In the Aug. '08 issue, we did a full rundown of Edelbrock's new aluminum Performer RPM 409 cylinder heads for Chevy W-series 348/409 engines, in addition to a line of foundry-fresh dual-quad intake manifolds, valve covers, and a high-efficiency water pump for the legendary W engine. It's been a long time since we've seen a buildup of a serious 409 engine, so we followed along as Edelbrock put together a complete engine to test its new parts.

We won't keep you in suspense: Gulping 91-octane unleaded, the 421-cube mill (0.060 overbore) cranked out 466 hp and 461.9 lb-ft with a stock stroke, conservative 9.6:1 compression, dual Thunder-series 500-cfm carburetors, and out-of-the-box heads. Step up to a 470-plus-cube stroker kit, add a point of compression, swap on a set of 750-cfm carburetors, and do a little porting and you'll nudge 600 hp for sure.

Now that we have that out of the way, let's take a minute to examine a critical weakness of the original 409, as installed in '61 to '65 Chevy passenger cars ('66 in heavy trucks only). While the '58 to '61 348 (also installed in trucks through '66) was a respectable performer with a good reputation, when Chevy bored and stroked it to 409 cubes in the '61, a star was born. But as hot rodders really pushed the 409, many discovered the connecting rods were not up to snuff and catastrophic engine failure often resulted, thus tarnishing an otherwise excellent reputation.

The stock 409 crank is a quality forged piece that weighs 641/2 pounds. It was sent out to Marine Crankshaft for journal refurbishment cuts (0.010 mains, 0.020 rods), chamfering, and nitride-hardening.

The stock 409 crank is a quality forged piece that weighs 641/2 pounds. It was sent out to Marine Crankshaft for journal refurbishment cuts (0.010 mains, 0.020 rods), chamfering, and nitride-hardening.

The root cause of these 409 engine failures can be traced back to the W engine's unconventional combustion chamber layout-and the need for heavy pistons to make it work. Unlike the Chevy small-block (and the vast majority of postwar Detroit OHV V-8s), which placed the combustion chamber volume in the cylinder heads, the W has combustion chambers located at the top of the cylinder bores. By machining the deck of the block at a 74-degree angle to the cylinder bore centerline and topping the decks with flat-faced heads, a wedge-shaped chamber results.

The snag is that the layout called for heavy pistons with unusually thick crowns to fill the void. Heavy pistons in and of themselves don't doom an engine to also-ran status-check out any 426 Hemi for proof-but hefty pistons demand equally rugged connecting rods for survival when hot rodders take it to the next level, and that is where the stock 409 was flawed. Even though Chevrolet beefed up the 348 connecting rod for use in the 409 with thicker beams, 0.135 inch less length (from 6.135 to 6.00), and extra weight (from 24.71 to 27.16 ounces each), it wasn't enough.

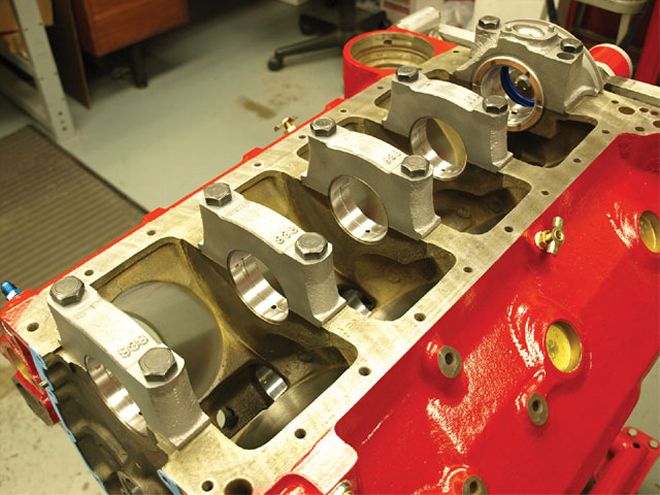

Unlike Chevy small-blocks and big-blocks, which were available with four-bolt main caps, all 409s have two-bolt caps, even the exotic '63 Z-11. Pro-Gram Engineering offers billet steel four-bolt cap conversion kits that are plenty strong up to 550 hp for those seeking extra beef. Clevite semigrooved main bearings are installed with the grooved half in the block.

