I needed to call AFR boss Rick Sperling to give him the great results I had just seen with a pair of his company's small-block Chevy heads on a 350. In a way, I was just bragging, because our combination had exceeded his predicted numbers by almost 30 hp. After we were done on that subject, Rick asked if I would like to test the latest version of their street as-cast 325cc runner big-block heads. Sure, but there was a problem. I was on deadline, and time was not on my side. But I had an idea. My co-conspirator on many engine build projects over the last four years, UNC Charlotte engineering student Dusty Kennett, had accrued much experience with pretty racy small-block Chevy and Ford engines. But his big-block experience was minimal, and I had a suspicion he was hot to trot on something bigger than just a regular 350 or 383 small-block. So I asked Dusty, "You wanna build a 500-inch big-block Chevy to test AFR's new heads?" Response: a big smile, and, "Yeah, sure!"

Never one to needlessly reinvent the wheel, Dusty started by calling budget big-block building expert Lloyd McCleary of T& L Engines for some basic advice. Here is what he got: "Big-blocks love compression, but in a 454 or smaller motor, that means a big piston dome, which they don't like so much. To avoid this, stroke it. From here on out, it's a question of good induction, good heads, and the right cam." Yeah, Dusty, no problem. Go for it!

Short-Block

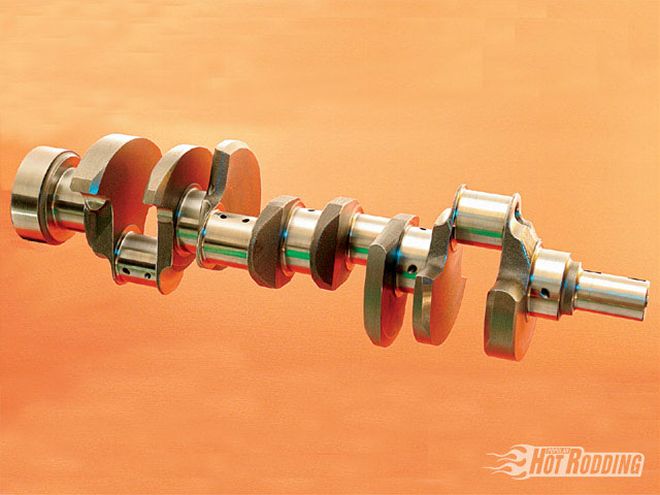

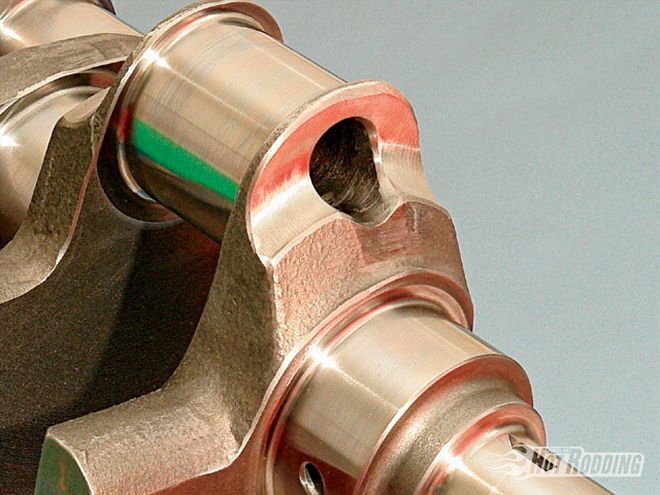

As it happens, Dusty had located a Gen IV block, just in case a build opportunity came his way, so at this point it was a question of dragging it out of storage and checking it out for suitability. It proved to be crack-free, and the sonic tester showed it was OK for our intended build. The next job was to drop it off at T&L for a top-to-bottom machining job. T&L put the block through the system, and when it came back from boring (.040-over), honing, decking, etc., we checked it out with some high-tech equipment, and it was right on the money. The crank we chose was a 4.25-inch stroker from Scat. There were many reasons for going with the Scat brand. First, all of these cranks are ground in their Redondo Beach, California, plant on the same grinders that do their Cup Car, Top Fuel, and Pro-Stock cranks. Secondly, the Scat cranks are cast from an alloy that is about the top of the line in cast steel, and runs some 10,000 psi stronger than many of the cast steel cranks available today. Third, Scat has a $250 balancing service that has much to commend it. You can get an entire rotating assembly from Scat as a balanced kit, or you can have the crank balanced to suit whatever pistons you have. The real beauty of having Scat balance the rotating assembly is that they machine off most of the excess material from the counterweights in a lathe. This means that each counterweight not only gets the right proportion of metal removed to keep the intended mass distribution, but also very little drilling is needed to finish off the balancing. All this, plus a windage radius on the leading face of the counterweights, makes for a good-looking crank that is lighter and stronger than average at a very reasonable cost.

