It’s hard to believe GM’s “new” small-block has been with us for 17 years, and as the years have passed, its acceptance into the hot rod fraternity has been overwhelming. It wasn’t always that way. When the LS supplanted the traditional small-block Chevrolet, traditionalists greeted it with mistrust, while some in the press criticized the inline two-valve pushrod layout as “primitive.” What the LS undeniably did have was performance, even in OEM form. The LS offers a combination of power, cost, and durability in a package that’s downright compact compared to its competition from Chrysler and Ford.

Engine builder Ron Shaver was no stranger to LS power when he contemplated which engine to enter in the 2013 AMSOIL Engine Masters Challenge. “We do a lot of LS engines, and we have for quite some time,” Ron says. “We really got indoctrinated into the LS early on when GM came to us to do drift-car engines. We picked the LS because it responds the best to basic hot rodding of any two-valve engine we have messed with.”

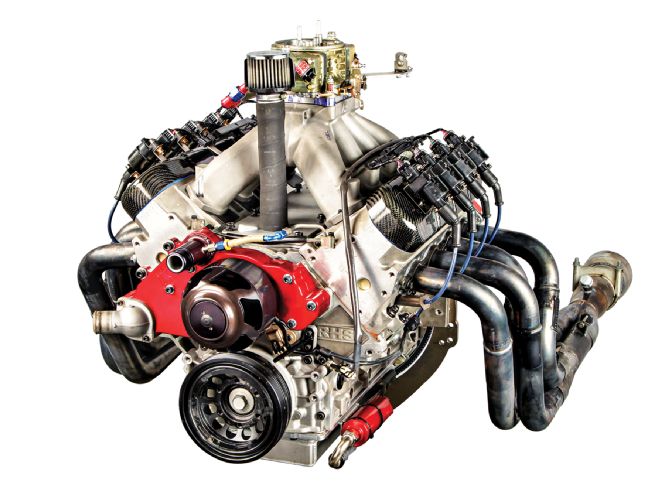

While builders of high-powered LS engines often favor aftermarket iron blocks, the Ron Shaver RHS Aluminum LS block offers the best of both worlds: race-block features wrapped in lightweight alloy. Blocks are available in raised-cam and tall-deck configurations.

While builders of high-powered LS engines often favor aftermarket iron blocks, the Ron Shaver RHS Aluminum LS block offers the best of both worlds: race-block features wrapped in lightweight alloy. Blocks are available in raised-cam and tall-deck configurations.

All-Aftermarket Build

The foundation here is Racing Head Service’s (RHS) GM LS aluminum race block. The RHS block takes a capable design and optimizes it for performance or racing applications: “The block is really well done,” Ron says. “It is heavier-duty than the GM block and allows for a lot of flexibility in creating different combinations. It is available with different deck heights, so you can package a very large stroker engine combination. In this build, we decided to make it a 7.0L because in the Engine Masters Challenge [EMC], somewhere between 400 to 430 ci is the magic range for scoring well. The combination we had in mind included a 0.100-inch longer rod, and a 4.00-inch stroke and 4.125-inch bore.”

Scat supplied the 6.125-inch H-beam rods, which link a set of Mahle forged flat-top pistons wrapped with a 1.2/1.2/1.3mm ring package from Total Seal. The Mahle pistons are designed for a short pin, helping reduce reciprocating weight.

Scat supplied the 6.125-inch H-beam rods, which link a set of Mahle forged flat-top pistons wrapped with a 1.2/1.2/1.3mm ring package from Total Seal. The Mahle pistons are designed for a short pin, helping reduce reciprocating weight.

Ron says everything fits in the RHS block better than the GM blocks. “They are really nice castings and have heavy-duty, billet-steel main-bearing caps,” he says. “These blocks are heavy wall and the sleeves are heavy wall and don’t move around. They leak down at zero percent once you have them warm—they are nice. We used a slightly taller deck block, and that made it easy for us to get the rod selection we wanted. With the GM block, you are locked in as far as deck height.”

