We've all heard rumors and opinions about what size, style, or manufacturer's carburetor is better for the engine in your Mopar. At Mopar Muscle we've tried just about every combination on the cars we drive and race. And while we feel we have a pretty good idea what size carburetor works well for a given combination, a comment we often hear at cruise night is that a certain engine is "over- or under-carbureted." You may have your own opinion about what size carburetor would be best for your Chrysler engine, but an engine dyno is the only real way to see which size carburetor makes the most torque and horsepower. This month we'll test six different sized Holley four-barrels on a Mopar big-block to see which performs best.

Since we had a 383 Chrysler big-block on the Superflow engine dyno at Auto Performance Engines, we decided it would be a good time to settle an age old question: What size carburetor is best for the Mopar 383, the most widely produced high-performance big-block? From the factory, the 383s with the highest horsepower were rated at 335 horsepower and came equipped with a 650-cfm Carter AVS. Our 383 is basically the 335 horsepower combination, with flat-top pistons and 906 casting cylinder heads. At just over 10.0:1 compression, this is a great pump gas engine, which we've modified in a similar way many 383s are modified.

In stock form, the big-block Mopar engine is one of the toughest engines around, and pre-1972 versions all have a forged steel crankshaft. Our 383 is a '68 version, with a forged crankshaft, windage tray, stock oiling system, and stock connecting rods with ARP bolts. The only deviation from stock is the .030-inch overbore and appropriately sized flat-top pistons. We topped this engine with 906 heads that were treated to a multi-angle valve job, new valveguides, and Comp valvesprings to match the .500 inch lift flat-tappet camshaft. Knowing this combination would like the upper rpm flow of a single-plane intake, we chose an Edelbrock Victor 383 intake manifold.

A carburetor's size is dictated by a rating called cubic feet per minute (cfm), which is the amount of air the carburetor is capable of flowing at wide-open throttle. The cfm requirements for any given engine can vary depending on a lot of factors, so choosing the correct carburetor from the huge variety available can be a daunting task. It would also be a daunting task to test all of the carburetors available for your Mopar on the dyno, so we narrowed it down to six different Holley models between 650 and 1050 cfm. In our experience, carburetors from Holley, Carter, Edelbrock, Quick Fuel, and other manufacturers all work very well if properly tuned. For the purposes of this article, we'll be testing all Holley carburetors since we had a variety of that brand on the shelves. Follow along and we'll show you which size four-barrel carburetor performed best on the big-block we tested.

1. Holley 650-cfm vacuum secondary

Starting small and working our way to carburetors with higher cfm ratings, we installed a Holley 650 vacuum secondary unit on our 383. It may look a little rough, but it works fine. This is the smallest carburetor we'll test, and is the same size that the factory installed on '68 383 HPs like the one we're testing. Using an Innovate Motorsports oxygen sensor to monitor air/fuel ratio, we made our first pull, but power was down from our initial break-in pulls. This is a clear indication that our 383 wanted a larger carburetor, like the 750 we used for break-in. On its best pull with the 650, our 383 made 368 lb-ft of torque and 356.9 horsepower.

2. Holley HP 750-cfm mechanical secondary

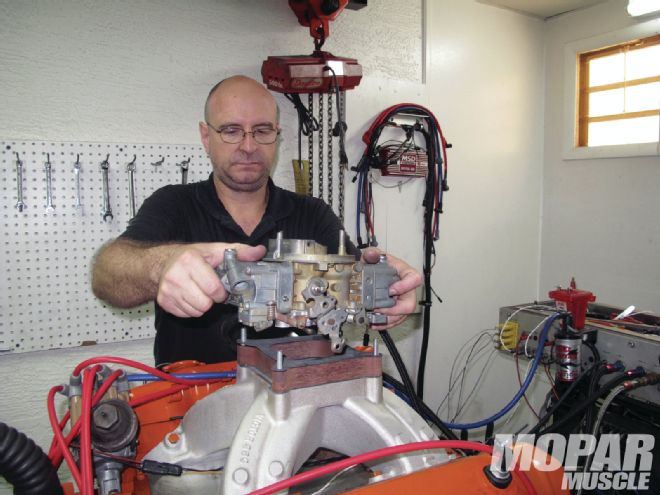

The next carburetor we bolted on our 383 was a Holley 750-cfm unit with mechanical secondaries and both front and rear accelerator pumps (hence the term double-pumper. And while the extra accelerator pump and mechanical secondaries of this unit won't necessarily help peak dyno numbers, the 750's larger cfm rating means our big-block should get more air and fuel, and make more power than the 650 did. Our first pull with the 750 showed definite improvement, and the best dyno pull with the 750-cfm carburetor installed netted 391.6 lb-ft of torque and 387.6 horsepower.