In a stock 409 or 425hp 409 application, the factory-installed mechanical cam and valve-springs went into valve float before piston speed could wreak havoc on the marginal connecting rods. But as soon as hotter cams and springs entered the picture, 409s spent more time in the upper rpm ranges, placing too much stress on the forged-steel rods and eventually causing failure. That was then.

Today's 409/348 builder can choose from numerous aftermarket forged- and billet-steel connecting rods to solve the problem, thus opening a whole new world of potential. Add Edelbrock's heads and intake to the mix and the W engine gets a new lease on life.

Jung worked with JE to design 9.6:1 pistons (right) that compensate for the truck block's extra chamber volume. Ask for job No. 668050 for an exact copy of these 0.060 oversize goodies. If your bore or compression needs differ, use forging No. 277274 as a starting point and fine-tune the details with JE's tech advisers. Anti-409 types cite the 409's lopsided piston crown as an inherent flaw that whips the rods and slaps the skirts with an uneven load. Jung says the threat is overstated, and he offers this comparison of a typical big-block Chevy piston (left). Note that the pop-up dome is positioned in a similar off-center fashion. He notes: "You'd have to run a 409 at 8,000 rpm for extended periods for the uneven distribution of piston crown mass to become a tangible durability issue."

While the JE forged pistons weigh a considerable 814 grams, replacing the weak Chevy forged rods with much stronger Eagle forged H-beam rods nullifies the threat that plagued 409 racers of yore. The rods are basic 6.135-inch Chevy big-block items that fit the 409 crank perfectly. For comparison's sake, standard 348 Chevy 9.5:1 cast pistons (similar to 409) weigh 787 grams, while the 11:1 cast pistons installed in the so-called 348 police cruiser weigh 826 grams. Trivia buffs will note that 348 rods measure 6.135 inches center to center, while OE 409 rods are shorter at 6.00 inches. The 0.135 extra length of the Eagle BBC rods was dialed in to the JE piston pin height formula. The ARP 7/16 12-point capscrews are far superior to the 3/8 bolts used in original 409 rods.

With the Clevite rod bearings in place, Jung applies ARP assembly lube to the threads and torques the rod bolts to 63 ft-lb. Regular 30-weight oil is used when torquing the stock 1/2-inch Chevy main cap bolts to 95 ft-lb. The main cap fasteners are tightened in three steps and crankshaft endplay is set at 0.008 inch. Piston rings are JE moly with end gaps set at 0.020, 0.022, and 0.031 top to bottom. You must use a thin strap-type ring compressor during piston installation in the block. Typical machined collars are too thick to fit inside the deck counterbores.

A conventional big-block Chevy Melling high-volume oil pump does the job, but Jung welds the pickup tube into the pump body to guard against loosening and air leaks caused by harmonics. He uses a TIG welder with silicone-bronze wire to minimize heat and get good penetration. Jung also welded a few rust patches to revive the truck-sourced oil pan. Brand-new 6-quart steel oil pans are also available from Show Cars Automotive. Traditional SBC and BBC oil pans are not suited to the W engine's larger end crescents.

