Two of the most basic, but also most important, settings on the front of the car are caster and camber. These two conditions affect the driver's feel when steering the car through the turns as well as the amount of footprint the tire will ultimately have.

Two of the most basic, but also most important, settings on the front of the car are caster and camber. These two conditions affect the driver's feel when steering the car through the turns as well as the amount of footprint the tire will ultimately have.

Caster and camber settings are set relative to the type of car and the design of the racetrack. When you determine the correct settings for each, you need to maintain those settings. We will discuss what affects caster and camber in our racecars as well as how to properly measure them.

It is important to know how to properly measure for the amount of caster and camber in your racecar. All teams need to learn the proper procedure for determining the amount of each that exists in the front-end geometry of their racecars.

CASTER DEFINED

Caster is a design condition that, in addition to the spindle kingpin angle, serves to cause a wheel to want to track straight ahead. A common example is a bicycle front-wheel and fork assembly. The tube that the handlebars are mounted to is mounted in a set of bearings above the fork. From a side view, this tube is angled so that the bottom bearing is ahead of the top bearing. If we turn the front wheel to 90 degrees from the direction of travel, it will want to return to straight ahead by the effect of caster. The same effect is present in the front-wheel assemblies of our racecar.

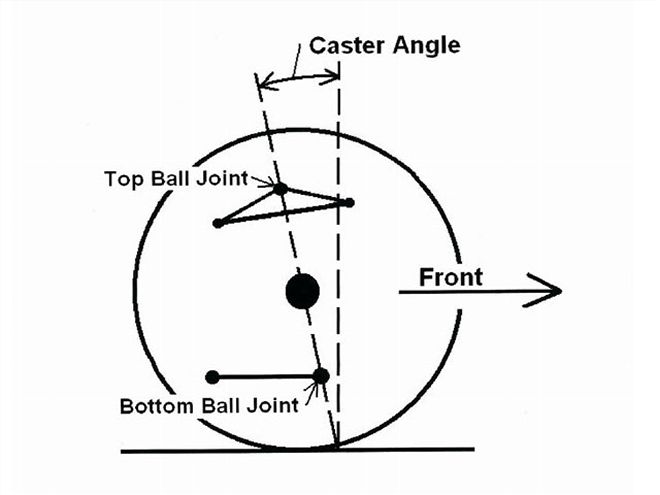

Positive caster in the front-wheel assembly is created when the ball joints are offset, from a side view, so that the upper ball joint is farther to the rear of the car than the bottom ball joint. The degree of caster is related to the angle in degrees that a line through the ball joints forms from a vertical line.

Positive caster in the front-wheel assembly is created when the ball joints are offset, from a side view, so that the upper ball joint is farther to the rear of the car than the bottom ball joint. The degree of caster is related to the angle in degrees that a line through the ball joints forms from a vertical line.

What Caster Does

To ease the amount of effort it takes to turn the wheel in our race cars, we introduce caster split into the design. Split means that we set different caster amounts into each wheel assembly so that the car will want to turn to the left and thereby reduce the amount of effort it takes for the driver to hold the steering wheel when negotiating the turns.

Proper split for circle track racing means that the left-front wheel will have less positive caster than the right-front wheel. In some cases, teams have been known to set negative caster in the LF wheel and positive caster in the RF wheel.

To measure caster in each wheel, we use a caster/camber gauge. This tool attaches to the wheel hub. To check the amount of caster, we need to follow these instructions:

1. Attach the caster/camber gauge to the right-front wheel hub first.

It is a good idea to use turn plates in order to know exactly when you have turned the wheel 20 degrees, the proper amount for caster measurements according to SAE standards.

It is a good idea to use turn plates in order to know exactly when you have turned the wheel 20 degrees, the proper amount for caster measurements according to SAE standards.

