A solid roller camshaft is a great way to improve the power your engine produces, and if your Mopar is equipped with a big-block or Hemi, a roller cam can be installed without much in the way of modifications. If your Mopar is equipped with a small-block, however, there is an issue that stands in the way of installing a roller cam, and that issue involves the oiling system. If the proper modifications aren't made, the roller tappets will bleed off oil pressure and your engine will fail from oil starvation. This month, we'll show you how to prevent that scenario by modifying your block to be compatible with roller lifters.

We're all aware that roller cams make more power, but there is a common misconception that the additional power comes from reduced internal friction. While we can't argue that less internal friction will equate to more power at the flywheel, we can say that this is not the primary benefit of a roller camshaft. The real way a roller cam makes more power is by allowing a camshaft lobe with a steeper ramp rate than is capable with flat-tappet lifters. In other words, the roller cam gets the valves opening faster and keeps the valve at a higher lift for a longer period of time, allowing more air and fuel into the combustion chamber. Unfortunately, the design of the Mopar small-block, combined with the way roller lifters are built, will cause a loss of oil pressure if the engine's oil system is left stock. Luckily, the modifications to make a small-block compatible with roller lifters are fairly simple and can be performed by anyone with decent tools and mechanical skills.

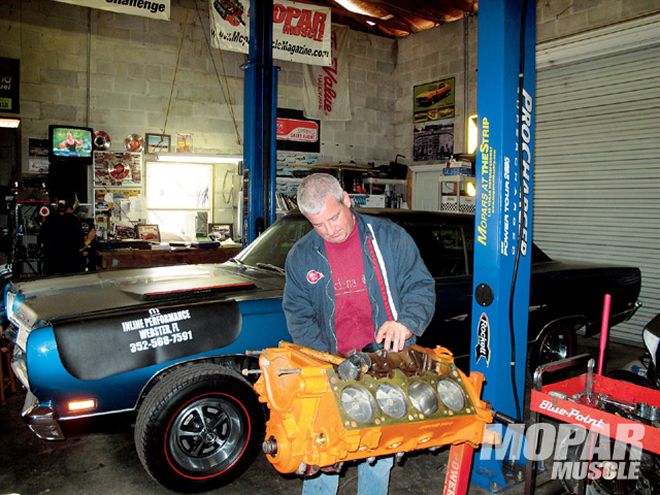

If you're building a small-block Mopar, installing a mechanical roller camshaft requires a few modifications to the engine's oiling system. Follow along and we'll show you how to make your small-block roller cam compatible.

If you're building a small-block Mopar, installing a mechanical roller camshaft requires a few modifications to the engine's oiling system. Follow along and we'll show you how to make your small-block roller cam compatible.

The problem with the roller lifter is that it is built with a relief, like a wasp's waist cut into the lifter body. Depending on the lifter design, at either maximum lift or on the base circle, this relief can extend out of the top or bottom of the small-block Mopar's lifter bore, dumping oil pressure from the lifter oil-galley into the engine valley. Since solid roller lifters require far less oil than their flat-tappet counterparts, the easiest and least expensive way to correct this problem is to block the oil going to the lifter galleys on each side of the engine. On the right side, this involves installing a copper tube into the lifter galley, then peening the tube to clear the lifters and re-drilling oil passage holes. On the left side of the engine, oil is kept from the lifter galley by threading the block with a tap and installing a plug in the feed galley from the number one main bearing, or tapping the front of the oil lifter galley deeply enough that a threaded plug will cover the oil supply hole coming from the main bearing. Of course installing bushings in the lifter bores does accomplish the same goal, and is mandatory if a hydraulic roller cam will be installed, but involves the services of a machine shop, which can be costly. Additionally, some feel that boring and sleeving lifter bores can weaken the block around the lifters, so you should carefully consider lifter sleeves before deciding which method is best for your application. For the purposes of this article, we'll show you how to save money by modifying your block for a solid roller cam yourself.