Did we raise more questions than we nailed down answers? Once upon a time I had this idea: While strolling the aisles at SEMA last November-the largest automotive aftermarket trade show in the universe-amongst all the glitz that is Vegas, I spied a set of hedders (that's how Hedman has always spelled it) for a Pontiac. But these were different; they were shorty hedders-a style made famous by late-model Mustangs, Camaros and Firebirds.

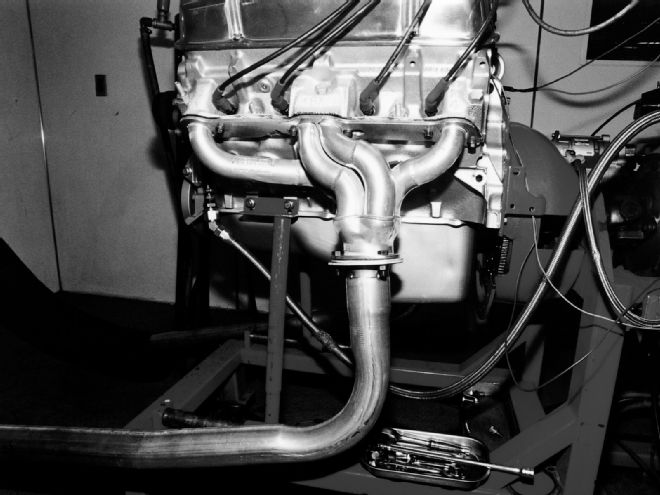

Here is the 455 engine with the Hedman long-tube hedders set up on the dyno.

Here is the 455 engine with the Hedman long-tube hedders set up on the dyno.

They were certainly something new and different for the traditional Pontiac engine, so of course I decided that we should test a set. In speaking with the Hedman reps, I was informed that the display models were prototypes and that sellable versions should be ready after few months. In the meantime I had to get an engine and a dyno facility, and come up with parameters for the test. I felt that the real questions in everyone's mind were:

• Where in the performance ladder would these hedders fit?

• Are they better than stock log manifolds?

• How do they compare with H.O. manifolds?

• Could they possibly be as good as full-length headers?

• Well, there's one way to find out and that was to test them.

A 389 Tri-Power engine had been going together at Jim Taylor Engine Service for some time. We covered the Tri-Power unit's build up and the changeover to screw-in studs for the heads in past issues and the engine was nearing completion. Scheduled to make about 400 hp, I felt that it would be great for testing the shorty hedders against a set of Hedman long tubes, a set of reproduction ram-air/H.O. manifolds and a set of stock log manifolds.

After jockeying for parts, we finally procured a set of shorty hedders and a set of 1.75-inch diameter long tubes from Hedman. Both sets were metallic ceramic coated (called HTC High Tech Coating by Hedman). Jim Wical at Hedman also warned that the shorties don't do much on a stock engine. I assured him that our 389 was not stock. Performance Years provided a set of ram-air manifolds featuring 2.25-inch outlets and Jim Taylor had the factory log manifolds. It appeared that we were ready.

This bird's-eye view of the dyno console reveals all of the controls and gauges as well as the computer for this Stuska unit built by Hoffman Machine.

This bird's-eye view of the dyno console reveals all of the controls and gauges as well as the computer for this Stuska unit built by Hoffman Machine.

Taylor made arrangements with Bitner Automotive in Trenton, New Jersey (609-888-1199,) to do the dyno work and a date was set. HPP contributor, Jim Dietzler, covered the test. Because of a miscommunication between Taylor and HPP, the 389 engine ended up with much less cam in it than we had originally planned. As Jim explained, the customer who purchased the engine in the interim wanted more docile street manners so with the Hedman long tubes installed, the 9:1 compression 389 pumped out 367 hp at 5,400 rpm with 407 ft-lb of torque at 4,350 rpm. Basically, we had Tri-Power engine making stock horsepower yet I promised 400 hp to Jim Wical at Hedman. So we took advantage of the situation that we had and tested the long tubes, the shorties, the ram-airs, and the logs on the Tri-Power engine to learn how they affected a nearly stock powerplant built for low compression.

