Over the past few years, we've taken on various project cars with real-world, on-the-track testing, racing, and evaluation. We're involved in this so that you can see our progression and, hopefully, we can all improve on the processes involved in building, setting up, and racing a race car. I can honestly say that few of our projects have gone exactly as planned. However, we have had excellent results in being able to improve both the team's processes and success, as well as in the presentation of information to you, our readers.

In a perfect world, we would be there to observe and be in on every decision a project team makes and be a total part of that process. That's not always the case because in a lot of instances it's not practical. We have influenced certain teams and improved on their processes, and in all cases tried to steer them away from experimentation without evaluation. And that is our overall goal as a technical magazine.

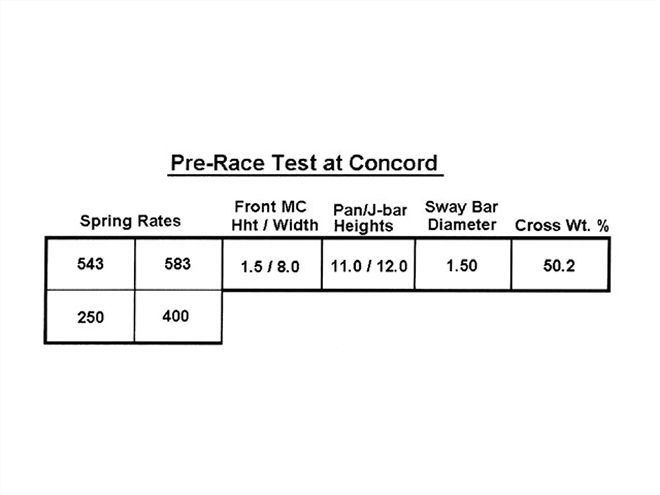

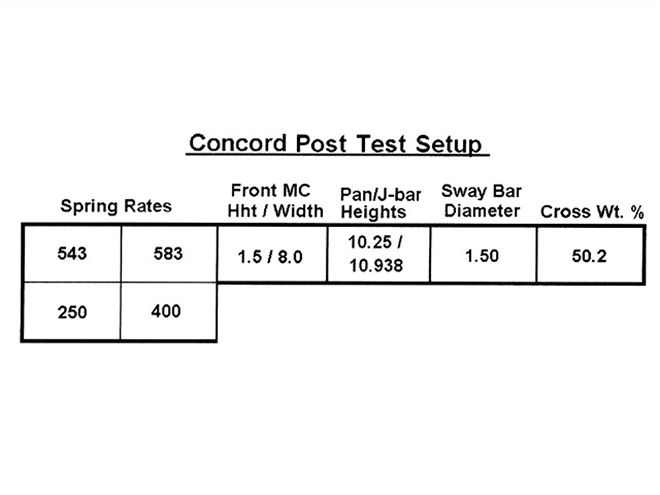

This was our designed setup for our first test at Concord Speedway in Concord, NC. We decided to go with a soft / conventional setup using a moderately stiff sway bar. We balanced the setup and went through the car checking alignment and security of bolts, and so on.

This was our designed setup for our first test at Concord Speedway in Concord, NC. We decided to go with a soft / conventional setup using a moderately stiff sway bar. We balanced the setup and went through the car checking alignment and security of bolts, and so on.

We don't own race cars and teams because there's no budget here for that. So, for the most part, the golden rule applies; those with the gold rule. We sometimes are content to sit back and observe for the most part, and the end result is telling you how a team either did things right or might have done things differently and done better.

Back in the day, when I was recruited by a team as a consultant, I made them understand that I was to be in total control of all aspects of the setup. That had to be how it was in order for me to properly evaluate the car and do what was right to make it competitive. Most problems come from a team using setup pieces and parts from other teams that don't necessarily fit the design of their car. One of our primary goals in doing project cars is to help teams refrain from doing that.

Keep in mind that this is a report. It uses test, practice, and race notes including driver comments, tire temperatures, lap times, and a record of changes made to the car. As you follow along, try to compare what is happening to how your team does things. There may be a few lessons to be learned.

