Most of us are aware of the newer setups being run in both asphalt and dirt racing these days. Many of us are experimenting with trying variations of softer front springs combined with either coil-bind or running on bump rubbers for both types of racing. Interest is high as to how to accomplish those setups correctly.

The BBSS setups are finding their way into late-model trucks. Long a choice of straight rail late-model asphalt cars, the process is one that takes some attention to detail to get right. We’ll discuss how it should work.

The BBSS setups are finding their way into late-model trucks. Long a choice of straight rail late-model asphalt cars, the process is one that takes some attention to detail to get right. We’ll discuss how it should work.

What is happening on a large scale is that racers are guessing on spring rates, shock settings, and so on and getting way off on the balance of the cars and the performance suffers. But, we do know that some racers are getting it right and making it work.

So, we had a little discussion with Jason Enders, one of the founders of RE Suspensions in Mooresville, North Carolina. It supplies shocks, springs, and other components to almost all stock car racing classes and works with road racing teams too. RE's level of knowledge is up there as to staying on top of current trends and making them work on the track.

We divided this discussion into two segments, first asphalt racing and then dirt racing. Each is different in the goals and approaches we use. There are some similarities, but the information is best divided. Most of the information you will read here is a result of explanations Jason provided. The plus in all of this is that I totally agree with the information provided, as do many professionals who are winning races with this knowledge.

The discussion centers on the use of bump rubbers. It's generally understood and accepted that coil-bind reduces the suspension to a solid state whereby the tires provide the only "spring rate." This isn't acceptable to the author or Jason and not the most efficient way to set up a race car.

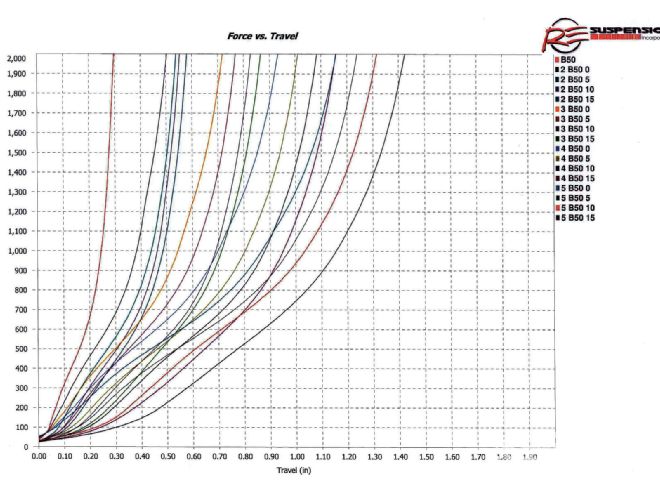

This is a graph of travel distance verses spring rate for a brand of bump rubbers. This is typical of most standard rubbers where the rate starts to gain slowly and then ramp up to very high rates. Each line represents a different hardness of rubber. With these graphs, you can predict your shock travel and then choose a rubber whose rate increase will match the shock travel.

This is a graph of travel distance verses spring rate for a brand of bump rubbers. This is typical of most standard rubbers where the rate starts to gain slowly and then ramp up to very high rates. Each line represents a different hardness of rubber. With these graphs, you can predict your shock travel and then choose a rubber whose rate increase will match the shock travel.

Asphalt

For the purpose of this section we'll refer to asphalt setups used for the straight-rail cars. There are some differences between this class and other asphalt racing classes, but those differences are mostly spring rates and the resulting shock design to go along with those rates.

The BBSS setups require that we run on either coil-bind or bumpstops on one or both front corners of the car. Please choose bumpstops or rubbers. When deciding on which corner to do this, we need to think out the process. The whole intent of the BBSS setups is to attain a low and more level profile of the front of the car. Most racers interpret this to mean getting the left front down to make the front more level and parallel to the track.

That is a good goal, but can be taken too far. If taken to extremes, the balance of the setup can be disturbed and the car won't handle or be fast. Most successful application of BBSS setups incorporate getting the left front down.

There is a term that has been around since the late '90s and originated in Cup racing in setups for Daytona and Talladega. It's "tie-down" shocks. Many of us professional engineers reacted harshly to that term insisting that you can't tie down any corner of the car since we can't bolt the tire to the track.

