The fun of assembling a hot engine combo comes from the anticipation of what we expect it to do. If you've been following the progress of this twin-turbo, 505ci engine buildup for Jeff Hutchens' '67 GTO, then you know it's dyno time! In this installment, we show you how much power it makes and discuss some aspects of tuning its FAST (Fuel Air Spark Technology) electronic fuel-injection system.

FAST's EFI system aids in making a seemingly impractical-for-the-street engine like this much more tractable on the boulevard. Yes, turbocharging has been around for a long time, but up until electronic fuel-injection systems became readily available, street tuning a turbo involved more compromises than most care to admit.

Don't let this apparent rat's nest of wires scare you off. The FAST wiring harness is clearly labeled and easily connects the FAST ECU to all of the various sensors.In this application, there's a 3-bar (up to 30 psi) map sensor; water and air temp sensors; an idle air control motor; a throttle position sensor; and, of course, a wideband (9-1 to 19-1 A/F ratio) oxygen sensor.

Don't let this apparent rat's nest of wires scare you off. The FAST wiring harness is clearly labeled and easily connects the FAST ECU to all of the various sensors.In this application, there's a 3-bar (up to 30 psi) map sensor; water and air temp sensors; an idle air control motor; a throttle position sensor; and, of course, a wideband (9-1 to 19-1 A/F ratio) oxygen sensor.

The real benefit of an EFI system is very precise control over fuel and spark functions across the entire rpm and load ranges. It's critical that these parameters are precisely set. That's why an experienced tuner is so important to a build such as this, so Travis Quillen of Quillen Motorsports Engineering was called upon to tune the 505 for the break-in and power pulls at Wheeler Dyno Service in Blaine, Minnesota. A professional EFI tuner knows how to set up safe timing and air/fuel ratios at the start so the engine isn't destroyed on the first pull. It can run rich with retarded timing all day long-but excessively lean and too advanced only once. This is especially true under boosted conditions.

One myth that we should dispel right away is that EFI in and of itself will produce significant power gains. The truth is, a properly tuned carburetor that has an equal flow rate to the EFI system will pretty much match what an EFI system will produce when it comes to peak power. But with very accurate control of the fuel and timing, you might be able to push the limits a little closer to the edge and run a little more compression or boost, and a little more timing. Improvements in part-throttle operation and in the lower-rpm ranges can be possible with judicious tuning because there is more control over the fuel and timing at every rpm and load level than with a carb and standard distributor.

FAST can supply a dual-sync distributor that sends cam position info to the ECM to run sequential injection instead of bank-to-bank firing of the injectors. The advantages of sequential injection are individual control over each cylinder's fuel, and less stress on the fuel system since the injectors are actuating one at a time.

FAST can supply a dual-sync distributor that sends cam position info to the ECM to run sequential injection instead of bank-to-bank firing of the injectors. The advantages of sequential injection are individual control over each cylinder's fuel, and less stress on the fuel system since the injectors are actuating one at a time.

One way that EFI has more flexibility is with the ability to switch back and forth between more than one tune. You can optimize the first for general cruising on pump fuel and have the second for when you are feeling restless and want to dump in some C16 and go racing. Think of it as a jet-and-timing change by way of a laptop. Consistency should also improve because EFI systems can be more accurately tuned.

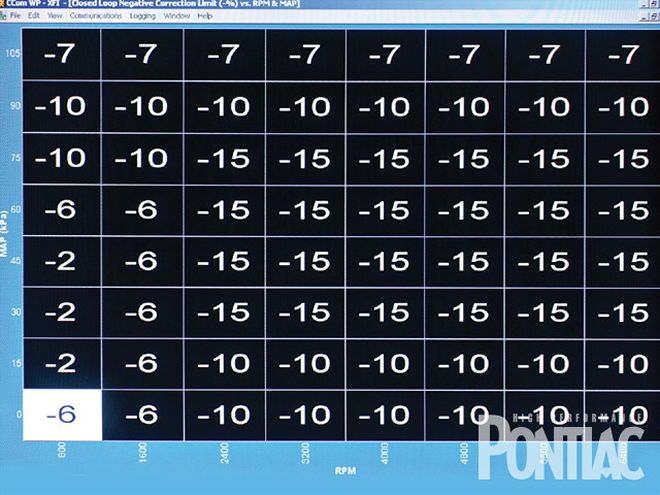

At the heart of the FAST system are tables or "maps" that control the amount of fuel delivered at every rpm and load; the amount of timing at every rpm and load; and target air/fuel ratio for every rpm and load. Quillen is an experienced tuner who knows how to program these tables with safe numbers for any engine. Initially, he likes to be conservative regarding timing, beginning just a little rich with the fuel, and only allowing moderate boost until he can get a good baseline pull he can use to find out what each engine really likes.

While showing all of the steps in this process is really beyond what we have room for here, we will show you some highlights so you can speak intelligently with your tuner. (FAST also has a rather in-depth DVD that is worth a serious look.) In simple terms, the tuner will decide on a target air/fuel ratio and then modify the volumetric efficiency table until that target air/fuel ratio is reached with a near-zero correction on the oxygen sensor.

