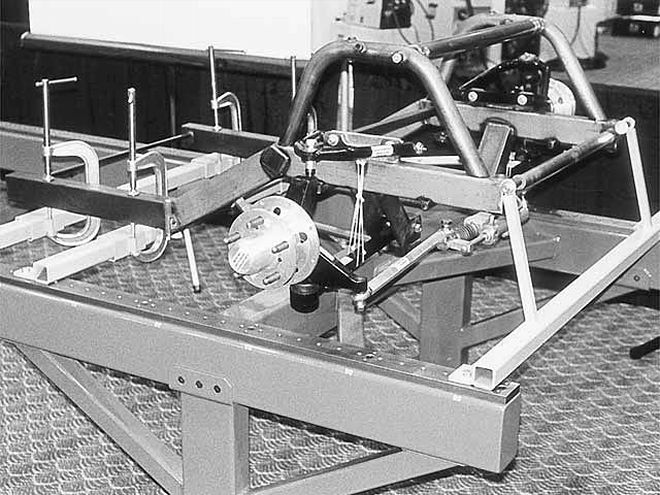

The Unijig Pro from DCS Peformance Engineering accepts frames from GM,Ford, Off-Road, Winston Cup, Saturday-night late Models and StreetStocks.

The Unijig Pro from DCS Peformance Engineering accepts frames from GM,Ford, Off-Road, Winston Cup, Saturday-night late Models and StreetStocks.

Wrecks and bent chassis are part of racing here's how to use a jig toget it all straightened out.

Consistency in racing is what brings a driver and his team achampionship. However, if you think about it, this consistency does notjust relate to a driver's performance on a given Saturday night orSunday afternoon. Not only does the driver have to drive a consis-tentlygood race lap after lap, weekend after weekend; the car itself has to beconsistent as well. Of course, engine performance is a major factor inthis equation, but another major factor is the chassis, and how good ofshape it is in.

We have all seen, or even been through, this scenario--you have builtthe best car you have ever driven, and you already won three out of thefirst five races of the season with it. Minor adjustments need to bemade here or there with each race driven, but that is a given. Then thatfateful sixth race comes along. After leading the majority of the race,you and the rear end of your prized race car meet the wall of Turn3--hard. What are you going to do now? The damage to the rear end is sobad that you have to work on the car just to get it in the trailer totake home. Why not just junk the whole thing?

Luckily, you don't need to take this drastic and ultimately expensivestep. The good thing to come out of this scenario is that the rest ofthe car is in fairly good shape. Those rubber donuts can always berubbed out, your front end is still straight, and the motor seems to berunning OK. So what do you do about your race car that now looks like ahatchback?

This is where the chassis jig comes into play. "A chassis jig is what isused to manufacture a frame in a manner where every frame is exactly thesame from one to the next," says Wayne Lensing of Lefthander Chassis inRoscoe, Illinois. "The jig keeps the chassis square and consistent."

Lensing and Lefthander Chassis build frames for short-track oval racers.According to Lensing, there are a few key measurements when building orrepairing a frame. "When you build a chassis, you want all yourframerails to be parallel," he says. "One key point to measure is yourlower control arms. You always want them to be in the same spot so yourtrailing arms are consistent. Every Lefthander Chassis comes with thesepoints of measurement."

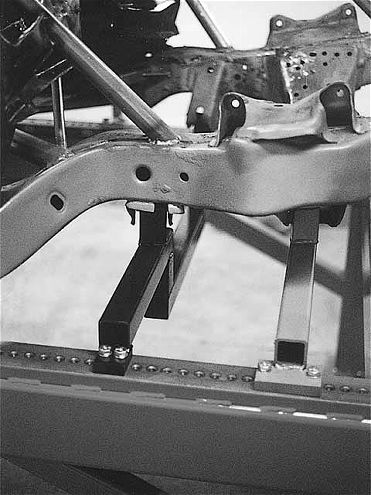

Fixtures (the white square tubing) for specific chassis may be madeavailable through chassis manufacturers, or you can make them yourselfto fit your favorite frame.

Fixtures (the white square tubing) for specific chassis may be madeavailable through chassis manufacturers, or you can make them yourselfto fit your favorite frame.

