There is absolutely nothing like the sound of an engine singing in perfect tune on the dyno. At the beginning of the pull, the operator, or conductor if you will, loads the engine, pulling it down to a low, pounding baritone chant. As he releases the brake, the tone rises in a violent crescendo, finally peaking in a visceral scream that raises goose bumps. That was the sound and fury that Bill Trovato's 401-inch Oldsmobile unleashed on the DTS dyno at the '08 Jegs Engine Masters Challenge (EMC).

The birth and life of an engine reads like an opera. And like any opera, there is a story that accompanies the melody. The birth of Bill Trovato's Olds occurred when he received his acceptance invitation to the EMC. He had to choose a combination that he was familiar with, knew would make great power, and be reliable. Being intimately familiar with the Olds platform, he knew its strengths and weaknesses and decided to continue his foray into the Olds niche by building a 400 incher.

This was anything but Bill's first performance on stage. In the '90s, he ran a W-30 442 in NHRA stock Eliminator, and later joined the ranks of the NMCA EZ Street class running mid 9s in a 4,000-plus pound Olds. He also played some behind-the-scenes roles with the NMRA, increasing his knowledge of reading rules as a tech inspector and multitasking as a race director. Through the '80s and '90s, Bill repaired and operated industrial machinery. "Like all the industrial stuff, after NAFTA was introduced, everything went to Mexico, and I lost my job." With some money from a buyout and a lot of faith, in 2004 Bill launched BTR Performance with state-of-the-art manual and CNC equipment. With a full machine shop at his disposal, Bill's clientele grew as word of his talents traveled.

Team members Earl, Jim, and Steve whipped up this custom pan to pull the oil away from the rotating assembly, and still fit within the rules. Though it might look like just an oil bucket on the outside, the BTR crew designed the pan to incorporate features like a windage screen to pull extra oil from the crank, and an extra deep sump allowing the oil to settle to the bottom of the pan without foaming and decreasing pressure in the pump.

Team members Earl, Jim, and Steve whipped up this custom pan to pull the oil away from the rotating assembly, and still fit within the rules. Though it might look like just an oil bucket on the outside, the BTR crew designed the pan to incorporate features like a windage screen to pull extra oil from the crank, and an extra deep sump allowing the oil to settle to the bottom of the pan without foaming and decreasing pressure in the pump.

"Probably 50 percent of the shop's business is high-performance Olds business, and the other 50 percent is everything else, Ford, Chevrolet, nitrous stuff, naturally aspirated, whatever."

When asked more specifically why he chose the Olds when he was clearly experienced in such a wide variety of engine families, he replied: "The main reason was the cylinder heads. I had a few customers who would purchase them, so I did the R&D on this set we did for the Challenge, and then in turn, sold sets to other customers. So that was kind of what started it. Secondly, I got enough [Olds] stuff laying around that it wouldn't cost me a million dollars."

The 400 Olds is an almost square engine, meaning with a 4-inch bore and just under that in stroke, it lends itself to being a torque motor. The EMC runs in a limited rpm range, so the big stroke took to the project naturally. Not a typical 400 block was used, however. A quick search (thank the all powerful Google) reveals that there are a number of different variations in the big-block line. In 1965, just a year after Olds introduced their new 330-inch small-block design, Olds made a big jump and brought out the 400 and 425 big blocks, with the legendary 455 following just a few years later. Changes in bore, stroke, lifter diameter, and lifter angle all changed throughout the years, amazingly enough though, some crazy guy on the Olds design team made sure that just about every peripheral part (water pump, timing cover, rockers, flexplate) was interchangeable between big- and small-blocks! Trovato picked what he felt was the best starting point, a '67 Toronado 425 block, as his blank music sheet, and started writing notes.

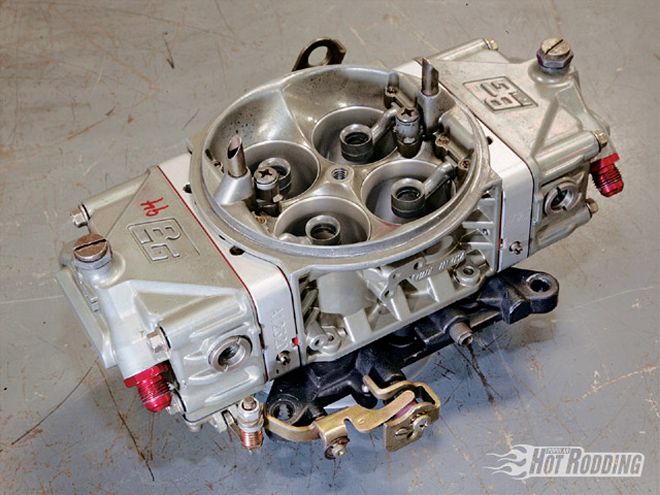

The Barry Grant carb uses removable venturi sleeves, allowing the engine builders to change the carb flow ratings to suit their needs. Like any good tuner, Trovato writes the jet numbers on his float bowls so he knows the next ones to grab if he wants to make a change.

The Barry Grant carb uses removable venturi sleeves, allowing the engine builders to change the carb flow ratings to suit their needs. Like any good tuner, Trovato writes the jet numbers on his float bowls so he knows the next ones to grab if he wants to make a change.

