Last month we began building the late-model Hemi engine for our '10 Dodge Challenger drag car by bolting together a 426-inch bottom end using a factory 6.1 Hemi block. Our intentions with this late-model Hemi are to show Mopar Muscle readers how well the latest version of the Chrysler Hemi can run when built properly using a combination of factory and quality aftermarket components. We've challenged ourselves to make big power from this engine, and we decided to build the engine to run on pump gas to reduce the weekly costs of operating our bracket car during race season.

Inside our factory block, we used a forged crankshaft and rods from Callies' Compstar line, Diamond forged pistons, a Comp hydraulic roller camshaft, and a Milodon oiling system with a Melling oil pump to keep things lubricated. With a bore of 4.090 inches, and a stroke of 4.050 inches, displacement is just shy of 426 inches. Of course you can see all the details of this engine's short-block in the March issue of Mopar Muscle, or read about it here. And while the short-block of an engine such as our late-model Hemi is important in terms of power and durability, the best components in the world won't matter if the engine isn't topped with the proper cylinder heads and induction system.

Chrysler has made several versions of the Hemi cylinder head since the inception of the third generation Hemi, and all are impressive in terms of power potential. All late-model Hemi heads feature dual spark plugs, a feature that improves both the power and efficiency of this engine. Dual spark plugs, located in the center of the combustion chamber, have been shown to not only improve reliability, as in aircraft engines, but have also been proven to increase power through a more thorough burning of the air/fuel mixture. Additionally, the dual plugs reduce emissions by burning the air/fuel charge more completely, allowing the engine to meet government emissions standards using less restrictive catalytic converters. Chrysler really did their homework when designing the late model Hemi head, and it shows in power these engines make right from the factory. With aftermarket companies such as Indy Cylinder Head further developing this technology for use in high-performance applications, the late model Hemi is in our opinion the best option for a performance build when power, weight, and efficiency are considered.

Since we're working with Indy Cylinder Head on this project, we knew that whatever late-model head choice we made would be treated to Indy's proprietary “Windjammer” CNC porting, and that we could make very respectable power with a set of the 5.7, 6.1, or 6.4 cylinder heads. The latest offering from Mopar, however, offers some distinct advantages when compared to earlier late-model cylinder heads. Utilized on the 6.4 (392) engines, the newest late-model Hemi head is called the Apache head, and is the cylinder head we chose to top our late-model bracket engine.

The Apache head in stock form helps the 392 Hemi achieve its rated 475 horsepower and 460 lb-ft of torque in part thanks to longer valves and high-flowing square-shaped intake ports. The exhaust ports of the Apache head are D-shaped, and also flow better than any of the previous late-model Hemi head designs. The 6.1 head was no slouch, flowing more than ten percent better than the 5.7 head, and the Apache head has been shown to flow even better, up to 340 cfm on the intake side in stock form. These numbers are impressive, but with Indy's Windjammer porting, our Apache heads flow better than 370 cfm on the intake side, more than any other factory Chrysler cylinder head. Apache heads also offer a closed chamber design, with 74cc chambers, which combined with our Diamond flat-top pistons, will help us achieve a pump-gas friendly 10.85:1 compression ratio.

In addition to the CNC porting, we had Indy perform a multi-angle valve job, and install new 2.14-inch intake, and 1.65-inch stainless steel exhaust valves. To fasten our ported Apache heads to the block, we utilized a set of ARP head studs and Cometic MLS (multi-layer-steel) head gaskets. At 10.85:1 compression we aren't really pushing the limits in terms of cylinder pressure, but we want to make sure our heads stay in place for multiple seasons of drag racing and that our engine remains consistent and maintenance free. MLS gaskets ensure a proper combustion chamber seal and the ARP head fasteners are far superior to the factory head bolts, and unlike the factory bolts, the studs can be reused without the fear of stretching.

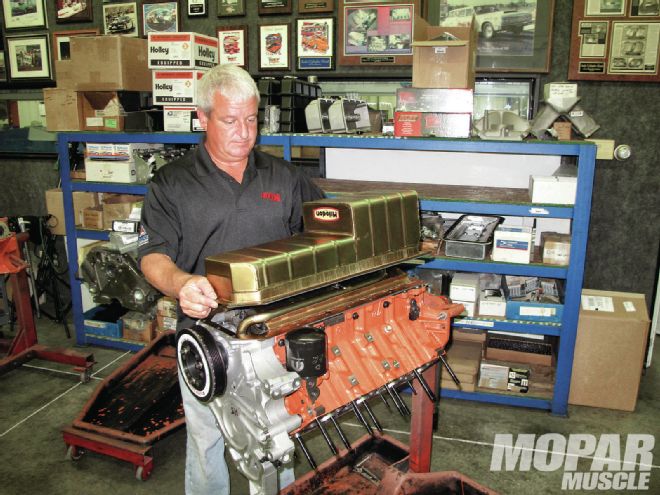

Standard engine building techniques are utilized when assembling a late-model Hemi, and we tightened the head studs in three sequential steps to a final torque of 100 lb-ft. With the heads in place, it was time to concentrate on our intake manifold, which also means addressing the ignition system of our engine. Since all late-model Hemis lack a distributor or a provision for a distributor, the ignition system must be controlled by a computer attached to individual coil packs for each cylinder. Indy Cylinder Head has come up with a great way to incorporate the coils under the intake manifold, using plug wires for the spark plugs just like the first and second generation Hemi engines.