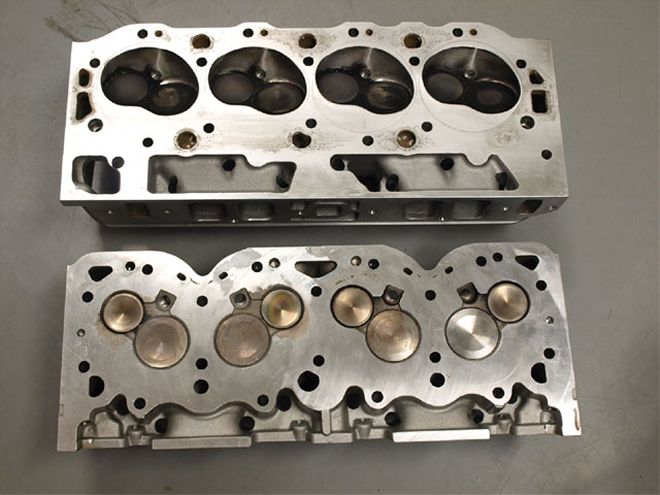

The pen points out the 409's unorthodox combustion chamber scheme. Not including the head gaskets or the minuscule 17cc channels placed around the valves in the cylinder heads (put there by GM to protect the valve heads from shelf damage and retained in Edelbrock's redesign), combustion chamber volume measures 70 cc. Chevy's original intent was to tailor compression ratio using piston shape and block machining so a single cylinder head casting could be used for manufacturing simplicity.

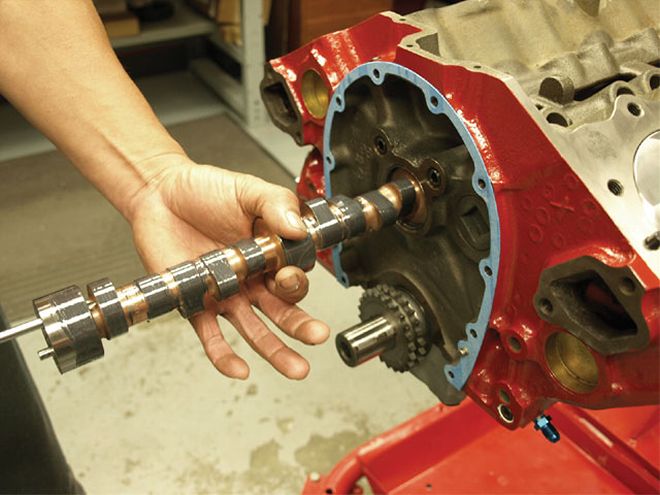

The cam is a Crane hydraulic roller with 0.616/0.628 lift and 292/296 advertised duration (230/234 at 0.050). Quite a bit hotter than the 0.511-lift Z-11 cam of 1963, this roller grind has fast ramps that allow rapid valve movement while preserving cylinder pressure. The 409 takes small-block lifters, so Edelbrock SBC hydraulic roller lifters are used. The box-stock single valvesprings (with surge dampers) showed no hint of valve float at the 6,000-rpm test ceiling.

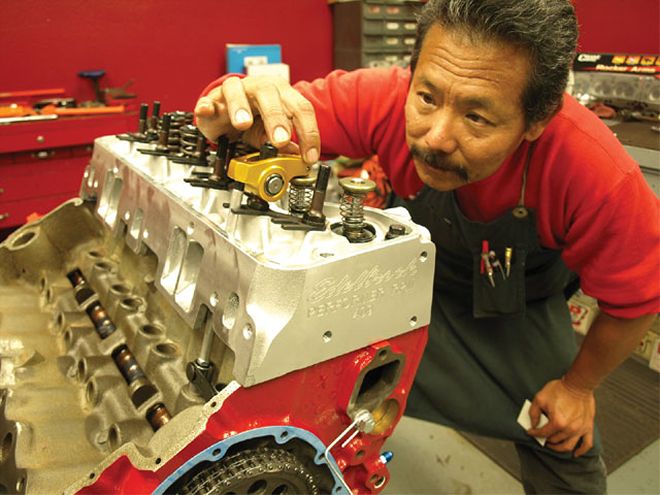

Piston-to-valve clearance measures 0.115 inch (intake) and 0.252 (exhaust), leaving plenty of room for wilder cam timing in the future. On original 348 and 409 heads, the intake rocker studs are offset 8 degrees from vertical and the exhaust rocker studs are offset 12 degrees from vertical. Edelbrock split the difference, so both studs are aligned on the same 10-degree plane to allow simplified flat pushrod guideplates. Stock Chevy rocker studs are failure-prone press-fit (pinned on 409 heads); Performer RPM 409 heads use upgraded 7/16 screw-in studs to end valvetrain problems.