For those in the know, the 425 actually has a bigger bore than a 400. To achieve the desired cubic inches, Bill sleeved the rare D-code block down to that of a standard bore 400. The added thickness of the sleeves increased the strength of the cylinder walls without having to resort to hard blocking the coolant passages. Another tidbit of info that escapes common knowledge is that Bill's particular casting uses larger-diameter lifters in conjunction with an improved 39 degree lifter angle. This allowed the flat-tappet cam to be ground more aggressively than even the big Mopar cams.

All of the early big-blocks used a forged crank, so Bill plucked a good one from his stash, and gave it the works. He created a CNC program for reshaping the crankshaft throws, allowing them to cut through windage without whipping up a frothy mochaccino in the oil pan. A set of CAT H-beam connecting rods easily handled the job of snatching the pistons back just in time to avoid a collision with the heads over 100 times per second. The grateful pistons were a custom design built by CP, using a dish and a pair of valve notches big enough to move the cam around while tuning. The slugs also featured narrow ring grooves to accommodate the low-tension Mahle/Clevite rings.

In the middle of the short-block, a Comp Cams flat-tappet shaft hummed along in half-time. Not bothered by the Harrison Ford-like frantic action of its surroundings, the bumpstick happily did its job lofting the valves to almost 0.700-inch lift. Pretty stout lift for a fairly small duration cam, Bill says: "I actually had something a little bigger in there at first, but I didn't like it, so I yanked it out." Like many engine builders, Bill is careful breaking in a new cam, and was pleased that the Royal Purple synthetic oil did such a great job protecting his baby.

Having a CNC mill on hand has its benefits. Bill makes his own tapered carb spacers in-house. Using a 1/8-inch roll pin to locate it on the intake ensures it will line up again perfectly if removed.

Having a CNC mill on hand has its benefits. Bill makes his own tapered carb spacers in-house. Using a 1/8-inch roll pin to locate it on the intake ensures it will line up again perfectly if removed.

If the short-block provided a musical foundation for his performance, then certainly the heads played lead. As many Olds engines as they have built, the BTR Performance crew knew that the available cylinder heads (save for some really high-dollar stuff) have never been built with all-out performance in mind. Most are designed for great street/strip performance, but none of them had exactly what Bill was looking for. Bill and crew decided there was no reason they couldn't redesign the ports and chambers to be more efficient, so with a call to Edelbrock, they ordered several blank, unmachined heads, and began their R&D process.

Trovato says, "The castings were raw, and it allowed me to do some things different from the standard ones that you buy. I made the bowls pretty deep and I barely cut the spring pockets. If they were the standard Edelbrock head, the way they cut the spring pockets, it would have been into the port." Using past experience more than the flowbench, Bill designed the ports the way he felt they should be with the cross-sectional areas and venturis sized appropriately, and the runners raised as high as possible. When asked if he had any flow numbers for the heads he said, "Yeah, they flow like junk. The flow number at 0.700, which is what everybody goes by I guess, is 312 [cfm], and the exhaust is 185. I'm not lying. But there's more to this than flow numbers." This shift from engine builders relying solely on flow numbers to the overall shape and dimensions of the runners and chambers is taking steam and growing. Focusing on the correct design instead of an arbitrary number, Bill says the main job of his flowbench now is to hold his jar of pickles. With his EMC heads, once he had the runners dimensionally to his liking, he digitized them and was able to recreate them on his three-axis CNC mill.

Raising the runners on the heads means raising the intake runners as well. Epoxy lines the floors, and the ports are widened to the proper cross-sectional area.

Raising the runners on the heads means raising the intake runners as well. Epoxy lines the floors, and the ports are widened to the proper cross-sectional area.

With a touch of epoxy and a little work with a grinder, Trovato matched up an Edelbrock Victor intake to the heads. Chevy and Ford guys were visibly jealous of the long sweeping runners and four corner watering the intake featured. Long runners build torque down low, and torque is the name of the game in Engine Masters. Taking advantage of a loophole that none of the other competitors did, Bill used pre-drilled and tapped holes in the intake water passages to bring hot water from the rear of the engine to the front, reducing hot spots and increasing power. Bill's on-hand CNC genius, Steve Gerrard, whipped up a tapered carb spacer that was sandwiched between the Vic intake and a Barry Grant carb.

Once the BTR guys had the mechanicals assembled, Bill used an MSD 7531 programmable ignition box as his baton to conduct the movements. The unit has the advantage of allowing various custom ignition curves to be instantly installed based on what the engine wants. In the end though, Bill found just as much power with the timing locked, so that was how he ran it. For the contest, Shell V-Power 91-octane fuel would be lit off, and make the transition through the chamber and into a set of American Racing A-Body Cutlass headers, then blasted out the rear through a pair of Magnaflow mufflers.

With all the players in place and the stage set, the team from BTR Performance raised the curtain on this Engine Masters Top 10 performance. The depth and anger of the singing Olds made the ground shake. Cutlass owners would've thrown roses on the dyno room floor had they witnessed the performance, for Bill Trovato and his accompanists breathed life and song into a mass of inanimate objects. The opera was now complete. Encore!

Bill took advantage of the holes that were drilled and tapped in his manifold by running water lines from the rear to the front of his engine. Allowing the two ends of the engine to "talk" to each other evens out the heat transfer, and overall the engine runs cooler. This translates to more power with less chance of detonation.

BY THE NUMBERS

Bill took advantage of the holes that were drilled and tapped in his manifold by running water lines from the rear to the front of his engine. Allowing the two ends of the engine to "talk" to each other evens out the heat transfer, and overall the engine runs cooler. This translates to more power with less chance of detonation.

BY THE NUMBERS