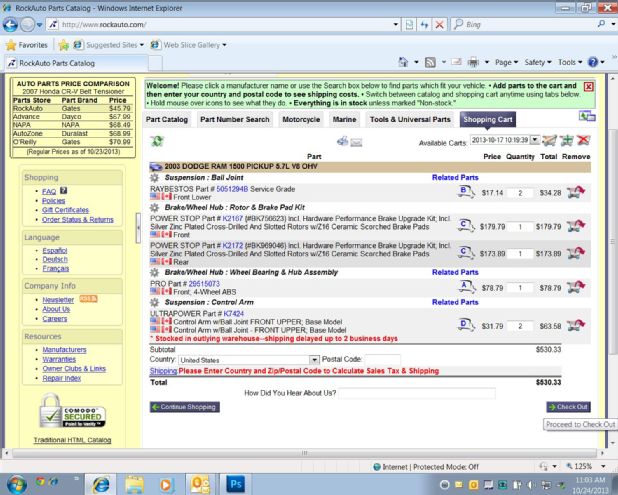

Once I got to where I was going, a cursory inspection under the truck revealed that the ball joints and wheel bearings were nearing the end of their life span. So, it was time for a rebuild, but going to an auto parts store can relieve your wallet of more cash than you're prepared to let go of. So, I did a little research, and found out that Rock Auto not only carries everything needed, but is cheaper than a local auto parts store. So we ordered up the parts we needed, and within a couple days, the parts were in our hands, and we could begin the work.

We started at the front of the truck, and started yanking parts.

We started at the front of the truck, and started yanking parts.

With the old brakes and hub-assembly removed, the new assembly could be installed. Since the truck had 135,000 miles on it, we're guessing that it was about time.

With the old brakes and hub-assembly removed, the new assembly could be installed. Since the truck had 135,000 miles on it, we're guessing that it was about time.

The hub was an easy bolt on, but what it comes to upper control a-arms, and ball joints, you need to think before you act.

The hub was an easy bolt on, but what it comes to upper control a-arms, and ball joints, you need to think before you act.

Think about things like the alignment. When everything is finished, you will need to get the vehicle aligned. We marked the location and positioning of the control arms before we removed them, that way we can reinstall the new parts in the exact location. It isn't going to make it perfect, but it will get you close enough to get to an alignment shop.

Think about things like the alignment. When everything is finished, you will need to get the vehicle aligned. We marked the location and positioning of the control arms before we removed them, that way we can reinstall the new parts in the exact location. It isn't going to make it perfect, but it will get you close enough to get to an alignment shop.

Once the upper ball joint is disconnected from the spindle, things will come apart in a hurry. We supported the lower control arm with a heavy support, as once the upper ball joint was separated, the pressure of the truck's spring will want to come out very rapidly.

Once the upper ball joint is disconnected from the spindle, things will come apart in a hurry. We supported the lower control arm with a heavy support, as once the upper ball joint was separated, the pressure of the truck's spring will want to come out very rapidly.

Now it's time for the lower ball joint.

Now it's time for the lower ball joint.

With the upper control arm and the spindle out of the way, you can get to the lower ball joint. The ball joint is held in place by “swedges”, that retain it, these need to be ground smooth so the joint will come out.

With the upper control arm and the spindle out of the way, you can get to the lower ball joint. The ball joint is held in place by “swedges”, that retain it, these need to be ground smooth so the joint will come out.

Press away

Press away

The new ball joint is now held in place with a snap ring.

The new ball joint is now held in place with a snap ring.

With the suspension reassembled, reinstall the new brakes. We chose these slotted and drilled rotors, for their better ability in dissipating heat and brake gasses, which aids in better braking.

With the suspension reassembled, reinstall the new brakes. We chose these slotted and drilled rotors, for their better ability in dissipating heat and brake gasses, which aids in better braking.

With the suspension reassembled, reinstall the new brakes. We chose these slotted and drilled rotors, for their better ability in dissipating heat and brake gasses, which aids in better braking.

With the suspension reassembled, reinstall the new brakes. We chose these slotted and drilled rotors, for their better ability in dissipating heat and brake gasses, which aids in better braking.

With the suspension reassembled, reinstall the new brakes. We chose these slotted and drilled rotors, for their better ability in dissipating heat and brake gasses, which aids in better braking.

With the suspension reassembled, reinstall the new brakes. We chose these slotted and drilled rotors, for their better ability in dissipating heat and brake gasses, which aids in better braking.

Ordering from Rock Auto really is that easy, just open up the web site, enter your vehicle information, and select the parts you need or want.

Ordering from Rock Auto really is that easy, just open up the web site, enter your vehicle information, and select the parts you need or want.