There are still a bunch of hard-core real Pontiac enthusiasts out there keeping the old Indian alive, and they remember the glory days when a well-built Pontiac could run up front with anything. The only things lacking to do the same today were modern 21st century cylinder heads.

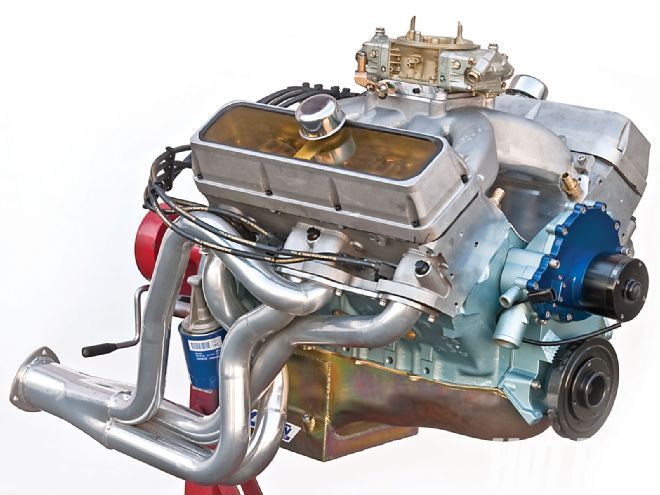

Equipped with a Scat rotating assembly, a Comp solid roller cam, Roland heads, a 1,000-cfm Holley atop a 1-inch spacer on a Roland single-plane intake, Hooker headers, and a Meziere electric water pump (PN WP103B), this Hardcore Racing-built street/strip 495 Pontiac makes 679 hp and 603 lb-ft on 91-octane gas. Bring it on, Rat motors!

Equipped with a Scat rotating assembly, a Comp solid roller cam, Roland heads, a 1,000-cfm Holley atop a 1-inch spacer on a Roland single-plane intake, Hooker headers, and a Meziere electric water pump (PN WP103B), this Hardcore Racing-built street/strip 495 Pontiac makes 679 hp and 603 lb-ft on 91-octane gas. Bring it on, Rat motors!

That's where the guys at Roland Racing came in: They took a clean sheet of paper and designed a canted-valve cylinder head for the traditional Pontiac V-8 that still uses many off-the-shelf parts from other engine makes to keep costs under control. The end result is a state-of-the-art head with intake flow numbers akin to such mainstream big-block Chevy heads as Brodix's BB-1 series.

With modern, high-flowing Pontiac heads finally available, big-inch Pontiac motors are no longer just head-limited torque monsters-they have the potential to make big power numbers, too. Witness this pump gas ultimate street engine built by Andy Mitchell of Hardcore Racing Engines for one of his Australian customers. Based on a 400ci production Pontiac block, it's packed with a Scat rotating assembly for 495 ci and a Comp Cams bumpstick and valvetrain components, then topped off with Roland's big, new cylinder heads to produce at least a 680hp/603-lb-ft package ready to chew up the pavement.

As radical as the new package is, it barely taps the potential of the Roland heads, which were installed out of the box with no porting. More radical porting and machining options plus new aftermarket Pontiac blocks could easily support up to 577 ci and 1,100-plus horsepower.

The engine design may be half a century old, but now Pontiac fans can once more proudly proclaim, "We have a contender."

Roland CV-1 Heads

Roland CV-1 canted-valve heads are a departure from anything previously seen on a real Pontiac V-8, but they are also different from typical Chevy or Ford canted-valve heads. Unlike other canted designs, on CV-1 castings, the valve heads seat horizontally in the chamber. Combined with rolled-over valve angles, this permits the use of larger valves for a given bore size, particularly important with the relatively small-diameter bores found on production-based Pontiac blocks. The valves are tilted toward the center of the bore, so as they open they move farther away from the cylinder wall, unshrouding the valves for improved flow.

As cast, the CV-1 intake ports displace 285 cc, perfect for 428 through 535ci engines with the correct cam and gearing. There is a 215cc port available for smaller engines or for use in high-end apps where extensive custom porting is desired. The heads have all the stock accessory boltholes, even those for air conditioning.

As cast, the CV-1 intake ports displace 285 cc, perfect for 428 through 535ci engines with the correct cam and gearing. There is a 215cc port available for smaller engines or for use in high-end apps where extensive custom porting is desired. The heads have all the stock accessory boltholes, even those for air conditioning.

The CV-1 intake port design eliminates the pushrod restrictions found on typical Poncho heads, yet on standard Roland castings, offset lifters and/or rocker arms are not required (although there is an optional version with minimized pushrod scallops for max porting that does mandate offset rockers). Unique-length head bolts or studs will be required. Hardcore offers a kit using ARP fasteners (PN CV-1HBK).