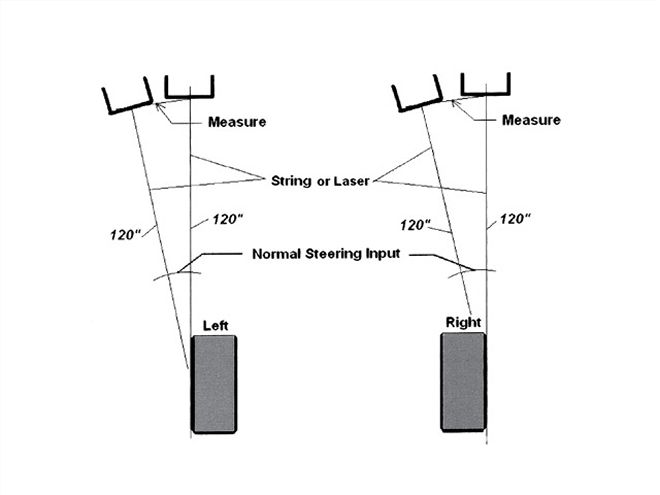

Before you race, do a quick and easy Ackermann check. You can use string or lasers. Project the wheel alignment out to 10 feet in front of the wheels with them pointed straight ahead. Make a mark on the floor (use wide masking tape). Then turn the wheels about the same number of degrees you would in the turns. Again, project the wheel alignment out 10 feet and make a mark. Then measure between the two marks.

Before you race, do a quick and easy Ackermann check. You can use string or lasers. Project the wheel alignment out to 10 feet in front of the wheels with them pointed straight ahead. Make a mark on the floor (use wide masking tape). Then turn the wheels about the same number of degrees you would in the turns. Again, project the wheel alignment out 10 feet and make a mark. Then measure between the two marks.

The Plan

The team consists of driver John Gibson; his father and team manager Chuck; John's mom, Kristy, very active note keeper and timer; crew chief Justin Lages, from my hometown; car chief Josh Corbridge; media relations Erica Smetters; and junior engineer Adam Wall. We initially evaluated the car that was built by Steve Leavitt and determined a setup plan. I wanted to go with a soft, conventional setup that would provide positive aspects of a lower profile in the turns while staying off of the bumpers and avoiding coil bind that can quickly change the spring rate of the suspension and take it to infinity.

I've talked with many hundreds of teams over the past five years about the evolution of the Big Bar and Soft Spring setups. What I've learned is that most, if not all, of the very successful teams have drawn back from extreme soft setups and very large sway bars for the most part. With rough and bumpy tracks, they unanimously stiffen up to keep the suspension free. Concord Motorsports Park is a track where the transitions are pronounced and can upset a car with a large sway bar.

The setup

I came up with was one where we used 500-600 pounds per inch (ppi) front springs, a 11/2 inch diameter sway bar, and a 250 ppi left rear spring and a 400 ppi right rear spring. RE Suspensions built us a set of hlins shocks that had a wide range of adjustment so that we could tune the transitions. The Panhard bar was set to complement the spring layout and weight distribution of this car using a computer software program designed to do just that.

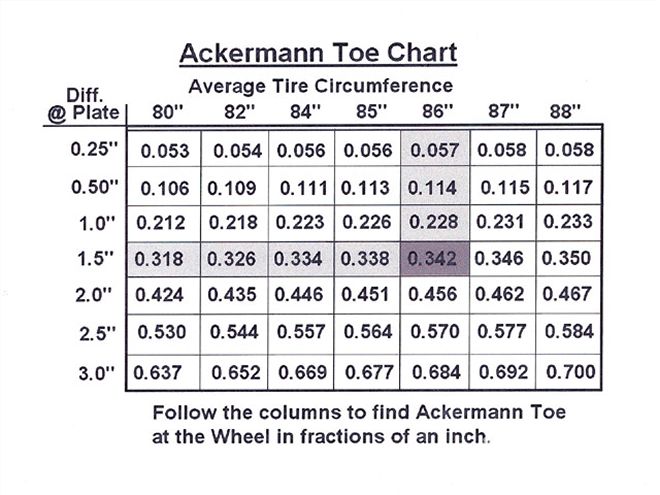

When you do your Ackermann check, this is a table to tell you how much added toe to expect due to the difference in width between the marks placed at 10 feet related to the tire circumference you are running.