At this point we had half a test as far as I was concerned. Knowing what these pieces will do on a stock engine is nice background information but what we really want to know is how they compare on a hotter engine. Enter the 450-horse 455 street/strip stump puller that we used for a second dyno test. In setting up the second dyno test, we made one change. The log manifolds were replaced with Ram Air Restoration Enterprises 2.45-inch outlet ram-air manifolds and its 2.50-inch mandrel-bent head pipes. This was going to be a very interesting test. But first let's meet the players.

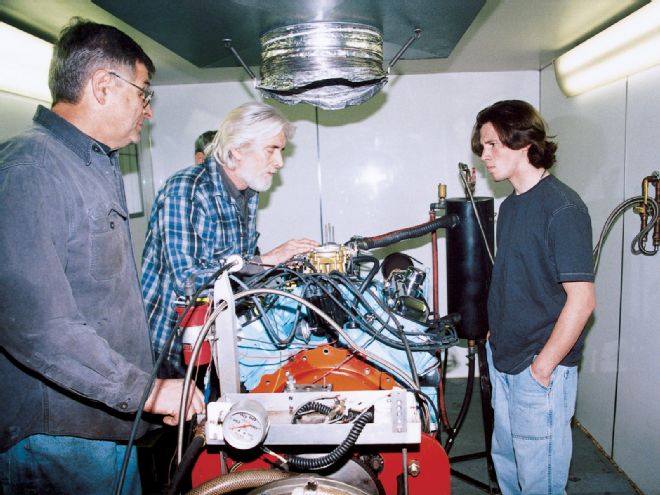

Fred Bitner of Bitner Automotive and Jim Taylor and Mark Erney of Jim Taylor Engine Service check out the Tri-Power's carbs during the first hedders vs. manifolds test.

Fred Bitner of Bitner Automotive and Jim Taylor and Mark Erney of Jim Taylor Engine Service check out the Tri-Power's carbs during the first hedders vs. manifolds test.

About The Contestants

Hedman Long-tube Hedders

The Hedman long-tube hedders are a true 4-tube design that feature a 1.75-inch primary diameter and a 3-inch collector. The tube steel units arrived ceramic coated and have fairly thick flanges to ensure a good seal.

Advantages: The long tubes outperformed the shorties and the manifolds in testing on the 389 and the 455. They look very aggressive under the hood and they are lighter than manifolds.

Disadvantages: Typical fitment and clearance issues in the engine compartment and with the ground come with the territory with all long-tube headers. They also require more care and maintenance and can rust through when they are not ceramic coated or properly painted. Installation can require some gymnastics depending upon the headers' application, the chassis, and the amount of options the Pontiac has. They also require custom head-pipes per application.

Hedman Shorty Hedders

These steel-tube shorties are a new design for Pontiacs. They are also 4-tube units but feature a Torque-Step design with a 1.625-inch primary diameter that opens to 1.75 at a predetermined length from the flange. This distance is based on volume and velocity information input to and determined by a computer program. Hedman's shorty hedders feature the same semi-beefy flanges as the long tubes. The hedders do not fit GTOs as first advertised when HPP got them. A revised design for A-bodies is being developed.