We're utilizing a Mopar Performance Drag Pack intake manifold on our 426 Hemi, and the crew at Indy machined provisions in the bottom of the intake so that the eight individual coil packs could be bolted underneath using one of their coil plates. Using a Hemi-6 programmable controller, wiring harness, and coils from MSD, along with plug wires from Indy Cylinder Head, this technique allows for a much cleaner, somewhat nostalgic look for the late-model Hemi. The MSD ignition box also allows the ignition to be run as a stand-alone system, without the complexity of fuel injection. The Hemi-6 controller is easily programmed with a laptop computer, and the harness plugs right into the factory crank and cam sensors, as well as the coolant temp and MAP (manifold air pressure) sensor.

What this means for old-school tuners, is that the late model Hemi can be used with a carburetor, just like the first and second generation versions. And while we certainly aren't opposed to fuel injection on our street cars or even a race car, running a carburetor on our dedicated bracket racer will make things easier in terms of wiring, fuel system plumbing, and overall simplicity. To top our Mopar Performance single-plane intake, we decided to test two different Holley Ultra-HP carburetors, an 850-cfm and a 950-cfm version. We've had great luck with these new Holley carbs since they came out, finding them to be very accurate right out of the box. The Ultra HP carbs also offer some great convenience options like a drain plug for each float bowl, making tuning even easier than previous Holly carbs.

Once we had our engine complete, we bolted it to the dyno and connected a set of tti headers to find out how our combination would perform. The headers we're using are tti's Drag-Pack units, featuring 17⁄8-inch primary tubes stepped up to 2 inches, with 3-inch to 4-inch tapered collectors. These headers will also be installed in our '10 Challenger once we get the engine in the car.

Running on 92 octane pump gas, from the station right up Southeastern Avenue from Indy's shop, we fired up our Hemi for some break in time and dyno pulls. The Comp hydraulic roller cam in this engine has a fairly wide 114-degree lobe separation, and combined with 10.85:1 compression our Hemi had a fairly smooth idle and sounded pretty docile when running at low rpm. We had some pretty good expectations for this engine, but our Hemi certainly didn't have the idle quality or cackle of a high-powered race engine. Once the throttle opened, however, this late-model Hemi came to life.

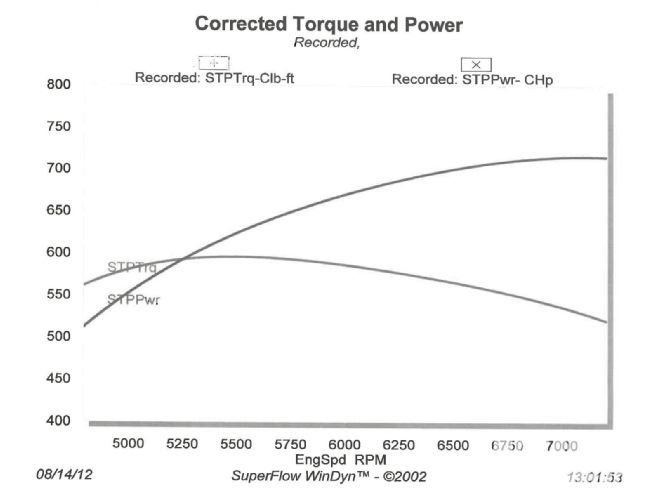

Making a couple of short pulls to help seat the rings, we were impressed when our power numbers already topped 600. Comfortable that our engine was sound and properly broken in, we quickly programmed the MSD Hemi-6 ignition controller for 13 degrees of total ignition timing. With the 850 Holley carb, horsepower was tickling the 700hp range, so we decided to see if this engine wanted more fuel and air. Swapping from the 850 to the 950-cfm Holley Ultra HP, we made a full pull on the engine to 7,000 rpm. When the dyno numbers appeared on the computer screen we weren't just impressed, we were astounded. By race engine standards this is a fairly mild combination, running on pump gas, and it made well over 700 horsepower. With a single jet change, we achieved an amazing 719.5 horsepower at 7,000 rpm, and 605 lb-ft of torque at 5,300 rpm.

Having built many Mopar big-blocks, small-blocks, and early Hemi engines, we can say that without a doubt this late-model Hemi produces more power with a milder combination than any other Mopar V-8. The power and torque numbers we achieved from this engine are real race engine numbers, without the huge displacement, high compression, or aggressive solid roller cam that most race engines require to make this kind of power. If any of our readers weren't sure about the late-model Hemi, we encourage you to carefully review the specs of this engine. In our opinion, this is the best platform available for a Mopar engine build, whether for a late-model car or an earlier Mopar. We can't wait to get this engine into our Challenger and hit the track, so be sure to watch future issues of Mopar Muscle to see what kind of numbers we run.

Price Tag 6.4 late-model Hemi heads $1200.00 Indy preparation and cnc porting $1080.00 Holley Ultra HP 950 Carburetor $810.00 Mopar Drag Pack intake manifold $1039.99 MSD Hemi Six ignition box $474.95 MSD Hemi Six wiring harness $185.95 MSD coils $442.95 TTI late-model Hemi headers $740.00

16. Corrected Torque and Power - Broad torque and power curves are common with late-model Hemis, and our engine exemplifies this trend. To make this type of power with a small-block, big-block, or second generation Hemi would require substantially more cam, compression, displacement, and carburetion than our engine has. We’re convinced that the late-model Hemi is the most efficient and powerful engine Chrysler has ever made.

16. Corrected Torque and Power - Broad torque and power curves are common with late-model Hemis, and our engine exemplifies this trend. To make this type of power with a small-block, big-block, or second generation Hemi would require substantially more cam, compression, displacement, and carburetion than our engine has. We’re convinced that the late-model Hemi is the most efficient and powerful engine Chrysler has ever made.