So why would you want build an LS engine? Because they are cheap horsepower and it's easy to build. Over a million trucks were made with V-8-powered LS powerplants since 1998. Tons of aftermarket companies are now making parts for these engines and our test engine ended up making 415 horsepower with minimal parts. So why not build an LS?

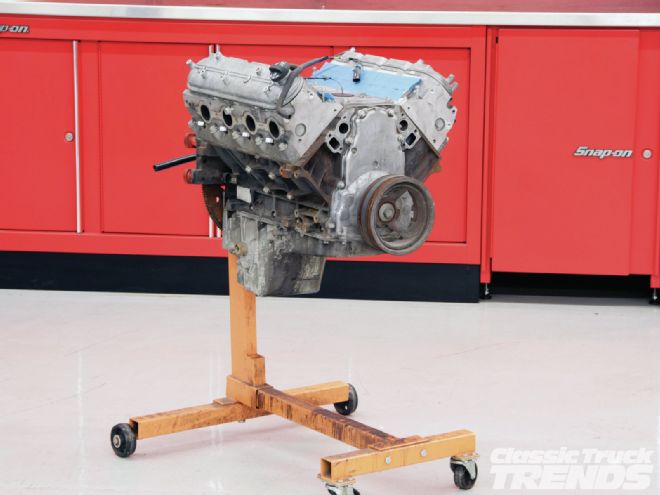

After pulling a 5.3L LS truck engine out of a junkyard, I wanted to find out for myself how easy it was to get it running again. The junkyard guy said that the engine was in fact a 5.3L out of a 2004 Chevy truck. As I looked over the engine I thought, “Hey, that would be a perfect engine to use for one of my many project vehicles.”

After loading the engine in the back of my pickup, I pondered on what I wanted the engine to look like, but more importantly what can I do to bump up performance. Several different directions passed through my head, like keeping the stock LS intake or purchase one of the many available aftermarket fuel-injection systems. Ultimately keeping the engine simple and swapping the fuel injection for a Holley 650 carb, MSD coil pack controller, and an Edelbrock dual-plane intake was the easiest way to go.

Now that I had a direction on what parts I wanted to use, I looked on the Summit Racing website and found the Edelbrock dual-plane intake (part number 71187), (ARP-200-2401) carb studs, and (SUM-G1418) carb gasket. Instead of ordering the complete Edelbrock intake/controller kit, Steve from Westech Performance suggested that I use the MSD 6LS Ignition Controller (part number 6010) because of the ability to tune the timing curve while on the dyno or with a laptop at home. Steve also recommended that I use a Comp Cams (54-416-11) hydraulic roller camshaft – specs are 220/224 int./exh. at 0.05-inch duration with 0.530-inch / 0.0534-inch int./exh. lift at 112 LSA. The stock cam specs are 190/191 int./exh. at 0.05-inch duration with 0.466-inch / 0.457-inch int./exh. lift at 114 LSA.

If you know anything about camshafts, then our Comp Cams choice does not seem like a huge jump, but boy did it make a big improvement on the dyno. The cam is rated at an rpm range of 1,600-6,600 so off-throttle response is good and it makes great power at higher rpm.