When you do your Ackermann check, this is a table to tell you how much added toe to expect due to the difference in width between the marks placed at 10 feet related to the tire circumference you are running.

The first track test For our first test, we went to Concord prior to the race that was scheduled for that track. The setup was developed by me and I drove up to meet the team at the track. We got less than 15 laps in on the first try when our engine came unglued. It was taken back to Keith Dorton who personally oversaw the disassembly and assessment. After fixing the problem, the team reinstalled the motor and we went back to the track to resume the test.

After the first visit, we decided to make a change to the truck arm mounting. We had previously mounted the front of the arms in the top holes for minimum rear steer, but felt we needed more bite off the corners. We lowered the left truck arm to the bottom hole (of three holes).

The initial runs showed a very loose car at all points in the turns. The car was loose in, loose in the middle, and driving off was impossible. This led me to believe that there might be an alignment problem although the team assured me that the rearend had been squared.

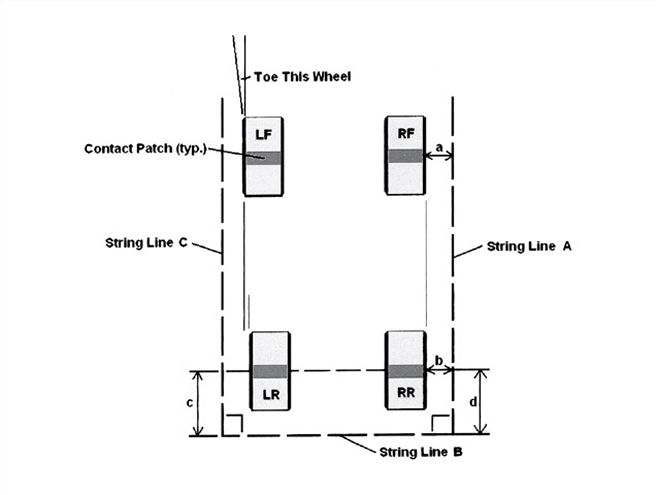

A quick and easy way to check your alignment at the track is by using a string. You can measure from the string to the framerail if that's your reference and then to each right-side tire sidewall. Make sure you're not putting the end of the tape onto a letter protrusion or anything other than the actual sidewall of the tire. If measuring at hub height, compensate for the cambers. To get the contact patches lined up, the RF tire will always be closer to the centerline of the car due to the added camber.

A quick and easy way to check your alignment at the track is by using a string. You can measure from the string to the framerail if that's your reference and then to each right-side tire sidewall. Make sure you're not putting the end of the tape onto a letter protrusion or anything other than the actual sidewall of the tire. If measuring at hub height, compensate for the cambers. To get the contact patches lined up, the RF tire will always be closer to the centerline of the car due to the added camber.

We pulled out a string and put the steering box at center and locked the shaft. I noted right away that the right front wheel was pointed to the right. I had the team loosen the left and right-side tie rod adjusters and we aligned the right-side wheel straight ahead. We would toe the front wheels out using the left front wheel later on.

Once we had the right front straight, we looked at the right rear and noticed that it was toed or pointed right. We had already checked the rear for toe and it measured zero toe. This meant the RR was behind the LR and I decided to move the RR forward to align the rearend. We made two changes to the slugs and that produced a movement of 3/16 inch of the truck arm. That would result in a movement at the RR wheel of 0.250 forward and the LR wheel movement rearward of 0.137 inch. That is the equivalent of moving one wheel approximately 3/8 inch. Once the RR wheel was straight ahead to the RF wheel, we could proceed with the test.

The car was now more neutral in the turns. We did lower the right-side Panhard bar 1/2 inch, adjusted the shocks with less rebound in the RF and more rebound in the LF. We had a stability problem through the transition of the banking from Turn 2 all of the way to Turn 4. And, the car was very loose off Turn 2 and through the dip leading up to the backstretch. These changes made a marked difference and the car both looked good and was very comfortable to drive.

