In our September issue, Steve Dulcich began answering Lawren Minor's question of what he should know about basic engine rebuilds. In the first installment, Steve covered basic block machining and preparation, proper reconditioning of cylinder heads, how to choose the right crankshaft, and basic rod and piston configurations. In this, the second installment, Steve covers proper piston-ring selection, camshafts, quench, and engine balancing.

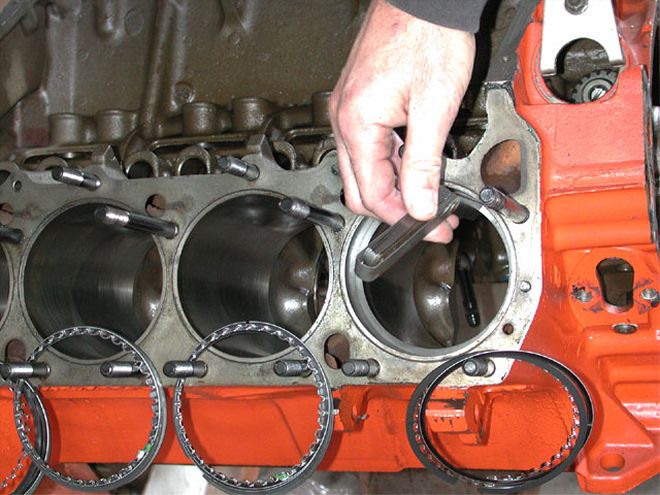

Rings may all look similar, but the difference in materials makes a difference in performance, longevity, and engine life. Moly rings are the favorite of most engine builders.

Rings may all look similar, but the difference in materials makes a difference in performance, longevity, and engine life. Moly rings are the favorite of most engine builders.

Rings-O-Fire

Two things to consider when choosing a set of rings are size and type. Size is simple; they have to fit the bore and the pistons. Type refers to material and coatings. Cast-iron is the entry-level ring-the kind you get in a cheap remanned engine or a discount rebuild kit. Plain cast-iron rings were used in most stock Mopar engines, and like the stockers, they usually wear out the bore in 100,000 miles. Moly rings are the type favored by engine builders and OEM manufacturers today. The moly face of the ring conforms better to the cylinder bore and retains a wick of oil, which helps bore life considerably.

Moly isn't a ring material itself, but it is applied to the ring in a receiver groove or coated over the full face of the ring. Better moly rings are based on a ductile-iron ring body, which is superior to the standard-iron ring material, particularly in extreme applications.

File-fit rings are individually fitted to each bore for optimal endgap, capturing as much precious cylinder pressure as possible. Insert the ring in a bore, square it to the cylinder with a ring-squaring tool or inverted piston, and measure the gap with a feeler gauge.

File-fit rings are individually fitted to each bore for optimal endgap, capturing as much precious cylinder pressure as possible. Insert the ring in a bore, square it to the cylinder with a ring-squaring tool or inverted piston, and measure the gap with a feeler gauge.

Chrome-faced rings are as the name implies-chromed on the face, giving the ring a hard wear surface. Chrome rings were once quite popular, but slow break-in on the chrome and advancements in moly-ring technology have made chrome the less desirable choice.

Rings can be acquired in standard-fit or file-fit sizes. They have an open end, and when installed, there is a gap. This gap is open to compression leakage, and in a high-performance engine, minimizing the running gap of the ring pays off measurably in power. Pregapped or standard-fit rings have somewhat more than ideal endgap, but usually drop into a specified bore size without additional work. File-fit rings are made a few thousandths-inch larger in diameter and are filed on their ends to provide the exact endgap the engine builder is after. File-fit rings add to the work of putting an engine together, but there is some power to be had.

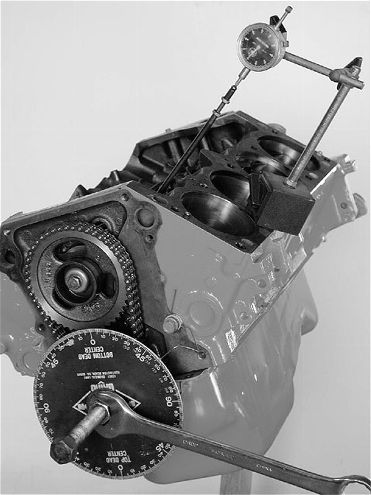

To get the cam timing events occurring at the designed specifications, the cam should be degreed-in, which involves checking the cam's position relative to the crank.

To get the cam timing events occurring at the designed specifications, the cam should be degreed-in, which involves checking the cam's position relative to the crank.