The intake side requires complementary CV-1 intake manifolds, but the D-shaped exhaust ports are based on the traditional round Pontiac Ram Air IV pattern, raised approximately 3/8 inch over stock for improved performance (most off-the-shelf Ram Air IV-style headers should still work). There's also a high-end convertible-exhaust option that removes most of the long Pontiac runner for high-end racing that does require custom headers.

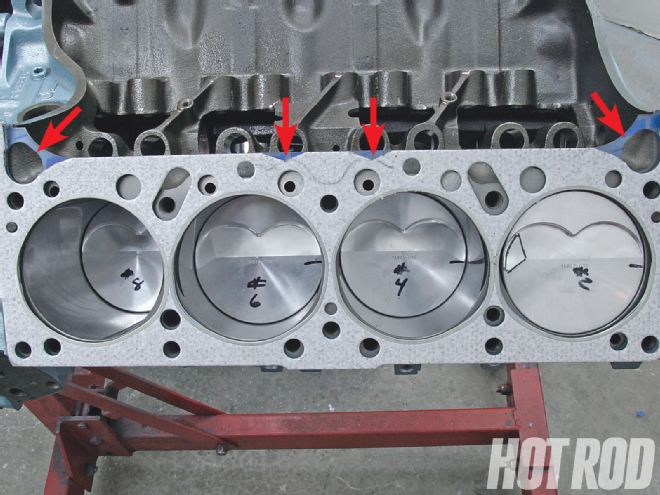

While no block clearance-grinding is needed to accommodate the different pushrod angles, off-the-shelf Pontiac head gaskets need modification in four places for exhaust pushrod clearance, as shown (arrows) by Mitchell's reworked Mr. Gasket gasket (PN 5810) overlaid on an unmodified Fel-Pro version (PN 1016).

While no block clearance-grinding is needed to accommodate the different pushrod angles, off-the-shelf Pontiac head gaskets need modification in four places for exhaust pushrod clearance, as shown (arrows) by Mitchell's reworked Mr. Gasket gasket (PN 5810) overlaid on an unmodified Fel-Pro version (PN 1016).

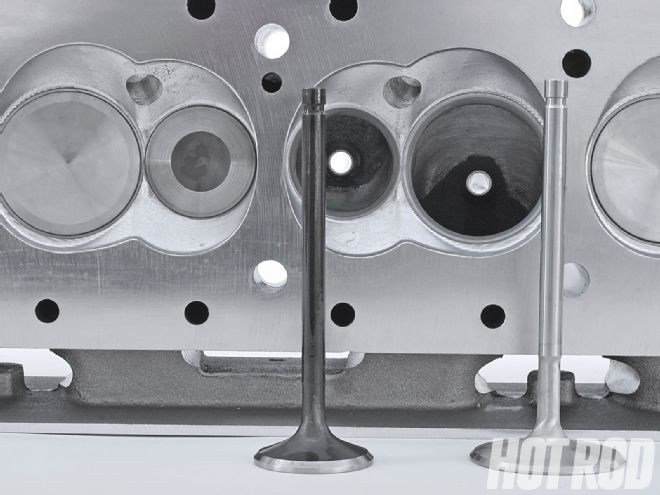

SI supplied the stainless valves used on the standard, as-cast Roland heads installed for this build. The 2.3-inch intakes are for a big-block Chevy; the exhaust side uses a 1.71-inch Ford Cleveland-style valve with SI's Black Knight antiheat coating.

As tested on Westech Performance's SuperFlow bench, the heads flow just under 350 cfm at 0.700-inch lift on the intake side. Even by conservative estimates, that's sufficient to support about 720 normally aspirated horsepower. And the flow just keeps on climbing all the way through a full 1.00-inch valve lift.

Dual-quench 65, 81, or 92cc chambers have opposing squish pads for uniform mixing and a centralized spark plug location to equalize flame fronts and reduce required ignition lead. Up to 2.35-inch intake and 1.73-inch exhaust valves can be accommodated. This motor uses 2.3/1.71-inch valves in the 92cc chambers.

Dual-quench 65, 81, or 92cc chambers have opposing squish pads for uniform mixing and a centralized spark plug location to equalize flame fronts and reduce required ignition lead. Up to 2.35-inch intake and 1.73-inch exhaust valves can be accommodated. This motor uses 2.3/1.71-inch valves in the 92cc chambers.

Head Flow Data

As-cast Roland heads with 2.30-inch intake and 1.71-inch exhaust valves were flowed at 28 inches of water with the heads installed over the listed bore-orifice sizes; a 0.50-inch radiused guide was used on the intake and a 2-inch flow tube on the exhaust. All values are in cfm, except lift, which is in inches.

