At one time it wasn't unusual for a hot rod's emphasis to be strictly based on performance; the goal may have been top speed on the dry lakes, or a low elapsed time at the dragstrip, but proper gearing always played an important role n achieving the objective. Of course, some cars played a dual role and were used on the street as well, but that meant compromises had to be made. If you were a drag racer, it didn't take long to learn that highway gears didn't work at the drags any better than a close-ratio four-speed and a 4.88:1 ring-andpinion did on the highway. So, unless a quick-change was used, the only choice was to have more than one center section with gears appropriate for whatever it was you intended to do.

While performance is still important to most street rodders, drivability is even more so, and choosing the proper gear ratio is just as critical for one as the other. In the December '07 issue of STREET RODDER, we published a story called "Playing The Numbers" that showed the relationship between various engine components and how they increased horsepower and torque. The point was engine components have to be compatible to achieve the best results; and the point here is the rearend ratio of a street rod has to be compatible with the engine and a variety of other components as well.

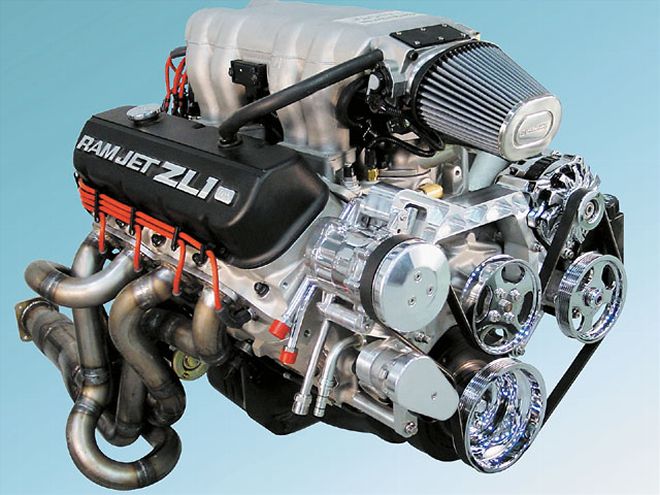

Getting the most out of any engine requires a coordinated approach when selecting the transmission, rearend gear ratio, and tire size. Accessories are also part of the mix-this ZL1 is equipped with a Vintage Air Front Runner drive system to spin the alternator, A/C compressor, and P/S pump at appropriate speeds.

Getting the most out of any engine requires a coordinated approach when selecting the transmission, rearend gear ratio, and tire size. Accessories are also part of the mix-this ZL1 is equipped with a Vintage Air Front Runner drive system to spin the alternator, A/C compressor, and P/S pump at appropriate speeds.

Final Gear Ratios

When selecting a final gear ratio for a race car, the general idea is to take advantage of the engine's power curve and make it go as fast as possible in the confines of the course on which it's competing. Taking advantage of the power curve is a little harder to define with a street rod because it depends on how the car is being used; but one common mistake is over-gearing, and it's usually the result of several factors. One is tire size- bigs 'n' littles are a part of the package on most street rods, but those tall tires also serve to raise the effective gear ratio. (For our purposes here, a higher gear ratio is lower numerically; in other words, 3.00:1 is higher than 4.00:1.)

As an example of how tire size impacts gearing, the engine in a street rod with a transmission having a 1:1 high gear, 3.70: rear gears, and 25-inch tall tires (effective diameter accounts for some "squish" under a load and is usually tire diameter .094, or in this case 23.537 inches) will turn 3,081 rpm at 60 mph. With 29-inch tires (27.26-inch effective diameter), engine speed drops to 2,656 rpm (these numbers may not be exact, but they're close).

Now let's take that same combination and add a 700-R4 overdrive automatic with a 0.7 high gear. With the 25-inch tires, the engine will turn 2,157 rpm at 60 mph; engine speed drops to 1,859 rpm at 60 mph with more street rod-like 29- inch rubber. What's really interesting is Fourth gear at 5,500 rpm would work out to be 178 mph. The same combination with 3.08:1 rear gears would result in 1,548 rpm at 60 mph, and 213 mph at 5,500 rpm if the engine could pull it-great for Bonneville, but not for the street.