Box-stock Crane 1.7 big-block Chevy roller rockers work with Edelbrock 3/8 chrome-moly pushrods. Hydraulic roller lifter preload is set at one turn past zero lash. Edelbrock's Mike Sessa was free to design the cool polished aluminum valve covers without oil fill or PCV holes because W engines fill oil to the lifter valley through an access tube in the intake manifold. And while vintage 409 manifolds had road draft tubes, Edelbrock's Chad Magana cleverly hid a PCV valve at the rear of the intake manifold for more effective crankcase vapor and pressure evacuation.

At 31.5 pounds each, the aluminum heads weigh exactly half as much as iron stockers. Fel-Pro composite gaskets have a 0.048 compressed thickness and are available from Edelbrock as well as most parts stores. A Cloyes double roller timing set and Teflon thrust button are used.

Ignition is via an MSD 409-specific Pro Billet distributor and 8mm solid-core wires. Ideal timing is 34 BTDC for this combination, an indicator of excellent thermal efficiency. Edelbrock's Curt Hooker reconfigured an old set of 17/8 small-block Chevy Sprint Car headers to fit the 409 dyno mule. Current off-the-shelf headers are mainly block huggers intended to suit the contours of the '58 to '64 Chevy X-frame. Until the aftermarket responds, custom-built headers are your best bet-especially if your 409 is destined for a Chevelle, Nova, or Camaro.

It's just not a 409 without dual quads. The eight-barrel intake mounts a set of 500-cfm Thunder series carburetors. While Performer series carburetors also work well, the Thunder carburetors feature externally adjustable secondary air valves. In dual-carb applications, the spring-loaded secondaries make tuning easy with a screwdriver. The box-stock 0.086 primary jets were left alone for the dyno testing, but wide-open throttle (WOT) revealed 13.2:1 air/fuel (A/F) measurements. Increasing the 0.077 secondary jets to 0.080 (a 5 percent enrichment) yielded a more ideal 12.1:1 air/fuel ratio at WOT and an extra 8 hp for our grand total of 466.

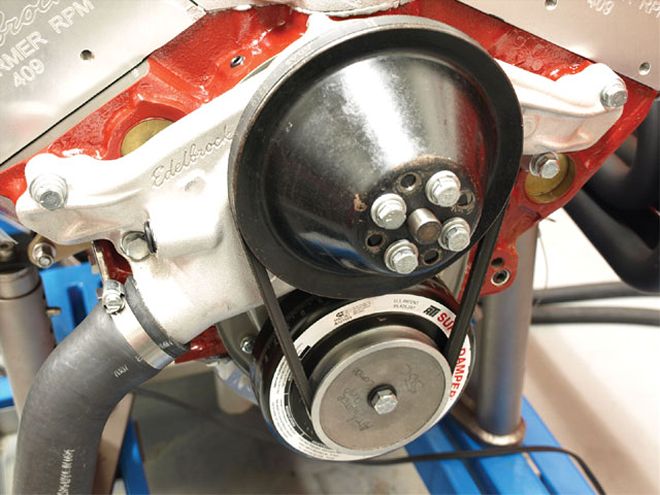

W engines take a wider water pump housing than other Chevy V-8s. Edelbrock's new high-efficiency 348/409 pump is also sure to find favor with Ford flathead builders-a simple adapter is all it takes. The W crankshaft snout accepts small-block harmonic dampers; a neutral-weight ATI Super Damper is used.