Shaver also went to RHS for its Pro Elite cylinder heads: “We picked the RHS head because it has features like extra head bolt provisions to match the block. There is no question about it—the more fasteners you have to clamp the heads, the better off you are. These RHS heads use the LS7 configuration, and Carl Wagner did the port work for us. They use a 2.200-inch intake valve and a 1.615-inch exhaust, and flow more than 400 cfm on the intake side at 0.800-inch lift. We used multilayer steel (MLS) head gaskets from Cometic to seal them to the block.”

A look downstairs shows the beefy main structure of the RHS block, equipped with billet-steel main caps and ARP fasteners. The Scat crank features the popular 4.00-inch stroke and rides on King bearings.

A look downstairs shows the beefy main structure of the RHS block, equipped with billet-steel main caps and ARP fasteners. The Scat crank features the popular 4.00-inch stroke and rides on King bearings.

Filling The Bottom End

Ron elaborated on the short-block’s parts: “It’s a really easy short-block combination to build. For a good street engine you’re going to take to the drags, it is hard to beat a Scat crank. Everything on the crank is standard dimension. We used King tri-metal bearings with a lead/tin overlay. We recommend them because of the quality; if you buy 10 sets, they are all going to be exactly the same. I feel that even the steel backing is higher quality than some of the competitive bearings.

Making use of the engine’s rpm potential while making it live requires quality components throughout the valvetrain. Comp Cams provided the bulk of the equipment—from the limited-travel, hydraulic-roller lifters and 1.8:1-ratio, shaft-mounted rockers to the retainers and locks. Springs are from PAC, while the pushrods are heavy-wall, 3⁄8-inch Smith Brothers pieces.

Making use of the engine’s rpm potential while making it live requires quality components throughout the valvetrain. Comp Cams provided the bulk of the equipment—from the limited-travel, hydraulic-roller lifters and 1.8:1-ratio, shaft-mounted rockers to the retainers and locks. Springs are from PAC, while the pushrods are heavy-wall, 3⁄8-inch Smith Brothers pieces.

RHS Pro Elite LS7-style cylinder heads deliver the airflow, topping the 400-cfm mark at 0.800-inch lift, aided by port work by Carl Wagner. The steel valves measure 2.200 inches on the intake and 1.615 inches on the exhaust.

RHS Pro Elite LS7-style cylinder heads deliver the airflow, topping the 400-cfm mark at 0.800-inch lift, aided by port work by Carl Wagner. The steel valves measure 2.200 inches on the intake and 1.615 inches on the exhaust.

“We used Mahle for the pistons because they have a very good off-the-shelf piston, and they are light. These pistons use a short 2.281-inch-length pin and are machined for a 1.2/1.2/1.3mm ring package. The rings are from Total Seal with a steel top ring and tapered-faced second. It is a really good package for what we wanted to do. We got a custom piston with a little shorter compression height because we went to the 0.100-inch-longer rod and slightly taller block deck height, and everything worked out nice.”

Completing The Flow System Although fuel injection is favored by most of the competitors at the EMC competition, Ron went with a simple carburetor. “The manifold is from a company called All Pro, and Carl [Wagner] ported it. We developed the heads and manifold in unison as a flow system. Sitting on top of the manifold is a Carb Shop–modified, 1,000-cfm Holley HP carb. Once it was set up, it worked well.”

The header comprises the other side of the flow system, and here Shaver developed a unique arrangement. “We built a custom header; it was a tri-Y that fell into place because we have been doing a pretty big tri-Y program on our sprint-car engines and having good success. We took what we learned and applied it to this engine. Compared to a 4-into-1 header, it was worth 25 points in the EMC competition. The headers have stepped primaries from 17⁄8 to 2 inch, and then into a 2¼ secondary into a 2¾-inch choke to a 13-inch merge collector that ends at 3½-inch diameter. The total length of the primary was 22 inches, and the length of the secondary pipe was 8 inches. We knew what we needed to start with, but we did a lot of playing around with it until we came up with what worked the best.”

