When building a street rod there are some decisions that seem like a good idea at the time but turn out not to be so hot when you have to live with them. A case in point is the under-the-floor master cylinder in the 1934 Chevy coupe belonging to SR's group publisher, Tim Foss.

Although a below-deck master cylinder is cool for keeping the firewall clean, things that are out of sight are often out of mind. That's another way of saying if you don't see the master cylinder the fluid level may not be checked as often as it should. And, when you do decide to take a look, gaining access is often difficult unless you're adept at standing on your head—and it's well known that Foss hates to mess up his hair.

To make life easier, Foss' coupe was delivered to the Source Interlink Media Tech Center where Jason Scudellari, our in-house installation whiz kid, would be installing an OTB Gear remote brake reservoir on the firewall. Not only does it look cool, it also makes checking and filling that vital fluid easier. While the brake system was getting a tune-up there was another issue to be addressed. The Chevy had been equipped with a 1-inch Corvette master cylinder and a 7-inch booster, a commonly used combination with four-wheel discs. However the brakes were very touchy, so it was decided to resolve that issue as well.

Master cylinder bore size is a subject that often causes confusion. Simply put, a larger master cylinder bore produces more volume and less pressure while by comparison a smaller bore produces more pressure with less volume. With the wide variety of brake components available, recommending a master cylinder without knowing specifics is impossible. According to the experts at Wilwood, to select an appropriate master cylinder the combined piston area and piston volume of the calipers along with the pedal ratio must be known. Whether the system is boosted or not is another consideration. Then to determine the appropriate master cylinder bore for any specific application, review Wilwood's Tech Tip Guide or contact a Wilwood Sales Technician at (805) 388-1188 or email sales/tech support at customerreply@wilwood.com.

While we can't give blanket recommendations, with the combination of components used in this car a 7/8-inch bore master cylinder without a booster provided excellent stopping power without the over sensitivity that existed previously. With a new Wilwood master cylinder for better brakes and an OTB remote reservoir for filling it, the Chevy's brakes are out of sight—every way.

1. OTB’s double-remote fill brake fluid reservoir is cast in aircraft-grade aluminum. Fluid lines can be run from the bottom or the backside of the unit.

1. OTB’s double-remote fill brake fluid reservoir is cast in aircraft-grade aluminum. Fluid lines can be run from the bottom or the backside of the unit.

2. Wilwood's tandem chamber master cylinders are machined from a premium alloy die casting and has a slotted mounting flange to accommodate bolt centers between 3.22 to 3.40 inches, side-mount holes on hole 6.40-inch centers.

2. Wilwood's tandem chamber master cylinders are machined from a premium alloy die casting and has a slotted mounting flange to accommodate bolt centers between 3.22 to 3.40 inches, side-mount holes on hole 6.40-inch centers.

3. A common combination: a 7-inch vacuum brake booster and a Corvette master cylinder. In this case the result was overly sensitive brakes.

3. A common combination: a 7-inch vacuum brake booster and a Corvette master cylinder. In this case the result was overly sensitive brakes.

4. The original booster and master cylinder compared to the replacement. To connect the master cylinder to the pedal assembly a new pushrod was fabricated.

4. The original booster and master cylinder compared to the replacement. To connect the master cylinder to the pedal assembly a new pushrod was fabricated.

5. The Wilwood tandem master cylinder has a total piston stroke of 1.10 inches and a 2:1 volume ratio between the primary and secondary chambers. It’s available in 7/8-, 1-, or 1-1/8-inch bore sizes with a media burnished or black E-coat finish.

5. The Wilwood tandem master cylinder has a total piston stroke of 1.10 inches and a 2:1 volume ratio between the primary and secondary chambers. It’s available in 7/8-, 1-, or 1-1/8-inch bore sizes with a media burnished or black E-coat finish.

6. As the master cylinder was relocated, new brake lines were required. Scudellari used an Eastwood bender to form replacement stainless steel lines.

6. As the master cylinder was relocated, new brake lines were required. Scudellari used an Eastwood bender to form replacement stainless steel lines.

