Without a doubt, one of the most impressive looking engines of all time is the Chrysler Hemi. But before you get carried away with images of black wrinkle-finish valve covers installed on bright orange blocks and heads, there's something we need to remind you. The Hemi was around 13 years before all these muscle car guys came in and stole the Fire Power's thunder. Most of us are aware of the origins of the early Hemi and the fact that not only did Chrysler use them to power some of their passenger cars, among other things, but so did Chrysler's Mopar sibling companies: DeSoto and Dodge. And by the time those bright orange engines were running NASCAR, the older Hemis had already been proving themselves on the streets, at the drags, and at the lakes for years. Just ask Don Garlits, the Chrisman brothers, or Fred Larson and Don Cummins, all of which had very successful early Hemi-powered race cars in the '50s and on. When Chrysler pulled the plug in 1958, the Hemi's reputation had already been firmly established as the motor to beat.

This would be all fine and good if this were 1958 and there were piles of engines in the junkyard or available at the local Mopar dealer. Problem is, it ain't 1958, it's 2010 and 59 years have passed since the first-gen block rolled off the assembly line. But while the engines themselves are slightly more elusive than they were 50 years ago, there exists today a booming aftermarket industry that supports vintage engine builds such as the early Hemi, perhaps in a more progressive way today than ever before. A number of the weak spots in those old engines have been addressed, such as the water pumps, which companies like Hot Heads offers adapters to run readily available small-block Chevy pumps in their place, as well as adapters for more transmissions than you can shake a stick at. And internal items such as pistons, bearings, seals, gaskets, rings, cranks, and camshafts, and even CNC'd aluminum heads are all readily available.

The point is, it's easier today to build up a reliable vintage engine such as the Hemi than it's ever been. And with every John, Dick, and Harry running small-block Chevy crate engines, dropping a vintage mill in your truck ensures that it will standout from the crowd and separate you from the cookie-cutter guys. In a hobby where it's nearly impossible for the average guy to build a truck in his garage that competes with what the pros are doing, dropping in a vintage engine ups the ante that little bit that just may set it head and shoulders above the rest.

That was exactly my mentality when it came time to pick a mill for my '52 F-1 pickup. Sure I could have ordered up a crate engine from any of the suppliers across the country and I probably could have had my project on the road months ago, but who wants to take the easy way out? Always up for a challenge and wanting to do something different, I set out hunting for a good candidate to power my truck. As luck would have it, I found one locally in a barn that looked pretty clean and didn't appear to be too worse for wear. The price was right, a deal was struck and soon I was heading over to Speed-O-Motive with the engine in the back of my parts hauler to give those guys a thorough headache with my vintage "gem."

Speed-O-Motive has been known as the stroker experts since 1946, so there was no doubt in my mind that they would be the perfect choice to handle the machining chores. Another name synonymous with vintage engines is Egge Machine Company, who supplied all the internals for the Hemi, save the camshaft, crank, rods, and springs. They run a first-class business that cast pistons for everything from, well, Flatheads to Hemis, and also stock every internal part you can think of for vintage engines from 1900 to 1980. A camshaft was ordered up from legendary Mooneyes, ground by the master himself, Bill Jenks. With a spec sheet with that much history, I was sure to be in good hands!

With the 331ci Chrysler Hemi receiving the green flag from Speed-O-Motive, it was back in my hands to start assembling the rotating assembly, heads, and valvetrain. Being a greenhorn to a full-on engine rebuild, I was slightly hesitant to jump right into the assembly as I thought it would be quite a shame to ruin all the hard work that the machine shop had done. Suffice it to say, I learned a lot along the way, with many thanks to those who had to suffer with my constant pestering. I can't say enough kind things about those involved, namely the crew at Speed-O-Motive, Egge, Hot Heads, and Mooneyes for dealing with my "newby" questions. If there were ever any reluctance in getting your hands dirty building a vintage engine, sleep easy knowing that there's a number of people in our industry who are not only knowledgeable enough to provide you with the know-how to tackle such a project, but that they're more than willing to explain things and walk you through some of those head scratching problems that you may come across.

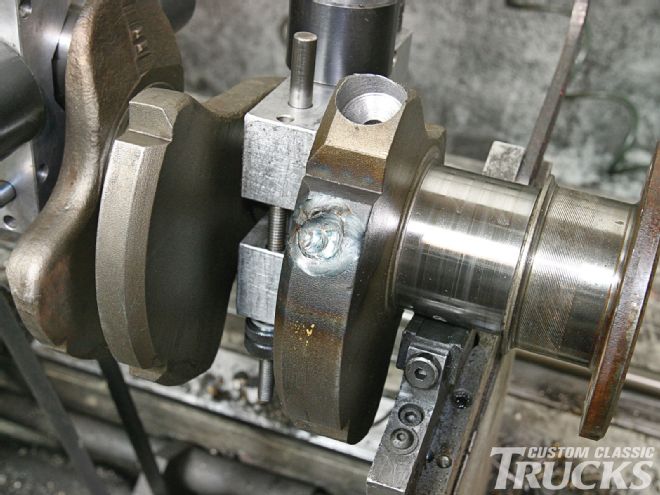

All engine machine work was accomplished by Speed-O-Motive using their Rottler CNC machines. Everything from boring and decking the block...

All engine machine work was accomplished by Speed-O-Motive using their Rottler CNC machines. Everything from boring and decking the block...

Building a vintage engine can be shrouded by old time voodoo secrets, ancient magic, and must-do speed tips, but be forewarned that a knowledgeable machine shop coupled with a competent parts supplier can take that ancient relic of Detroit's past and dumb it down to a tractor motor. The internal combustion engine is going on 100-plus years and while a great many innovations have been made, it all boils down to a simple few points. Get the gas in the cylinder, make it explode, expel the burn, and create power to get you down the road. There have been leaps and bounds in technology, but the general idea has been the same since Henry Ford first took the Model T coast to coast.

That said, I was able to convince myself to act as the guinea pig for those who wanted to build a vintage engine and do it in the confines of their home shop. I've worked on the Mooneyes dragster and even moonlighted on a Bonneville race car that made it into the 200 mph Club in 2004 (Todd Haas' So Cal Speed Shop-sponsored '34 roadster), but that hardly means I knew what I was doing. I was simply a bystander at the feet of bigger and better tuners, fabricators, and racers. But I had the itch and that's all that matters.

With this 331ci Chrysler build however, I was convinced that I could bring a down-home, do-it-yourself perspective to show that you don't need 40 years experience to assemble a reliable, vintage powerplant. Armed with fellow staffer Ron Ceridono's priceless Chrysler Hemi Engine Manual and the support of the named aftermarket companies, assembling the early Hemi has been both a labor of love and a fruitful provider of frustration. But as it came together, I've been exceptionally pleased with not only the fact that I did it, but that it will work and provide me with years of satisfaction as I'm driving the F-1 that it will eventually see life in. Sure a crate motor may have been the easy way out, but do you think that Michelangelo would have ordered up templates to paint the Sistine Chapel over the internet had he been given the opportunity 500 hundred years ago? I think not!

While building a vintage engine can have its ups and downs, today's vast aftermarket industry makes it easier than ever to build a bulletproof vintage engine that is as reliable as any crate motor out there. Just remember that if you can't find something that applies to your particular project, it doesn't mean it doesn't exist, but sometimes it is necessary to think outside the box.