Though not a part of this story, once the session at Wheeler Dyno Services is complete, the engine is off to MCR to be bolted into the GTO and tested on MCR's Mustang chassis dyno.

A chassis dyno provides a double bonus, as it can simulate real world run and drive conditions and it also can take into account the addition of air filters and a full exhaust system. The tuner can pay close attention to the transition periods, such as gear-shifts, full-throttle-to-closed, and cruising-to-full throttle operations when working on a chassis dyno.

Besides tweaking cold-start calibration and accelerator-enrichment functions, the tuner can closely monitor how this engine will respond on the street once it's turned loose on an unsuspecting public. The changes to the fuel maps are usually subtle, but that's what makes for a flawless driving experience. It's more than worth the price of admission.

Now let's see how much power we make.

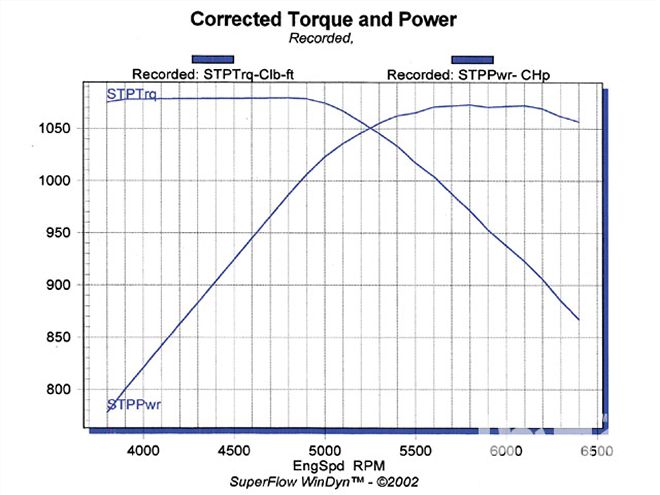

Dyno PullsFor the 91-octane pump-gas tests, the wastegates were basically open for each entire pull. Once on racing fuel, we adjusted the wastegates to provide about 4 more psi and saw peak power jump about 150 hp and torque climb 200 lb-ft. We intended to keep going, but Fiala noticed the fuel pressure falling just a bit at the end of our last pull, indicating the dyno fuel pump wasn't keeping up and we were running out of fuel. Unfortunately, we were out of time to swap pumps and so had to settle for the numbers here. Jeff feels very strongly that if we could have run the boost up into the mid-20s, we realistically could have seen another few hundred hp, but we could not document it.

PUMP GAS RESULTS RPM TQ HP BOOST PSI 3,500 739 493 6.2 4,000 761 580 6.5 4,500 802 687 7.6 5,000 817 778 9.0 5,500 829 868 10.9 6,000 798 912 12.7 6,200 779 920 13.4 RACE GAS RESULTS RPM TQ HP BOOST PSI 3,800 1,075 778 17.6 4,000 1,078 821 17.6 4,500 1,079 {{{924}}} 17.7 5,000 1,075 1,023 17.6 5,500 1,017 1,065 17.4 5,800 971 1,073 17.3 6,000 938 1,071 17.3 6,{{{200}}} 906 1,069 17.3EFI Rev-Limiting With Boosted Applications

One of the many benefits of EFI systems is their built-in rev-limiting abilities. At a preset rpm of the tuner's choosing, the system will randomly drop cylinders by cutting off fuel and/or ignition. Who knows how many engines have been saved by this technology, but there is a potential problem with engines under boost, especially the higher boost pressures this engine could see with racing fuel.

Wheeler Dyno Service recommends limiting rpm by dropping the ignition only, not by randomly shutting off injectors. This way the fuel is there once the cylinder gets spark again, so there is less chance of the cylinder firing lean and damaging the engine.

Yes, ignition-only cutout will cause some random rich cylinders, but that won't hurt anything, and the extra fuel will instantly clear once the power is back on.

HPP ENGINE BUILDUP WORKSHEET Engine Displacement: {{{505}}} CID Horsepower: 920, pump gas; 1,073, racing fuel Torque: 829, pump gas; 1,079, racing fuel Bore/Stroke: 4.350x4.250-in Bore/Stroke Ratio: 1.02:1 Rod/Stroke Ratio: 1.{{{57}}}:1 Here's where things go off the charts-literally. We poured in some C16 racing fuel, upped the boost from 13.4 to 17.7 psi, and quickly pegged the needle, so to speak, on the dyno. The reason the left side of the torque graph is flat is because it is up against the upper limit of the dyno's measuring ability. Peak power also occurred about 1,000 rpm lower than with pump gas-mostly because of greater boost coming in earlier. Because of the different burn rate with the C16, the fuel and timing tables needed some tweaking, but they were saved and can be loaded any time Hutchens is feeling bored.