4.175-INCH BORE

4.385-INCH BORE

LIFT INT. EXH. INT. EXH. 0.05 28 24 34 22 0.10 72 61 71 56 0.20 145 114 148 114 0.30 220 230 142 150 0.40 273 166 294 175 0.50 303 186 331 193 0.60 330 202 360 210 0.70 349 211 378 220 0.80 358 220 389 232 0.90 373 230 400 233 1.00 385 240 414 244Block And Rotating Assembly

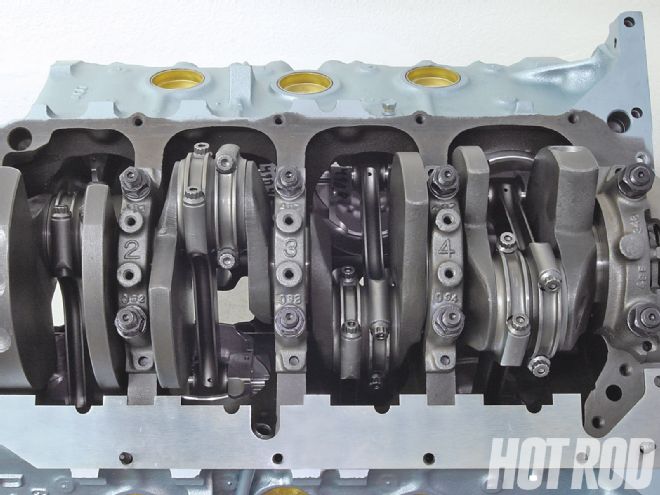

Mitchell started with a run-of-the-mill 400-inch production two-bolt-main Pontiac block. Why not use a larger 428 or 455? First, scarcity: Used 400s are still plentiful; their larger sisters are not. Second, bearing speed: The 400's smaller 3-inch main journals hold up better at high rpm than the 428/455 engine's huge 3.25-inch mains: The larger the journal diameter, the faster any point on the journal's circumference must travel as it rotates at a given rpm, putting greater stress on the bearings. A larger journal's added surface area also increases friction.

If you can find one, a four-bolt main block is preferred; however, two-bolt main blocks hold together through 6,500 rpm if ARP studs (PN 194-5401) are used to retain the caps (using ARP assembly lube, torque the rear cap to 105 ft-lb and the others to 85). Hardcore's crank scraper (PN HRP-400) helps the crank shed drag-inducing oil.

If you can find one, a four-bolt main block is preferred; however, two-bolt main blocks hold together through 6,500 rpm if ARP studs (PN 194-5401) are used to retain the caps (using ARP assembly lube, torque the rear cap to 105 ft-lb and the others to 85). Hardcore's crank scraper (PN HRP-400) helps the crank shed drag-inducing oil.

The block was bored 0.065 over to yield a 4.185-inch bore. The weird overbore is for greater ring set availablity; it's the same as a 0.060-over 400 small-block Chevy. With a Scat 4.5-inch-stroke crank and rotating assembly kit (PN 1-41610) that includes rods, pistons, and bearings, displacement comes in at 495.2 ci. Most 400s can go 0.090 over if desired, which with the same crank yields a 501. The main bearings are Clevite 77 standard replacement, as full-race Pontiac main bearings aren't available. However, the 2.20-inch-od big-block Chevy-sized rod journals run full-race Clevite 77 Chevy H-series bearings that support 6.7-inch center-to-center Scat big-block Chevy-style rods. Mitchell runs relatively tight clearances for a Pontiac: 0.0028-inch clearance on both the mains and rods, 0.004-inch crank thrust, and 0.014 to 0.018 rod side clearance.

Preferring a smooth cylinder wall finish, Mitchell honed the block with a torque plate and a 280 Sunnen stone before making a pass with a plateau brush to break off any remaining sharp edges. With a zero-decked block, the Mitchell-modified pistons' -5.5cc dish volume, a Mr. Gasket head gasket (0.038-inch compressed volume x 4.250-inch bore), and 92cc combustion chambers, compression came in at 10.54:1-OK for 91-octane pump gas with a big cam and the heads' quick-burn chambers.

Cam And Valvetrain

Standard Pontiac cams work with the Roland heads, but on a high-end engine, an optimized grind that better matches the heads' improved flow characteristics is preferred. Mitchell installed a solid roller cam with his own specified lobe profiles, custom-ground by Comp Cams. Optimized for high-ratio rocker arms, the lobes with 1.7:1 rockers have more than 0.770-inch lift, but their 270-to-280-degree duration at 0.050 is less than typical for a Pontiac in this engine's intended performance range. To make the cam more idle friendly on a street-driven car, overlap is minimized with a wide 112-degree lobe-separation angle. The wide LSA doesn't seriously impact overall performance because the intake port flows so well. Even with the big cam, piston-to-valve clearance still came in at a more than adequate 0.100-inch intake/0.220-inch exhaust. A custom Hardcore Racing aluminum valley cover was installed to clear the solid roller lifters.

