Fully ported heads are one of a high-performance engine's most expensive components. Are they really worth the bucks, or can you get by with just a valve job and bowl work?

To find out, we worked with Charlie Hupp at GT Alley Performance, a unique facility where you'll find 600ci Merlin big-blocks going together alongside 750hp Honda DOHC V-6 engines. For our portwork comparo, Hupp selected casting No. 3947041, a typical factory small-block Chevy head with 1.94-/1.50-inch valves and 64cc combustion chambers. Originally installed on many '69-'70 350ci/300hp engines and (with larger 2.02-/1.60-inch valves) on 350ci/350-360-370hp engines, the 041 heads' general port layout is similar to millions of its '60s and '70s small-block siblings, so our findings will be applicable to most other factory small-block Chevy heads from this period.

Baseline: Dead Stock

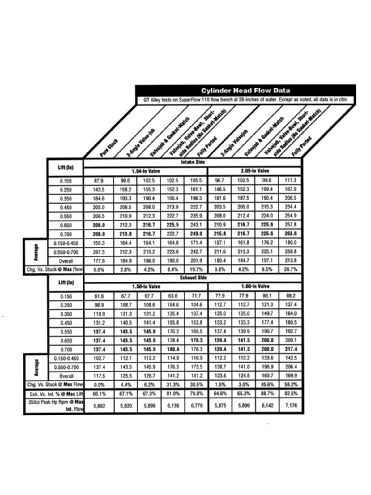

Hupp began by flowing the head in bone-stock configuration. The intake port peaked at 208 cfm at 0.650-inch lift, while the exhausts became saturated at 0.550-inch lift, and 137.4 cfm were recorded on GT's Super Flow flow bench. However, as shown in the Cylinder Head Flow Data table, the heads are essentially done by 0.450-inch lift, with little flow increase beyond that point on either the intake or the exhaust side. From the original GM designer's viewpoint, this is perfectly acceptable because production hydraulic cams all have under 0.450-inch lift.

Three-Angle Valve Job

The first improvement was a basic NHRA-legal, three-angle Pro valve job. Overall, the Pro valve job resulted in gains of 2.8 percent on the intake side, and 4.4 percent on the exhaust. Below 0.450-inch lift the intake improved by about 5 percent, while the exhaust was up 6 percent; above 0.450-inch lift, the improvement was only 1 to 2 percent.

Tim Jackson at GT Alley does the valve job the old-fashioned way using seat grinders; in the hands of a skilled operator, they develop superior concentricity, compared to automated cutters.

Tim Jackson at GT Alley does the valve job the old-fashioned way using seat grinders; in the hands of a skilled operator, they develop superior concentricity, compared to automated cutters.

Bigger Valves

The next step was to install larger 2.05-inch intake and 1.60-inch exhaust valves. On the intake side, the 2.05 valve flowed less than the 1.94 valve, except at 0.700-inch lift. Average flow numbers for the big-valve intake were less than those achieved with the 1.94 valve. Average flow numbers were also down on the exhaust side. Looking at actual numbers, the 1.60 valve flowed less than the 1.50 valve from 0.350 lift on up.

With an otherwise stock port, these results show that on small-block Chevy factory cylinder heads, big valves aren't effective-the question is, why? The answer involves the concept of Critical Area (CA). Think of CA as the minimum restriction or cross-sectional area in the port. The CA establishes the port's flow potential. GM factory engineers designed the head to flow down low to complement mild production cams, establishing this flow coefficient by the cutter diameter used with the stock-size valves. With factory ports, the smallest part of the bowl is the main flow-limiting factor.

With 1.94/1.50 valves, the three-angle valve job improves on the '69 factory valve job-it helps blend the CA of the port to the valve, and opens it up at the valve-but the throat-to-valve seat transition remains relatively smooth, maintaining the factory's original design intent. Big valves upset this relationship. Flow won't improve until you make the CA bigger to match the larger valves.