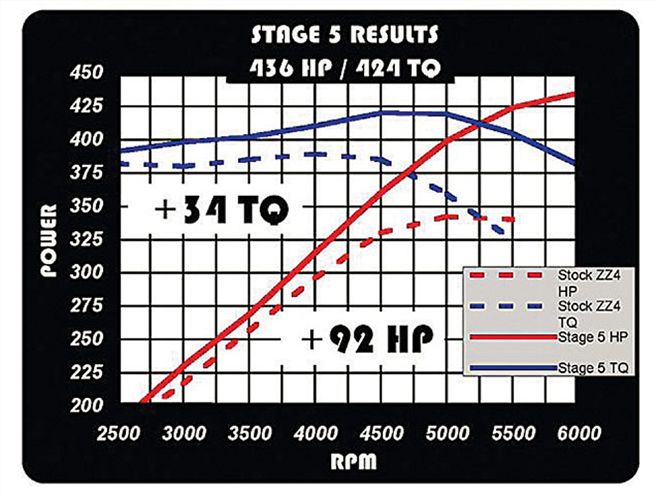

This is a dyno chart of a stock ZZ4 crate motor and a COMP Cams Stage V version (see SRM Dec. '07 for engine details); note the rpm for the horsepower and torque peaks. Engine specs should be compatible with the car's intended use, and gears should be matched to the engine.

This is a dyno chart of a stock ZZ4 crate motor and a COMP Cams Stage V version (see SRM Dec. '07 for engine details); note the rpm for the horsepower and torque peaks. Engine specs should be compatible with the car's intended use, and gears should be matched to the engine.

At a glance, many rodders would assume that high gears and cruising at low rpm would be advantageous, hence the widespread use of overdrive automatics. But the fact is running an engine too slowly will reduce its effi ciency. Throttle response will be poor, engine vacuum will often drop to the point where mileage suffers, and the slightest attempt to accelerate usually results in the transmission downshifting one or more gears, which is not only unnecessary but also annoying.

We recently discussed this issue with Joe Abbin of Roadrunner Engineering. He took the time to do some computer simulations, and his research suggests that peak part-throttle operating effi ciency for many gas engines falls in the area of 2,000 to 2,500 rpm. This confirms why most factory overdrive transmissions keep the engine in this approximate rpm range at highway speeds. Keep in mind there are variations with higher-performance engines. Look at the following dyno results and you'll see the horsepower and torque peaks move up the rpm scale (roughly 500 rpm in this example) with a more aggressive cam and related parts; the same will hold true for part-throttle numbers. Simply put, mild engines are happier at lower rpm than their high-performance counterparts, and gearing should reflect that; as one engine builder put it, "You don't plow with a racehorse or race a plow horse."

Although the ideal rearend gear ratio will vary with a number of factors, including how fast you like to drive, here are some ballpark numbers (using 29-inch tires). With a mild engine and a 700-R4 transmission, a good choice would be rear gears in the area of 3.90 to 4.10:1-60 mph would result in 1,960 to 2,286 rpm and 70 mph would be 2,060 to 2,403 rpm, respectively. For a hotter engine with peaks slightly up the rpm scale, 4.30:1 gears might be a better choice and would result in 2,161 rpm at 60 mph and 2,521 rpm at 70 mph.

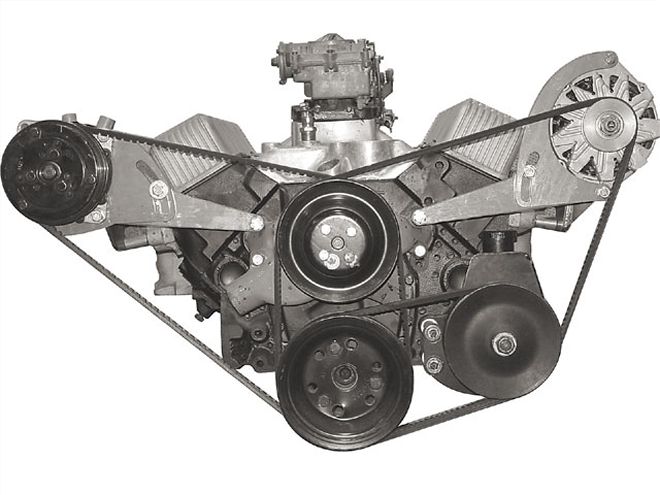

Alternator rpm is critical, particularly in an accessory laden vehicle. It is possible to run the battery down at low speeds with high electrical demands if the alternator is not spinning fast enough.

Alternator rpm is critical, particularly in an accessory laden vehicle. It is possible to run the battery down at low speeds with high electrical demands if the alternator is not spinning fast enough.