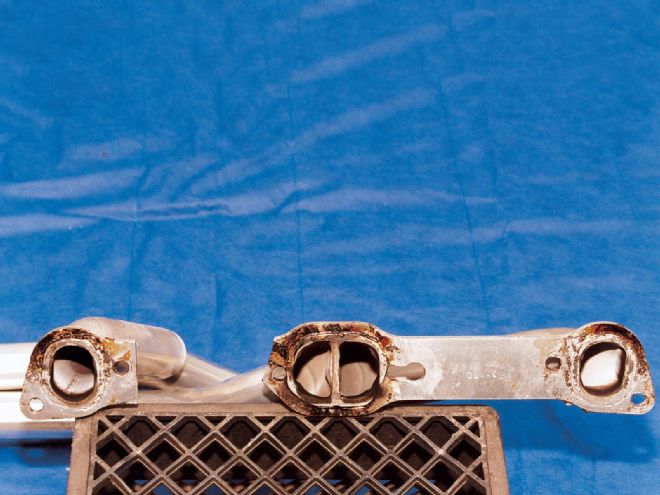

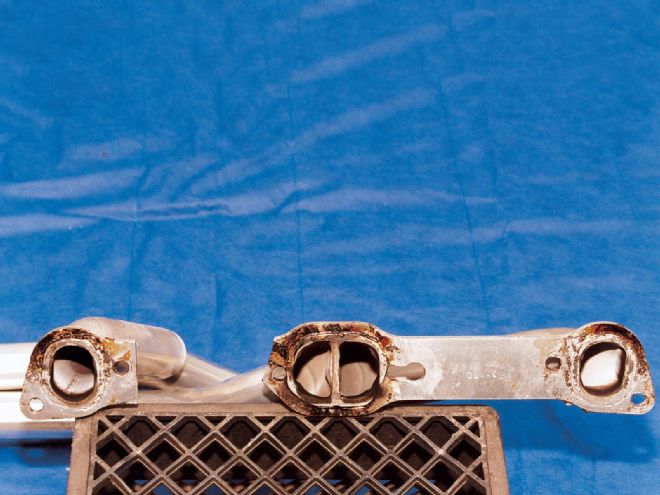

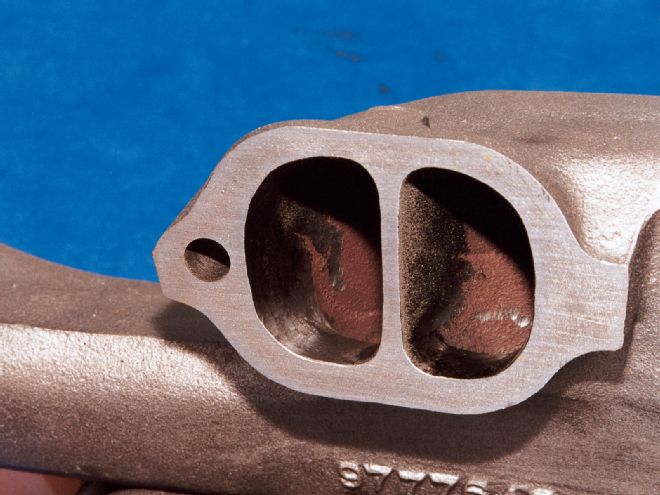

Please excuse the dirty flange as this shot was taken after the dyno runs (also the flange was cut for dipstick tube clearance) they were pristine as delivered. The ports at the flange were uniform in size and clean regarding welding slag on the long tubes.

Please excuse the dirty flange as this shot was taken after the dyno runs (also the flange was cut for dipstick tube clearance) they were pristine as delivered. The ports at the flange were uniform in size and clean regarding welding slag on the long tubes.

Advantages: In theory the fitment issues of the long tubes should be mostly alleviated and the shorties fit '67-81 Firebirds. The Torque-Step design is said to improve torque and peak power. They are lighter than H.O manifolds, perform 1 hp better in our tests and offer some eye candy under the hood.

Disadvantages: Shorties retain some classic woes of headers, i.e. higher maintenance, possible tricky bolt access, and possible rust-out. Also, they require custom head-pipes, which is true for ram-air manifolds when swapped in for logs but at this point there are various outlets for readymade pipes. To date I haven't seen a company making bolt-in head-pipes for these the shorty hedders so you will have to rely on a shop to custom bend them until the aftermarket catches up. They posted less power than the long tubes in both tests.

