Springs, shocks, antisway bars, wheels, tires: That's what usually comes to mind when we think "handling." Choose the right balance of these components, and the car oughta corner like it's on rails, right? Not necessarily. Just as the hottest engine parts package may fail miserably if you don't know how to tune the combination, even the best handling package may deliver less than expected performance if you overlook the basics.

We all know that even very small changes in an engine's state of tune can dramatically affect power output. Similarly, very slight changes in your vehicle's suspension can result in measurable changes in its handling characteristics, and many of us have even played with different wheel alignment settings and tire pressures. But according to recognized suspension experts like Dick Guldstrand (Guldstrand Motorsports) and Jeff Cheechov (Progress Technology), one of the most overlooked contributors to proper suspension performance is the vehicle's weight distribution.

Huh? Why is weight distribution so important? All too often, a car doesn't respond the same way through mirror-image left and righthand turns. For example, a car may be quick through righthand turns, but in a lefthander you have to turn the steering wheel an additional amount to stay on the proper line through the corner. This is known as "push" or "understeer." So maybe you play with tire pressure and alignment settings, perhaps even mess with the antisway bars, springs, and shocks. After much blood, toil, tears, and sweat, the car is now neutral in left turns ... but--d'oh!--it requires a decrease in the amount the steering wheel is turned as you go through a righthand turn (a condition known as "oversteer," which is really dicey unless you're an experienced competition driver).

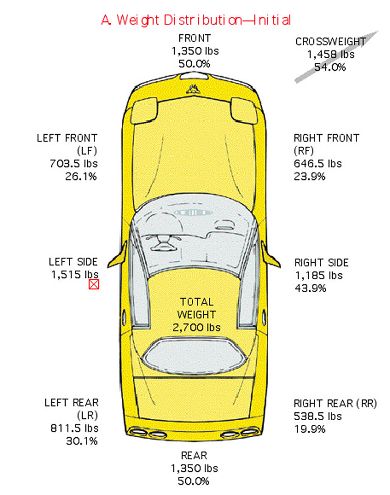

The probable cause for this mystifying situation is improper vehicle static corner weights. Three fundamental aspects of vehicle corner weight are important for setting up a car: the rear weight distribution, the left weight distribution, and the crossweight percentage. The values are determined by the amount of weight resting on each tire contact patch--left-front (LF), right-front (RF), left-rear (LR), and right-rear (RR)--with the car on a level surface. The driver (or a weight simulating the driver) should be in the car, with all the fluids topped off. Of course, fuel quantity doesn't remain constant. Most tuners set up the car with a half-tank of gas.

Left-Side Weight Distribution

Left weight percent = (LF weight + LR weight) / total weight

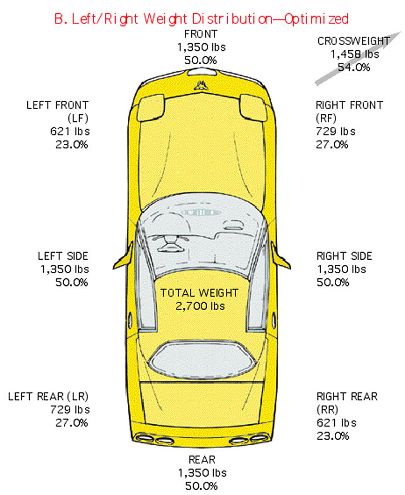

For road-racing, slaloms, or high-performance street handling, a 50 percent left-weight value is preferred because it equalizes cornering forces in both the righthand and lefthand directions. Many cars can't quite get to 50 percent due to driver weight or vehicle design, but you should still try to get as close as possible.

Rear Weight

Rear weight percent = (LR weight + RR weight) / total weight

The ideal front-to-rear weight distribution is not as clear-cut, and may vary depending on the specific vehicle. Again, 50 percent is the normative goal for a conventional handling application, but as power levels increase, putting more static weight over the drive wheels aids straight-line acceleration that helps plant the tires at the drags, and in moderation may improve acceleration off the corners in a handling application. However, rear weight percentage is heavily dependent on the overall vehicle's design layout, so it's much harder to make significant changes fore-and-aft than it is right-to-left. But that's not always bad: Drive wheels on a front-wheel-drive (FWD) application are up front, so a FWD can benefit in some applications with more static front-end weight (which it naturally has anyway due to the transverse engine and transaxle).

For instance, in a FWD sport compact drag-race application, Progress' Cheechov tries to get the mass as far forward as possible. The addition of wheelie bars extends the vehicle's functional wheelbase, transferring the weight farther forward. On the road-course, he uses every trick in the book to get weight off the front axle but usually has to settle for a less-than-ideal rear-weight percentage (well, at least the cars drive off the corners OK).

One place FWD cars shine is in land-speed racing (LSR or Bonneville). High-speed aerodynamic forces want to unload rear tires. That's not good when your rear wheels are the drive wheels! But "no prob'" on a front-heavy front-driver.