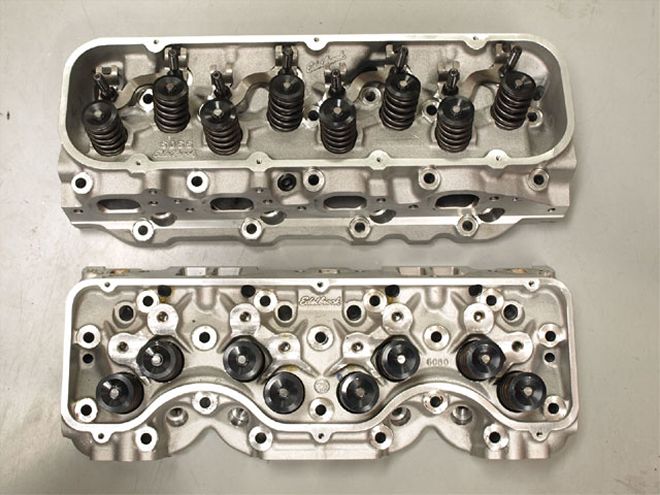

Distant Cousins Chevrolet intended the original '58 348 W engine-and '61 409 derivative-to take over in passenger-car and truck applications where the original 265 and 283 small-blocks lacked sufficient torque for the job. To ensure capacity for future displacement increases, the bore spacing was set at 4.840 inches, and Chevy's first big-block engine family was born. This visual comparison of Edelbrock's 60809 Performer RPM 409 and 60559 Performer RPM 454-R heads will help you get your head around the similarities-and differences-between the W engine and the '65-and-up Chevy big-block Rat motor.

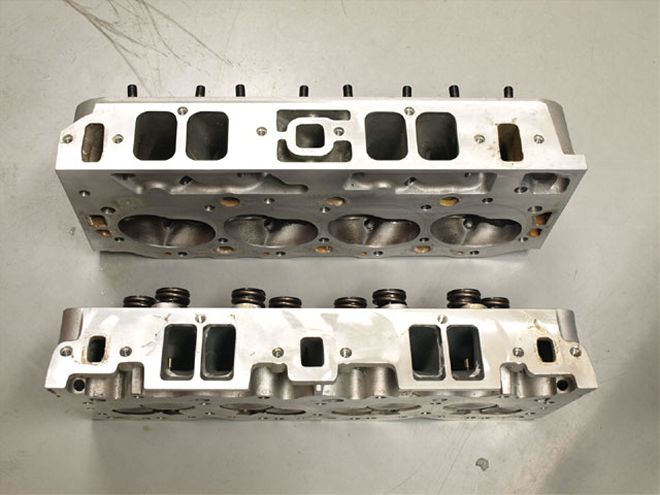

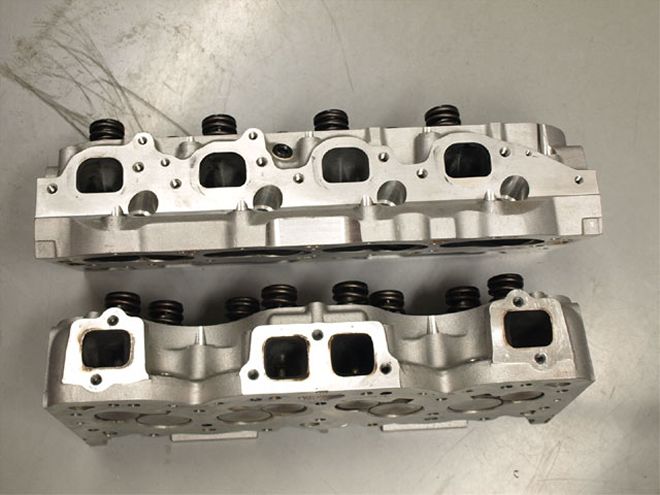

The W's unique staggered valve layout (bottom) was intended to place the valve heads close to the port openings to deliver short, efficient runners. The Rat maintains the theme but tilts the valves so they open toward the center of the cylinder bore for reduced shrouding. The W features six head bolts around each cylinder bore; the Rat uses five. Unlike the Rat, the W's spark plugs are positioned above the header flange, so burned ignition wires and knuckles are never a problem on 348s and 409s.

