Piston rings hold a bit of a strange place in the engine building world. Circle Track works with lots of engine builders on different engine projects. And almost every engine builder we talk to admits that filing piston rings is the job he enjoys least out of the entire build process. There's no other way to cut it, the process of file-fitting piston rings is tedious, boring, repetitive and-we'll say it again-boring.

But, on the other hand, we've also noticed that engine builders are willing to invest more money than ever in a good set of rings. And that's because a set of well-made, low-tension rings can make power. A high-quality set of rings that are made to exact tolerances and properly ground can reduce the amount of friction produced as they move up and down the cylinder walls while still maintaining good oil control and longevity.

The function of a set of piston rings is to seal the gap between the piston and cylinder wall. Since the piston is constructed from aluminum and the cylinder bore of iron, they will have different expansion rates from the heat of combustion. The ring must also be able to adapt for these changes as well.

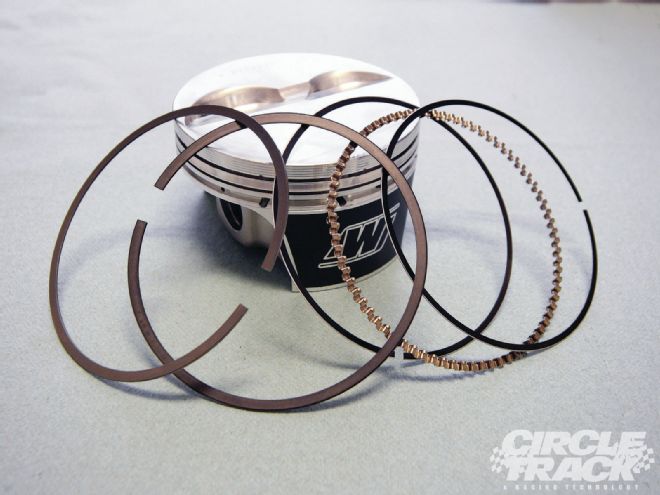

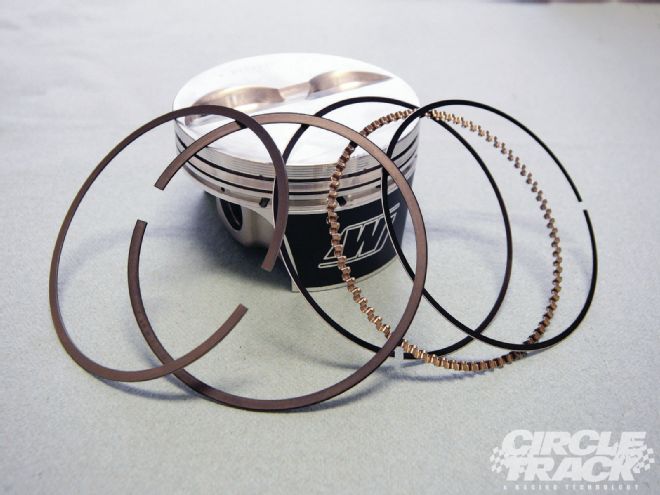

On almost all stock car engines, a package of three rings is used to seal the piston to the cylinder wall. The top ring requires a special construction since it is in direct contact with the flame from combustion and sees the most heat. Most modern racing rings for the Saturday night level use a top ring constructed with a moly coating to help it live in such a harsh environment. But just because it's popular, that doesn't mean that a moly face is the absolute best option for every situation. Wiseco, for example, sells the popular "GFX" ring package with its racing pistons that uses a stainless steel gas nitrided top ring that works extremely well.

The top ring's primary purpose is to seal the combustion chamber so that no gas (or as little as possible) makes it past the piston and into the crankcase. To achieve this, the ring must be precisely gapped so that once the engine is at operating temperature the ring has expanded to the point that the gap has nearly disappeared. Normally, the ring manufacturer will offer guidelines as to how large the gap should be based on several criteria such as the engine's compression ratio, how far down the piston the top ring is located, piston diameter and other factors. It all relates to heat-the more heat the ring sees, the greater the cold gap should be. So the gap for a street rebuild will be less than for a stock car racing motor, and that gap will be less than a ring specified for a supercharged drag racing engine.

A high quality ring pack, like this GFX package from Wiseco, can unleash power by reducing friction as the rings slide up and down the cylinder bores, but properly gapping any ring set is still critical.

A high quality ring pack, like this GFX package from Wiseco, can unleash power by reducing friction as the rings slide up and down the cylinder bores, but properly gapping any ring set is still critical.

For instance, we recently gapped the rings while rebuilding the Circle Track dyno mule. We're using a set of Wiseco 4.030-inch forged racing pistons and a set of GFX rings Wiseco provided to go with them. For circle track racing with these rings Wiseco recommends the cold gap be the diameter of the cylinder bore multiplied by 0.0050 for the top ring and 0.0057 for the second. That equals a top ring gap of 0.022-inch and 0.023 for the second.

The reason the second ring gap is larger is because in racing the purpose of the second ring is primarily for oil control and not to seal the combustion chamber. Any high-pressure combustion gasses that make it past the first ring and get trapped by the second can cause the top ring to flutter, which can significantly affect power production. So the larger gap with the second ring helps allow any gasses to move on past and not get trapped between the first and second rings.

The second ring is typically constructed of a softer material than the first because it is protected from the intense heat of combustion by the top ring. The softer material also helps the ring seal to the cylinder wall better for improved oil control. On most economy-level ring packs the second ring features a taper so that only the bottom portion of the outside edge of the ring comes into contact with the cylinder wall. This helps reduce friction as the ring moves up and down the cylinder bore and also helps it to function better as an oil scraper. But the face of the second ring will wear with engine use, and it must be replaced when the taper is gone so that the entire face of the second ring is in contact with the cylinder wall.

A more advanced design for the second ring is a Napier face. A Napier-style piston ring has a notch or ridge on the bottom of the ring so that the outside edge of the ring is narrower than the inside (which sits inside the piston ring land). This gives the ring extra rigidity inside the ring land where it is most important, but reduces that thickness at the cylinder wall where a thinner ring means less friction. Just a few years ago, Napier-style rings were only used in high-end dry sump race engine applications, but lately they have become more affordable and are used in all types of race engines. The GFX ring package we are using for the dyno mule features a Napier second ring, and Wiseco recommends it for all types of wet- and dry-sump engine packages these days.

Lowest on the piston is the oil ring, which is actually two very thin rings sandwiching an expander ring. The oil ring's only job is to scrape oil off of the cylinder walls and dump it back into the oil pan. Many pistons also use oiling ports off of the land for the oil ring to direct some oil toward the wristpin.

Many street-oriented ring packs come pre-gapped, but that's not precise enough for racing. High end piston rings require the engine builder to gap them specifically to the cylinder bore it will be going into. In general, it is better to gap your rings too large rather than too small. A ring gap that's too big will only suffer from poor control of oil and combustion gasses, but a ring that is gapped too tightly can lead to major engine problems. If the ends of any ring are allowed to butt together, that will lead to scuffing the cylinder walls, and possibly a broken ring or even a busted piston. So you obviously want to avoid that as you tackle the job of prepping piston rings for an engine build.