If you believe that technology made automotive paint more difficult, then take note. We have good news for you. The latest innovations have actually made modern paints easier to use. In fact, if you cut your teeth shooting lacquer then spraying these new coatings will feel like going home again. They don’t require mixing beyond reduction. The absence of catalyst gives these paints infinite pot life. Finished parts dry to the touch in minutes and the transfer style makes runs nearly impossible. Blemishes can be repaired almost immediately, making these paints friendly for absolute beginners.

Not that you’ll have that many blemishes to fix, mind you. The composition of these new formulas eliminates the static that attracts dust and small bugs to a freshly painted surface. In fact, these new formulas won’t attract any attention at all; they don’t stink like their solvent-based predecessors. Not even the cleaning solution smells. So what is this magical formula? Waterborne basecoat.

OK, now we know exactly what you’re thinking. The first generation of production waterborne finishes flew like a lead zeppelin. If you’re not old enough to remember, or just plain weren’t paying attention, those early waterborne entries back in the ’80s and early ’90s didn’t live up to expectations.

A lot has happened in the past 25 years, though. Regulations passed to discourage solvent-based paints have actually worked in enthusiasts’ favor, if you can believe it. Motivated by impending legislation, paint manufacturers developed truly viable finishes that contain practically no volatile organic compounds, the stinky solvents that contribute to pollution in the same way unburned engine fuels do.

This isn’t a case of manufacturers using the general public for beta testing either. To meet stringent VOC regulations, auto manufacturers adopted these waterborne technologies years ago. And high-end manufacturers like Mercedes-Benz and Rolls-Royce won’t stake their reputation on questionable products and processes. The coatings technologies they use have to work.

We won’t blame you for accusing us of sounding like a marketing agent for a paint manufacturer but the praises for waterborne finishes we heard didn’t come from a paint rep. They came from a car builder and world-class painter whose name you’ve probably heard—you may even recognize his face from the television shows he’s appeared on. Charley Hutton is one of the most enthusiastic advocates of waterborne paint.

He converted to PPG’s Envirobase High Performance waterborne basecoat not because it’s safer or cleaner (although he admits he appreciates it now) but because of its ease, reliability, and durability. In fact with very few exceptions Hutton uses it exclusively. He even converted his entire in-house mixing station at his Nampa, Idaho, shop, Charley Hutton Color Studio, to waterborne. And you can take his endorsement as testimony since, like Mercedes-Benz, he has a stellar reputation that he says he wouldn’t risk on an unproven product or process. After all, if something doesn’t perform as intended it’s on him to retrieve the car and right the wrong, regardless of location. So, needless to say he doesn’t gamble.

He doesn’t waste time, either, so when he invited us to his facility in Nampa we jumped at the chance. Accompanied by PPG territory rep Ron Wolfe, Hutton very graciously granted us a full-boat demonstration of how PPG’s latest breed of waterborne automotive paint works.

First off, don’t let the water content fool you; it serves exclusively as a carrier (the water bears the paint, get it?). That’s the same function that solvents serve in conventional coatings: they transfer the plastic resins to the painted surface at which point those carriers evaporate. The primary difference, of course, is that water doesn’t pollute the air or our bodies as it evaporates from the finish.

The Envirobase line has another feature: the toners contain anti-settle technology that keeps components in suspension and prevents pigments from settling at the bottom. Simply shake an Envirobase toner bottle five to six shakes by hand and it’s ready to pour. It’s a feature that eliminates mechanical mixing machines and ensures consistently accurate color matches. Oh yeah, about the anti-static thing: static can’t generate in the presence of water.

According to Hutton, waterborne finishes actually repair easier than those solvent-based. For starters, the waterborne basecoat won’t attack an existing finish like a conventional solvent-based formula will. That eliminates the telltale halo line that can appear around the edge of most solvent-based repairs. Waterborne repairs can be blended further into existing paint to create a near-seamless boundary without risking a large-scale catastrophe.

Naturally, waterborne basecoat has a few special needs. For one, it can’t level any imperfections; dry-film thickness ends up at about 0.5 mils or about half the thickness of most solvent basecoats. Hutton recommends finish sanding with at least 600-grit paper. The thinner finish has a secondary benefit: thinner coats are less likely than thicker ones to chip.

