Precision powder-forged connecting rods have become available for racingapplications. Powder-forged components have been used inhigh-performance applications like Formula 1 racing and have been partof the domestic original equipment automotive products since themid-'80s.

Precision powder-forged connecting rods have become available for racingapplications. Powder-forged components have been used inhigh-performance applications like Formula 1 racing and have been partof the domestic original equipment automotive products since themid-'80s.

Technology has proven to be the key to unlock better performance. As methods are tested and found to be beneficial, the supporters line up to take their programs to the next level. Advantage is the universal element sought by all racers.

Sometimes, the advantage can lie deep within the engine. Expensive exotic metals are one way to go about it, but there is a far more cost-effective way to get reliability and performance in some key engine parts.

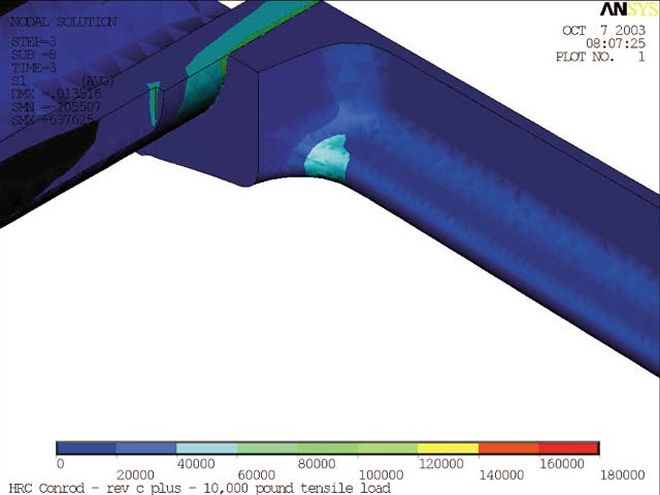

The design for Howards Racing Components' PPF Con Rod utilizedstate-of-the-art computer programs for modern efficiency.

The design for Howards Racing Components' PPF Con Rod utilizedstate-of-the-art computer programs for modern efficiency.

Howards Racing Components has joined with GKN Sinter Metals to unveil a line of connecting rods for racers. These rods are manufactured in the precision powder-forged process. This allows the rods to be extremely durable for high-horsepower applications. In addition, the cost of the rods is going to be within the range of an average racer's budget.

The name "precision powder-forged connecting rod" has been shortened to "PPF con rod," which is the way it will be referred to from this point forward.

The goals of the PPF con rod were simple. The companies wanted to design a part that was stronger and lighter while keeping cost affordable. The combination of strength and light weight is a definite boost to the production of horsepower.

The goals of the powder metal forged rod included strength and lightweight. The economics became an added bonus.

The goals of the powder metal forged rod included strength and lightweight. The economics became an added bonus.

The technology is new to short-track racers. It has been used for high-performance applications for more than two decades. Auto-motive original equipment manufacturers have also used components using powder metal for nearly 15 years. There's a good chance your street vehicle contains some powdered metal components.

The Process

Just like most operations, the process begins with a need and then a plan to fulfill the need. Once there is an established plan, the part must be designed. In the case of the connecting rod, the designing phase utilized the concept of solid modeling. The solid modeling phase used a CAD (Computer Aided Design) system that insures design integrity. It allows for the accurate prediction of overall weight and center of gravity of the part. Once the manufacturer is satisfied, the file is transferred to FEM (Finite Element Modeling) analysis and used by a CAM system for prototype production.

In the design phase, the components go through the Finite ElementAnalysis...

In the design phase, the components go through the Finite ElementAnalysis...

... Visual inspection allows manufacturers to ascertain potentialtrouble before any investment is made in building the part.

... Visual inspection allows manufacturers to ascertain potentialtrouble before any investment is made in building the part.

In the case of this connecting rod, Howards and GKN worked together to determine the best piece. The companies reviewed current billet and conventional forge designs available to the racer. The finished design was machined from billet stock to serve as a proof for the concept. During the analysis of the Finite Element Modeling, the weight was further reduced, and stress areas were identified.

