Fuel-pressure regulators are fuel-pressure regulators are fuel-pressure regulators, right? Wrong! While they all accomplish the same purpose, there is a big range when it comes to price, material, fuel type, and other options. There are fuel-pressure regulators for all kinds of street performance and motorsports, including circle track racing. An Outlaw drag car with three stages of nitrous has very different needs than a Street Stock with a small two-barrel carb, and there are options for everything in between. Deciding what your best options are, is going to come down to your specific combination.

Whether you run a carburetor or EFI, pump gas, or methanol, there are regulators out there to fit every need. It’s a safe assumption that as your fuel system needs get more complicated, horsepower gets higher, and fuels get more exotic, you’re going to need a better, more expensive fuel-pressure regulator. But what separates a $20 regulator from a $300 regulator? After a conversation about just that with Curt Spalding from Allstar Performance, we decided it was worth taking a more in-depth look.

Making a decision on a fuel-pressure regulator will be largely based on your specific needs. Companies like Aeromotive, Allstar Performance, Holley, and Summit Racing offer many different regulators, with many different configurations and options. These options will be based on what fuel you run, whether you want to run a return or returnless style fuel system, how many ports you need, and whether you run a carb or EFI. To start it all out, we are going to take a look at the basics of fuel delivery so you have a solid general understanding of how it all works.

Fuel Delivery

In every fuel system there are some key components—the tank or fuel cell, fuel pump, lines, regulator, and carb or fuel rails and injectors. Filtration is also extremely important, but that can be a story by itself, and we aren’t going to get into that here.

Aeromotive Regulator- PN 13109, $149.95

Aeromotive Regulator- PN 13109, $149.95

Without getting too off track, it’s important to take what you are doing in mind when designing your system. In circle track racing, lateral g-forces can move the fuel to one side of the cell in the turns, so it’s important to have the fuel pump pick-up in the correct location, so the pump isn’t starved when the fuel moves in the cell. Pump, lines, regulator, and method of delivery (carb or EFI) all need to be taken into consideration when choosing line size, filter size, pump capacity, and so on. Knowing what you have and looking at your goals is important. Skimping on one piece of the puzzle could mean replacing the entire system later if you decide to make more power.

Volume vs. Pressure

Volume and pressure are two completely different things when you talk about fuel, but they must work together to give you the proper air/fuel mixture delivery. Both carburetors and EFI systems require the proper fuel volume to make the desired horsepower, but the pressure differences between the two are quite different. A carbureted setup requires very low fuel pressure—somewhere between 5 and 9 psi, while an EFI setup, on the other hand, could require as much as 60 psi on the high side. This means the fuel pump needs are entirely different, and regulating pressure is different as well. Regulator manufacturers make regulators specifically for each application.

Aeromotive Regulator- PN 13205, $89.95

Aeromotive Regulator- PN 13205, $89.95

The needed volume is based on fuel requirements to make a certain amount of horsepower. Fuel volume is going to directly dictate what size fuel lines are required to reach a given horsepower range. In a carbureted setup, the pressure is going to affect the float levels, which will change the air/fuel mixture. If the fuel volume is correct for your setup, there shouldn’t be any changes in pressure from idle to part throttle to wide open throttle. The key here is having more fuel pump than you need, and regulating it correctly. In a dead-head–style regulator, only the regulated fuel goes to the carb, and what is left sits as a reserve in the fuel line. If you don’t have enough fuel pump, the reserve will be depleted at WOT, and you’ll see fuel pressure drop. The same goes for a return-style fuel system, but in this type of system, the fuel reserve is constantly circulating.

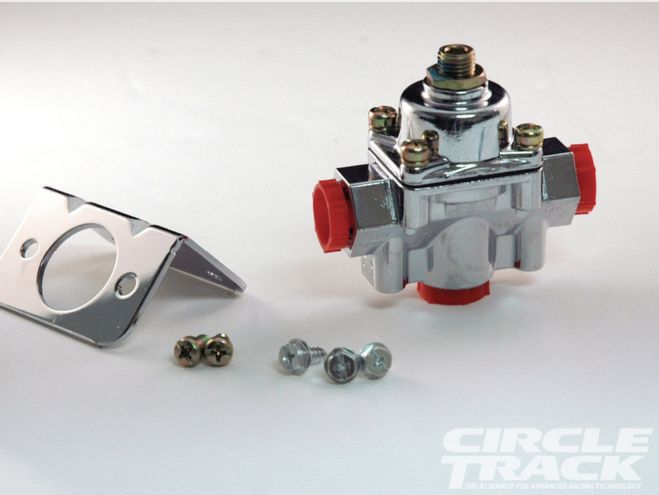

Allstar Performance Regulator- PN ALL40290, $64.99

Allstar Performance Regulator- PN ALL40290, $64.99

Return vs. Returnless

You might be saying, “What difference does it make if my fuel system is a return style or returnless style system?” Well it can make a big difference. A returnless fuel system consists of one fuel line that feeds the carb or fuel rails. The regulator controls pressure, and the stream of fuel deadheads at the rails or carb. While this is an effecting way to deliver fuel, it does have some downfalls. The fuel backs up behind the regulator (the regulator acts as a restrictor) and the fuel waiting in the line moves much slower on its way to the engine, absorbing heat as it goes. While it may not seem like a big deal, heated fuel has a different specific gravity than cooler fuel, which will change the mixture. Beyond that, hotter fuel is more susceptible to pre-ignition (detonation), although higher-octane fuels can remedy this problem.