So, I will still use the term tie-down, but the meaning will be related to higher rebound settings in the shocks, which will produce a slow rebound movement to restrict rebound of the suspension to hold the spring in compression longer. There is a logical reason why we need to do this that will be explained.

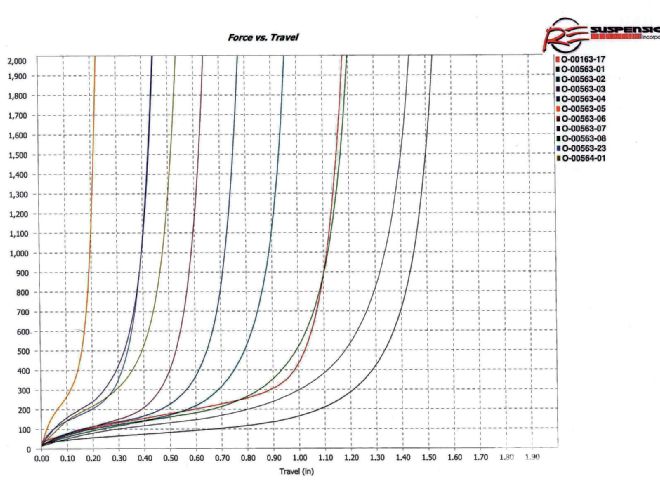

In this illustration, the bump rubbers are much softer where there is a higher amount of compression of the rubber possible until the rate goes up. Then, after a certain compression amount the rate goes up very quickly and stays somewhat more consistent.

In this illustration, the bump rubbers are much softer where there is a higher amount of compression of the rubber possible until the rate goes up. Then, after a certain compression amount the rate goes up very quickly and stays somewhat more consistent.

Getting the car down on bumpstops at the left front is, in actuality, causing a change in spring rate. You might be running a 150-lb/in spring in that corner and mechanical downforce causes movement that takes the shock down onto a bump rubber that has a rate of 1,000 lb/in to 1,500 lb/in.

The trick is to match the movement or ride of the shock so that you will be operating in that range and not higher. If you move too hard onto the bump rubber, the rate could well increase to upwards of 2,500 lb/in on to infinity.

This is just the mistake most racers make. By running a right rear spring rate that is too high, you force more load onto the left front suspension and cause the bump rubber to compress to very high levels of spring rate.

Jason states, "Too many racers are overly concerned with how the car looks." The front end doesn't have to be perfectly level to the track and the valance doesn't have to scrape the asphalt in order for everything to work correctly.

A solid suspension doesn't promote continued and high levels of adhesion. Loss of grip at any corner will cause loss of performance. When the suspension goes solid, the tire spring rate will need to control irregularities in the track. Most asphalt racing tires have a spring rate of upwards of 2,500 lb/in.

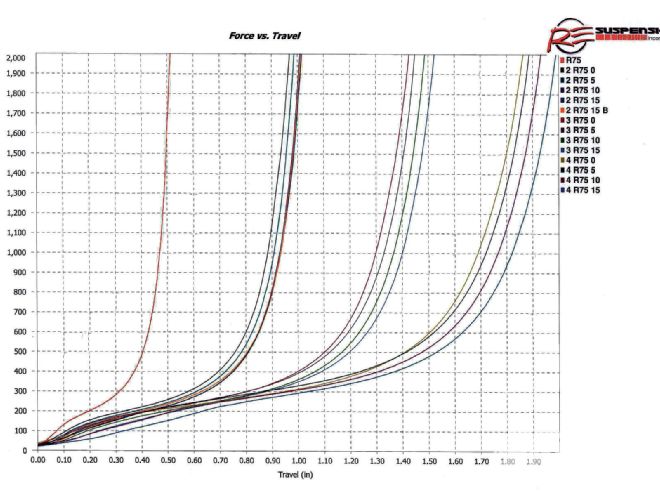

Here we see the results of stacking different rate spring rubbers. The stacked spring effect shows and the stack gains rate slowly until a defined travel is reached before the rate increases drastically. With this chart, you can match the stack to your specific shock travel.