Component RPM

Not long ago, we received an interesting letter from a street rodder who was having trouble keeping his street rod's battery charged on long trips; after driving long distances then shutting the engine off, it wouldn't restart. It turned out that the alternator couldn't keep up with the demand thanks to a combination of gearing, underdrive pulleys, and every electrical gadget known to man. Another similar problem struck closer to ome. An editor ofanother publication was stranded on a crowded SoCal freeway with a dead battery-the engine in the project car he was driving was never revved high enough for the one-wire alternator to energize.

As we've said, component compatibility is the secret to making everything on a street rod work properly; the charging system is no exception. According to Powermaster's Stacy Edelmann, they show output based on alternator rpm. She added, "We started Component rpm is critical to performance and longevity. for street rods; underdrive pulleys are often used normally a good choice for street applications. showing output in this form in our catalog because there are so many pulley options that a standard rating doesn't always tell the customer what the alternator's output will be with the combination being used (a big crank pulley and little alternator pulley as an example). What we recommend is a 2.75 or 3:1 pulley ratio. unfortunately there are some pretty, but poorly thought-out, pulley kits out there. Alternator pulleys that are significantly oversize (or crank pulleys that are significantly undersize) may spin the undersize) may spin the alternator too slow to keep up with the vehicle's electrical demands. But, at the same time, you have to be careful not to go too far in the other direction and over-spin the alternator.This is much harder to do, but it's still possible. This would bean alternator rpm of 18,000 or more.

Component rpm is critical to performance and longevity. In most cases, stock pulley ratios work fine for street rods; underdrive pulleys are often used by drag racers to reduce power loss, but are not normally a good choice for street applications.

Component rpm is critical to performance and longevity. In most cases, stock pulley ratios work fine for street rods; underdrive pulleys are often used by drag racers to reduce power loss, but are not normally a good choice for street applications.

"Something to watch for with one-wire alternators is the speed necessary to excite or turn them on. We turn them on. We reject anything that doesn't turn on by 3,000 rpm, but there are some that require higher speeds. This only matters when the car is initially started, as once a one-wire alternator is on, it stays on until the car is turned off."

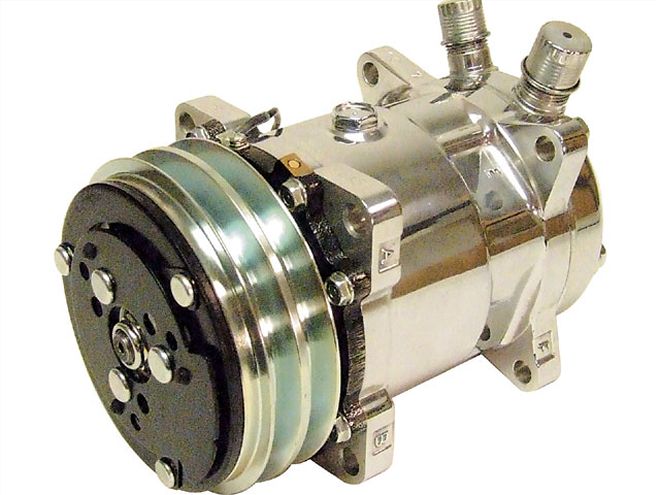

A/C Compressors

Another common accessory found on street rods is air conditioning. We wanted to know minimum and maximum rpm for A/C compressors, and, according to Ryan Zwicker of Vintage Air, the answer is yes. "Compressor operating speed is very important, both on the low end and at the high limit," he said. "We try to target at least 1,000 rpm at the compressor under idle conditions. On the Front Runner systems, we run the FSB and LSX at 1.41:1, and the SBC/BBC at 1.47:1. Both of these ratios give approximately 1,000 compressor rpm at 700-rpm engine idle. These ratios allow us to take the Front Runners to 6,500 rpm without damaging the compressors. There is a bit of a safety factor as well. We know that Front Runners have been run over 7,000 during races with no failures, but at those speeds the power steering pumps make a lot of heat and must use a cooler. The sweet spot that we'd like to see the compressor run at on the highway is around 3,000 to 4,000 rpm. Anything over 4,500 rpm at the compressor just builds heat and doesn't help in cooling the car.