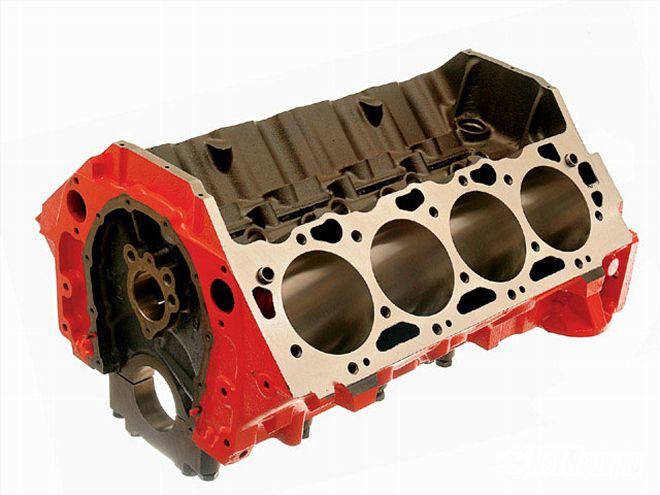

The basis of our 492ci buildup was a Gen V 454 big-block. Here's how the block looked as we received it from T&L. Before any major assembly work was started, all the installed bearing sizes were checked to see that they would produce the correct clearance with the crank and rods being used.

The basis of our 492ci buildup was a Gen V 454 big-block. Here's how the block looked as we received it from T&L. Before any major assembly work was started, all the installed bearing sizes were checked to see that they would produce the correct clearance with the crank and rods being used.

As for rods, it is a good move to go for a longer-than-stock rod, especially if a stroker crank is used. Big-block Chevys already have a rod that is a little on the short side to begin with, so it makes no sense to aggravate the situation by adding stroke and retaining a stock-length rod. We used a set of Scat's 2-ICR6385 rods. These 4340 forged I-beam rods sport a 7/16-inch cap bolt, and though they will go higher for a drag race-only application, are about bulletproof up to 7,500 rpm and 850 hp. With the stroke in our crank, they allow the rod/stroke ratio to be put back to almost stock-1.5 for our stroker versus 1.53 for a stocker.

At this point, we come to the pistons. As it happens, KB had just introduced a new design of inexpensive heavy-duty forged pistons, and we were eager to try a set. In the line-up, they had a spec (PN KB-789) that gave us precisely the 10.5:1 pump-gas ratio we wanted. This piston is machined from a nice-looking and robust forging. The crown itself is reinforced with stiffening ribs that indicate great nitrous capability without much of a weight penalty. Rings are of a conventional 1/16-1/16-3/16-inch pattern, so not much out of the ordinary there, but when all is said and done, this is a proven ring pack that is relatively inexpensive. At face value, the pistons looked good, but at the end of the day, the dyno numbers will be the deciding factor.

The first test would be to see how freely the assembled short-block turned when tested with a torque wrench. Dusty makes a power move that, though time consuming, is worth passing on. He takes a Scotch-Brite pad and gently polishes the rings so they feel smooth. This takes about 60 seconds a ring. As for the bores, the treatment depends on the quality of the bore finish. If done to Cup Car quality, then leave as-is, but for a regular street hone job, make a few passes with the Scotch-Brite in a vertical motion up and down the bores. This takes the micro-sized ragged edges off the top of the hone pattern. This speeds break-in, and causes less wear. It also cuts friction, and that means a little extra power. A post assembly torque turning test showed our 4.25-inch stroker, with street-oriented clearances, turned at a very creditable 28 lb-ft, whereas 33-35 lb-ft is about normal for a typical street build.

This is the latest iteration of Scat's cast steel 4.25-inch stroker crank. A relatively recent material upgrade makes this cost-conscious cast steel crank almost as strong as a forged crank.

This is the latest iteration of Scat's cast steel 4.25-inch stroker crank. A relatively recent material upgrade makes this cost-conscious cast steel crank almost as strong as a forged crank.

Last item on the agenda for the bottom end is the pan. Any time a stroker crank is used, the chance of the crank picking up oil and entraining it is very real. Personal experience has shown that it's easy to lose as much as 15 hp when this happens. The fix is a good pan. We used one of Moroso's basic pans, which did the job nicely.