2. Turn the steering wheel to the right so that the right-front wheel has turned exactly 20 degrees.

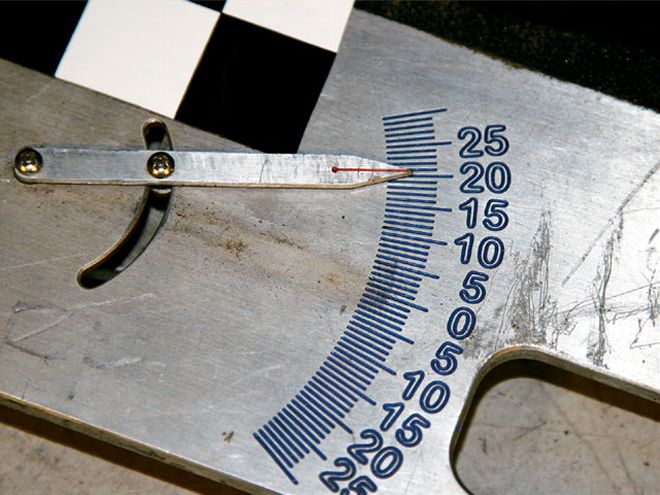

3. For a manual gauge, level the gauge and set the adjustable caster bubble vial so that the bubble is at the zero mark on the caster side of the tool. For a digital gauge, set the tool to caster and zero the display.

4. Turn the steering wheel to the left so that the right-front wheel is turned past straight ahead and ends up left of straight ahead by 20 degrees.

5. Again, level the gauge and then note the location of the bubble on the scale of the manual gauge and record the amount of caster in the right-front wheel. For a digital gauge, level the gauge and read the display.

6. While the wheels are still turned left 20 degrees, remove the caster/camber gauge and place it onto the left-front wheel hub.

7. Level the gauge and set the bubble on the caster gauge to zero or set the digital display to zero.

8. Turn the steering wheel to the right past straight ahead until the LF wheel is turned 20 degrees to the right of straight ahead.

9. Level the gauge and read the bubble scale or display to know how much caster is in the LF wheel.

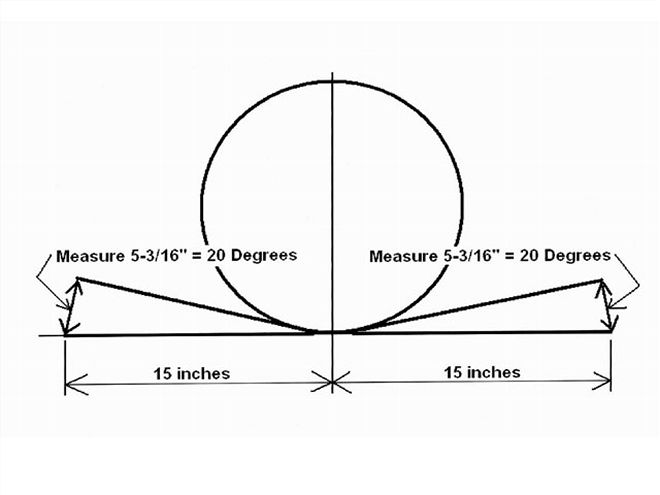

To measure on the floor to get exactly 20 degrees of steering, cut a 30-inch piece of 1x6-inch wood, or a similar straight, flat piece, and lay it against the tire. Mark midway on the wood (15 inches) and line that up with the center of the hub. Mark the outside corner of each end of the wood. Turn the steering wheel until the ends have moved 531/416 inches and you will have turned the wheel 20 degrees.

To measure on the floor to get exactly 20 degrees of steering, cut a 30-inch piece of 1x6-inch wood, or a similar straight, flat piece, and lay it against the tire. Mark midway on the wood (15 inches) and line that up with the center of the hub. Mark the outside corner of each end of the wood. Turn the steering wheel until the ends have moved 531/416 inches and you will have turned the wheel 20 degrees.