"With the SD508 compressors, you can run a bit lower at idle, but you can't go as high at the top," Zwicker continued. "If the expected max speed of the engine will exceed the rated max of the compressor, a shutoff device should be used to protect the compressor. That said, I know of SD508s running momentarily over 8,000 rpm without problems, but it's just a matter of time before it grenades. I know of an SD7B10 compressor that has seen in excess of 11,000 rpm without failure, but if it does fail, the warranty obviously won't apply."

The thought of running 4.11:1 gears scares some rodders, but keep in mind that with a 0.70 overdrive, it's roughly the equivalent of a 2.80:1 ring-andpinion with a 1:1 top gear in the transmission.

The thought of running 4.11:1 gears scares some rodders, but keep in mind that with a 0.70 overdrive, it's roughly the equivalent of a 2.80:1 ring-andpinion with a 1:1 top gear in the transmission.

Power Steering Pumps

Last but certainly not least, we wanted to find out if there was an optimum speed for power steering pumps, so we asked Steve Cole at Flaming River for some comments. According to Cole, "There is a direct correlation between engine speed and the performance of any of the accessories driven via the crankshaft. This includes the power steering pump. Power steering pumps are designed to operate within an envelope determined by the pump's shaft speed, which is determined by the pulley.

"The lower engine speeds that are the trademark of overdrive transmissions (and taller-diameter rear tires) will lower the operating speed of the pump," he continued. "This in turn lowers the volume of power steering fluid delivered to the rack-and-pinion or the steering box. The net result is the steering feels heavier and less responsive at low cruising speeds.

"The problem can be overcome by utilizing a smaller pulley to speed up the pump shaft speed and deliver the required volume. Many OEM and aftermarket standard pulleys are 5- to 7-inch diameters, designed for transmissions without overdrive.

In most cases, you'll have to live with the diameter of the A/C compressor clutch pulley, so ratio changes are made with the crankshaft pulley.

In most cases, you'll have to live with the diameter of the A/C compressor clutch pulley, so ratio changes are made with the crankshaft pulley.

"To address power steering fluid volume, Flaming River recommends the use of its Stage II pump equipped with a 4-inch pulley (V- or serpentine drive). This pump and smaller pulley accomplishes two things. At low rpm cruising speeds, it ensures the volume is adequate to provide proper steering response. A related issue is steering response at highway speeds. The tuned internal bypass valve of the Flaming River Stage II pump comes into play at 1,700 rpm (pump shaft speed), bypassing the excess volume and providing the driver with a predictable, stable steering pattern similar to manual steering.

"Another possible solution would be a smaller accessory drive pulley on the crankshaft, but that should be approached with caution. What might work for one component on the accessory drive may be incorrect for another item and create another set of problems.

"Is there a maximum/minimum/ideal when discussing power steering pump speeds? It is a matter of pump design, rack-and-pinion or steering box design and operating ranges, plus the intangible of personal preference. In the end, personal preference will probably be the most significant factor. Keep mind what may be acceptable for a 200lb man may be too heavy for a slender woman.

Flaming River suggests a 4-inch pulley with its Stage II power steering pump.

Flaming River suggests a 4-inch pulley with its Stage II power steering pump.

"It would seem the best choice is to evaluate the use of smaller-diameter pulley, with the understanding that it might negatively impact steering sensitivity at highway speeds because the pump's valving will directly impact steering behavior. You must know how your pump will respond to this change at both ends of the spectrum. If there is a choice, do not change the pulley size if there will be an adverse effect at higher speeds, for you can deal with the heavier steering much easier than a car in the ditch (or worse) because of super-sensitive steering response.

"Another very simple solution is to lock out the overdrive low cruising speeds, which will raise the engine speed to meet the needs of the pump and the rack or box to provide the desired steering performance."

It Comes Down To Choices

There are a variety of difficult decisions to be made when choosing individual street rod components, and the most challenging part of choosing them is ensuring all the mechanical components are compatible. But never fear-there are a host of computer programs and free calculators on the Internet that will help, and here are some handy formulas if you want to your own pencil pushing:

MPH = (Rpm X Tire Diameter) · (Gear Ratio X 336)

RPM = (Mph X Gear Ratio X 336) · Tire Diameter

Gear Ratio = (Rpm X Tire Diameter) · (Mph X 336)

Tire Diameter = (Mph X Gear Ratio X 336) · Rpm

Do some number crunching before you start building; it's much easier and less painful to use an eraser to change a simulation than your time and money to change your street rod.