Port-Matching

Port-matching the head's intake entry and exhaust exits to their respective gaskets is an enduringly popular modification, especially because it's one mod the average car crafter can do at home. Hupp uses enlarged dimensions based on his intended performance window instead of any specific gasket outline, transitioning down to the original port diameter about 1 1/2 inches in from the entrance. The exhaust ports are merely "squared-off" rather than enlarged, with the final shape based on Hupp's years of experience.

Based on the previous CA discussion, it's no surprise that-whether with small or big valves-port-matching provides little airflow benefit. As Hupp puts it, "A chain is only as strong as its weakest link, and a port will flow only as much as its smallest part." With the CA in the bowl still smaller than the port opening or exit, opening up the intake face and exhaust exit doesn't help. However, match-porting can be beneficial when the throat CA is ported-out larger than the intake entry or exhaust exit sizes.

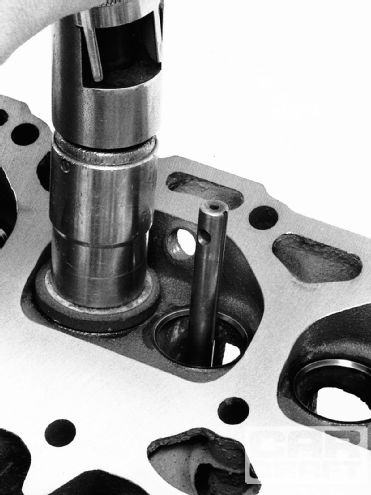

The intake valve is undercut (right) to enhance flow. Undercutting does not provide any benefits on the exhaust side, as the flow travels a different direction over the valve.

The intake valve is undercut (right) to enhance flow. Undercutting does not provide any benefits on the exhaust side, as the flow travels a different direction over the valve.

Bowl Work

Hupp next ported the bowl and short-side-without port-matching-and once again compared both the large and small valve sizes after porting. "Every experienced heat porter knows how to make a head flow at low lifts or at high lifts," Hupp says. "One takes from the other." He chose to port this head for high lifts, "where most street race guys run, anyway."

Hupp believes that "for every valve size, there is one and only one perfectly designed port." The optimum port has "all the top-secret curves and angles, and it blends. It does all the fancy high-velocity, highflow fuel atomization and special angle of attack stuff. But ultimately it is directly related to the size of the valve. When you have got this perfect, the flow will jump in size from lift to lift, and when it doesn't, there is a restriction somewhere else."

Achieving an optimum runner shape mandates considerable metal removal from the bowl, the CA, and the short-side radius. For example, the stock 1.580-inch intake CA diameter was moved out to 1.710 with the 1.94-inch valve; the 2.05 valve required removing an additional 0.110-inch of metal (for a final 1.820-inch diameter) to maintain the "perfect" port.

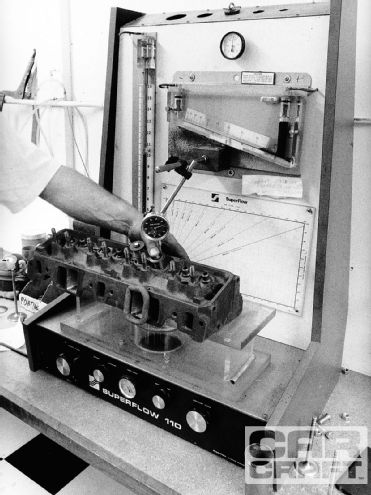

All tests were conducted on GT Alley's fully instrumented SuperFlow 110 flow bench.

All tests were conducted on GT Alley's fully instrumented SuperFlow 110 flow bench.

After the bowl work, the 1.94 intake port flowed slightly better at low lifts but really came alive above 0.350-inch lift. It achieved its peak 225-cfm flow number at 0.650-inch lift. The big 2.05 valve's intake port was still down compared to the 1.94 valve below 0.350-inch lift, equal to the 1.94 at 0.350-inch lift, slightly better between 0.450 and 0.460, and about equal from there on up. The 2.05's average flow numbers-at low lift, at high lift, and overall-are marginally superior to those of the 1.94.

