Anytime you begin a project, especially when you start on your hot rod, it is always a good idea to plan your work and work your plan. When we left off last month, the team at the Rolling Bones Hot Rod Shop in Greenfield Center, New York, had just completed some of the major surgery required to bring a fresh element of sleekness to Dick DeLuna’s 1934 Ford Highboy coupe.

With the groundwork laid, it was time to focus on completing the cowl drop and the fabrication of an updated subrail assembly. Wasting no time, team member Keith Cornell took the reins and got started by using a Powermax 30 plasma cutter to cut the previously removed lower frame point section in half. He then took the rearmost portion and moved it forward along the bottom of the framerail near its original midpoint. By doing so, he reestablished the lower frame line while also adding additional strength to the structure.

When we last left off, the frame point had been liberated from the frame, the cowl bottom was shaved off, and the changes to the framerail had created a dramatic update to the overall look of the ’34.

When we last left off, the frame point had been liberated from the frame, the cowl bottom was shaved off, and the changes to the framerail had created a dramatic update to the overall look of the ’34.

The section was then tacked in place using a Millermatic MIG welder. With that completed, it was time to focus on creating the dropped cowl and rocker progression. Instead of fabricating the replacement panel from standard flat stock, a decision was made to utilize a pair of steel replacement panels, which already possessed the needed lower body reveal line.

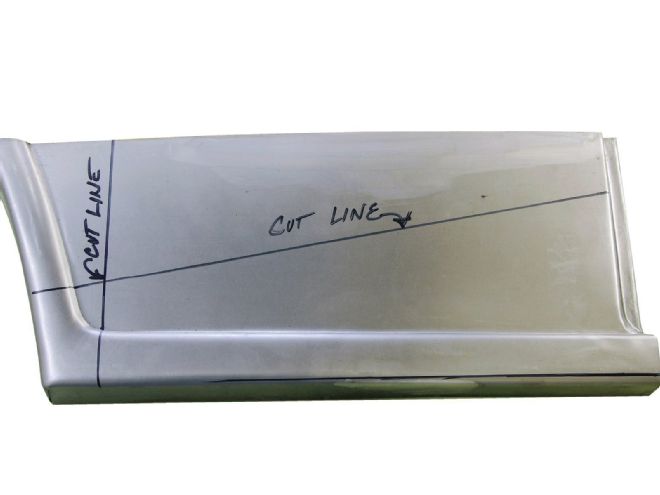

A call was made to Dick Spadaro Early Ford Reproductions to order a pair of their ’32 Ford five-window coupe lower rear quarter patch panels. Working with the original cardboard template used to outline the initial cowl drop, the first replacement panel was marked for trimming, beginning at the doorjamb side at 4-3/4 inches in height. (Note that the doorjamb reveal will be retained for use at a later date when designing the hood sides and frame covers.)

The original frame point was cut in half and its rear section moved forward to carry the newly established line of the framerail.

The original frame point was cut in half and its rear section moved forward to carry the newly established line of the framerail.

Following the template, it was then measured rearward to just before the vertical reveal line intersect. These cut lines were then marked with a black marker and square for accuracy. While wearing proper eye protection, Cornell trimmed the panel using a plasma cutter. The section was then deburred with a 5-inch grinder topped with an 80-grit disc. It was then placed atop the doorjamb edge of the second panel and measured rearward to complete the overall length of 29 inches and 1 inch in final height. A plasma cutter was again used to complete the incisions that were also deburred once completed. Using a duckbill Vise-Grip, the two sections were secured together and mocked in place to be sure their dimensions were accurate. The panels were then tacked together using a Lincoln-Electric Precision TIG welder.

To create the base for the new subrail, a thin section of cardboard was placed in between the body and top of the framerail. To obtain the measurements, Cornell first measured inside the body from the front to the rear of the cowl base, which equaled 15 inches, establishing the dimension of the new upper subrail base section. From outside the body, the cowl line was then marked to complete the template design that had a gradual increase in width from 2-1/4 inches front to 3-1/2 inches rear.

Using the original cardboard template created to illustrate the amount of the cowl drop, the main cowl section panel was marked for trimming.

Using the original cardboard template created to illustrate the amount of the cowl drop, the main cowl section panel was marked for trimming.

The body to frame mounting holes were then marked completing the template. The subrail base was then traced out of a section of 1/8-inch mild steel using a black marker and cut out with a plasma cutter. The section was then deburred and its body mounting holes were added using a drill press and 7/16-inch drill bit. Before proceeding, the section was test-fit in place and a graceful curve was added to mirror the top of the framerail. With the upper subrail base bolted in place, a rectangular section of 16-gauge mild steel plate was clamped to the exterior of the framerail adjacent to it. This portion was then tacked to the base using a MIG welder. The subrail section was then removed and the final MIG welding was completed on a workbench producing a rock-solid replacement unit.

At this moment Cornell shifted gears and returned to the new lower cowl panel extension to finesse the reveal line where the two units were welded together. Using a combination of a hammer and dolly and bench vise, the new panel was massaged to perfection. The welds were then ground to a smooth finish using an air-driven 3-inch grinder topped with an 80-grit disc.

Using a Millermatic MIG welder, team member Keith Cornell tacked the relocated frame point to the framerail.

Using a Millermatic MIG welder, team member Keith Cornell tacked the relocated frame point to the framerail.

That completed, he then focused on wrapping up the trimming needed to the rocker panel area. He reconfirmed the 29-inch length measured from the front of the cowl rearward and used a square to make sure everything was razor sharp before proceeding with an air-driven cutoff wheel. After deburring the incisions to the rocker area, the cowl panel extension was mocked in place to recognize any final adjustments needed. Due to the gentle curve of the body side a number of relief cuts were required to the bottom plane of the cowl panel extension. Cornell made the small incisions using a cutoff wheel in gradual increments and once the curve was affirmed, the cuts were TIG-welded, making the panel complete. The subrail was then bolted back in and the cowl extension panel was held in place to confirm the trimming needed to the subrail side plate. With a 3/4-inch tapeline confirming the trim lines, a plasma cutter was used to trim off the excess. After the trimmed areas were ground smooth, the subrail was given a 90-degree outward bend to the bottom plane of its side plate using a sheetmetal brake.

With the subrail’s construction complete, it was then MIG welded to the inner body structure. To prepare the body for the cowl extension installation, Cornell used an air-driven angle grinder topped with a small wire wheel to remove any primer on the body where welding would be required. The new panel was then clamped securely to the body and carefully MIG-welded into place. The final work required was to fabricate a small section of 18-gauge sheetmetal to close the gap at the front of the panel adjacent to the framerail. With all of the welding completed, a grinder topped with an 80-grit disc combined with a flat file got the newly installed panel looking factory fresh. From any angle the completed updates have brought a newfound raciness to the personality of the coupe with the final changes coming up fast to the front framerails. Stay tuned.

While wearing adequate eye protection, a Hypertherm Powermax 30 plasma cutter was used to trim the panel.

While wearing adequate eye protection, a Hypertherm Powermax 30 plasma cutter was used to trim the panel.