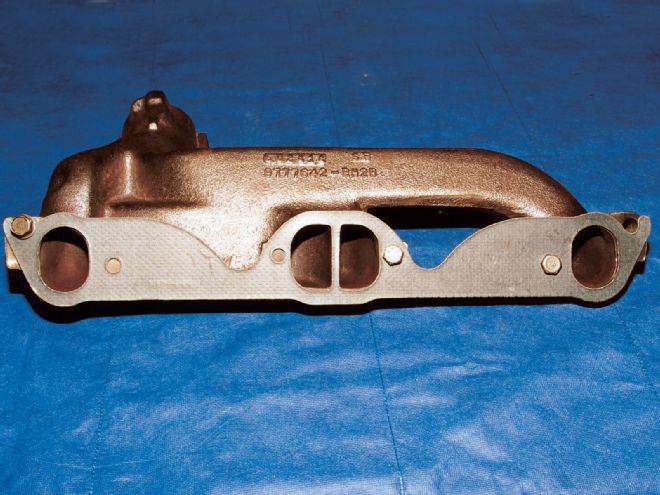

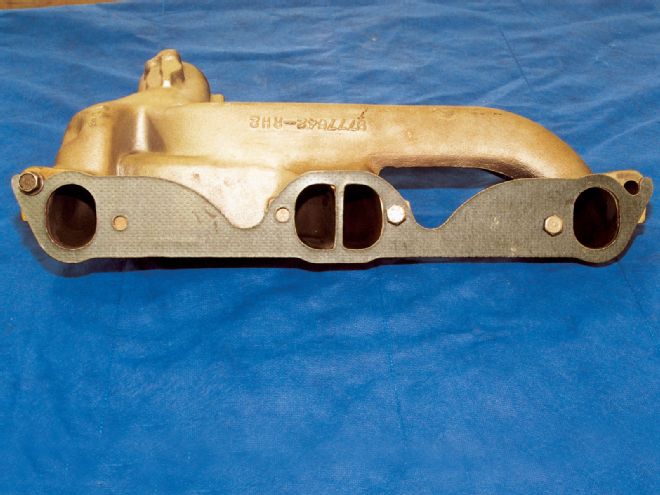

Performance Years Ram-Air Manifolds From Classic Reproductions

These 2.25-inch outlet cast-iron manifolds are based on the factory ram-air/H.O. manifolds that Pontiac designed for its hipo engines of the '60s and early '70s. They are robust everywhere with regard to material, are made by Classic Reproductions, and are distributed through Performance Years and a host of other parts houses, since Classic Reproductions does not sell directly to the public.

But the collector area could use a little bit of cleanup work.

But the collector area could use a little bit of cleanup work.

Advantages: They fit better than headers and are an improvement over log manifolds while retaining a stock look. These repros are cheaper than used factory-made ram-air manifolds due to the latter's rarity. Thick flanges and lots of iron should ensure longevity and they're basically maintenance free except for cosmetics once installed. New mandrel-bent head-pipes are readily available from Performance Years Pypes division.

Disadvantages: These manifolds are much heavier than headers and they produced less power than long-tube hedders in our testing. Each set is delivered rough-cast leaving the owner to clean them up and port match them if he so desires. They require new head-pipes.

Ram Air Restoration Enterprises Ram-Air Manifolds

RARE cast-iron manifolds were delivered dressed for the dyno. The only thing that they lacked was ceramic coating because the deadline for getting them to us was too tight. RARE manufactures its own manifolds and sells its exhaust components directly to the public. These pieces were port-matched and featured more work in the ports than I've seen on some race heads. Owner Paul Delfeld says that they all leave his company this way-port matched based on original Pontiac blueprints. Our units featured a larger 2.45-inch outlet (RARE also has 2.25-inch manifolds).

Advantages: They have similar advantages to the competition's manifolds when comparing them to headers and log manifolds. These pieces were on a diet however, weighing a bit less than the other products and they had much more finishing work done with a gasket match and internal porting performed. New mandrel-bent head-pipes are readily available from RARE and were used for the 455 test.

These are Hedman's new shorty hedders for Pontiacs and the original reason for this test. Ours were HTC coated prior to shipping and arrived very shiny. Here they are bolted up to the engine, with 2.5-inch compression bent pipes, waiting testing.

These are Hedman's new shorty hedders for Pontiacs and the original reason for this test. Ours were HTC coated prior to shipping and arrived very shiny. Here they are bolted up to the engine, with 2.5-inch compression bent pipes, waiting testing.