VITAL SPECIFICATIONS

427CI CHEVY LS

Team leader and Members Ron Shaver; Mark Engle and Tom Masek Engine type Chevy LS Claimed displacement 427 ci Block RHS Bore x stroke 4.125 x 4.00 in Compression ratio 11.47:1 Compression height 1.115 in Crankshaft Scat Engine bearings King Engine Bearings Connecting rod Scat, 6.125 in Connecting rod bearings King Engine Bearings Pistons and rings MAHLE Clevite, Total Seal Compression and Second ring 1.2mm / 1.2mm Camshaft COMP Cams Cam duration at 0.050 256/260 deg Valve lift 0.855 / 0.848 in Head gasket Cometic, 0.051-in thick Cylinder heads RHS Pro Elite Valves (intake/exhaust) 2.200 in / 1.615 in Valve lifters COMP Cams Pushrods Smith Bros. Rocker arms COMP Cams, 1.8:1 Engine gasket set Fel-Pro, Cometic Intake manifold All-Pro Carb The Carb Shop Carb spacer HVH Ignition system MSD Performance Spark plugs and wires Bosch, NAPA Fasteners ARP Flywheel McLeod Engine damper Performance Race Balancer Water pump Meziere Headers Schoenfeld Valve covers CFI AMSOIL oil viscosity 5W-20 Oil pump System One Filters Oil pan Olson Motorsports Mufflers Flowmaster

The tri-Y header system with merge collectors was built at Shaver’s. The design borrows from extensive research and development at the company with similar header layouts for their sprint-car engine program.

The tri-Y header system with merge collectors was built at Shaver’s. The design borrows from extensive research and development at the company with similar header layouts for their sprint-car engine program.

Working The Valves

Shaver worked closely with Comp Cams to develop a cam profile for the fattest power curve possible within the EMC test range of 3,000–7,000 rpm while meeting the competition’s hydraulic-cam requirement. The cam was a product of Billy Godbold [camshaft design engineer] at Competition Cams. “The basics here were a tight lobe center with lots of lift, a lot of rocker [ratio], and a lot of spring to control it. The cam duration was 256 [degrees] intake and 260 exhaust with 105 degrees separation, and we had it in at 99 degrees intake centerline. We used Comp’s limited-travel hydraulic lifters, which I am sure were bottomed-out instantly and acted like solid lifters.”

With the Comp shaft mounted 1.8:1 rocker arms delivering 0.855/0.848-inch lift, maintaining valvetrain control into the upper rpm range required a very capable valvetrain. Ron filled us in on the setup: “The springs were made for us by PAC with something like 250 pounds closed load and more than 750 pounds of pressure on the nose. The rest of the valvetrain was all Comp, including the rockers, timing set, retainers, and locks.”

On the dyno at the University of Northwestern Ohio for the 2013 AMSOIL Engine Masters Challenge, Shaver’s 427 LS delivered outstanding output, posting 741 peak horsepower at 6,600 rpm and 656 lb-ft of torque at 5,600.

On the dyno at the University of Northwestern Ohio for the 2013 AMSOIL Engine Masters Challenge, Shaver’s 427 LS delivered outstanding output, posting 741 peak horsepower at 6,600 rpm and 656 lb-ft of torque at 5,600.

To The Dyno

With the finishing touches, including an MSD ignition controller to fire the LS7 coil packs, Ron hit the dyno at Shaver Specialty Co. to fine-tune the combo for competition. He found the LS to be a capable performer right out of the chute: “It made 750 hp and 650 lb-ft on the first real dyno pull—I couldn’t believe it. We then started working on getting the power range broadened out to bring up the scoring total for the Engine Masters competition.”