Adjusting Caster

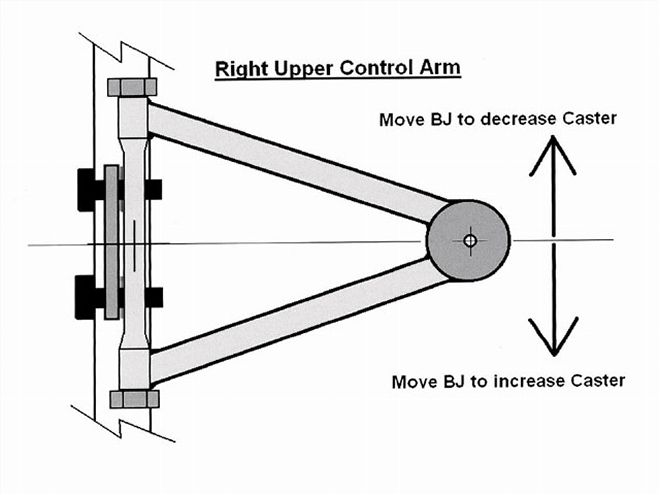

To adjust the amount of caster in each wheel, you will need to move the upper ball joints fore or aft. To increase the amount of positive caster, move the top ball joint toward the rear of the car. Some cars have slots cut into the upper chassis mounts for this purpose.

If you have permanently attached vertical mounting plates that the upper control arms are attached to, then you can vary the amount of shim spacing for each of the bolts that attach the control arm to the chassis. Wider spacing at the front bolt (control arm shaft inside of the mounting plate) will move the upper ball joint to the front, creating less caster at that wheel and so on. This is not the preferred method, though.

Once you have established the exact caster amounts for each wheel using the above method (if not using slotted control arm shafts), you should order an upper control arm that has the ball joint offset to give the correct amount of caster at each wheel. That way, you can use the same shim spacing for each mounting bolt to connect the upper control arm shaft to the chassis.

How Much Caster Split

The normal caster split for most short-track asphalt applications is around 2 to 4 degrees of difference. The left-front caster might be 1-2 degrees and the RF caster might be 3-5 degrees. The higher the banking angle of the racetrack, the less caster that is needed because less steering effort is needed due to the banking. On the other hand, the tighter the turn radius, the more caster split is needed.

Driver preference plays a big role in getting the caster split right for your application. Most drivers prefer to have some feel where they need to pull slightly on the wheel to make the turn. What no driver wants or needs is to have more caster split than needed so that they will need to apply backpressure on the steering wheel at midturn.

CAMBER DEFINED

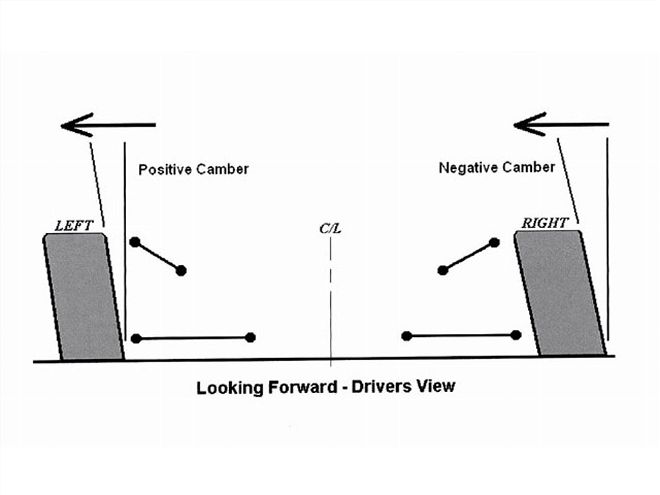

Camber is when a wheel is tilted so that the top of the tire is either closer to or farther from the centerline of the car. Negative camber is when the top of the tire is closer to the center of the car than the bottom of the tire. Positive camber is when the top of the tire is farther away from the center of the car than the bottom of the tire.

From a driver's view, positive left-front camber is when the top of the tire leans out, away from the centerline of the car. The opposite is true of the RF tire, which has negative camber where the top of the tire leans toward the centerline.

From a driver's view, positive left-front camber is when the top of the tire leans out, away from the centerline of the car. The opposite is true of the RF tire, which has negative camber where the top of the tire leans toward the centerline.