AFR Cylinder Heads

Because of its large displacement, a big-block Chevy really needs a lot of airflow. But this is far from the only factor that dictates success. To see what we were dealing with, our AFR heads (PN 2101-1) were tested on the bench along with some other brands that we've used to successfully make strong torque and power curves. What we found was that flow was up with the best. Also, swirl was good, and port velocity and velocity gradient were a little better than most. So things looked good. As far as volumes were concerned, the intake ports (good and bad) averaged 319 cc, while the chambers, which are CNC machined, checked out at 119 cc. For our 10.5:1 compression, we planned on milling to 112 cc. But there's more. AFR has established a reputation for using top-quality hardware on their heads, and these big-block heads are no exception. Instead of the more normal 3/8-inch valve stems, the AFR heads sport much lighter 11/32-inch valve stems. Additionally, AFR uses a more costly spring package. Because these springs can be run at a higher stress, they are lighter for a given poundage, and this results in better valve action, especially with a hydraulic roller. The smaller springs also mean a lighter valve retainer, and all this weight reduction adds up to superior valvetrain control, and that's all good for more power. By any standard, these AFR heads are a great deal, and promised to deliver well on the dyno.

Induction System

We tend to think of Dart as a cylinder head manufacturer, but the truth is they also make some outstanding intake manifolds. With four years of engine building experience, Dusty had found this fact out for himself. Drawing on this experience, he selected a Dart intake manifold (PN 4112400). This intake was to be used with a Dominator-style carb, so it has to have plenty of flow for the job. So often, big-blocks end up being undercarbureted. For a big-block targeting over 600 hp, it almost inevitably runs best on a Dominator-size carb. Just looking at airflow proportionally to a small-block, we can see that if a relatively stout 355 needed 800 cfm, a 500-inch big-block would, on a pro rata basis, need 1,125 cfm.

The carb Dusty chose was a relatively new AED Dominator. AED has made some great strides with these carbs in driveability and low-speed output. Just in case you think 1,200-plus cfm is too much carb for a 492ci street big-block, try this for size. The last engine Dusty built was a 355-inch small-block. On this he tested AED's claim that this carb allows much more flow for a strong top end without necessarily compromising the low end. The carb ran flawlessly on a 355 incher. It was only down about 5 lb-ft over a purpose-built 900-cfm 4150 at 2,000 rpm, but was up over 20 hp at peak, and about 30 up at 8,000 rpm.

After mocking up the heads on the block, the Dart intake was first port-matched to the heads. Only a minor amount needed to be removed to achieve this goal. The intake runners were dressed out with 60- and 80-grit emery rolls to remove casting flash. The last operation on the runners was a coarse bead blast. Last item on the agenda was to modify a Moroso 1-inch four-hole spacer. This is worth about 5-7 hp from about 5,000 on up, with no measurable downside at lower rpm.

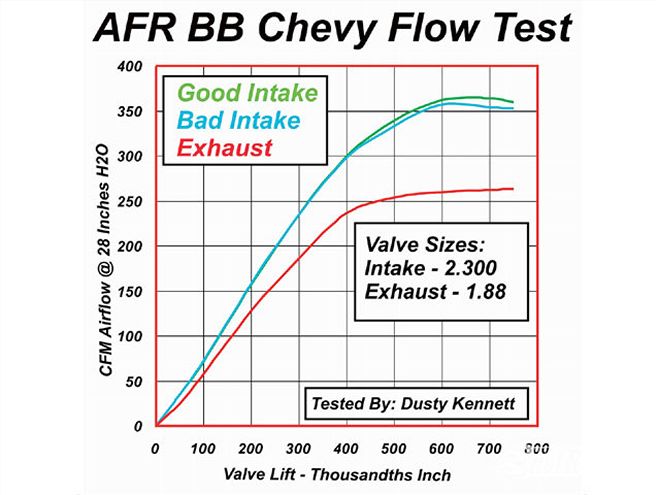

Flow tests of AFR's 325cc big-block head are among the best of a series of heads tested. Good flow figures, a moderate port volume, and good swirl promised to deliver the results we were looking for on the dyno. Here are the flow figures produced by our test heads. Note that the curve substantially levels out by the time .700-inch lift is reached. This should work well with a valvetrain lifting to a little over .650 inch.

Flow tests of AFR's 325cc big-block head are among the best of a series of heads tested. Good flow figures, a moderate port volume, and good swirl promised to deliver the results we were looking for on the dyno. Here are the flow figures produced by our test heads. Note that the curve substantially levels out by the time .700-inch lift is reached. This should work well with a valvetrain lifting to a little over .650 inch.

Cam And Valvetrain

If the valves are opened and closed at the wrong time, no matter how good the heads, intake, and carb are, the motor will not produce anything like its full potential. The factors affecting what the engine needs in the way of valve events are the cubic inches, valve sizes, compression ratio, rocker ratio, rod length, and a lot more. All too often, cams are chosen on the basis of prior luck. In my shop, we use a Cam Master computer program that, give or take a degree or two, gives the opening and closing points needed for a specific peak power rpm. It also delivers the lift figures for maximum output, and identifies the LCA within one degree. We were looking for peak power at 6,000 rpm. The Cam Master program predicted that the engine needed a cam of 283 and 282 duration (intake and exhaust) at the effective lash point and on a 107.9-degree LCA at 4 degrees advance.

