Most would be happy with 580 hp and 611 lb-ft of torque from a 455 street engine, but DCI knows there’s more inside

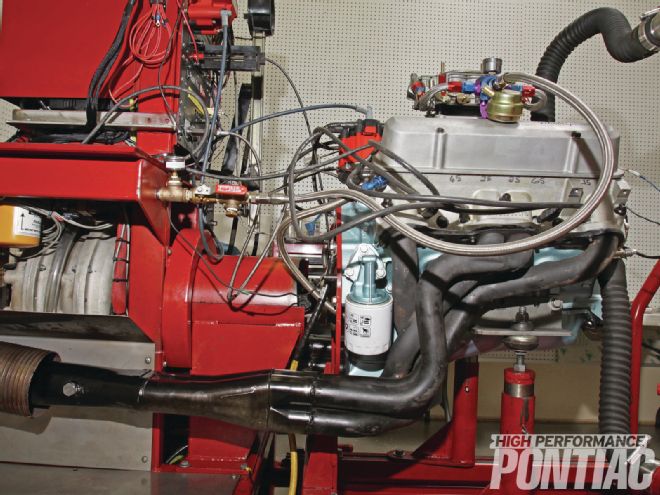

Gary Cygan does a pull on the DCI-built 455 on his Stuska engine dyno.

Gary Cygan does a pull on the DCI-built 455 on his Stuska engine dyno.

Once upon a time, we went to the dyno to test a 455 Pontiac. It all started innocently enough. We wanted a hot street-engine dyno-test story for HPP, so we called Don Johnston at DCI Motorsports in Atwater, Ohio, to see if he had any interesting combos coming together. Don needs no introduction to most HPP readers, as he has been in multiple magazine engine buildup and head stories over the past eight years.

It turns out one of his personal engines, as it happens for most business owners, had been back-burnered to handle customer work, but this was the perfect excuse to start wrenching on it again. It had spent two seasons in his racecar, and Don was considering putting together a combo for Popular Hot Rodding magazine’s Engine Masters Challenge that would also make for a very strong street engine.

We contacted Gary Cygan at Cygan Speed Engineering in Renfrew, Pennsylvania, to see if he, his pristine dyno cell, and his Stuska dyno were available for our testing. Gary’s son’s 468ci engine was featured in the Aug. ’07 issue of HPP. The story can be found at highperformancepontiac.com (keyword: Cygan). Gary has been a serious Pontiac guy for over a quarter of a century. He builds his own engines and racecars, and runs a dyno business that will test just about any engine a customer can come up with. He was onboard for the test, so we set a time and date.

DCI’s 455 engine and some of its parts have been used in the Engine Masters Challenge before. Don recalls, “We used these heads on a 409ci Pontiac engine in 2004 for Engine Masters and made 670 hp at 6,700 rpm. In competition, however, it made 630 hp because our coil wasn’t compatible with the dyno’s ignition box. We put the heads on the 455 to see what it would do in the 2008 competition, and despite a serious lean condition, it still made 618 hp and 597 lb-ft torque—with a flat-tappet cam!”

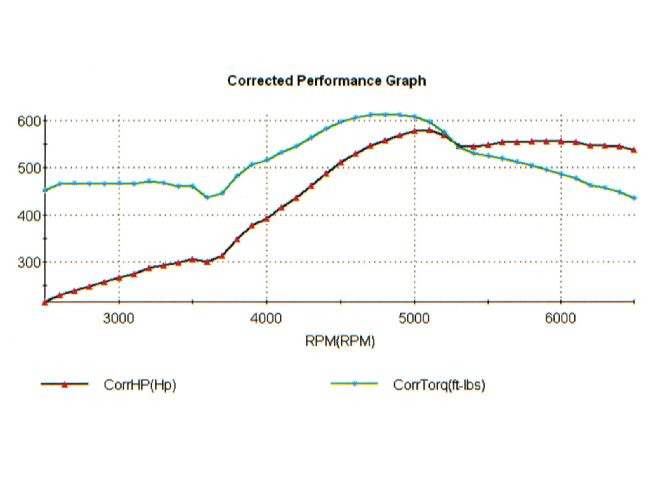

Once at Cygan’s, the 455 with the current roller-cam combo was put on the dyno and warmed up. The first pull revealed a promising 580 hp and 611 lb-ft of torque, but the power peak came at 5,100 rpm on an engine that should rev to and peak nearer 6,400 rpm. A backup pull revealed similar numbers and engine traits to confirm the first pull.

Since the air/fuel ratio looked lean up top, the first tuning was to richen the primaries and secondaries. Don and Gary decided to take a large step to #86/#93 jets to see if it was in the right direction. The engine sounded healthy and retained the torque, posting 605 lb-ft, but lost 24 hp. Despite further tuning of jets and timing in either direction, performance continued to degrade and torque began to fall off as well.

The carb and the ignition system were checked out and both appeared to be working properly. There were no sounds of valve float or any noises that would cause concern, but the engine wasn’t responding to tuning, so we stopped the dyno session and tore down the top end to take photos of the inside for this story.

At this point, the consensus is that the valvesprings, which are a few seasons old, were weakening with each pull. Remember, this is not a new engine, but it had been disassembled, checked, and reassembled prior to the dyno test.

Though we saw the engine lose power on the dyno, the first three pulls showed 600-plus lb-ft of torque at 4,800 rpm, which is substantial for a 9.3:1 compression 455. Once the new springs are in, we’ll head back to Cygan Speed Engineering to coax more horsepower from this 455—Don feels, it should do about 610 hp—and possibly produce a little more torque. Stay tuned.

Here’s the best pull—580 hp at 5,100 rpm and 611 lb-ft of torque at 4,800 rpm. You can see the horsepower drop off a ledge just after 5,100.

Here’s the best pull—580 hp at 5,100 rpm and 611 lb-ft of torque at 4,800 rpm. You can see the horsepower drop off a ledge just after 5,100.