At the 2013 AMSOIL Engine Masters Challenge, the Shaver LS proved its worth when run on the SuperFlow Powermark dyno at our University of Northwestern Ohio host facility. Limited by the event’s constraints in the key areas of compression ratio, carb size, and the hydraulic cam requirement, these engines are meant to represent the radical end of street-oriented performance—not unlimited racing engines. Ron’s LS definitely pushed the performance boundaries, delivering 741 peak horsepower at 6,600 rpm and 656 lb-ft of peak torque. The upshot here is Ron’s engine did not rely on one-off or custom-fabricated, handmade parts. All that power was the result of expert machining and assembly using the most capable aftermarket LS parts available.

ON THE DYNO

427 LS Chevrolet

RPM TQ HP 3,000 504.3 288.0 3,100 503.0 296.9 3,200 486.9 296.7 3,300 466.9 293.4 3,400 444.0 287.4 3,500 431.4 287.5 3,600 439.5 301.2 3,700 506 356.5 3,800 585.5 423.6 3,900 620.4 460.6 4,000 585.8 446.1 4,100 604.6 472.0 4,200 622.3 497.6 4,300 632.4 517.7 4,400 640.3 536.4 4,500 645.7 553.3 4,600 648.1 567.7 4,700 647.3 579.3 4,800 647.4 591.7 4,900 649.6 606.0 5,000 652.2 621.0 5,100 653.4 634.5 5,200 654.8 648.3 5,300 656.0 662.0 5,400 654.3 672.7 5,500 652.2 683.0 5,600 650.9 694.0 5,700 647.0 702.2 5,800 642.8 709.8 5,900 637.7 716.4 6,000 631.1 720.9 6,100 624.9 725.8 6,200 618.6 730.3 6,300 612.1 734.2 6,400 605.5 737.8 6,500 598.6 740.9 6,600 589.8 741.2 6,700 580.4 740.4 6,800 569.3 737.1 6,900 557.4 732.3 7,000 546.0 727.8

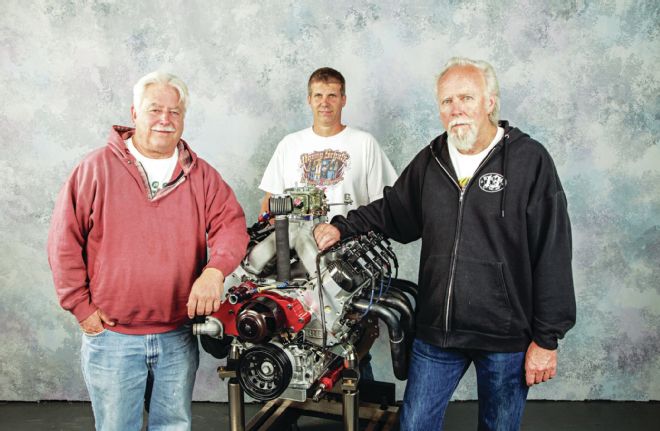

Representing Shavers Specialty Service at the Challenge were (from left to right) Ron Shaver, Mark Engle, and Tom Masek. The effort resulted in the best showing at the event for a carbureted engine combination.

Representing Shavers Specialty Service at the Challenge were (from left to right) Ron Shaver, Mark Engle, and Tom Masek. The effort resulted in the best showing at the event for a carbureted engine combination.

What Is the Engine Masters Challenge?

The Engine Masters Challenge is a yearly competition Popular Hot Rodding magazine has hosted for more than a decade. The emphasis of the Challenge is to build hot street-style engines using OEM-replacement-style parts while retaining the factory engine architectures. In 2013, the invitational brought together engine builders from around the country to dyno-test motors modified to produce horsepower and torque in the 3,000–7,000-rpm range. Key limitations were a 7,000-rpm redline, a compression ratio max of 11.5:1, hydraulic cam, and OEM-replacement-style heads and valvetrain. Testing was conducted at the University of Northwestern Ohio’s School of High Performance Motorsports dyno facility using a Superflow Powermark engine dyno, running on VP unleaded fuel.

In 2014, HOT ROD will have the privilege of covering the AMSOIL Engine Masters competition and sharing the secrets of America’s best engine builders. We begin this month with an inside look at an LS7-based, 427ci engine that competed in the 2013 event.