Waterborne paints won’t tolerate thick applications either since heavy coats will mottle. Waterborne finishes also won’t tolerate over-reducing or any water in the air lines for the same reason. The ultra-thin coverage coats quickly flash to a matte finish.

Though water-based, this latest generation—the third so far—works with many of PPG’s solvent-based Deltron primers and clearcoats. That too is changing, again for the better. The company recently released its first generation of waterborne clearcoat. So far PPG considers it a specialty clear but indicates that subsequent generations will make it more production viable. But probably more intriguing is a production-ready waterborne primer PPG launched this past September.

At this point PPG offers nearly every color, whether OEM or custom, in the Envirobase line. About the only colors the line can’t duplicate are candies but a multi-purpose, midcoat layer for waterborne basecoats offers the medium for special effect pigments, such as pearls, flakes, and tri-coat finishes. Its application as a transparent coating over custom graphics and effects increases depth and distinguishes appearance.

What we’ve covered so far may sound too good to be true but it isn’t: production painters across the globe use this technology on a daily basis. What’s more, shooters like Hutton maintain that it’s practically made for amateur enthusiasts.

This is the friendlier side of technology, the stuff that actually makes our work easier and improves our quality of life. I know it sounds strange to say but rather than victims we’re the beneficiaries of incredible new coatings technology.

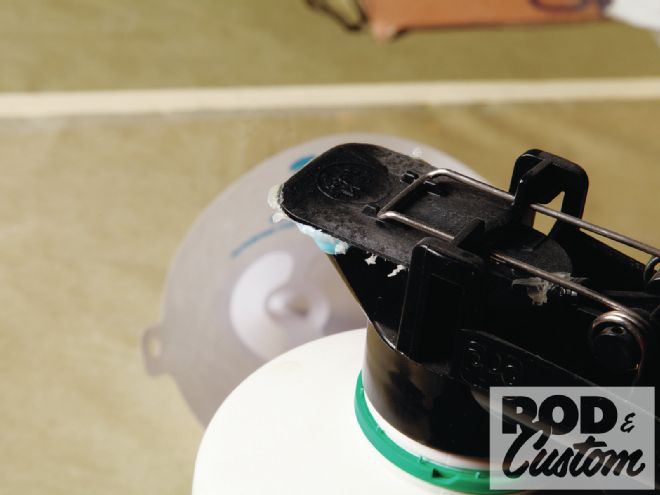

1 Waterborne can be matched precisely by formula but it doesn’t lend itself to matching by eye. It shifts blue when wet as seen on this valve lip. So don’t freak out if a freshly painted panel looks funny.

2 All paint should be reduced to a specific viscosity but waterborne is a bit more sensitive. A DIN 4 (4mm) drain cup makes the task foolproof, though.

3 Simply submerge the cup fully to fill it, raise it well out of the paint, and time how long it takes to drain. PPG recommends a 23- to 28-second window; thin with the water specified by the manufacturer to reduce pour time.

4 PPG recommends applying Envirobase over cured finishes and panels finished with its Global-series coatings. Hutton prepped the test panel with 600-grit paper.

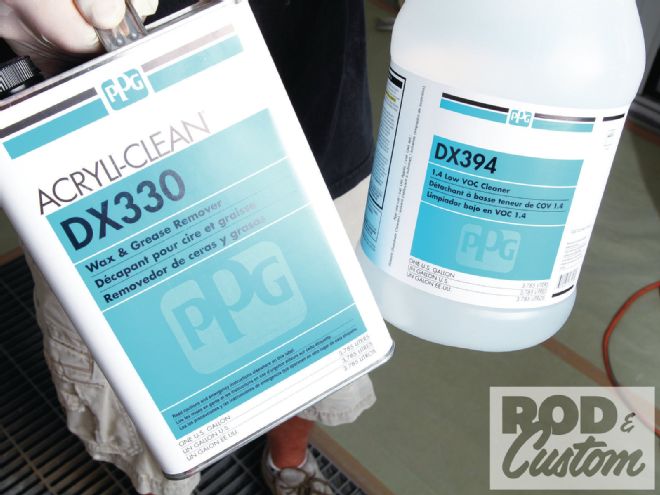

5 Conventional wax-and-grease removers (left) cut oils but won’t touch water-soluble contaminants like salts. A water-based remover, like PPG’s low-VOC DX394 to the right, will.

