Go to the buffet table one too many times and you're likely to be the slowest one on the team. The same holds true for your race car; carry too much weight in the wrong place, and chances are you'll be slower than a 602 crate motor at a World of Outlaws race.

When we set out to build Project DLM, one thing we wanted to do was minimize the weight in certain areas of the car. We realized that one primary area that needed attention was the wheel assembly. The car had the original hubs, rotors, calipers, and wheels from when it was built in 2002. Seven years is a long time in the race parts business and with companies coming out with new products every year, we knew that the stuff we had on the car was outdated, with a capital O.

As a side note, cutting weight out of the wheel assembly also happens to be one of the easier areas to save some pounds because you're literally swapping out one product for another.

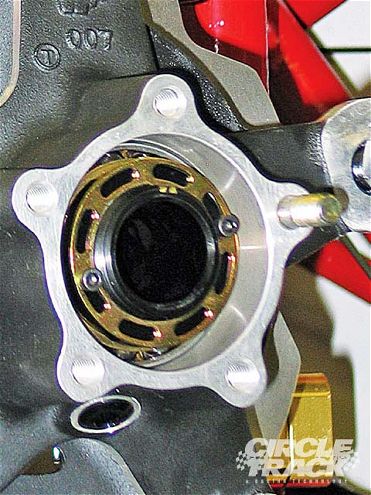

Check out the unique five star design of Winters Performance's new 007 hub.

Check out the unique five star design of Winters Performance's new 007 hub.

Hubs Our first stop was the hubs. Hubs are one of the biggest weight hogs on a wheel assembly. So you want to pay careful attention to your choice. Be sure it's correct for your racing application. We heard about a new type of Wide 5 hub from Winters Performance that we just had to get our hands on. Not even a year on the market when the UPS man dropped them off at our Tampa, FL, shop, the 007 hubs are being billed as the ultimate hub by many of their dealers. The 007 brings an innovative design to the Wide 5 hub market. These lightweight magnesium hubs reduce rolling resistance by using ball type bearings and oil instead of grease. That's right folks these hubs are filled with Mobil 1 80-90w gear oil as opposed to typical bearing grease.

The 007 hubs include drilled studs, an aluminum drive flange, lug nuts, seals and bearings. Because of the design, and the fact that they're magnesium, these hubs are exceptionally strong and exceptionally light.

A close-up look reveals the ball type bearings used in the 007 hub. Instead of traditional bearing grease as the lubricant, these hubs use oil which translates into a big reduction in rolling resistance.

A close-up look reveals the ball type bearings used in the 007 hub. Instead of traditional bearing grease as the lubricant, these hubs use oil which translates into a big reduction in rolling resistance.

Rotors Stop number two was the rotors. Rotors are perhaps the second and, in some cases, the first heaviest component of your assembly. They're also an area that you need to pay particular attention to; rotors, and the soon-to-be discussed calipers, need to work in sync with one another. We chose AFCO rotors and calipers to put on the car. More on the calipers in a minute, but the rotors are designed using premium grade alloys, to deliver superb thermal shock stability.

AFCO's rotors are machined and Blanchard ground. Blanchard grinding uses a special machine where the grinding wheel is mounted on a vertical spindle, and moves in a direction counter to the rotation of the magnetic chuck. The process leaves a specific finish pattern on the surface and boasts tolerances that can be as little as one-thousandth of an inch, ensuring a precisely flat finish. This is critical in brake rotors since a warped or uneven rotor will adversely impact its ability to stop the car. By the way, Blanchard grinding gets its name from the Blanchard Machine Company, a specialist in rotary grinding machines. In addition to the weight-saving drilled designed, the placement of the vanes is designed for high volume cooling.

Calipers In order to match up with our AFCO rotors, we went with AFCO's F88i calipers. These calipers are machined out of 6061-T6 billet aluminum making them exceptionally strong. AFCO also machined lightening pockets inside the caliper for maximum weight reduction without sacrificing rigidity.

It's a little hard to see from this angle, but trust us when we tell you that AFCO machined lightening pockets inside the caliper for maximum weight reduction without sacrificing rigidity.

It's a little hard to see from this angle, but trust us when we tell you that AFCO machined lightening pockets inside the caliper for maximum weight reduction without sacrificing rigidity.

Stainless steel is used in the internal components, such as the abutment plates (which reflect heat and protect the caliper from pad gouging), the heat shields (which reflect heat from the caliper helping to reduce fluid temperatures), and the pistons (which further reduces fluid temperature as well as piston wear). The exclusive interlocking design significantly reduces caliper flex and distortion. This extra rigidity provides for more consistent stopping performance, less brake pad taper, and less brake pedal effort. You'll remember in Circle Track's "Brake System Checklist" (Feb. '09), Bob Bolles discussed how critical pad taper or minimizing it is to having a properly functioning system.

These four piston calipers also feature stainless steel pistons that help reduce fluid temperature and piston wear.

Keep in mind that while the weight of the calipers is important, it won't affect the rotating weight of the wheel assembly because they are mounted to the chassis. So our final weight comparisons do not include caliper weight.

Wheels Our final piece of the puzzle is a new set of wheels. Weld Racing recently introduced a new design for its left-side rear racing wheels (see Circle Track's Sep. '08 "Quick Tech"). The XL Series Dirt Late Model racing wheels feature a design that incorporates a dzus-on mudcover without having to run a beadlock. The LR wheel (PN 559-5465) also boasts an inside beadlock. While that in itself is not unique, the engineers at Weld reworked the inner rim half in order to maximize clearance using the largest brake packages available in today's racing market as their guide. The result is a wheel that will clear any brake caliper out there.

Excess space is very important but we're talking about weight savings in this article. Weld offers these features on two types of wheels, the XL and HS. The XL stands for Extra Light, while the HS is, not surprisingly, the High Strength version. By going with the XL, we were able to trim 3.4 pounds from each one of our wheels which will help us keep the overall weight of the assembly to a minimum.

The Bottom Line Or should we say, why is this exercise so important? Here's the bottom line: rotating weight. The concept of rotating weight has been applied to numerous components in a race car, from crankshafts to driveshafts (can you say carbon fiber?) to wheels. By swapping out the components that we did on Project DLM, we were able to lower the overall weight by 30 pounds. That's significant because any time you can reduce rotating weight on something, you're going to free up power. Without getting overly technical, our original wheel assembly required a certain amount of energy (read horsepower) to make it turn or rotate. By lightening the weight of the assembly, we reduced the amount of power needed to turn it. That's power which, theoretically, can be applied somewhere else, preferably to the track if the setup is correct and working well.

A word of caution, cutting weight for the sake of cutting weight is not the answer. You must always remember that when you trim weight you have the potential to sacrifice strength. Be very careful in any process where you are trying to trim weight, always research the strength and rigidity of the product for the specific application.

Weld's XL Series Dirt Late Model racing wheel combine a reduced weight with superior strength, which fits perfectly with our goal of creating a lightweight wheel assembly.

A bonus of choosing the XL from Weld is its inside beadlock wheel has been designed to accommodate the biggest calipers and rotors on the market.