Here are the setup numbers after the test at Concord. The Panhard bar heights changed, but the biggest change was in squaring the rearend and adding a good deal of rebound to the LF shock.

Here are the setup numbers after the test at Concord. The Panhard bar heights changed, but the biggest change was in squaring the rearend and adding a good deal of rebound to the LF shock.

Since the loose off condition was a transitional problem, we didn't want to make basic setup changes that would upset the middle of the turn performance. The only real adjustment we had was in the shocks. Joe Berardi with RaceWorks suggested a significant increase in the LF shock rebound settings. He thought that might make the car loose, but I disagreed and thought it might just solve the tight off problem. Here's why.

When the car accelerates, load is transferred from the front to the rear. The front of the car lifts when the load leaves it and this movement can be used to redistribute the loads on all four tires. Increasing the LF rebound takes a lot of load off that tire and distributes it onto the other three tires. This increases the load on the RF, LR, and RR. The overall load increase on the diagonal, RF and LR, causes the car to be much tighter by increasing the crossweight percent.

In subsequent runs, that's exactly what happened. The loose off condition was greatly improved and the overall attitude of the car going through the transitions was much better. Now we had a car that looked good, was quick and had even tire temperatures front to rear for each side of the car. The loose off condition was not completely fixed, but we were running on tires that had many heat cycles on them and the track was green and fairly hot.

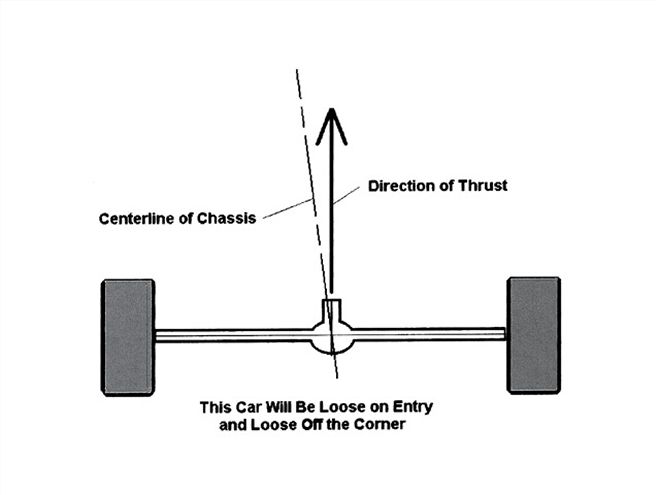

When the rearend is out of alignment, it's pointed either right or left of the centerline of the car. When it's pointed to the right, as in our case in the first test, the car is going to be loose at all points in the turns and very loose off the corner due to the direction of the thrust of acceleration. This can't be fixed with setup changes and must be addressed early on in the test.

When the rearend is out of alignment, it's pointed either right or left of the centerline of the car. When it's pointed to the right, as in our case in the first test, the car is going to be loose at all points in the turns and very loose off the corner due to the direction of the thrust of acceleration. This can't be fixed with setup changes and must be addressed early on in the test.

We recorded lap times in the lower 17.0s and 17.1s at the end of the test with tires that had approximately 70-80 laps on them. John still reported that the car was loose off in the final two runs. We also noticed that the car didn't want to accelerate well and would later find out that the carburetor was not adjusted properly with the float levels. With better acceleration, our lap times might have been better. I was looking forward to the race.

The Seven-Post Rig Analysis

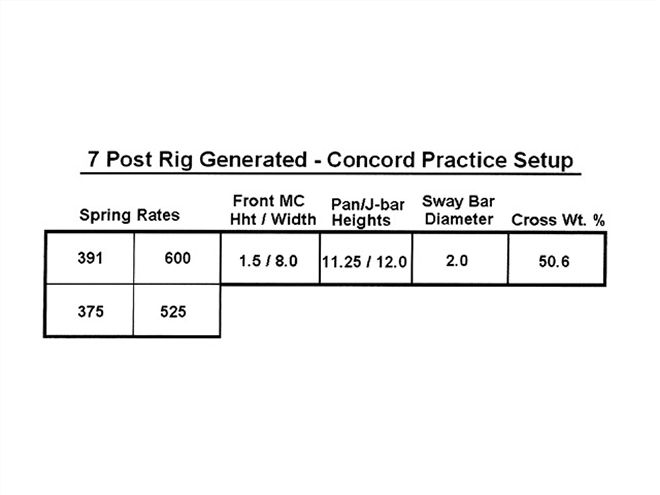

Refer to the article in this issue for the complete coverage of the seven-post rig test. For the purpose of this analysis, we will report that the team made significant setup changes to the car for the evaluation process at the sevn-post test and then decided to keep these changes in the car to be run at the Concord race.