Crossweight

After optimizing the car's static weight distribution, the next thing you need to look at is the vehicle's crossweight percentage. This value compares the car's weight totals at diagonally opposite corners to the car's total weight. To calculate crossweight percentage:

Crossweight percent = (RF weight + LR weight) / total weight

If the crossweight is over 50 percent, the car is said to have "wedge"; if it's less than 50 percent, the car has "reverse wedge." The more wedge a car has, the more likely it is to understeer (or "push") in a turn. On the other hand, wedge lowers the ride height at the LR tire, which helps the car come out of the turn better. Turn right, however, and these effects are reversed. Usually the handling degradation in one direction more than offsets any gain in the other direction.

Say the "jack-test" indicates the problem is up front. Pull the front coils and check that both have the same free-length. If they're off, replace them (trimming changes the rate). With torsion bars, just turn the adjusting nuts. Leaf springs can be re-arched. If the springs are OK, the frame is probably tweaked. Correct this stuff before proceeding further.

Say the "jack-test" indicates the problem is up front. Pull the front coils and check that both have the same free-length. If they're off, replace them (trimming changes the rate). With torsion bars, just turn the adjusting nuts. Leaf springs can be re-arched. If the springs are OK, the frame is probably tweaked. Correct this stuff before proceeding further.

As crossweights move away from 50 percent, the car's handling becomes unpredictable. It doesn't respond the same when turning left or right, as in the original example. For the average street handling application, road-course, or slalom event, you want no wedge, or 50 percent crossweight (plus or minus 0.5 percent). Once again, on nose-heavy, transverse-engine FWD cars, getting to 50 percent may be difficult. These cars may be 3-5 percent off on the crossweight. (That's why there's so much interest in coilovers among sport-compact guys.) It's a different story on cars that turn primarily in one direction--like left-turning oval-trackers, which usually have "stagger" (the RR tire has a larger circumference than the LR tire). Stagger usually loosens handling in left turns, so more crossweight is used to tighten it up.

Due to torque-twist on acceleration, a RWD drag car tends to lift the left-front and right-rear tires. It is one case where the car may benefit from reverse-wedge (under 50 percent crossweight). Likewise, occasionally a road-racer may want to deviate from the "50/50 rule." For example, Willow Springs, a southern California road-course, has a preponderance of very long, fast righthand turns; some drivers intentionally dial in reverse-wedge to maximize performance on this course.

Adjustments

Which brings us around to the proper procedure for determining and fixing these settings: First, find the existing values using four wheel scales, with one scale placed under each wheel. All tires must have exactly the same circumference (measure them!), and be inflated to exactly the same air pressure. Disconnect the antisway bar links. The vehicle ride-height must be level side-to-side. If it's more than ½-inch off, check for frame damage; otherwise, it's probably caused by dissimilar length or rate springs. Fix these problems before weighing the car with fluids and driver.

The only way to change the left-side and rear weight balance is to physically move weight or ballast in the car. To lighten the left side, add weight to the right side--as far to the right as possible. If the front's nose-heavy, shift weight to the rear. Left and rear weights are interrelated in the sense that altering one of these usually affects the other to a greater or lesser extent. Both should be adjusted before fine-tuning vehicle crossweight. Relocating stuff changes weight distribution, but it won't change the crossweight percentage!

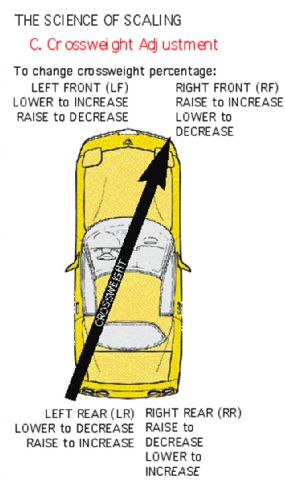

You change crossweight by changing the ride-height at any corner. Once you have the rear weight and left weight percentages as close as possible to 50 percent (for a standard handling application), go to work on the crossweight percentage. Raising the ride-height at one corner increases the weight on that corner, as well as the diagonally opposite corner; the other two corners will lose weight. Lowering the ride-height at one corner causes that corner and the diagonally opposite corner to lose weight; the other two corners will gain weight.

Coilover springs that adjust with a spanner wrench make changing corner height easy. Traditionally reserved for all-out racecars, these days they're being seen more and more on street-driven vehicles as well.

For cars with traditional coil springs, you can change the ride height with spacers or by repositioning the spring within the pocket. Cutting the coils is a last resort because it alters the spring rate (usually you want the same rate on each side of the vehicle, except on some FWD applications where spring bias may be needed to overcome torque-steer).

Leaf springs are more complex. You can affect ride-height alterations by changing the rear spring eye location in the shackle, adding spacer blocks, and/or removing and re-arching the spring.

Very few production-based vehicles have perfect--or even near-perfect--weight distribution characteristics, but if you pay attention to getting the weight at each wheel right, the end result is a much better performing vehicle, and any further wheel, tire, and suspension enhancements will yield even more effective results.