The exhaust side is a different story. There, the 1.50-valve runner demonstrated over a 30-percent max flow improvement compared to stock, while the 1.60 port was up over 45 percent! A peak 180.4 cfm blasted out of the 1.94 port at 0.700 lift, while the 1.60 port hit 200 cfm at 0.650 and 0.700.

Yet, the big intake and exhaust valve ports become saturated at 0.650-inch lift. On the intake side, that's because with the big valve there is now a new critical area-namely, the runner's pushrod bulge. That's also why the 2.05 valve shows only marginal gains over the 1.94, even with bowl work. This is an example where port-matching the intake face would be beneficial.

The basic 1.94-/1.50-inch valve seat and bowl configuration: 45-degree seats tangent within 0.010-inch to the valves' outside edge are 0.060- and 0.080-inch-wide on the intake and exhaust, respectively. Top 30-degree and bottom 60-degree angles complete the valve job, establishing the correct diameter and seat width.

The basic 1.94-/1.50-inch valve seat and bowl configuration: 45-degree seats tangent within 0.010-inch to the valves' outside edge are 0.060- and 0.080-inch-wide on the intake and exhaust, respectively. Top 30-degree and bottom 60-degree angles complete the valve job, establishing the correct diameter and seat width.

The exhaust side doesn't have a pushrod bulge, but for this test the port exit was not enlarged, either. Nevertheless, further improving the exhaust flow without corresponding improvements to the intake flow is not recommended because it would be detrimental to optimum intake/exhaust flow balance (see sidebar).

Fully Ported

Finally, Hupp completely ported both the big- and small-valve runners. "Full porting" included the good valve job, intake entry and exhaust exit port-matching, bowl and short-side porting, and complete runner shaping and polishing. On the intake side, this resulted in peak flow numbers of 249 and 263.6 cfm at 0.700-inch lift for the 1.94 and 2.05 ports, respectively. Of course, the really big gains occur over 0.350-inch lift, but both valves are up throughout the entire tested rpm range. Flow peak to flow peak, we're looking at a 19.7 percent increase compared to stock for the 1.94 port, and a whopping 26.7 percent increase for the 2.05 valve. The port saturation problem has been eliminated at least through 0.700-inch lift, the highest lift point tested.

Fully porting the 1.50 (small-valve) exhaust runner produced no discernable real-world advantage. Overall, it's a wash compared to just bowl and short-side work. Compare that to the 1.60 runner, which flowed a whopping 217.4 cfm at 0.700 lift, up 58 percent over stock and 20 percent over the fully ported 1.50 runner configuration. The shape and overall contour of the exhaust side is critical; to maintain real-world driveability, the overall area (in square inches) of the exit should be equal to the area (in square inches) of the valve head. This means that the 1.50 port exit should not be enlarged to equal the 1.60 port's cross-sectional area. The new small-valve-runner critical area is the limitation of the exhaust valve size itself.

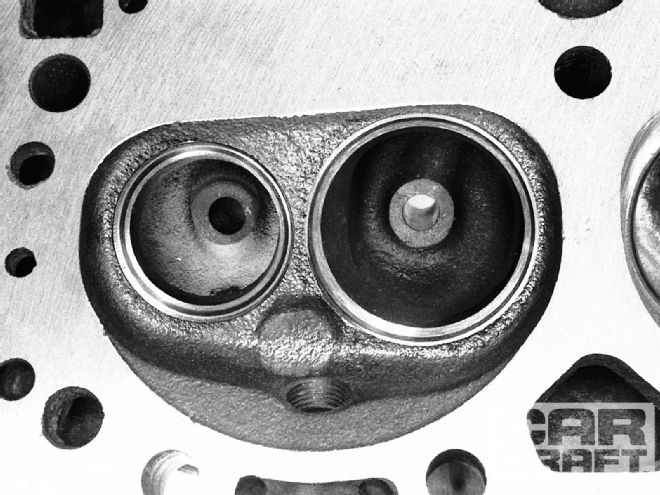

The basic 2.05/1.60 valve seat: Compare the 60-degree cut's width to that of the 1.94 seat; the 2.05 cut is so wide it screws up the blend. Low-lift flow is down because the blend from the critical area to the valve gets screwed up; at high lift, the small throat-area limits max flow.