Disadvantages: Just like the others, they are heavier than headers and produced less power than the long tubes in our testing. Flanges on the manifolds and for the head-pipes are thinner due to the increase in outlet size and the nuts are close enough to the pipes to require an open end wrench to R&R them but a positive flange seal is still achieved. These manifolds require new head-pipes as well.

389 Tri-Power Dyno Test

With hedders and manifolds in hand, contributors Jim Dietzler, Jim Taylor, and Mark Erney headed over to Bitner Automotive to test the exhaust pieces on the 389 Tri-Power. Here are the results of that dyno test.

The Hedman long-tubes performed best followed by the ram-air manifolds, then the logs and the shorties followed. I was told that the shorty hedders didn't do much on stock engines but less than logs was surprising. In another test performed by Terry McGean at Car Craft the shorties showed no horsepower gain over logs on a stock 455 but showed some torque increase (after mods the shorties performed well). However that wasn't the case with this test. So we were curious. As you will learn, the showing of the shorty hedders may not have been the fault of the hedders. More on that later. See "389 Tri-Power Dyno Results" chart for the numbers.

Pipe Extensions

In order to run these varied manifolds and hedders on the dyno, extensions had to be made to reach from the manifolds/hedders to the dyno exhaust pipes to ferry the spent gasses out of the chamber. Due to the angles of the outlets of each of our manifolds and hedders, and the different sizes needed, custom pipes had to be made for each set that we were testing. Yes we were adding a second variable to the testing but we felt that there was no choice at the time given the constrictions. Also, there is no way that you can use the same piece of pipe on the long tube, on the shorty and the manifolds anyway. And the 2.25 outlet manifolds were to use a 2.25 diameter pipe and the 2.45-inch outlet manifolds a 2.50-diameter pipe in the second test.

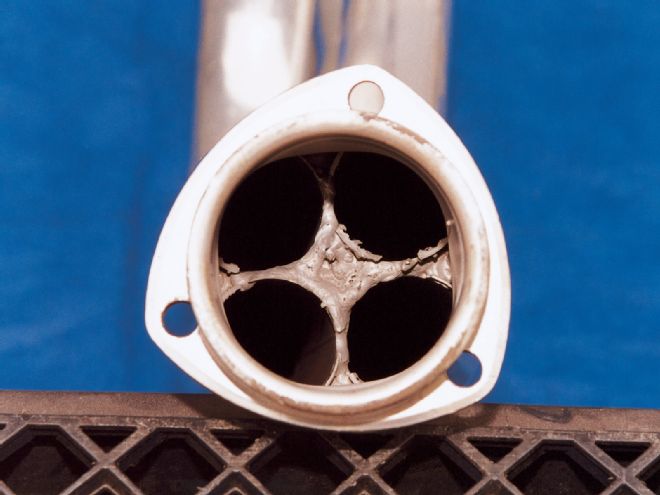

Check out the as-delivered gasket match of the RARE manifolds. (Note, the gasket shown was used for comparison only, it's not the metal gasket provided by RARE.)

Check out the as-delivered gasket match of the RARE manifolds. (Note, the gasket shown was used for comparison only, it's not the metal gasket provided by RARE.)

So Dave and Keith at a nearby Meineke Car Care Center took on the task of expertly making extension pipes for the each set of hedders and manifolds to feed into the dyno exhaust. Would the different compression-bent pipe designs make a difference in the numbers? Read on.

455 Dyno Test

Finally, we would learn what these products are worth on an engine that makes some serious power. As Taylor related, "this engine is very typical of what guys are building today. It's a 9.0:1 .030 over 455 with 6x heads and a 228-degree cam. It's not a tricked-out, thinly disguised, race engine just to post big dyno figures but one that will provide ample power in a street/strip car and stay together."