BOTTOM END Block Description: IA II Deck Height: 10.220-in Crank: Butler Performance forged, 4.250-in stroke with 3.00-in mains Preparation: Balanced by Wheeler Balancer: ATI Rods: Scat 4340-forged steel, 6.700-in Bearings: Sealed Power Pistons: Ross forged, 49cc dish Piston-to-Deck Height: 0 Piston Pins: Ferrea (big-block Chevy style) full floating Rings: Total Seal, file-to-fit Fasteners: ARP

OILING SYSTEM Windage Tray: Milodon Oil Pan: Milodon Oil Pump: Melling high-volume

HEADS Casting: Edelbrock Performer, ported Combustion Chamber Volume: {{{90}}} ccsMaximum Flow at 28 Inches of Water Intake: 304 cfm at 0.{{{600}}}-in lift Exhaust: 232 cfm at 0.600-in lift Compression Ratio: 7.96:1 Valves: Edelbrock SS, 2.11/1.66-in Angles Used in Valve Job: 30, 45, 75-deg Rocker Arms: Comp Cams aluminum roller, 1.5:1 Pushrods: Smith Brothers restrictor-type, 0.040, 3/8-in

CAM Brand: Comp Cams custom hyd. roller Duration at 0.050: 258/248-deg Lift: 0.541/0.541-in Centerline: 111-deg Lobe Separation Angle: 115-deg Installed Position: Straight up Lifters Brand: Comp Cams roller Valvesprings: Edelbrock Seat Pressure: 140 pound Open Pressure: 360 pound Timing Chain: Cloyes Tru-roller

Here's where things go off the charts-literally. We poured in some C16 racing fuel, upped the boost from 13.4 to 17.7 psi, and quickly pegged the needle, so to speak, on the dyno. The reason the left side of the torque graph is flat is because it is up against the upper limit of the dyno's measuring ability. Peak power also occurred about 1,000 rpm lower than with pump gas-mostly because of greater boost coming in earlier. Because of the different burn rate with the C16, the fuel and timing tables needed some tweaking, but they were saved and can be loaded any time Hutchens is feeling bored.

BOTTOM END Block Description: IA II Deck Height: 10.220-in Crank: Butler Performance forged, 4.250-in stroke with 3.00-in mains Preparation: Balanced by Wheeler Balancer: ATI Rods: Scat 4340-forged steel, 6.700-in Bearings: Sealed Power Pistons: Ross forged, 49cc dish Piston-to-Deck Height: 0 Piston Pins: Ferrea (big-block Chevy style) full floating Rings: Total Seal, file-to-fit Fasteners: ARP

OILING SYSTEM Windage Tray: Milodon Oil Pan: Milodon Oil Pump: Melling high-volume

HEADS Casting: Edelbrock Performer, ported Combustion Chamber Volume: {{{90}}} ccsMaximum Flow at 28 Inches of Water Intake: 304 cfm at 0.{{{600}}}-in lift Exhaust: 232 cfm at 0.600-in lift Compression Ratio: 7.96:1 Valves: Edelbrock SS, 2.11/1.66-in Angles Used in Valve Job: 30, 45, 75-deg Rocker Arms: Comp Cams aluminum roller, 1.5:1 Pushrods: Smith Brothers restrictor-type, 0.040, 3/8-in

CAM Brand: Comp Cams custom hyd. roller Duration at 0.050: 258/248-deg Lift: 0.541/0.541-in Centerline: 111-deg Lobe Separation Angle: 115-deg Installed Position: Straight up Lifters Brand: Comp Cams roller Valvesprings: Edelbrock Seat Pressure: 140 pound Open Pressure: 360 pound Timing Chain: Cloyes Tru-roller

INDUCTION Type: FAST EFI, MAP 3-bar, sequential Throttle Body: 70mm Accufab Fuel Injectors: FAST 83-lb/hr Computer (ECM): FAST

FUEL SYSTEM Fuel Pump: FAST electric Intake Manifold: Edelbrock Victor {{{Pontiac}}},port-matched

POWER ADDER Turbocharger: Two 70mm Turbonetics; pair of 35mm Evolution wastegates, mechanical Downpipes: 3 inches Max Boost: Tested to just under 18 psi Intercooler: Bell air-to-air 2.5-in Blow-off Valve: Turbonetics Godzilla

IGNITION Distributor: MSD Crank trigger, modified for cam sync Amplifier: MSD Coil: MSD Pro Power Wires: Moroso suppression 8mm

EXHAUST Headers: Full custom stainless steel, fabricated by MCR Primaries: 2-in Collectors: 3-in

INDUCTION Type: FAST EFI, MAP 3-bar, sequential Throttle Body: 70mm Accufab Fuel Injectors: FAST 83-lb/hr Computer (ECM): FAST

FUEL SYSTEM Fuel Pump: FAST electric Intake Manifold: Edelbrock Victor {{{Pontiac}}},port-matched

POWER ADDER Turbocharger: Two 70mm Turbonetics; pair of 35mm Evolution wastegates, mechanical Downpipes: 3 inches Max Boost: Tested to just under 18 psi Intercooler: Bell air-to-air 2.5-in Blow-off Valve: Turbonetics Godzilla

IGNITION Distributor: MSD Crank trigger, modified for cam sync Amplifier: MSD Coil: MSD Pro Power Wires: Moroso suppression 8mm

EXHAUST Headers: Full custom stainless steel, fabricated by MCR Primaries: 2-in Collectors: 3-in