I was not consulted about this change and only became aware of it after the race. So, our analysis now is one of looking back and trying to sort out what went on with this new and untested setup.

Changes included the softening of the LF spring to 391 ppi, stiffening the LR spring to 375 ppi and stiffening the RR spring to 525 ppi. They installed a 2-inch diameter sway bar, up from a 1.5 inch diameter. This increased the bar rate from 1,020 pounds to 2,750 pounds, or equivalent to installing 3,000-pound front springs to equal the roll resistance of that sway bar change. Now they were much closer to a full blown BBSS setup. Unfortunately, that defeated the original plan.

Concord Practice and Race

The team arrived for the Friday practice before the Saturday race with an untested setup. In my analysis, the car was setup tight. I would have run a larger RR spring and rear spring split to go along with the larger sway bar, and in a talk with Joe Berardi, he agreed. The other significant change was to reduce the LF shock rebound that we found most successful in helping get the car off the corners.

When the car went to the seven-post rig, various changes were made to improve the data the rig generates. These changes were left in the car for the race at Concord. As an untested setup, a lot of work went into sorting it out and making it work in the Friday and Saturday practice sessions. The crew did a very good job working it all out to end up with a very decent handling balance. I'm unsure as to the effectiveness of the dynamic balance of this setup.

When the car went to the seven-post rig, various changes were made to improve the data the rig generates. These changes were left in the car for the race at Concord. As an untested setup, a lot of work went into sorting it out and making it work in the Friday and Saturday practice sessions. The crew did a very good job working it all out to end up with a very decent handling balance. I'm unsure as to the effectiveness of the dynamic balance of this setup.

In the first runs where the tires showed heat, the car was again loose off and the team made basic setup changes to try to fix that problem. Subsequently, the car was never quite right and the lap times showed it to be off our previous test by 2-3 tenths, even with the correctly adjusted carburetor, newer tires, and the aide of other cars running and laying down rubber.

The tire temperatures looked decent with matching right-side and left-side temps. This would indicate a fairly balanced setup, but with a tight loose condition the tire temperatures can be misleading. In hindsight, the team should have dealt with the transition problem with the shocks, not with changes to the Panhard bar, spring rates, or weight distribution.

To adjust for the tight off condition, the team lowered the track (Panhard) bar, increased the crossweight, moved the right truck arm back 1/16 inch, and made changes to the right front shock. The car ended up still very tight with a development of loose off, or a tight/loose condition. On Friday late in the day, they put on stickers and ran a 16.84.

During the Saturday, race day, practice, the team continued to adjust the car and improved the speed. The car ran a 16.89 with more than 40 laps on the tires and 16.93 and 16.94 laps with 50-plus-lap tires. One of the last comments was that the car was borderline loose. That was a long way from the very tight condition they started with.

An analysis of the final tire temperatures showed that the LF and RR were hotter by about 5 degrees than the RF and LR pairs. This can be an indication of a tight setup being made neutral with reduced crossweight percent. Where the LF and LR tire should be equal and the RF and RR tires equal, the diagonal tires were equal. If you pull cross out of the car to compensate for a tight setup, you end up with cooler crossweight diagonal tires being the RF and LR as we see.