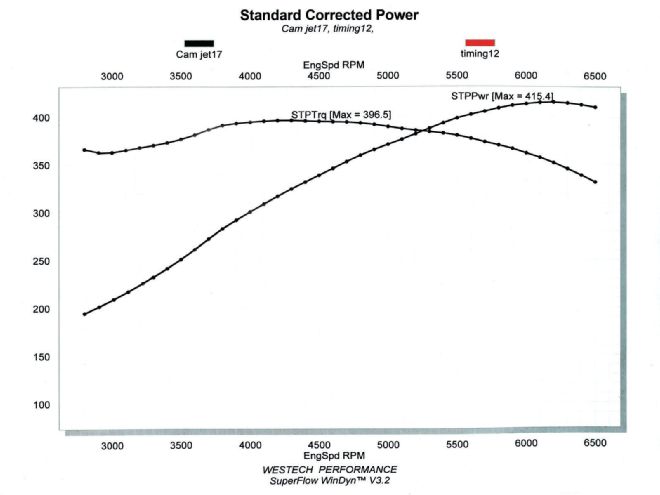

The stock 5.3L is factory rated around 320 hp with 340 lb-ft of torque. When on the dyno at Westech we were able to get close to the stock numbers – 315 hp and 325 lb-ft with our 650 Holley carburetor swap, MSD controller, and Edelbrock intake. So it was cool to see the how well the LS engine will improve to simple changes – 415 hp and 396 lb-ft from what was a basic cam change.

Is it a 4.8 or 5.3? You need to know what the engine is before you order performance parts, especially if you are planning on replacing the heads down the road.

The only way to tell the difference is to either remove a cylinder head or use a bore scope such as this one I picked up from Harbor Freight. The 4.8L pistons are flat on the top and the 5.3L pistons have a small dish to them.

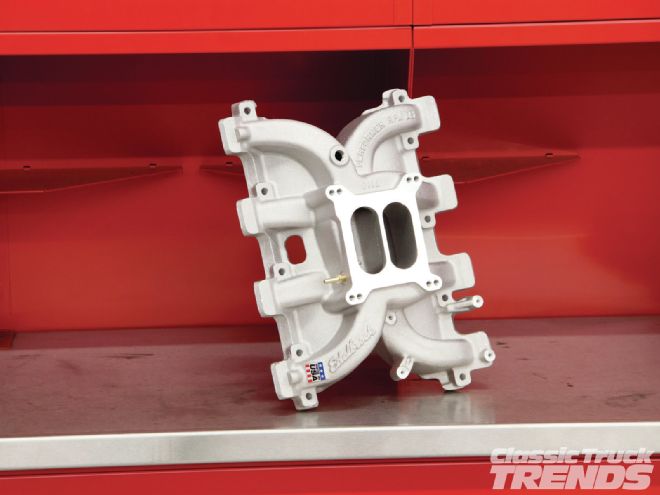

The Edelbrock dual-plane intake is perfect for our application. It features an air gap under the intake that allows the intake to not get hot like a traditional small-block intake. The air gap also allows us to run the stock LS crossover tubes for the coolant.

We flipped the intake over to install the rubber gaskets. Unlike the small-blocks of the past we didn't have to use silicone to seal the intake, the LS gaskets just push right on.

I cleaned the surface and installed the intake with the provided bolts.

I used a Holley 650 Ultra Double Pumper carb to provide fuel to the LS engine. Holley says that Ultra Double Pumper carburetors feature all-aluminum construction and are equipped with metering blocks and a base plate made from 6061–T6 billet aluminum. Three different anodized color options (red, blue, or black) allow for a personalized look while maintaining the ultra-high strength and durability you get from billet. They weigh approximately 5 pounds less than a comparable zinc carburetor.

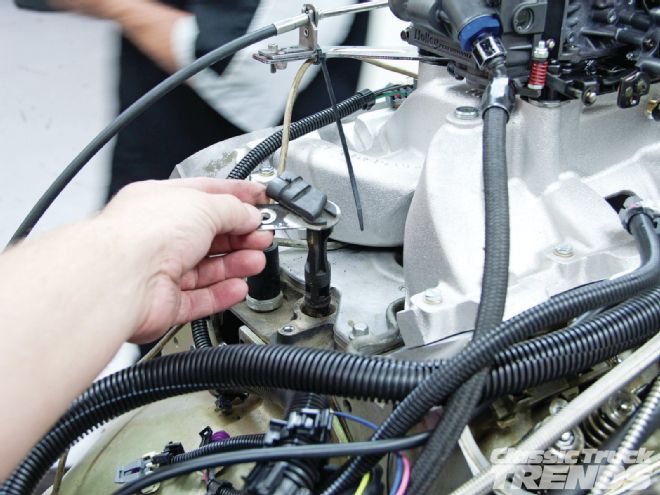

I then bolted the MSD 6LS Ignition Controller (part number 6010) to the top of the intake. This provided the spark to the coils via the stock coil wiring, the crank sensor, and cam sensor. On our engine we had a 24-tooth crank sensor reluctor wheel and you will need to know what year engine you have to figure that out.