When we got to Bitner's we had high hopes for a solid performance from all of our contestants. The engine was bolted to and run on the dyno to get it up to operating temperature and to check that the sensors, electronics, fuel, and cooling hookups were attached correctly. Water temperature, oil temperature, and fuel pressure were monitored on the console. Fred Bitner ran each test. His son, Mark, took care of the computer and the printouts, while Jim Taylor and Mark Erney swapped the exhaust parts, and I took photos of all of the parts, the engine, and the dyno.

Though tough to see beyond the gasket match in the photos, there was a lot of cleanup and finessing inside the ports as well. At first blush you might think that these are ringers, but owner Paul Delfeld has assured us that all of his manifolds receive this same attention prior to shipping.

Though tough to see beyond the gasket match in the photos, there was a lot of cleanup and finessing inside the ports as well. At first blush you might think that these are ringers, but owner Paul Delfeld has assured us that all of his manifolds receive this same attention prior to shipping.

The engine was untouched for the duration of the test. Timing was set to 36 degrees and jets were #80 square. The only changes for each test were the manifolds/hedders and their accompanying pipe extensions.

After a few shakedown pulls the engine hit its stride and produced 443 hp at 5,400 rpm on a pull that began at 4,350. It also posted 450 hp on a pull that began at 4,700 rpm but since all of the other pulls began in the 4200-4300 range we used the 443 hp pull for comparison. Then two pulls were made with each set of manifolds/hedders in place. The highest horsepower runs of the 2 are listed in the chart "455 Dyno Test Results With Compression Bent Custom Exhaust Extensions."

The long-tubes were fitted with 2.5-inch straight extensions from the collectors to the dyno exhaust. A set of 2.5-inch mandrel bent pipes were installed on the RARE manifolds, 2.25-inch compression bent pipes were installed on the Performance Years manifolds and 2.5-inch diameter compression bent pipes were used on the shorty hedders.

Once again the long tubes were the heroes posting 20 more hp than the rest of the pack but we were curious about the Performance Years manifolds and the Hedman shorties, which still seemed to be struggling.

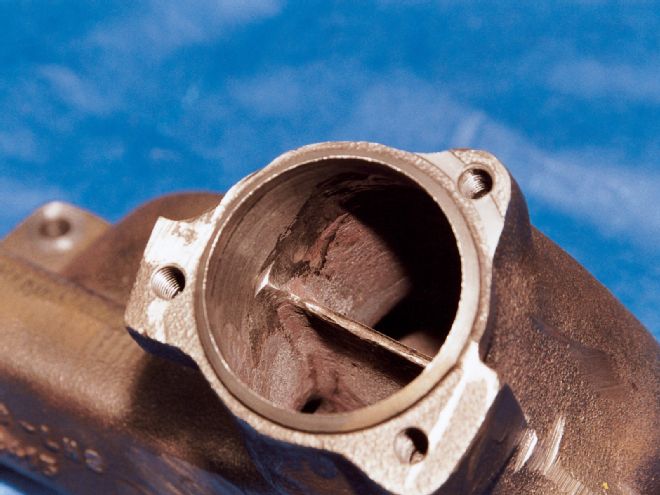

The RARE manifold shows off its 2.45-inch outlet and the work inside the manifold to open up the area. Notice the flange mounting area is not as wide as the 2.25-inch manifolds because of the larger opening but it still seals properly.

The RARE manifold shows off its 2.45-inch outlet and the work inside the manifold to open up the area. Notice the flange mounting area is not as wide as the 2.25-inch manifolds because of the larger opening but it still seals properly.

Unlike the 389 test, for this outing we had the mandrel-bent pipes from RARE that were sent with the company's manifolds. After some careful eyeballing, it was determined that we probably could put these pipes on both the Performance Years 2.25-inch manifolds (2.50-inch pipes will fit on the 2.25-inch manifolds) and with a couple of extensions quickly welded on, we could get them to clear the dyno on the Hedman shorty hedders. The results were very interesting.

As you can see in the chart "455 Dyno Test Results With Mandrel-Bent Extensions," the compression-bent pipe extensions were a restriction. Thankfully the RARE pipes were designed in such a way that they would fit on the different manifolds and shorties and would allow us to remove that second variable in the test.