The basic 2.05/1.60 valve seat: Compare the 60-degree cut's width to that of the 1.94 seat; the 2.05 cut is so wide it screws up the blend. Low-lift flow is down because the blend from the critical area to the valve gets screwed up; at high lift, the small throat-area limits max flow.

Net Worth

These tests showed that stock-size valves work great in a stock-size port (as they were intended to), so long as you get a professional valve job. A good three-angle valve job in conjunction with bowl-porting is the most cost-effective mod; the small valves still perform adequately at this level of modification. For no-compromise fully ported heads, big valves are definitely the answer. If because of rules restrictions you're valve size-limited, fully porting the intake side while only doing the short-side and bowls on the exhaust makes sense. In any case, match-porting isn't required until after you've done the good valve job and bowl work. Naturally, this data is valid only for traditional small-block Chevy heads. Other makes and models (as well as aftermarket race heads) may respond differently.

Does More Flow Always Mean More Power?

Not necessarily. The big flow numbers must occur at a lift that's commensurate with your camshaft. For example, if the flow gains occur primarily over 0.450-inch lift but your cam has only 0.447-inch lift (like the old 327/350hp L79 hydraulic grind did), they won't do you much good. Overall top-end power might increase slightly, but the car might be a dog under part-throttle, daily driving conditions.

Huff points out that it's important to consider the engine as a total combination. How much air and fuel the intake side of the heads suck in determines the engine's peak horsepower rpm point. Decide what rpm you want to achieve peak power at, then have your porter optimize intake flow accordingly. Below is the basic equation relating the max theoretical horsepower rpm point with intake port flow, in cfm. The factor "1.68" converts common 28-inch-water-pressure-flow bench readings to 10 inches. Naturally, it can be algebraically reshuffled to solve for any desired missing variables. With the cylinder head flow established, it's a relatively simple matter to select a complimentary cam, intake manifold, and carb.

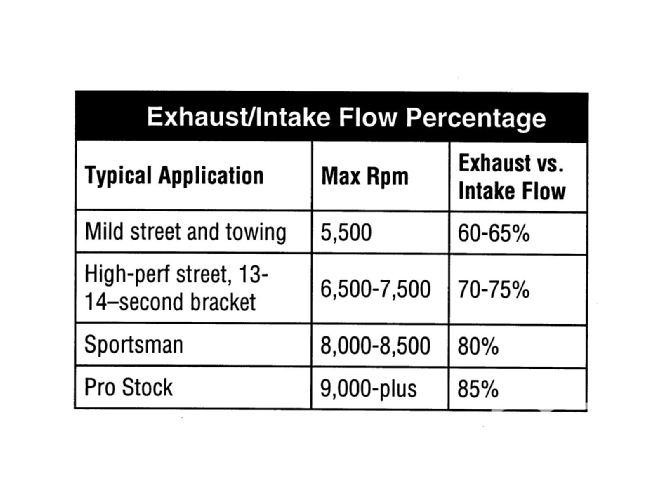

You must also pay attention to maintaining the proper intake/exhaust flow ratio. According to Huff, the exhaust side determines the width of the powerband. The greater the exhaust flow as a percentage of intake flow, the narrower the powerband. He offers these guidelines that equate exhaust flow to the engine's intended maximum operating rpm:

The cylinder head flow table includes both the theoretical peak horsepower rpm points for each stage of the porting mods described in this article (based on a 350ci engine displacement), as well as the exhaust versus intake flow percentages.