Circle Track Camber

In circle track racing, we use positive camber on the left-front wheel of the car and negative camber on the right-front wheel. We can easily check the amount of camber by using a caster/camber gauge and reading the amount directly on the camber bubble vial.

We have learned some interesting and important aspects of tire camber for short-track racing. We have always known that a racing tire will flex under the stress of cornering and the tread will move and roll under the wheel when the extreme forces associated with cornering are present. Different brands of tires have different stiffnesses of sidewall construction and therefore roll over more or less.

Tire temperatures tell us more about how much static camber we need than anything else. The overall goal is that we need the tire contact patch to be relatively flat on the racing surface at midturn in order for the tire to be able to provide the maximum amount of traction. This is often referred to as the maximum "footprint."

Tire temperatures can alert us to improperly set static cambers. A front tire that is hotter on the inside edge (side toward the inside of the racetrack) usually has too much positive camber in the case of a left-front wheel, or too much negative camber if it is the right-front wheel.

Move camber adjustment shims back and forth from each mounting bolt, or slide the control arm shaft if it is slotted, to adjust the amount of caster in each wheel. This will move the upper ball joint forward (to reduce caster) or to the rear (to add caster).

Move camber adjustment shims back and forth from each mounting bolt, or slide the control arm shaft if it is slotted, to adjust the amount of caster in each wheel. This will move the upper ball joint forward (to reduce caster) or to the rear (to add caster).

Camber Change

The cambers will change as the car dives and rolls when it enters and negotiates a turn. True camber change is a product of both chassis dive and chassis roll. Gone are the days when we would jack up the wheel and measure how many degrees the camber changed in each inch of bump. Those numbers really don't tell us anything. They are only part of the answer. Chassis roll has an effect that adds or subtracts from what dive does. So what we really need to know is what the dynamic camber is after the car dives and rolls, just like it does in the turns.

The left front always loses a lot of camber, so we need to allow for that in setting the amount of static camber. Generally, if we end up with between 11/42 and 1 degree of positive camber at the left-front wheel after the car dives and rolls, then that tire will have the dynamic camber that it needs.

The right-front camber change is a little different. We can design our car so that the right-front camber does not change after dive and roll. This is actually exactly what that tire wants for most short-track applications. The reason for this is that as we enter the turn, the right-front tire takes a set fairly quickly. If the camber continues to change after that initial set, then the tire will give up traction and the car will usually push.

The right upper control arm angle mostly controls the right-front camber change, so we try to work with that control arm angle. Once we have the proper camber change (zero), we leave that angle alone as we further design our front end for moment center location.

SPINDLE HEIGHT

Spindle height affects the amount of camber change at each wheel. The taller the spindle, the less camber change will occur. Trends that have taken place in the past 10 years or so have resulted in excess camber change due to the use of shorter spindles. That trend is in the reverse mode now as the car builders move toward using taller spindles.

Measuring Camber Change

We can measure camber change by several different methods. In the shop, we can set the chassis ride heights just as they would be at midturn on the racetrack and then directly measure the camber at each wheel. To do this, we will need to know the shock travel at midturn, which is very hard to estimate.

If we look at the shock travel indicators on the shaft of the shock, it always tells us total shock travel, which includes braking, going over bumps, banking changes such as exiting the racetrack and driving down onto the apron (this could be quite a lot of left-front shock travel at some high-banked racetracks), or something as simple as steering the car back and forth to warm the tires before running hot laps.

CONCLUSION

Remember that caster settings are mostly adjusted for driver preference and comfort, and camber settings are important so that the front end will have the maximum amount of footprint and traction to use to turn the car at midturn. Many of our problems related to a car that won't turn well come from incorrect camber settings and camber change problems.

Often, a car that has a serious push can be helped by analyzing and adjusting the static camber as well as knowing the camber change amounts. For dirt cars, taking tire temperatures may not be feasible, but measuring tire wear can tell us a similar story as temperatures. The more wear, probably the more temperature that part of the tire experiences. Even wear across the tread translates to more even tire temperatures and the best camber settings.