I would recommend using one of these Summit Racing adjustable engine leveler (part number SUM-G1022) so that you can easily load the engine in the truck or on the dyno without scratching parts or lifting the engine from the carb studs.

Once on the engine dyno at Westech Performance in Loma Linda, California, we filled the engine with Comp Cams Muscle Car & Street Rod 10W30 blended synthetic oil.

I used a Lokar Anchor Tight Locking Flexible Engine Dipstick to clean up the engine bay and to easily check the engine oil.

The engine started up great and with a few adjustments to the floats Steve Brule of Westech ran it on the dyno. We were not getting enough fuel at mid to top end so Steve opened up the fuel bowls and replaced the front and rear main jets. We went from a 61 to a 70 main jet and retested the engine. Not bad for a stock engine – 315 hp and 325 lb-ft.

Now it's time to install some performance goodies from Comp Cams. We ordered a street/strip dual-valve spring kit, lightweight tool steel retainers, 7-degree steel valve locks, valve seals, and spring seats. Also a Comp cam.

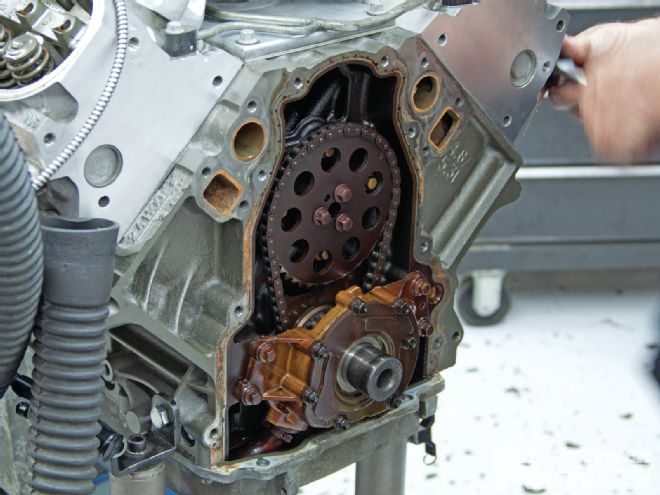

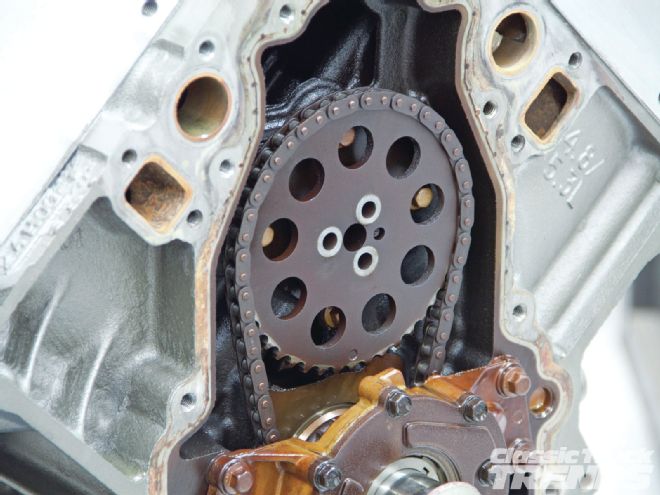

Steve started by removing the crank pulley and cover for the timing set.

The No. 1 cylinder is on the right-hand side of the engine or driver side if you're sitting in the vehicle. After Steve removed the cover for the timing set he needed to set it at top dead center.

He removed the rockers so that the engine would be easy to turn and so that the cam would slide out without the valvetrain applying pressure on the camshaft.

Steve found TDC by cranking the engine over via the dyno starter. Then he rotated the engine by hand to get the alignment marks lined up.