Cam Concerns

Camshafts can be sorted by type in two ways: Some camshaft lifters have a roller at the end (roller cam); others have a flat face (flat tappet). Also, some are solid-lifter designs, and others incorporate a hydraulic adjustment mechanism. Factory Mopar cams from the musclecar era were predominantly hydraulic flat tappets, yet a notable number of engines came with solid flat tappets. Hydraulic rollers appeared in Mopar OE engines in 1985, and these days, nearly all newer engine designs use this type of cam and follower. Hydraulic flat tappets are simple to install, require no adjustment once the engine is built, and are quiet in operation. Hydraulic cams get their name from the hydraulic mechanism designed into the lifter. An oil-filled plunger in the lifter body self-adjusts to remove any slack in the valvetrain. Hydraulic rollers share all these features, but the roller follower allows the cam lobe to be designed with a faster-opening profile, and it produces less friction.

Solid cams do not have the hydraulic mechanism in the lifter to remove the clearance from the valvetrain. Instead, a small amount of clearance must be set in the valvetrain to ensure the valves will close as the lifter comes off its lobe. This is valve lash, and it needs to be adjusted periodically to maintain the correct clearance specification. A hydraulic lifter's hydraulic mechanism has an increasingly difficult time maintaining control as rpm rises because the internal plunger can overextend, or, at times, bleed down.

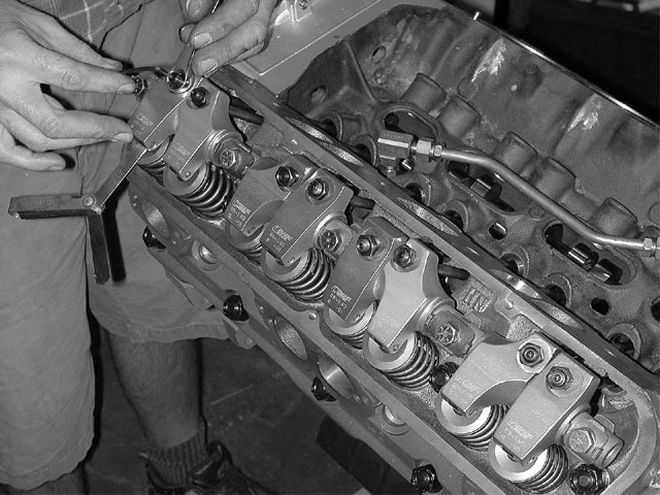

To go along with a hot cam combination, a valvetrain upgrade is advisable; with anything but a hydraulic, it's mandatory. The aftermarket has us Mopar guys covered with many quality choices, such as these affordable Crane roller rockers we used on a W-2- equipped small-block.

To go along with a hot cam combination, a valvetrain upgrade is advisable; with anything but a hydraulic, it's mandatory. The aftermarket has us Mopar guys covered with many quality choices, such as these affordable Crane roller rockers we used on a W-2- equipped small-block.

A solid lifter is fixed, so there is no compensating factor. Solid rollers are the top choice in racing since they maintain the benefits of a solid follower while the roller allows radical cam-lobe profiles. Solid rollers reduce friction where the lifter meets the cam, allowing much higher valvespring pressures than a flat tappet could endure.

Cam size is generally given as lift and duration. Lift is the amount the travel of the cam lifts the valve off the valve seat, while duration is a measure of the length of time a valve remains open in degrees of crankshaft rotation. When rating duration, cam manufacturers have traditionally played games using different start and stop reference points.

A standard was set in the industry to rate cams by duration at .050-inch tappet rise. This means the open duration is measured from the time the lifter moves up .050 inch on opening until it reaches .050 inch from closing. This is often referred to as duration at 50. This allows for more accurate manufacturer comparison of duration figures. Aftermarket cams are typically more aggressive in their action than a production camshaft, and the valvesprings almost always need to be changed. Follow the advice of the cam supplier for springs to match the cam and rpm range. Along with the springs, the retainers and locks (keepers) are often changed, either to fit the spring or to enhance reliability or rpm potential.

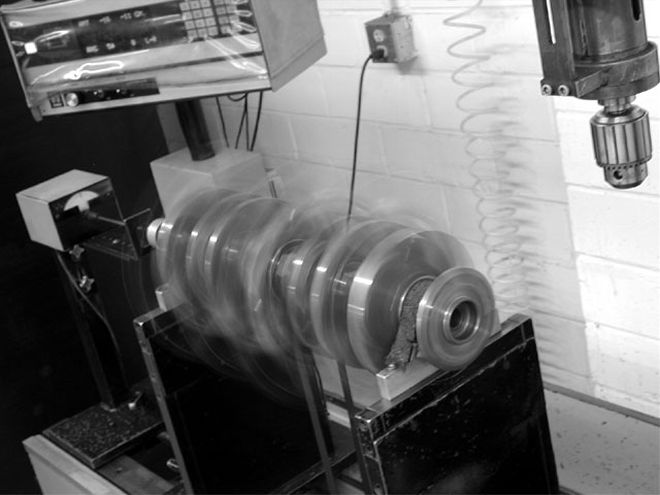

Balancing starts with weight-matching to get a weight spec for the internal engine components. Then, the effective weight-bob weight-is calculated.

Balancing starts with weight-matching to get a weight spec for the internal engine components. Then, the effective weight-bob weight-is calculated.