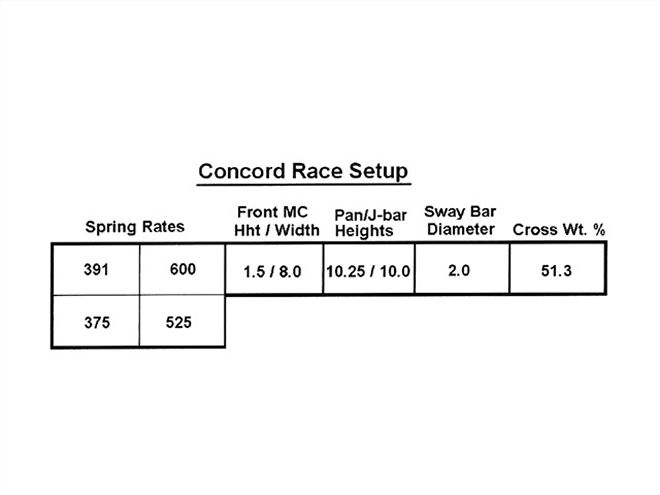

For the race at Concord, the setup change with the lowering of the Panhard bar and adding of crossweight to tighten the car off the corners.

For the race at Concord, the setup change with the lowering of the Panhard bar and adding of crossweight to tighten the car off the corners.

Coincidentally, in our previous test we saw the same phenomenon. The LF was always hotter than the LR. The one big difference in the two setups was that the difference between the average left-side temperatures in the first test at Concord was 23 degrees and the difference between average temperatures side to side in the final runs on Saturday showed a difference of 30 degrees. In Saturday's case, the right-side temperatures were showing the same average within a couple of degrees, more on this later.

In the race, the car ran in the top 15 for the most part; the team had to deal with a loose RF wheel that was the result of a bad wheel. Then John had a collision with another car that bent the right truck arm. It was unfortunate, since he put down a good qualifying lap and advanced in the race up until he tangled with that other car. John did the best with what he had and did improve his position.

On To South Georgia

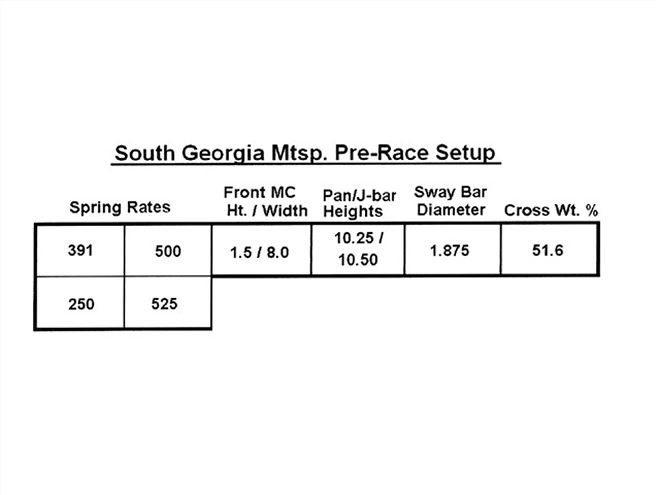

The next USARacing race was at South Georgia Motorsports Park, a flat track with lots of grip. We returned to the original setup we had in the first Concord test with the exception of using a 1.875-inch diameter sway bar, a 500 ppi RF spring and a 525 ppi RR spring. This was a compromise between what was raced at Concord and our original setup. We also reset the shocks to where we ended up at the end of the first test at Concord with the LF heavy in rebound.

We initially expected the car to be loose with the South Georgia heat in the middle of the afternoon, but the opposite happened. The car was very tight off the corners. I spoke with Justin Lages, John's crew chief, after the race and he said the car looked good in and through the middle, but developed a severe push coming off the corner.

The team went to the race at South Georgia Motorsports Park with the setup from the first test at Concord. The car was decent through the entry and middle but had a severe push off the corner. This was very unexpected and the team went through a lot of changes to help the car.

The team went to the race at South Georgia Motorsports Park with the setup from the first test at Concord. The car was decent through the entry and middle but had a severe push off the corner. This was very unexpected and the team went through a lot of changes to help the car.

I was not able to attend this race and the team was not able to communicate with me during the practice sessions. Admittedly, this would have been difficult with the noise in the pits, but in hindsight, I might have been able to help. My first reaction after studying the practice notes was that the LF shock's high rebound settings might not be right for this track. That could have served to tighten the car too much coming off the corners.