On a three-bolt LS cam the alignment bolt will point toward 3 o'clock.

The cam sensor was unbolted and removed so that we can slide the camshaft out of the block without damaging the sensor.

After removing the cam gear and placing the lifter tool that holds the lifters from falling into the block Steve removed the cam.

Some Lucas assembly lube for the new Comp cam and in it goes.

Everything was re-installed in reverse order and the camshaft along with the new valvesprings and pushrods were all in the engine. Time for some more testing.

With the camshaft change we needed to once again re-jet the carb. We ended up with 64 primary and 70 secondary and that helped our engine stay in better fuel control while in cruise conditions, heavy load, and wide-open throttle.

With the carb apart Steve also wanted to change the primary power valve. He did this because with the cam change the engine wanted the power valve to add more fuel while transitioning from idle to wide-open throttle.

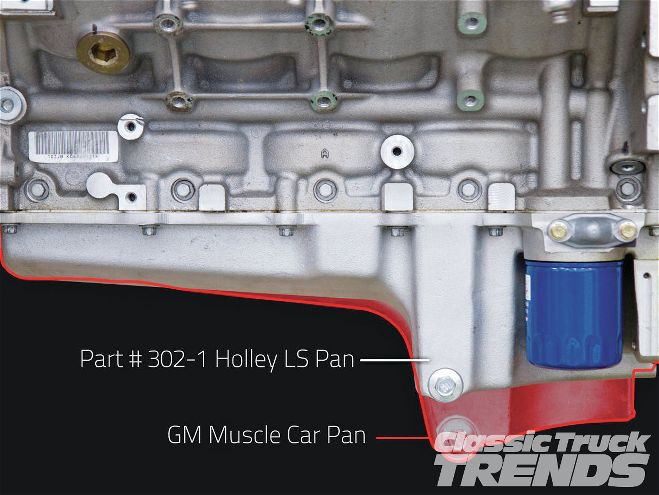

We took the engine back to the tech center to install a few more LS parts. On the way back I noticed that the engine was leaking oil near the bottom of the oil pan. Well I failed to properly transport the engine and managed to crack the stock oil pan. Now that was not a big deal since I was planning on replacing the oil pan with this Holley (part number 302) LS replacement oil pan. Since most of the readers lower their pickup trucks the oil pan helps add clearance for crossmembers and helps with ground clearance.

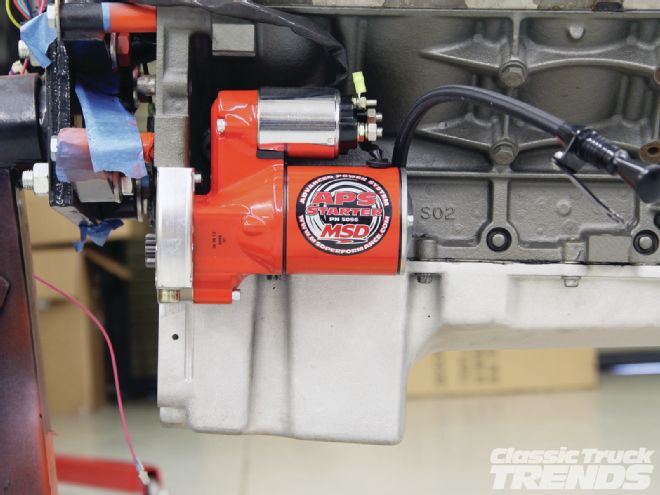

We also replaced the starter with the new MSD that has a gear reduction of 4.4:1 and improves torque for great cranking. It is downsized to help with clearance around the oil pan and aftermarket headers. Also the starter can clock in several different positions so that it can get out of the way.

Holley also has a cool line of valve covers that hide the coil packs of LS engines. Note: these will have to be cut to fit your application and will not fit over the stock truck coils.