Wes Van Winkle of Maxx Racing Chassis in Enid, Oklahoma, measuresseveral different points on the chassis to make sure it is consistentall around. "I measure the overall X on the frame, from one end to theother," Van Winkle says. It is wise to note that the overall X on aframe can be determined differently with each chassis builder but isbasically a set of crossmembers to make sure the frame is square. "ThenI go back and measure from the center of the front spring pad to thecenter of the rear spring pad. And of course, I always measure thewheelbase."

A good tip to remember is to ask your chassis manufacturer what theyconsider to be the overall X of the frame. In some cases, it could befrom the right front to the left rear and the left front to the rightrear. Others might measure just the rear in an X fashion. Van Winklealso suggests that you measure the steering linkage to make sure theyare at the right angles.

When you have damaged either the front or rear clip of your car, thereare a couple of options you can take. The first, and maybe easiest one,is to send your car back to the chassis builder. They will already havethe jig and measurements of your car in its original condition. Thisoption might take longer than you had hoped, especially if the buildertakes care of many of the racers at your track and it was a particularlymessy night. Many times you only have a span of a week, two at the most,to get your car repaired and ready to go back on the track.

There is always the option of getting your own jig. You can buy one, oryour other option is to build one.

Maxx Racing Chassis specializes in building frames for I.M.C.A. as wellas Limited Sportsman, Pro Stock, Street Stock, Factory Stock, and MiniStock classes. Because of the variety of chassis that Maxx RacingChassis puts out, Van Winkle built his own jig.

"I just used four-inch I-beam. You want to use something pretty rigid,"he says. "Though, a lot of guys will build their jigs out of 2x4 squaretubing. With my own jig, I can set it so we can just bolt a frame towhere everything will be level and square. I have built so many frameson it that I can now just lay a pattern on the jig and know where to cutthe hole in the frame to weld a piece of pipe, or I can drill holes torelocate all the front steering linkage in order to get the steeringgeometry correct. If you are going to work on a variety of cars, youmight be better off to design your own jig. With the jig I built, I canput a metric frame on it or I can put a full size GM frame. I can evenuse that same jig with a Ford frame."

The main feature of this jig, manufactured by Unijig, is itsadjustability, allowing you to move fixtures to fit frames fromdifferent manufacturers.

The main feature of this jig, manufactured by Unijig, is itsadjustability, allowing you to move fixtures to fit frames fromdifferent manufacturers.

Lensing mentions that a few companies are selling jigs to the averageracer. They are mainly used to repair a chassis rather than build them.

"Some of the larger racing teams are starting to buy their own jigs torepair damaged stuff themselves," he says. A jig such as this would runa race team about $5,000.

"We have sold a few jigs to some of our dealers," explains Lensing. "Ourdealers buy our chassis and then repair the cars later with their ownjigs. That helps us sell cars to other parts of the country. It seemsmore guys are apt to buy our chassis if they know that the dealers willsupport them when it comes time to repair the car."

DCS Performance Engineering out of Reedsburg, Wisconsin manufactures theUnijig (featured in the Oct. 2000 issue). The Unijig is a universalchassis jig that is designed to fit any type of racing chassis. An addedfeature for the average racer using this equipment from his backyardshop is that the Unijig also can be used as a welding and fabricatingtable. DCS uses CNC-machined 3/4- x 3-inch bolt rails that are mountedto the 3/16-inch steel-tube framework when manufacturing the Unijig.