An important point to consider is that many of you reading this story probably have compression-bent pipes on your Pontiacs right now. You can see what a difference it made in this test with the Hedman shorties especially considering the fact that it was 2.50-inch compression bent vs. 2.50-inch mandrel-bent pipes. But we won't blame it all on the compression bends. With the Performance Years manifolds the compression bent pipe was 2.25 inches and the mandrel bent was 2.5-inch so there was an added benefit there aside from pipe design. Another consideration is how sharp the bends are in the pipes as well. Our compression-bent pipes had 90-degree bends in some, where the mandrel pipe bends were much less angled. Pipe diameter and the sharpness of its turns conspire to help or hurt performance. This is no reflection on Meineke as they were given very rigid instructions for our pipes.

A Little Bit Of Flow Info

For comparison sake, a representative port of each of the ram-air exhaust manifolds was flowed. Taylor flowed the # 8 port because it is known to be the most restrictive. He made a fixture to flow the port on a Superflow 110 bench sans a cylinder head. Though a gasket match has been said not to pick up flow it seemed to in this case for the ram-air manifolds from Performance Years. An as-cast manifold flowed 172 cfm, while a gasket-matched manifold flowed 185 cfm. The RARE manifold flowed 190 cfm and were delivered already gasket matched. Time of course was an issue so other ports were not flowed nor were the hedders.

While this set has been gasket matched by Jim Taylor and these were the manifolds that were tested. Jim reasoned that he wanted to "level the playing field" so that the test wasn't merely one of finish work at the gasket area but the true performance of the manifolds. We had no as-delivered Performance Years manifolds at the dyno test so whether or not the gasket match actually improved performance is not known.

While this set has been gasket matched by Jim Taylor and these were the manifolds that were tested. Jim reasoned that he wanted to "level the playing field" so that the test wasn't merely one of finish work at the gasket area but the true performance of the manifolds. We had no as-delivered Performance Years manifolds at the dyno test so whether or not the gasket match actually improved performance is not known.

Conclusion

Did we really prove anything with this test? Sure we did. Basically, long-tube headers are still the best choice for peak performance. You can argue that since the long tubes we used were for a Firebird instead of a GTO that they may have had an advantage. But with all of the variations of long-tube headers available that differ due to options or drivetrains in the same chassis you would have to test every header made for GTOs and Firebirds to prove that point. Also note that all of the other hedders and manifolds tested fit more than one application already.

Shorty headers do have a place in the line-up. In our second test with the mandrel-bent pipes they posted 1 hp better than the RARE manifolds and 3 better than the Performance Years pieces. They are much lighter than the manifolds and will provide some sparkle under the hood with HTC coating. On how they fit in an engine compartment we cannot comment since we did not install them in a Pontiac chassis.

RARE's ram-air manifolds performed admirably in our test as well. Whether or not the 2.45-inch outlet is necessary for your combination you can decide. They did show a flow increase on the #8 port that we tested over the 2.25-inch outlet manifolds but the dyno sheets showed only a little improvement in power. Remember however, the Performance Years pieces got a gasket match after delivery and the RARE preparation of its manifolds prior to shipment was intense and included a port match. If you opt for RARE's Thermal Barrier Coating (TBC) in silver or gray, its manifolds should be maintenance-free once installed. Also, the 2.50-inch mandrel-bent pipes that RARE sent with the manifolds proved their worth by outperforming the compresssion-bent extensions that were made for the test.

Here you can see that the gasket match went just .5-inch into the port. According to Jim, all other areas of the manifolds were untouched.

Here you can see that the gasket match went just .5-inch into the port. According to Jim, all other areas of the manifolds were untouched.

The Performance Years ram-air manifolds held their own very well against the stiffest competition that they will ever face. As stated, these manifolds are delivered with no prep work so the gasket match and some cleanup work inside are up to you.

Hedman shorty hedders are for the Pontiac owner who wants a modified look and better performance than log manifolds without the normal headaches of long-tube headers. Both sets of ram-air manifolds are designed for the hobbyist who likes to surprise the competition with a stock looking combo that puts out serious power. On those bases all of these products deliver.