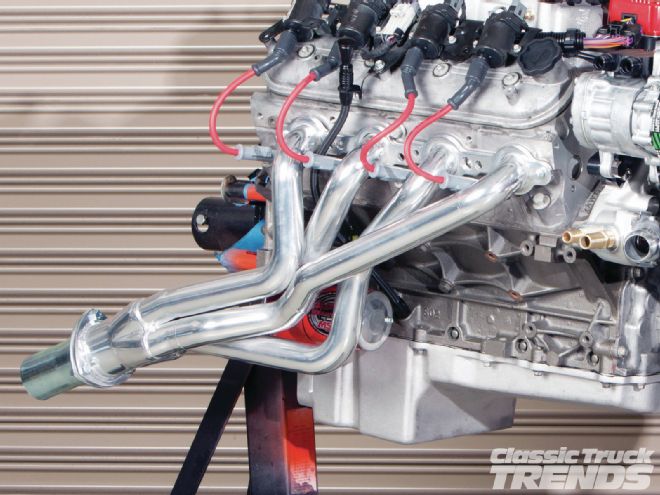

Shown is a very nice pair of Patriot coated headers for LS engines. These particular headers fit Gen-2 Camaros and the '75-79 Nova with the LS conversion. Patriot is also working on a few different style headers that will fit our classic trucks that include the popular '63-72 C10 and the later '73-87 C10.

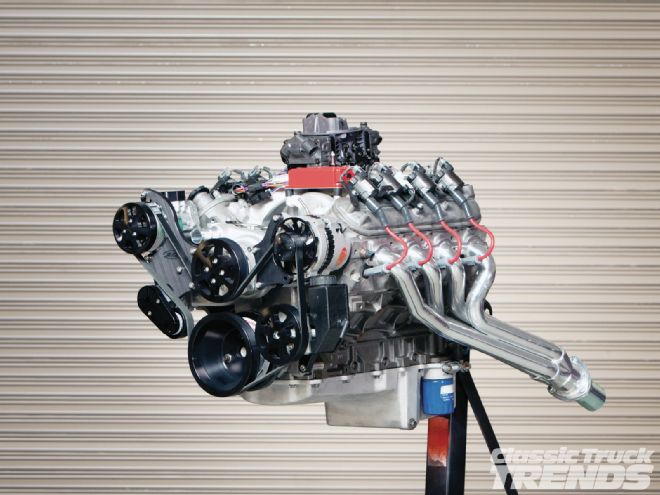

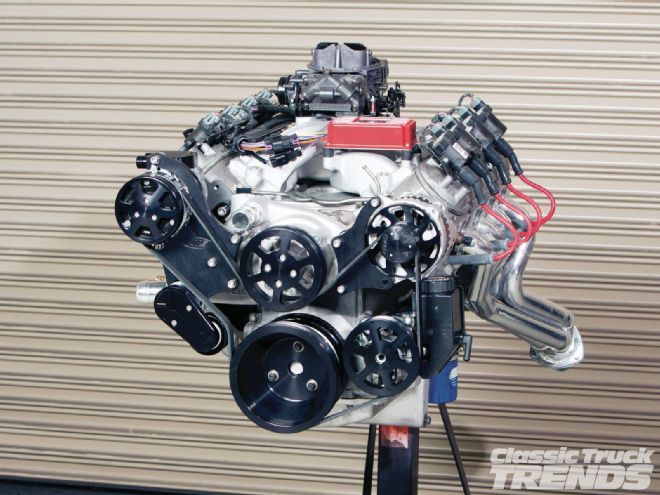

Eddie Motorsports has a cool serpentine kit that we installed on the LS engine. The S-drive Serpentine Pulley Kit comes complete with everything you need including all new name-brand components, Edelbrock rebuildable aluminum water pump, Sanden A/C compressor, Maval power steering pump, Powermaster 140a alternator, and ATI damper. Retail price for black anodized is (MS107-60CC) $2,595. The kit is also available in bright polished (MS107-60P $2,495), or raw machined (MS107-60M; $2,395) finishes.

It's cool to see how easy it is to build a reliable 400-plus-hp engine from a bone-stock bottom end. 415 hp with 396-lb-ft will make any truck scoot just fine.