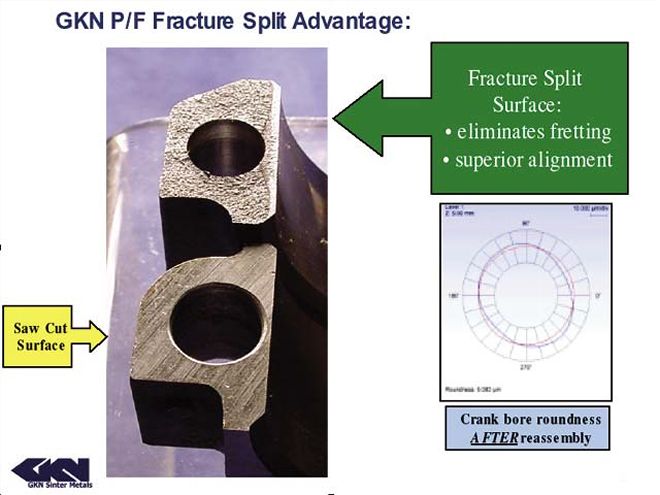

The fracture-split technology will provide better alignment for rodbolts.

The fracture-split technology will provide better alignment for rodbolts.

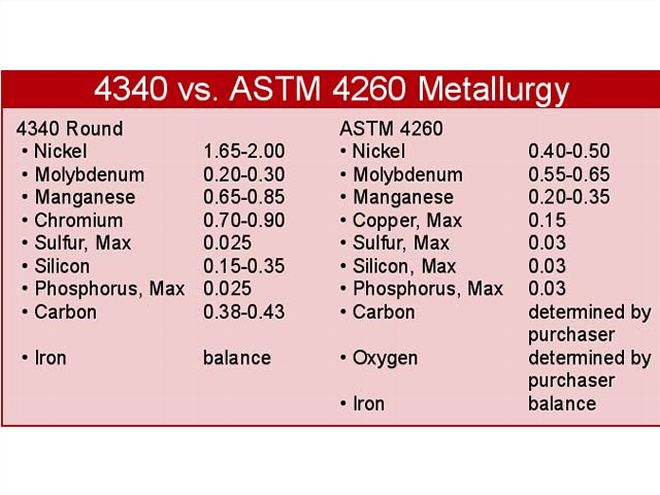

Click picture above for specs on 4340 vs. ASTM 4260 Metallurgy

Click picture above for specs on 4340 vs. ASTM 4260 Metallurgy

With a definite model in place, the process of determining material composition (a proprietary secret) is underway. A base powder is combined with selected alloying elements, and in some cases, lubrication materials or graphite is added. The newly formed combination is placed into a mixing apparatus for blending the components. This blending process points out one advantage of the powder metal. Custom blends can be accommodated, though GKN has standardized thousands of combinations for components. Physical characteristics can be enhanced with a slight change in the blended material. The process of mixing also allows for closer elemental interaction. Metal-forming alternatives like die-casting molten metals face limitations in alloy choices because of the behavior of the raw material when melted and processed.

After mixing, the material is fed into a compaction machine. The material is placed into a die cavity with two punches. A press squeezes the powder into the shape of the component. The compounds in the existing powder serve as an adhesive to form the part.