Here we see the results of stacking different rate spring rubbers. The stacked spring effect shows and the stack gains rate slowly until a defined travel is reached before the rate increases drastically. With this chart, you can match the stack to your specific shock travel.

What is encouraged is a setup where you use as much rebound in the shocks as is needed, and no more. Jason stressed this in our conversation. I've seen some shock graphs where the rebound was unusually high and that concerned me. But now, knowing more about the process and the spring rates that are associated with bump rubbers, I've concluded the rebound rate must control the spring rate.

If the bump rubber rate is 1,500 lb/in, then the shock must control that rate. If the rebound rate is not high enough, then that corner of the car won't stay on the bump rubber and the setup won't be consistent.

Sure, the rebound rates I've seen appear high in relation to more conventional setups, but we're not comparing apples to apples when we compare shock rates. That is why going from conventional setups to the BBSS setups requires much different shock designs. Organizations like RE Suspensions can be utilized to get the correct shocks for your application. The above illustrations tell why.

The key to reliable setups that are fast and consistent is in the combination of spring rates, bump rubber rates, and shock design to produce a balanced setup. This is the same balance we have talked about for many years now. It's the same process with a different approach.

Dirt Racing

The trend in Dirt Late Model racing has been to force the front ends lower with softer springs and then to a higher-rate spring to control the roughness of the track. This is a tall order but it can be

accomplished.

A dirt car can't run on bumpstops for 99 percent of the tracks it runs on. Sure, there are times when a track goes black and remains very smooth, but we can't rely on things being that way very often. So, what will work to accomplish the above stated goals?

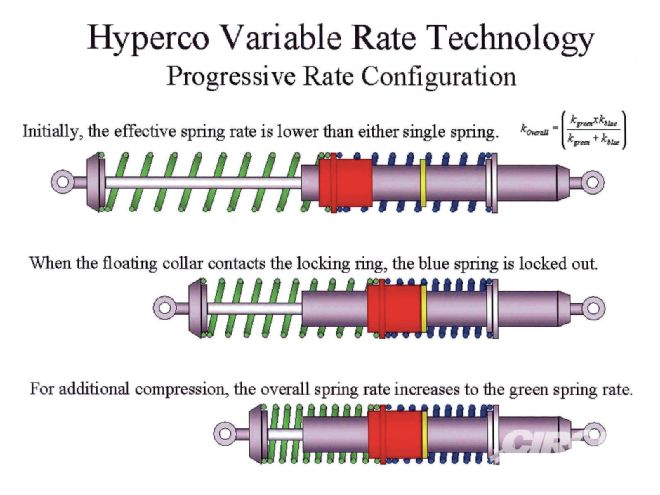

Hyperco Springs produced this illustration to show how the stacked, or dual spring configuration works for the dirt cars. This is known as progressive rate change due to the increase of rate with shock compression travel, but the progression is immediate as opposed to gradual. You are either on the stacked spring combined rate or the higher spring rate. The key to making this work is to know where to place the locking ring to time the rate change.

Hyperco Springs produced this illustration to show how the stacked, or dual spring configuration works for the dirt cars. This is known as progressive rate change due to the increase of rate with shock compression travel, but the progression is immediate as opposed to gradual. You are either on the stacked spring combined rate or the higher spring rate. The key to making this work is to know where to place the locking ring to time the rate change.

Double, dual, or stacked springs were introduced to me back in March 1998. Kelly Falls and Dewayne Ragland put together a plan to use stacked springs to soften the ride at one ride height and then cause a much stiffer rate at lower ride heights. Many combinations of stacked springs were tried on different corners of Dirt Late Model cars with varying success.

Until recently, honestly, it was hit or miss and I think the missing ingredient was in designing shocks that could work with that system to produce the desired results. Jason and I talked about this setup phenomenon and how racers can make stacked springs work.

If you read the asphalt section leading to this dirt section, you will understand the goals of going from soft to stiff spring rates. The goal is similar with dirt setups except that the corner in which we need to transition is the right front, not the left front as in asphalt racing.