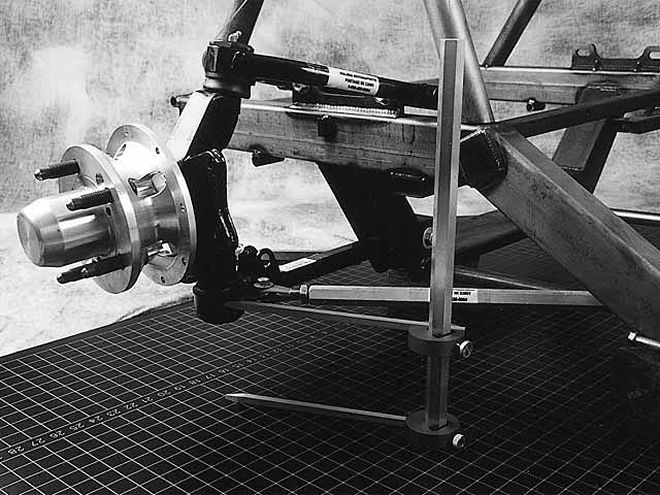

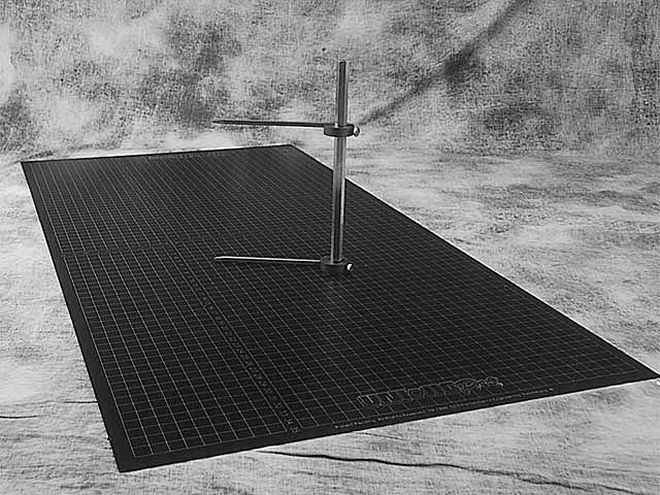

(above & below left) Here's a great accessory to go along with your jig. This laser-machinedplate, manufactured by Unijig, is designed to help make accuratemeasurements on all three planes. The plate is scribed with a large X/Ygrid, and the Z-axis caliper allows you to take accurate verticalmeasurements up to 30 inches. As with a jig, the key is to make sure theplate is level, or it will throw all your measurements off.

(above & below left) Here's a great accessory to go along with your jig. This laser-machinedplate, manufactured by Unijig, is designed to help make accuratemeasurements on all three planes. The plate is scribed with a large X/Ygrid, and the Z-axis caliper allows you to take accurate verticalmeasurements up to 30 inches. As with a jig, the key is to make sure theplate is level, or it will throw all your measurements off.

Another helpful feature included with this chassis fabrication equipmentare the adjustable steel fixtures that attach to the bolt rails. Theyare made to fit a variety of chassis and are available through variouschassis dealers or can be manufactured by the customer. Changing out aset of fixtures takes about 10 minutes to do. This allows the operatorto work on several different chassis models with one piece, savingprecious floor space in the shop.

If you decide to take your racer back to the chassis builder, or youwant to do it yourself, Lensing explains the basic process to fixing thedamaged areas:

"We will put the damaged car back on the jig to start repairing thedamaged area. Doing this will also tell us what kind of condition therest of the frame is in. There are usually lineup points where the stubwill fit in the jig. These lineup points are off of the mounting pointson the framerails. From here, all we do is cut off the damaged materialand replace it with either a front or rear clip or centersection--whatever needs to be done.

"A jig enables us to get the car back to the customer as quickly aspossible without a lot of tape-measuring and squaring. Sometimes he canhave it back by Monday, use the rest of the week to paint up the parts,and get it back together, so he can be back on the track on Saturdaynight."

So, what should you do if you think a jig is what you need for your shopbut have never used one? Lensing suggests you avoid the"trial-and-error" method.

"Hopefully, for the person who buys a jig for their home race shop, itwill come with the fixtures for your specific chassis manufacturer," hesays. Like the Unijig from DCS, many jigs should come with fixtures thatare interchangeable for all types of chassis manufac-turers. Along withthe fixtures, you want to make sure you are getting a pam-phlet orinstruction booklet that will tell you where to mount the fixtures thatwill clamp the car down.

"A lot of jigs, like mine from Chrysler, have centering marks," saysLensing. "You just put your car on the surface plate, line it up, andmeasure off of the centerlines to get everything on your chassis back toits original condition."

Of course, the damage may be so severe that you are not able to fix it.However, with the jig, you will still get as close to your race-winningvehicle as possible. Here are some tips to remember when you need torepair or have a new chassis built:

* If you are taking your frame back to the original builder, make sureyou have ample time. Sometimes, this can not be helped when you wreckone weekend and race the next. Just remember that you might need abackup frame.

* If you decide to do the repair work yourself, talk to the originalchassis builder and get as much information as possible regarding thekey measurement points discussed earlier. Being just a little bit off onyour measurements may affect the car's performance on the track.

* If you have bought a chassis jig for your own shop, make sure you havethe correct fixtures specific to your frame's manufacturer. Also makesure that the jig manufacturer from which you bought your equipmentprovides pamphlets and instruction booklets. You may even want to findout if it offers special training classes with delivery of your new jig.

* Remember that consistency wins championships.