Custom-spec'd by Andy Mitchell, the Comp Cams solid roller cam used in this engine is a high-lift profile designed to complement the CV-1 head's superior intake port. Custom order Grind No. PB 2234/2237 R112 (custom Pontiac cam PN 51-000-13).

Custom-spec'd by Andy Mitchell, the Comp Cams solid roller cam used in this engine is a high-lift profile designed to complement the CV-1 head's superior intake port. Custom order Grind No. PB 2234/2237 R112 (custom Pontiac cam PN 51-000-13).

The rockers on CV-1 heads are canted at the same angle as the pushrods, eliminating side loading and reducing parasitic power losses. Except for Roland-supplied guideplates, the top-end valvetrain consists of typical big-block Chevy parts, including Comp's Elite-series valvesprings that develop 240 pounds of seat pressure at a 2.00-inch installed height, with 685 pounds over the nose. For high-end motors, rocker stud girdles or even complete shaft-mount rocker arm assemblies would be unique to the CV-1 but are available through aftermarket sources such as Hardcore Racing.

Cam Specs

All values are in degrees except lift and lash, which are in inches.

Type: mechanical roller

Lobe lift: 0.455/0.455

Valve lift (0 lash, 1.7:1 rockers): 0.773/0.773

Valve lash: 0.016/0.

Tappet duration (0.020 lift): 305/311

Tappet duration (0.050 lift): 276/282

Lobe-separation angle: 112

Lobe centerline: 108/116

Intake opens/closes (0.050 tappet lift): 30 BTDC/66 ABDC

Exhaust opens/closes (0.050 tappet lift): 77 BBDC/25 ATDC

Oil System

Mitchell's oil system is decidedly nontrick: A modified Ram Air IV oil pump sucks oil out of a 7-quart (with filter) Canton street/strip trap-door oil pan. There are no internal oil passage mods. There are no top end oil restrictors. "You need oil to the top end to keep the springs alive," Mitchell says.

Fuel, Air, and Spark

Roland CV-1 heads require a dedicated intake manifold, also available through Roland. A single-plane as well as a dual-four-barrel tunnel-ram are offered, both with a choice of either the standard Holley 4150 flange or the larger 4500 Dominator flange. The engine's future owner preferred a 1,000-cfm, 4150-style Holley. None of the intakes has a stock-type built-in water crossover; if one's needed for street use, Kauffman sells a bolt-on crossover casting complete with thermostat housing. An all-MSD ignition system fires NGK PN 5671A-8 plugs gapped at 0.035 inch. For the dyno test, Westech installed a set of Hooker headers with 2-inch primaries and 31/2-inch collectors (PN 4201), along with 18-inch collector extensions.

On The Dyno

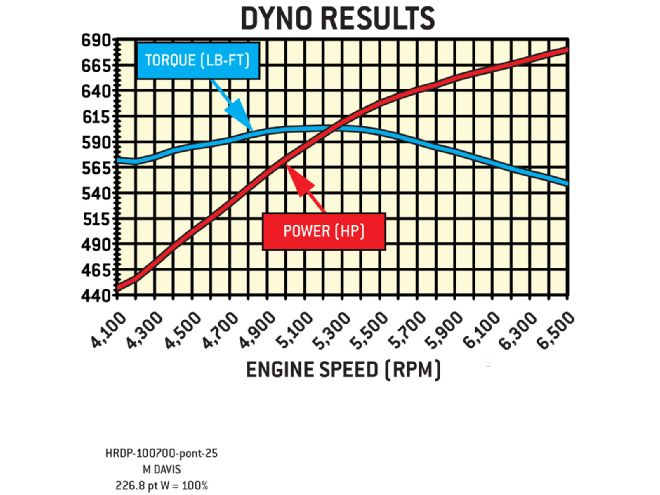

You'd expect a typical undersquare Pontiac to be a torquey stump puller, and this engine doesn't disappoint: On Westech Performance's SuperFlow dyno, Hardcore's 495 with the new Roland heads made a peak 603.2 lb-ft at 5,200 rpm, more than 600 lb-ft from 5,000 through 5,400 rpm, and more than 550 lb-ft from 4,100 (the lowest test point) through 6,400 rpm. What you don't expect is for a Pontiac to make big horsepower. But would you believe more than 500 hp from 4,600 rpm on up, more than 600 hp starting at 5,300, and an observed peak of 679.6 hp at 6,500-with the curve still on the upswing? Unfortunately, we couldn't cajole Mitchell into letting Westech run it in on up past tip-over: It seems the hoped-for rocker stud girdle hadn't shown up in time for the test, the bottom end had only two-bolt mains . . . and well, the motor was built for a paying customer all the way Down Under (Australia). But judging from the shape of the curve, with a little more guts and a little more tuning, this engine is easily a 700-plus-horsepower mill.