The 2.05/1.60 seat after porting the bowl areas: Dial calipers illustrate how much the bowl area is enlarged beyond the original factory dimensions. After relieving the bowl restriction, the intake runner's pushrod bulge becomes the new critical area.

Flow in cfm @ 28in

1.68

x 2000

= Peak hp rpm

Engine displacement (ci)

No. of cylinders

The 2.05/1.60 seat after porting the bowl areas: Dial calipers illustrate how much the bowl area is enlarged beyond the original factory dimensions. After relieving the bowl restriction, the intake runner's pushrod bulge becomes the new critical area.

Flow in cfm @ 28in

1.68

x 2000

= Peak hp rpm

Engine displacement (ci)

No. of cylinders

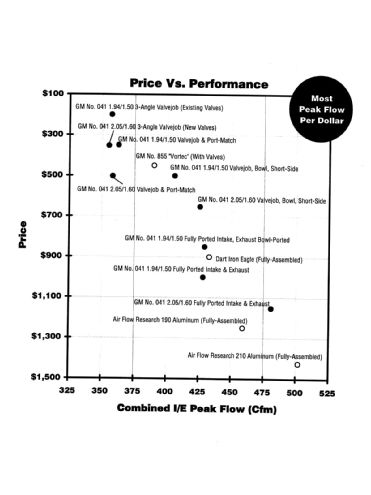

What's It Gonna Cost Me?

That could be a $1,000 question, if you go the fully ported route. On the low-end, you're looking at around $200 for a professional three-angle valve job with the existing 1.94/1.50 valves. Add bowl-porting and a set of big valves and you move up into the $500-$700 range. In terms of performance returned for this investment, the accompanying Price Vs. Performance graph is instructive. It compares the combined maximum intake and exhaust flow observed at each modification stage with the typical cost of those modifications. The data points with locations highest and farthest to the right represent the most return-per-dollar invested.

The now fully ported intake runner is limited only by the need to retain adequate material around the pushrod bulge. The intake entry dimension is enlarged to 1.250x2.050 inches.

The now fully ported intake runner is limited only by the need to retain adequate material around the pushrod bulge. The intake entry dimension is enlarged to 1.250x2.050 inches.

Also included on the chart are four popular aftermarket 23-degree valve-angle heads: GM's late-model 350 "Vortec" LT1 head, Dart's new "Iron Eagle" head, and two Air Flow Research aluminum heads. The combined flow data is taken from our sister publication Chevy High Performance's recent extensive flow tests of popular aftermarket heads, and represents their as-delivered, out-of-the-box configuration. The purchase cost of used 041 heads is not included because we assume you already have a set of stock heads. Pricing for both the 041 heads and the Vortec heads does not include valvesprings or ancillary components. The other aftermarket heads are quoted as complete assemblies.

This scatter-chart reveals several interesting trends. If all you want is a valve job, brand-new GM Vortec heads are a better choice than reusing old heads, delivering more performance for only $100 more. The chart's "sweet spot" (the best balance between performance and cost) is occupied by the 041's valve job, bowl, and short-side porting modification stage. Out-of-the-box Dart Iron Eagle heads are price competitive with fully ported 1.94/1.50 valve 041 heads. Fully porting the 041 heads with the big valves installed offers a better cost/benefit ratio than the high-zoot AFR heads, but the 041 iron units are much heavier and more detonation prone than the AFR aluminum heads. Of course, fully porting any of these aftermarket heads to the same level as our 041s would yield considerably greater performance gains, but the costs could easily double. There's no such thing as a free lunch.

Overall exhaust port volume isn't as important as its overall geometrical shape. Every porter has his pet theory on what the best shape should be-it's one of their "state secrets."

Overall exhaust port volume isn't as important as its overall geometrical shape. Every porter has his pet theory on what the best shape should be-it's one of their "state secrets."