The rest of the valvetrain needs to be matched to the requirements of the camshaft. Stock hydraulic-cammed big- and small-block Mopar engines used stamped-steel rocker arms and solid-steel pushrods from the factory. These work in mild hydraulic cam applications, but otherwise, the valvetrain needs upgrading. A solid cam needs a provision for valvetrain adjustment, so a rocker and matching pushrod change is a given. A hydraulic cam can also benefit from an adjustable valvetrain, allowing the depth of the pushrod's engagement in the lifter's hydraulic mechanism (the lifter preload) to be set for optimal performance. Stock big- and small-block rockers carry a design ratio of 1.5:1, meaning the valve is opened 1.5 times as much as the cam lifts the lifter. Aftermarket rockers can be acquired in higher ratios, such as 1.6:1 or more.

Engine Rebuild Basics: Part IIQuench Combustion

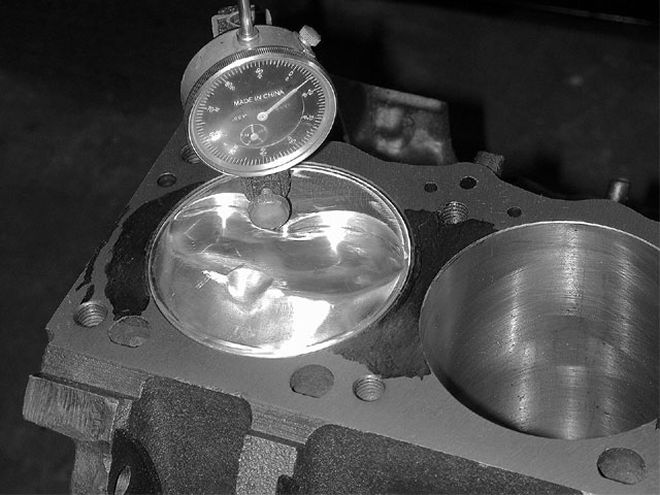

Selecting a piston that comes up even with the deck at TDC (typically with minor block decking) and using a standard .040-inch-thick gasket will be beneficial if used with a closed-chamber head. This tight clearance between the piston and closed deck of the head provides what's referred to as the quench effect, which adds combustion efficiency. Quench translates to more torque and better detonation tolerance, making the goal of an effective quench clearance worth considering when selecting pistons.

While a closed-chamber head naturally lends itself to a quench configuration, most Mopar engines used open-chamber heads. For these engines, pistons with a kick-up to provide a quench effect in open-chamber heads are available from many manufacturers. Be aware, however, that custom machining is required to make the most from the combination of a kick-up quench-dome piston and an open-chamber head. It may be cheaper and less hassle in many cases to buy an aftermarket closed-chamber head and use a flat-top piston.

To get a working quench clearance, it is necessary to plan in the engine-building stage to set the appropriate piston-to-head clearance. About .040 inch has been found to produce effective results, easily obtained by setting the piston for zero deck and using common .040-inch-thick head gaskets.

To get a working quench clearance, it is necessary to plan in the engine-building stage to set the appropriate piston-to-head clearance. About .040 inch has been found to produce effective results, easily obtained by setting the piston for zero deck and using common .040-inch-thick head gaskets.

Balance Basics

Engine balancing is an attempt to balance the forces of the reciprocating and rotating internal components of the engine. Balancing an engine involves figuring out the effective mass of the components hung on the rod journal, which amounts to the bob weight. The bob weight includes the pistons, pins, locks, rings, rods, and rod bearings. It is determined by weighing the parts and then using a formula to account for the parts' motion. It seems simple, but often the parts have widely varying weights; for example, some rods may weigh more than others. So, the first step in a balance job is to weight-match the components, particularly the rods. Once weight-matched, a bob weight can be determined. The crank is put on a balancing machine with bob weights of the derived weight attached to the journal, and the crank is dynamically balanced, much like a tire.

The bob weights are bolted onto the crank's journals to simulate the total weight effect of the parts, and the crank is spun on a balancing machine to determine the balance. Balance is corrected by drilling the counterweights. Sometimes, if more counterweight mass is required, weight is added by welding or inserting Mallory heavy metal in the counterweights.

The bob weights are bolted onto the crank's journals to simulate the total weight effect of the parts, and the crank is spun on a balancing machine to determine the balance. Balance is corrected by drilling the counterweights. Sometimes, if more counterweight mass is required, weight is added by welding or inserting Mallory heavy metal in the counterweights.

The factory balance job is a rough estimate, but it is close enough to provide acceptable smoothness. If the stock components are used in a rebuild, rebalancing isn't necessary. The same is true if replacement parts such as pistons are of similar weight to the originals. However, if aftermarket race parts such as pistons or rods are used which differ greatly from the stock weight, the factory balance job will not even be close. It's not uncommon for an aftermarket piston to be several hundred grams lighter than the originals, making balancing mandatory.