The Performer RPM 409's tall, narrow intake ports (bottom) measure 220 cc and flow 282 cfm at 0.600 lift. The Performer RPM 454-R intake ports measure 315 cc (long port) and 300 cc (short port) and deliver 314/297 cfm, respectively, at 0.600 lift. GM was clearly influenced by the success of the small-block when it designed the W's intake ports. Edelbrock's Ulises Gonzalez added plenty of port-wall thickness to the Performer RPM 409 heads for 409 builders wanting more flow.

The Performer RPM 409's square exhaust ports (bottom) measure 90 cc (center pair) and 115 cc (end ports) and flow 215.2 cfm at 0.600 lift. The Performer RPM 454-R's D-shaped openings measure 110 cc and flow 228 cfm at 0.600 lift. The big-block flow test data is taken from the Edelbrock catalog; the 409 numbers were supplied by Edelbrock's R&D department.

The Performer RPM 409 (bottom) uses 2.19/1.72 valves. The minuscule relief between the valves measures 17 cc. The Performer RPM 454-R features 2.19/1.88 valves and 118 cc open-style combustion chambers. The W engine's unique E-I-I-E-E-I-I-E valve layout forces the need for paired sets of pistons on each bank. Use care to make sure the pistons are installed correctly (with the intake valve notches in proper sequence). Failure to do so can result in bent valves. Both heads feature beefy 9/16-inch-thick decks.

RecipeDisplacement: 421 ciHorsepower: 466.1 at 5,800 rpmTorque: 461.9 at 4,300 rpmCompression ratio: 9.6:1Bore/Stroke: 4.3725 x 3.50Maximum safe engine speed: 6,500 rpmRecommended shift point: 6,200 rpmFuel requirement: 91-octane unleaded

Bottom EndBlock: '64 truck, casting No. 3857656Crankshaft: '64 truck, forged-steelBalancer: ATI Super DamperRods: Eagle forged H-beam (PN CRS-613530)Rod bearings: Clevite (PN CB743HN-20)Rod bolts: ARP 7/16, 12-pointPistons: JE 9.6:1 forged-aluminum, 0.060 oversize (job No. 668050)Rings: JE moly (PN J100F8-4375-5)Main caps and fasteners: Stock Chevy cast Arma-steel, 1/2-inch boltsMain bearings: Clevite semigrooved (PN MS458P-10)

Oiling SystemOil pan: '64 Chevy 409 truck, 6 quartsOil pump: Melling high-volume (PN M99HVS)

HeadsType: Edelbrock Performer RPM 409 (PN 60819)Valvesprings: Single w/damper (incl. w/heads)Intake valves: Stainless 2.190, 11/32 stems (incl. w/heads)Exhaust valves: Stainless 1.720, 11/32 stems (incl. w/heads)Retainers: Chrome-moly (incl. w/heads)Rocker arms: Crane Gold series billet aluminum roller, 1.7 ratioHead gaskets: Fel-Pro composite (PN 8007)

CamshaftType: Crane hydraulic roller (PN 159531)Advertised duration: 292/296 degreesDuration at 0.050 lift: 230/234 degreesLift: 0.616/0.628Lifters: Edelbrock hydraulic roller (PN 97383)Pushrods: Edelbrock 3/8 chrome-moly (PN 9635)Timing set: Cloyes double-roller (PN 9-3101)

InductionIntake manifold: Edelbrock dual-quad (PN 5409)Carburetors: Edelbrock 500-cfm Thunder AVS (PN 1804)

MiscellaneousDistributor: MSD Pro Billet electronic (PN 8393)Spark plugs: Champion RC12YC, gapped at 0.035 inchWires: MSD 8mm Heli-CoreWater pump: Edelbrock high-volume (PN 8858)Valve covers: Edelbrock polished cast-aluminum (PN 4140)Timing specs: 34 degrees