Unrelated to that, the battery discharged during the race and had to be replaced several times dropping John laps down at the end. We discussed the entire event and I concluded that some mechanical problem might have been the culprit for the handling problems. No matter what the team did to free the car up, it always had the push off.

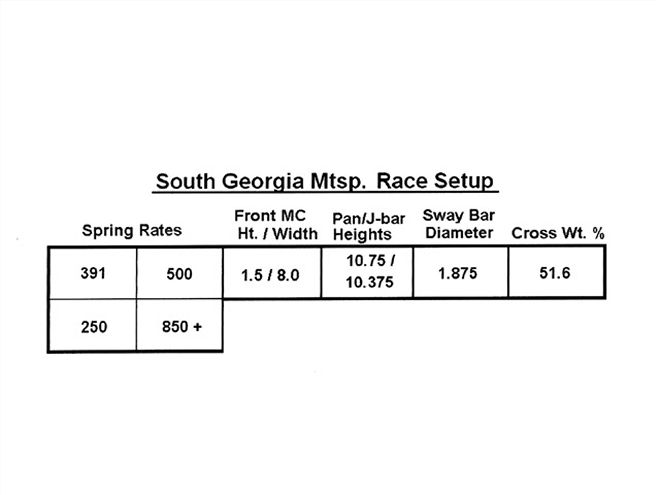

The changes made included raising the track bar, putting successively larger springs in the RR up to an 850 ppi with a full spring rubber, and moving the right truck arm back 1/16 inch. Changing the rear alignment to loosen a race car is considered a crutch, but in desperate times we do what we have to do.

In my computer analysis, the changes, if made to a car without any alignment or mechanical problems, would have made the car so loose John wouldn't have been able to drive it. When these extreme kinds of changes don't produce the desired effect, the team must start looking for the problem, because there is a problem.

Again, note that if your handling problem occurs in the transitional phases of entry or exit, the base setup usually isn't the problem. With the "real tight off" problem, as described by John early in the practice, I would have suggested taking rebound out of that LF shock to see if it was overpowering the setup. If that didn't work, we would have looked at alignment of the rearend because some work was done there to straighten the truck arm and the rearend could have ended up misaligned. Another setting that I have not checked personally is one of excess Ackermann.

This chart represents the extreme the crew went to in adjusting the car to be neutral off the corners. Note the RR spring rate. Along with that, the Panhard bar was raised, and the right truck arm was moved back 1/16 inch. The car ended up fairly neutral and ran decent lap times. We feel there may still be a problem and we will continue to search for the cause of the push off.

This chart represents the extreme the crew went to in adjusting the car to be neutral off the corners. Note the RR spring rate. Along with that, the Panhard bar was raised, and the right truck arm was moved back 1/16 inch. The car ended up fairly neutral and ran decent lap times. We feel there may still be a problem and we will continue to search for the cause of the push off.

Other issues might have been with one or more broken shocks, bent control arms (the car was crashed at Concord and we know from experience that damage can occur in the strangest places), bent axle tubes, and more. All of those items must be checked and eliminated as problems before the car hits the track again.

Conclusion

Now, in hindsight, which is more clearly seen than in the moment I admit, I would suggest staying with a setup program that involves a smaller sway bar, soft/conventional spring rates, quick adjustment to the shocks to tune the transitions and a program designed to check the car between races for alignment and other mechanical problems.

The team and I have spoken about these issues and I hope it takes my advice. The funding is provided by John's family and the final decision is theirs as to what they decide to run. We can only provide guidance and support after the fact.

John told me that he is very uncomfortable with the feel of this car. Last year, he ran almost the entire year with a setup that coil-bind the right front, and the feel was much like the Kart he raced for nine years. We don't know if the difference is in a possible problem or just the type of setup. We do plan on finding out and reporting that to you. We're still checking the car out as this goes to the press, so we'll have a new report in the next issue.

We hope through the process of review and analysis, you have learned something about the process of setup and how to work out your setup balance problems. I think one of the most important lessons any team can learn is to pick a program and stay with it until it proves successful or not, as the case may be, but give it time. We are on a planned course and hope to get this car sorted out quickly.