With this information, a COMP Cams single-pattern 280 XRS street roller, ground on a 108 LCA 4 degrees advanced, was ordered. This street roller profile gives about 285 degrees duration at the lash point. A street roller profile was chosen because it would be reliable over a very long haul. As for the rest of the valvetrain, lifters were COMP's Endurex items, which actuated the rockers through 3/8-inch Magnum pushrods. The pushrods were length-selected to optimize valve lift and the sweep geometry across the top of the valve stem. As for rockers, it should be said that COMP's aluminum rockers are more than up to the job. Nevertheless, we had a set of their Pro Magnum stainless rockers that we've been wanting to use, so that is what we used here. For sheer good looks, the valvetrain was topped off with a set of Moroso cast aluminum valve covers with a black crinkle enamel finish.

Ignition System

For spark, a Performance Distributors HEI was selected, and although it may seem out of step with a big-block build, it was selected with fuel economy in mind. We ordered our HEI from Performance Distributors with a vacuum advance. This little upgrade is often shunned by hot rodders, because it's seen as an unnecessary addition to the distributor. The fact of the matter is that at cruise, when the engine is pulling vacuum, the timing needs to be as much as 40-45 degrees advanced. If the vehicle is only turning 2,000 rpm at 70 mph, there will only be about 20-25 degrees advance if only static and mechanical are used. The difference between what timing the engine wants at cruise, and what it's given if no vacuum exists, costs between 2-4 mpg! A vacuum advance HEI is the fix.

This particular KB piston is a relatively new part number in KB's line of inexpensive forged pistons. If you have really big horsepower numbers in mind, then you'll be interested to know these pistons are nitrous-capable. As with any big-block, piston crown form is critical. Too much dome, and power can come down even if the compression is going up.

This particular KB piston is a relatively new part number in KB's line of inexpensive forged pistons. If you have really big horsepower numbers in mind, then you'll be interested to know these pistons are nitrous-capable. As with any big-block, piston crown form is critical. Too much dome, and power can come down even if the compression is going up.

In addition to a vacuum advance, the HEI was also ordered with a clear plastic cap so we could easily see that the rotor aligned OK with the pickup points in the cap. This is an easy way to see what they do during the build. The clear one can always be swapped out for a regular one right after alignment has been verified.

Carburetion

As mentioned earlier, carburetion is by a high-flowing AED Dominator-style carb. With its radically revised circuitry and calibration, this has shown to be versatile enough to produce outstanding results on engines as small as 355 inches, when appropriately calibrated. For a big-block, low-speed output with a Dominator-style carb is rarely in question. The engine is usually big enough to need all the carburetion it can get from a carb of this size. With the carb installed and a few other little details taken care of, our 492 was ready for the dyno.

Test Time

As is so often the case, our dyno testing was done at T&L Engines, in Stanfield, North Carolina. We used this opportunity to do a little impromptu testing of intakes and carbs, but time was limited, so any real fine-tuning was out of the question, except for the final spec we intended to use. First, the porting on the Dart intake looked to be worth about 10 hp, with gains starting at about 5,000 rpm. Also, the use of a two-plane intake and a high-flowing 4150-series carb are worth considering. This engine made low-speed torque like a steam loco, even with the single-plane intake and the big Dominator carb. So much so that, even when put on full load, it blew through the dyno's absorber to a lowest "hold-down" point of 4,500 rpm. If the two-plane made any more torque below that, we were not in a position to measure it. In the normal course of events, this combo probably did make more low end, but any extra torque could prove to be more of an embarrassment in all but the heaviest of vehicles. Above 4,500, the two-plane/4150 combo started to lag behind the single-plane/Dominator combo. By the time 6,000 rpm came around, it was down by about 50 hp. All this pointed to one thing: the spec we originally conceived was on the money. The conclusion is that the AFR heads work just fine, thank you, but any successful engine is a combination of the right parts, so take note of the cam, intake, compression, and pistons that were used with these heads. If you are in the market for a set of highly functional and cost-effective big-block heads, the suggested retail price for these AFRs is $2,485 a pair ready-to-install, but we've seen street prices below this. The tale of the tape showed the Dominator-topped, single-plane combo feeding the AFR pieces to the tune of 632 lb-ft at 4,600 rpm, and 656 hp at 6,100 rpm.

At the end of the day, we learned three important things about stroker big-block Chevys. First, a Dominator-style carb on top of a single-plane intake is preferable over a 4150 on a dual-plane, unless there are class rules or physical constraints, such as hood clearance. Secondly, AFR's box-stock 325cc big-block head is a relative bargain when compared to many of its contemporaries in the same price range. And finally, you can get an exact replica of this engine in crate form (less headers and water pump) from T&L for about $8,145-which, in big-block parlance, is an absolute bargain.