After all of the testing and hedder/manifold swapping and pipe swapping in the 455 test we ultimately saw a 3 hp difference between the 2 sets of manifolds and the shorty hedders. And a mere 5 ft-lb spread in measured peak torque between them (note that actual peak torque production in the engine would be reached at lower than 4,300 rpm). Average horsepower and torque figures were nearly identical. It's pretty obvious that any of these pieces would be a great choice for a performance improvement for your Pontiac. You just have to decide, which look you are going for and weigh all of the advantages and disadvantages discussed in this article.

Our dyno engines for both tests held up perfectly. Jim Dietzler, Jim Taylor, Mark Erney, and the staff at Bitner Automotive put in a lot of hours to help get this story done so we thank them for their efforts along with Dave and Keith at Meineke Car Care Center for the extension pipes.

Once upon a time I had an idea for a hedder test. Hopefully, it will now be of service to readers contemplating exhaust upgrades on their Pontiacs.

389 Tri-Power Dyno Results Part Peak HP/RPM Peak Torque/RPM Avg. HP Avg. Torque Hedman Long-Tube 367 at 5,400 407 at 4,350 355 382 Perf. Years Ram-Air 355 at 5,300 400 at 4,400 346 372 Log manifolds 347 at 5,300 395 at 4,350 339 364 Hedman Shorty 342 at 5,300 386 at 4,350 333 357All power numbers are rounded to the nearest whole number; all rpm rounded to nearest 50 all horsepower and torque figures were corrected using a factor of 1.048. Averaged figures calculated from the 4,350 rpm to 5,500 rpm range.

455 Dyno Test Results With Compression Bent Exhaust Extensions Part Peak HP/RPM Peak Torque/RPM Avg. HP Avg. Torque Hedman Long-Tube 443 at 5,400 479 at 4,300 424 456 RARE Ram Air 423 at 5,300 471 at 4,300 409 439 Hedman Shorty 414 at 5,300 469 at 4,250 402 435 Perf, Years Ram Air 404 at 5,300 458 at 4,250 394 424All power figures are rounded to the nearest whole number; all rpm rounded to nearest 50. Torque and horsepower were corrected to a factor of 1.055. Average figures calculated from the 4,300 rpm to 5,500 rpm range. The RARE manifolds used 2.50-inch mandrel bent pipes provided by the company.

455 Dyno Test Results With Mandrel-Bent Extensions Part Peak HP/RPM Peak Torque/RPM Hedman Long-Tube 443 at 5,400 479 at 4,300 Hedman Shorty 424 at 5,300 470 at 4,250 RARE Ram Air 423 at 5,300 471 at 4,300 Perf. Years Ram Air 421 at 5,300 470 at 4,250All power figures are rounded to the nearest whole number; all rpm rounded to nearest 50 torque and horsepower were corrected to a factor of 1.055 Note the Hedman long tubes and the RARE manifolds were not retested.

Best HP Dyno Pulls Of The 455 Test

In these pulls the shorty hedders, the RARE manifolds and the Performance Years manifolds all have the 2.5-inch mandrel bent pipes.

All power figures are rounded to the nearest whole number; all rpm rounded to nearest 100 Torque and horsepower are corrected to a factor of 1.055.

About The Dyno Engines

Both of our test engines the 389 Tri-Power and the 455 4-barrel were built by Jim Taylor Engine Service. Their pertinent specs are listed below.

Notes:

• A metallic ceramic coating called HTC can be applied to the Hedman hedders for $250 per pair.

• Hedman Hedders are delivered with gaskets, bolts and reducers and GTO shorty hedders are coming soon.

• A Thermal Barrier Coating can be applied to the RARE manifolds in silver or gray for $169 per pair.

• Performance Years Pypes Division has mandrel-bent head-pipes and larger outlet manifolds and RARE has smaller outlet manifolds as well, but since these products were not tested for this article, they are not included in the chart above.