Holley Regulator- PN 12-803, $28.95

Holley Regulator- PN 12-803, $28.95

A return-style fuel system keeps the flow of fuel through the entire system constant, keeping the fuel cooler. This will give you a denser air/fuel charge, and will keep the fuel pump cooler, as cooler fuel is constantly passing through it. Constant circulation of cooler fuel will also result in less vapor lock issues than a dead-head–style system, as fuel sits in the lines and carb absorbing heat from the engine.

Holley Regulator- PN 12-803BP, $69.95

Holley Regulator- PN 12-803BP, $69.95

How Regulators Work

At a glance, a fuel-pressure regulator is a metering device. It controls the flow of fuel to the your given method of fuel delivery, be it a carburetor or fuel injection. The body of the regulator houses a number of parts that are all critical to the performance of the regulator, including a spring (or multiple springs), a diaphragm, a seat, and the hardware to adjust pressure and hold it all together. While the type of parts can be pretty standard across the board, the quality of the parts can be the difference between a part that lasts, and a part that doesn’t.

Inside a regulator, the adjuster sets the spring pressure on the diaphragm, which controls fuel flow. The spring and diaphragm are what control the pressure. Keep in mind, fuel pressure is dynamic—it changes with throttle application. Keeping fuel pressure at a constant number is important, but so is how quickly the regulator reacts to changes in pressure. As the throttle opens and the reserve of fuel in the fuel bowls or fuel rails enter the engine, the regulator needs to open up to replenish that supply. The key is to replenish it without causing a spike in fuel pressure. Quick spikes in pressure, be it high or low, will change the air/fuel mixture causing a rich or lean condition. Even though this may be a momentary condition, it still adversely affects power and driveablity, as throttle response is affected.

Holley Regulator- PN 12-804, $28.95

Holley Regulator- PN 12-804, $28.95

Materials

Much of the cost of fuel regulators is directly related to the materials and the quality of the components used to build them. When you look at an inexpensive regulator, chances are the body of it is going to be cast, while the more expensive pieces are machined from billet aluminum. Inexpensive billet versions are most likely produced overseas with lower quality materials to lesser standards. The price and quality of the internal components also need to be considered. Cheap springs, and cheap rubber diagrams aren’t going to control fuel pressure as accurately as quality regulators will. Many times these components will bring the price up, but when you need precise control of your fuel pressure, it’s well worth the cost.

Summit Racing Regulator- PN SUM-220056, $71.95

Summit Racing Regulator- PN SUM-220056, $71.95

Fuel Types

The type of fuel you run in your race car is going to directly affect your regulator, and the rest of your fuel system for that matter. Regular pump gas, and even some high-octane race gasses have different characteristics than alcohol-based fuels. Methanol, and even fuels that are part-ethanol are much more harsh than non-alcohol fuels. Alcohols break down fuel systems components, including the metals that hard components are made out of. To combat this, manufacturers have gone to harder coatings on components that regularly come in contact with these harsh fuels. Internal components with hard-anodized coatings have become common, and many manufacturers offer products specifically designed for methanol and ethanol blends. If you run these fuels, be sure to look for components design to be used with them.

Summit Racing Regulator- PN SUM-220057, $105.95

Summit Racing Regulator- PN SUM-220057, $105.95

Summit Racing Regulator- PN SUM-G3131-1, $24.95

Summit Racing Regulator- PN SUM-G3131-1, $24.95

Ports

Fuel pressure regulators have inlet ports and outlet ports. The inlet port is the supply of fuel from the fuel pump to the regulator. The outlet supplies your method of fuel delivery. Multiple outlet ports allow you to supply fuel to more than one means of delivery (multiple fuel rails, or multiple carbs). Multi-port regulators are also used very frequently in nitrous applications in drag racing and on street cars.

Summit Racing Regulator- PN SUM-G3032B, $24.95

Summit Racing Regulator- PN SUM-G3032B, $24.95

For the circle track world, an extra port can be useful if you run a series where they take a fuel sample as part of tech inspection. An extra port can feed a ball valve, giving tech officials an easy and safe way to take a sample.

What It All Means

A fuel-pressure regulator might not be the glamorous part you save for and brag about when you get to the track, but they are extremely important. Controlling your fuel will directly affect your performance on track, and how can you overlook that?