6 Literature doesn’t specify it but Hutton suggests prepping with the water-based cleaner first and following with the solvent-based cleaner. It will disperse any residual water, which is to water-based paint what reducer is to solvent-based paint. He followed this with a wipe with a tack cloth.

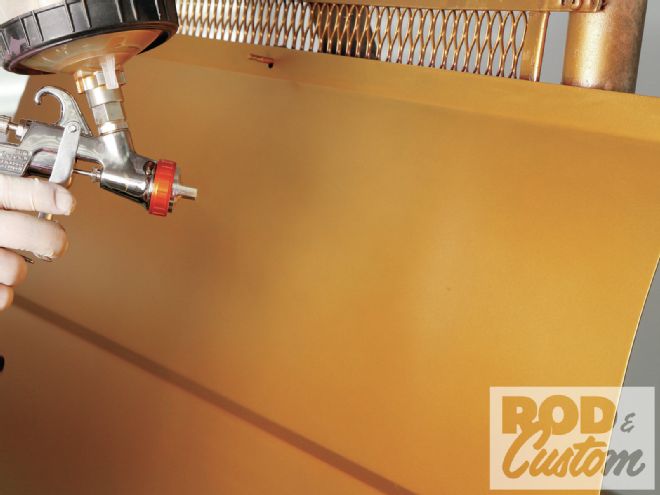

7 Hutton loaded the reduced paint into a conventional HVLP gun with a 1.3mm tip and applied the first coat by the conventional method: 6-inch distance with 50 percent overlap. It transfers blotchy so resist the urge to pile it on.

8 The paint transfers shiny but shifts matte when dry. A TriggerJet 22650PP, actually a low-cost spray gun commonly used to apply various industrial solutions, works well with air alone as a blow dryer. A word of caution: tape paper and bags tight to prevent blowing dirt around.

9 Hutton says the blotchy-looking first coat indicates proper technique if you can believe it. Remember, like lacquer it goes on thin and comparatively dry.

10 Hutton applied a second coat using the same spraying technique as the first.

11 Here’s the panel after the second coat and a blast from the TriggerJet. It’s blotchy yet looks better.

12 Using the same spray/dry technique Hutton applied a third coat. PPG indicates that solid colors require only three coats but metallics require a fourth orientation coat at twice the spraying distance with a 90 percent overlap, as seen here.

13 Most won’t believe us but Hutton achieved this beautifully complete coverage within about 10 minutes of first pulling the trigger. He says it dries so quickly that by the time he completes a full first pass he can usually start the second immediately.

14 Envirobase dries to touch within 15 minutes. Wilder yet, it dries to tape within five minutes. Pulled tape won’t leave a line, either. And the thin coat pretty much eliminates steps in graphics.

15 Find a flaw in the paint? No problem; Envirobase dries enough to sand within 15 minutes. Hutton and Wolfe discouraged wet-or-dry papers; according to them dry papers work best.

16 Hutton repeated the spray steps immediately after repairing the panel. Since he didn’t sand through the finish two coats were sufficient to bury the repair.

17 PPG suggests waiting at least 15 minutes to topcoat but Hutton says he usually lets the base dry overnight (apply another basecoat if more than 48 hours passes). He used D8152, a fast-drying clear that remains just soft enough to better resist chipping.

Oops!

The latest generation of waterborne paint is incredibly easy to spray but it won’t forgive everything. Hutton says most enthusiasts fall prey to the three following issues. The good part: they’re easy to correct. And as shown, waterborne paint lends itself to speedy repairs.

Water in the supply air manifests itself as droplets in the finish. It appears as if someone spritzed the panel with a squirt bottle … because that’s essentially how the gun behaves when water condenses in the system.

Spraying by the wet technique required by enamels and urethanes causes waterborne paints to de-wet and run. Waterborne lends itself to the standby light-layer technique that lacquer favors.

Waterborne base’s ultra-thin coverage won’t fill imperfections rougher than about 600-grit paper. If you can feel or see anything in the primer you’ll see it even better in the basecoat.

Luckily nothing cleans easier than waterborne paint. Just do as Ron Wolfe did here: douse the offending panel before the finish dries, wipe it clean, and start anew with proper technique.