7. AN fittings require a nut and ferrule. They are put in place then the end of the line is flared.

7. AN fittings require a nut and ferrule. They are put in place then the end of the line is flared.

8. The required 37-degree flares were formed with another Eastwood tool.

8. The required 37-degree flares were formed with another Eastwood tool.

9. Here's what the 37-degree flare looks like.

9. Here's what the 37-degree flare looks like.

10. Here the replacement lines have been tied into the existing plumbing.

10. Here the replacement lines have been tied into the existing plumbing.

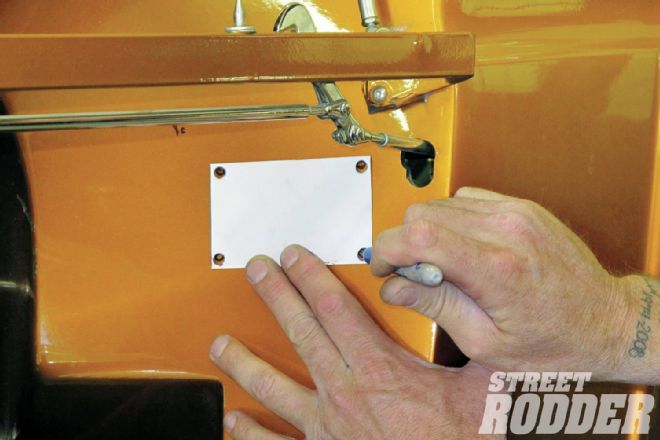

11. To mount the OTB reservoir on the firewall Scudellari made a template to locate the holes. Note the plugs in the back of the reservoir—those outlets can also be used to supply the master.

11. To mount the OTB reservoir on the firewall Scudellari made a template to locate the holes. Note the plugs in the back of the reservoir—those outlets can also be used to supply the master.

12. Scudellari determined the best location for the reservoir and marked the firewall for drilling.

12. Scudellari determined the best location for the reservoir and marked the firewall for drilling.

13. The reservoir attaches with screws from inside the passenger compartment. Make sure there’s nothing behind the firewall, like wiring or the fuse block, before drilling.

13. The reservoir attaches with screws from inside the passenger compartment. Make sure there’s nothing behind the firewall, like wiring or the fuse block, before drilling.

14. Secured to the firewall, the OTB reservoir has two compartments, one for each portion of the master cylinder.

14. Secured to the firewall, the OTB reservoir has two compartments, one for each portion of the master cylinder.

15. To connect the OTB reservoir to the master cylinder, standard automotive brake lines with inverted flare fittings were used.

15. To connect the OTB reservoir to the master cylinder, standard automotive brake lines with inverted flare fittings were used.

16. Both lines were secured to the firewall aluminum clamps.

16. Both lines were secured to the firewall aluminum clamps.

17. To accommodate the lines from the remote reservoir Scudellari marked the master cylinder’s lid for drilling.

17. To accommodate the lines from the remote reservoir Scudellari marked the master cylinder’s lid for drilling.

18. A hole for each compartment was drilled in the lid; the holes were then tapped for fittings.

18. A hole for each compartment was drilled in the lid; the holes were then tapped for fittings.

19. A pair of barbed fittings will accommodate short lengths of hose, leading the lines from the reservoir.

19. A pair of barbed fittings will accommodate short lengths of hose, leading the lines from the reservoir.

20. To allow the master cylinder to be filled from the remote reservoir the cap gasket was modified by cutting out the centers over each chamber.

20. To allow the master cylinder to be filled from the remote reservoir the cap gasket was modified by cutting out the centers over each chamber.

21. To bench bleed the master cylinder it was placed in a vice. Fittings were placed in each pressure port with clear plastic hoses submerged in fresh brake fluid in their respective chambers. The piston was then slowly pushed repeatedly until all the air bubbles disappeared.

21. To bench bleed the master cylinder it was placed in a vice. Fittings were placed in each pressure port with clear plastic hoses submerged in fresh brake fluid in their respective chambers. The piston was then slowly pushed repeatedly until all the air bubbles disappeared.

22. The master cylinder has been bled, the top modified, and it’s ready to be put in place.

22. The master cylinder has been bled, the top modified, and it’s ready to be put in place.

23. Clamps secure the rubber lines from the master cylinder to the steel supply lines from the reservoir.

23. Clamps secure the rubber lines from the master cylinder to the steel supply lines from the reservoir.

24. AMSOIL INC. offers Series 500 High Performance DOT 3 brake fluid that will maintain a boiling point well beyond DOT standards. Series 600 High-Performance DOT 4 brake fluid is designed for high-temperature stability and will remain virtually incompressible, even at the highest pressures generated in braking systems. Both Series 500 and 600 exceed Federal Motor Vehicle Safety Standard No. 116 and all requirements of the DOT.

24. AMSOIL INC. offers Series 500 High Performance DOT 3 brake fluid that will maintain a boiling point well beyond DOT standards. Series 600 High-Performance DOT 4 brake fluid is designed for high-temperature stability and will remain virtually incompressible, even at the highest pressures generated in braking systems. Both Series 500 and 600 exceed Federal Motor Vehicle Safety Standard No. 116 and all requirements of the DOT.