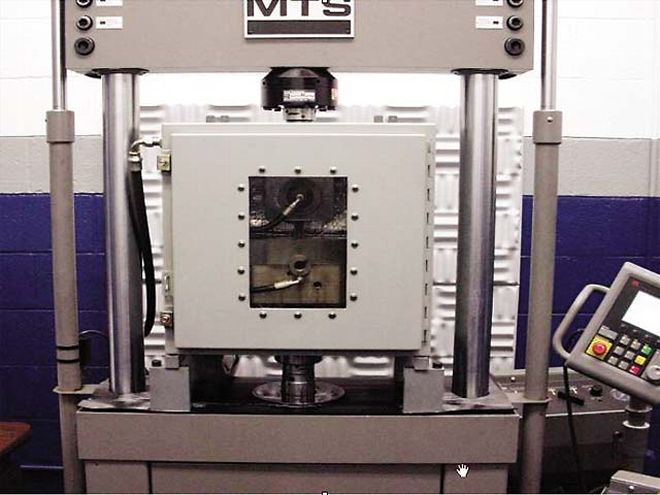

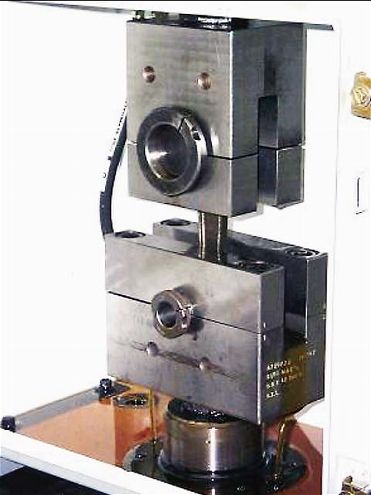

(above & below left) GKN's aggressive testing program was a key selling point in itsrelationship with Howards Racing Components. Static and dynamic testingis used to determine ultimate tensile strength (breaking point) as wellas endurance and fatigue.

(above & below left) GKN's aggressive testing program was a key selling point in itsrelationship with Howards Racing Components. Static and dynamic testingis used to determine ultimate tensile strength (breaking point) as wellas endurance and fatigue.

The next step is sintering. This is the process of forming a cohesive mass by the use of heat without melting the part. During the sin- tering process, parameters such as temperature, atmosphere, belt speed, and environmental factors are monitored and registered. Lubricants and binding agents are driven from the part. The heat of the sintering process forces the alloying agents to diffuse throughout the part. After the sintering operation, parts are maintained in a controlled atmosphere to prevent decarburization. At this stage, the rods are known as pre-forms. The pre-form is quickly heated to above 1,500 degrees, and a mechanical screw press is used for final forging. Force, speed, timing, tool temperature uniformity, and tool lubrication are controlled. The rods are now complete to near net shape and are forged to full density.

The rods also involve a practice known as fracture notching, which falls into the classification of "secondary operation." There are advantages to the fracture split technology that serve the part better than the standard saw cut. Superior alignment is assured with the processing. The fracture split surface will also eliminate fretting, thus there's no need for guide bushings with this procedure.

The parts require other secondary operations. These could include honing, boring, grinding, and drilling. If a chamfered or beveled face is needed for a product, this can also be implemented at this step.

The rods are the product of an evolution. They start in the briquetteform (left), go through the forging to reach the middle stage, and thenbecome heat-treated and finish-machined before shipment to the customer.

The rods are the product of an evolution. They start in the briquetteform (left), go through the forging to reach the middle stage, and thenbecome heat-treated and finish-machined before shipment to the customer.

The finished product is thoroughly tested to determine its ability to withstand the demands of the application. After satisfactory completion of the testing phase, mass production of the pieces can be ordered.

Precision powder forging has several advantages over the conventional forging process:

1. Greater material flexibility

2. Fewer burrs that require additional work to remove

3. Minimal weight fluctuation between pieces--allowing easy replacement of a single rod

4. No material textures

In terms of weight fluctuation, the tolerances are tightly maintained. The whole part is weighed and must fall within a total tolerance area. In the case of the connecting rods, by the nature of the part's design, the pin end has a 6 percent tolerance while the crank end has a 2 percent tolerance.

GKN has the capability of making 130,000 rods daily. The material used in the rods is ASTM 4260, which, in many ways, is superior to 4340 steel. The metal standard was established by ASTM International, formerly known as the American Society of Testing and Materials.

The rods will be made in America and can be easily reworked by using oversized bearings available from three different manufacturers. Initially, the rod has become available for the small-block Chevrolet applications. The cost savings was expected to reduce the racers' budget by as much as 40 percent in comparison to units of similar quality. Top quality rod sets, equally matched, are expected to cost $600 at the retail level. The target weight of the small-block Chevy rods is between 500 and 600 grams, and the approximate horsepower range is between 700 and 800.

The search for better technology has found the powder metal application starting at this point, but the drive to find more use is clearly underway. The methodology and materials have been proven in lab tests, product tests, and real life applications. Racers looking for competitive alternatives have to consider the advantages found in powder metal. If they don't, their competition will. CT

Editor's Note: Special thanks to Al Barra for research and material provided.