The successful use of stacked springs at the right front on Dirt Late Model cars is becoming more and more popular. The result is an attitude that is lower to the track and a spring rate that handles the forces of rough dirt tracks.

The shock is fitted with a stiffer top spring and softer bottom spring. The softer combination of the top and bottom springs allows the car to reduce its ride height using the same mechanical downforce we talked about in the asphalt section.

The movement of the shock causes the bottom support ring of the top spring to contact a locking ring located on the shock body. Then only the stiffer top spring rate comes into play. Now the car is lower and on a sufficient spring rate.

This higher, single spring rate is usually about what is recommended for single spring setups, but arrived at utilizing a much lower ride height. So, the setup hasn't changed, only the attitude of the car.

<strong>Before:</strong> This view of Don O’neal’s car at Batesville shows the right side ride height during the pace laps before the race starts. The right front is approximately 8 inches off the track. This high attitude is in preparation for the high travel this car will experience once the race gets under way.

<strong>Before:</strong> This view of Don O’neal’s car at Batesville shows the right side ride height during the pace laps before the race starts. The right front is approximately 8 inches off the track. This high attitude is in preparation for the high travel this car will experience once the race gets under way.

A lower attitude accomplishes several things. It improves visibility for the driver, a benefit not unnoticed by many top drivers. It's hard to see where the groove is located when the front end is above the sight line.

A lower attitude also improves aero downforce to produce more front loading. More grip up front helps the car turn which allows more rear grip to be dialed in for bite off the corners. Most of the gains come without any negative complications.

What racers need to understand is that other settings need to be adjusted to match the new ride height of these setups. If the overall position of the right front, and to some extent the left front, is lower, then the cambers will change more dramatically. Initial camber settings will need to change to compensate for increased camber gain at the RF and camber loss at the LF.

If you always ran 4-5 degrees of negative camber in the RF, you might now need to run less, up to 3 or 4 degrees less. The camber gain (more negative camber) will increase as the travel increases while maintaining the same relative roll angle.

Again, the use of higher spring rates through the turns requires the redesign of the shocks so that you can control those rates. Higher spring rates require a higher rebound rate. That is simply the way shocks are supposed to work. You provide just enough control to keep the spring movement under control and no more.

As with the asphalt setups, excess use of rebound in the shocks won't improve performance and may well cause loss of performance. Tune your shock rates to the spring rates the car is experiencing in the turns.

<strong>After:</strong> On the second lap of the race, we see a very different attitude at the right front. Where once there were 8 inches of height is now zero. With the right combination of shock rates, this car will maintain a balance where the combination of spring rates at the four corners will provide speed and consistency.

<strong>After:</strong> On the second lap of the race, we see a very different attitude at the right front. Where once there were 8 inches of height is now zero. With the right combination of shock rates, this car will maintain a balance where the combination of spring rates at the four corners will provide speed and consistency.

Testing

One thing Jason impressed upon me, and something I've always agreed on, is that shocks are the last tuning tool as far as setup is concerned. He stressed that teams must get their basic setup correct and all of the other settings such as cambers, moment centers, Ackermann, and so on straightened out before starting to work with shock settings.

When he agrees to attend a test with a team, he always shows up in the afternoon, after the team has sorted out all of the various "problems" usually associated with arrival at the track and the start of a test. That way, he can concentrate on the shock changes and their affect on a car that is sorted out for the most part.

He'll never allow a team to believe that shocks are the primary setup parameter, but instead a very important tuning tool to use once the basic balance and geometry issues have been taken care of. Then, and only then, can the shock expert help the car.

Conclusion

Be it asphalt or dirt setups, things have definitely changed over the past few years. Making sense of the new setups helps teams choose the correct components and settings. Low attitudes help with several long-established performance enhancing concepts.

Low causes a lower center of gravity and along with that, less load transfer. Low allows better aero efficiency and downforce which translates into more grip. And in the dirt cars, low provides a better view of the racetrack.

If you decide to try any of the new softer spring setups, or you're in the process of trying to figure this out, I recommend you consult with experts such as Jason who have had a lot of experience working with these types of setup. The savings in time and money can be substantial, not to mention the value of success. How do they say it in the commercials? Priceless.