3. Holley 780-cfm vacuum secondary

Stepping up a little in size, we next bolted a Holley 780-cfm 3310 series four-barrel onto our 383 to see if it would further improve our engine's torque and horsepower. Vacuum secondary carburetors are known to be more economical than carburetors with mechanically actuated rear throttle blades, and arguably improve drivability as well. And while neither of those factors matter much while attempting to achieve the best power and torque on the dyno, they can be important once the engine is installed in a car. We figured the 780 would perform about as well as the 750 and it did, but at 381.3 lb-ft torque was down by ten. Horsepower was also slightly lower, at 380.5, so our engine liked the 750-cfm Holley HP carburetor a little better than the 780. Are we verifying that you can over carburerate an engine? With 30 extra cfm for this portion of the test, it seems so. But one drawback of this carburetor is the lack of a rear metering block, making precise air/fuel adjustments more difficult. So without the tunability of rear metering, we'll have to see what happens when we go larger.

4. Holley HP 850-cfm mechanical secondary

Taking the next logical step, we decided an 850-cfm carburetor may just be what we needed to break the 400 horsepower barrier with this engine. Bolting a Holley HP series 850 to our engine, we made a couple of pulls and adjusted jetting for the proper air/fuel ratio. This carburetor improved torque and horsepower at every rpm, and sounded crisp and responsive. Even so, it fell a little short of our 400 horsepower goal, but it reached the one horsepower per cubic inch benchmark by making 393.2 lb-ft of torque and 388.2 horsepower. Our data indicated that this engine liked the 850-cfm unit, and we'd already gained more than 30 horsepower over our baseline with the 650 installed.

5. Holley 850-cfm mechanical secondary

We had another Holley 850 on hand, so we decided to see if there was much difference between two models of the same size. With a list number of 4781, this 850 is a non-HP version, and has a choke horn installed whereas the 850 HP doesn't have a choke horn. Otherwise, these carburetors are very similar, both featuring dual metering blocks and accelerator pumps. After tuning this carburetor's main metering circuit through a series of jet changes, we found that 87 jets in the front and rear, with the power valves blocked off, made the most power. On Auto Performance Engine's dyno, our 383 big-block with the Holley 850 double-pumper made a best pull of 392.5 lb-ft of torque at 4,500 rpm, and 401.4 horsepower at 6,100 rpm. Since our 383 seemed to like it each time we bolted a larger carburetor on, we decided to see if we could over-carb the engine with a Dominator.

6. Holley 1050 mechanical secondary (modified by Quick Fuel Technology)

Knowing that we'd likely reached our point of diminishing returns, we decided to test a 4500 series Holley 1050 Dominator that had been modified by Quick Fuel Technology just to see what would happen. For our mildly modified, relatively small-displacement big-block, a 1050 Dominator is a lot of carburetor, but since our results so far showed this engine liked larger carburetors, we decided to give it a try. Of course, the 4500 series has a larger flange than our intake, so we utilized a two-inch tall tapered spacer to make it fit. After a little tuning, it was apparent that although the 1050 ran well on our engine, it didn't make quite the power of the 850. On its best pull during this test, our 383 made 393.4 lb-ft of torque and 398.9 peak horsepower, indicating that while the 1050 is a good choice for many big-blocks, it was just a little much for our 383.

While our 383 was on the dyno, we also tested carb spacers with some pretty impressive results. Watch for a future article in Mopar Muscle comparing different styles of spacers, and be sure to check out www.moparmusclemagazine.com to see videos of our dyno pulls.

While our 383 was on the dyno, we also tested carb spacers with some pretty impressive results. Watch for a future article in Mopar Muscle comparing different styles of spacers, and be sure to check out www.moparmusclemagazine.com to see videos of our dyno pulls.

Results

The results of our testing make it apparent that the 383 we tested liked the 850-cfm size carburetor better than the others tested. And while the 1050 Dominator did seem a little much for the 383, it certainly performed well, making nearly the same horsepower, and slightly more torque, than the 850, but is a substantially more expensive carburetor. As a result of our testing, we determined that larger carburetors generally do make more power on a big-block like ours, and that proper carburetor tuning is an important factor as well. And, while we were testing for peak power and torque, our results show that even with a smaller carburetor, the engine made good power. Since unleaded gasoline is still over three bucks a gallon and smaller carburetors are known to be more economical for daily driving, you may want to choose the carburetor for your car based on economy, not peak power. So when is too much carburetor too much? When the dyno numbers stop going up!

Costs

PartCost Carburetors Tested$100 (used) to $879 (new) Dyno Time$650 Per Day 93 Octane Unleaded Fuel$3.56 Per Gallon (varies daily and by location)