Any time you push the boundaries of engine output, you know there will need to be some dyno testing, and that's exactly the case here. We had some boundaries to work within, so that the end result was a sane build for the average mid-budget hot rodder. These boundaries included pump gas, a minimum of 350 lb-ft at 2,500 rpm, and a near lope-free idle of no more than 850 rpm. As for output, our goal was to see if 600 hp from a 350 block running on pump gas was even feasible. In the process, we would look at some newer speed parts, plus some tried-and-tested parts. All this, it should be said, will be attempted without the aid of a blower or nitrous.

400 Cubes With A 350 Block!

It's doubtful any of us need to be reminded that more cubes means a stouter engine, but it's been some 35 years since GM made the 400-cube version of the small-block. These tended to have an overheating and cracking problem, which has resulted in a scarcity of usable ones. The same cannot be said of the 350 block. It's about as reliable as a block can get and there are still millions available to the hot rodder. Stretching a 350 to 383 inches has been a common practice for the best part of 20 years. The question here is, can we go more? In terms of bore diameter, there is not much room to go more than 30 over, although a sonic tester can find blocks good for as much as 60 over. The combination to get a 383 is to bore the block 30 over (to 4.030 inches) and use a 3.75-inch stroker crank. The stroke increase over stock is 0.27-inch. Crowding this into a 350 block normally means cutting more rod clearance into the bottom of the bores and the sides of the crankcase. The amount needed to do a 383 sometimes compromises the block, and the clearancing goes into the water jacket.

Here is the late-model four-bolt hydraulic roller block we started with. This was clearanced for a 4-inch stroker crank and then pressure tested.

Here is the late-model four-bolt hydraulic roller block we started with. This was clearanced for a 4-inch stroker crank and then pressure tested.

Because the possibility of finding water is not that remote of a reality, the 3.75-inch stroke has long been considered the sensible limit of a viable 350-based stroker. But hot rodding, by its very nature, is all about pushing boundaries. Working with crank and rod manufacturer K1 Technologies, Lloyd McLeary of T&L Engines in Stanfield, North Carolina, has developed a procedure to reliably get a 4-inch stroke into a 350 block to produce 408 inches.

The process of producing 408 inches starts with a block selection procedure that involves both visual and sonic inspections. The sonic testing is the most critical aspect of a 408's success. Only about 50 percent of the good blocks already pre-selected for high-output builds will safely take the 4-inch stroke. Even so, it's close, as there is not much room to maneuver here. A typical performance rod on a 4-inch stroker crank will regularly break through into the water jacket. A key factor in making all this work are the modifications T&L does to the K1 rods. They make two moves to give the outer rod-bolt head more room: First, the bolt platform of the rod is machined about .025-inch lower, then the end of the rod bolt is machined .025-inch shorter. This, in conjunction with a block selected on the basis of sonic test results, gets the job done. The final inspection is to pressure-test the block to make certain it is watertight at the ground clearance points.

A 4-inch stroke was delivered by this K1 forged crank. This, with a .030-inch overbore, resulted in 408 inches.

A 4-inch stroke was delivered by this K1 forged crank. This, with a .030-inch overbore, resulted in 408 inches.

Going to 408 inches in an effort to achieve our 600hp goal might look like a big expense, but a stock factory crank at this power level will be well on the way to its limit. This makes a stout aftermarket crank more or less essential to the engine's ultimate survival. If a crank is needed, then it may as well be a stroker crank, as this will contribute to the output as well as beefing up the bottom end.

The piston requirements to meet the needs of an engine such as this are a little more critical than normal. First, to ease the reciprocating loads brought about by a stroke increase of over half an inch, we need to go for a tough piston that is also light, and these two factors are, for the most part, diametrically opposed. Fortunately, Mahle has a piston that fits the bill really well. Not only is it light, but this high-tech piston features thinner rings that are also narrower in plan view. This makes them able to seal up better with less ring drag, and that's an important issue on a stroker motor.

At this point, we have a short-block based on a 350 block that displaces 408 inches. You could build this short-block at home if you wanted by ordering all the parts from the relevant suppliers and getting a fully prepped and pressure-tested block from T&L, but quite frankly, it would cost you at least as much as getting the built short-block from T&L. The cost for an assembled block and balanced rotating assembly with a roller cam of your choice installed (we will get to that later) is around $3,200.

A big part of the deal toward successfully installing a 4-inch stroker crank into a 350 block can be attributed to the low bulk around the highly-profiled journal end of the K1 rod.

A big part of the deal toward successfully installing a 4-inch stroker crank into a 350 block can be attributed to the low bulk around the highly-profiled journal end of the K1 rod.

At this point, our 350 upgrade is looking good. We have 58 cubes more than stock, but that will not be of much use if the heads can't supply the air to feed those extra cubes.

Cylinder Heads

When AFR introduced their 195cc port Eliminator heads, it was without any great fanfare, so attention from our direction was somewhat limited. But rumors of great results with these heads (typical street price under $1,500) kept cropping up, so it looked like time to investigate. That was a year ago. Since then, we have sat in on dyno tests on four occasions and the output figures achieved were strong. For an air-hungry 408, some top-notch heads would be needed if results were to reflect the investment of time and money in the bottom end. These AFR heads looked like they would fit the bill and do so at a great price.

The AFR Eliminator heads feature 2.05-/1.60-inch valves and are CNC ported. As a pioneer in the field of both aftermarket cylinder heads and CNC porting, AFR has over a quarter century of experience to draw on. The Eliminator heads are a culmination of this experience, and represent some serious fine tuning of the 23-degree Chevy heads.

The heads selected for the job were the CNC-machined AFR Eliminator heads (PN 1036). There proved to be a lot more to the high-performance capabilities of these heads than just big airflow numbers.

The heads selected for the job were the CNC-machined AFR Eliminator heads (PN 1036). There proved to be a lot more to the high-performance capabilities of these heads than just big airflow numbers.

AFR has always been very strong in the cost department. This is because they CNC port these heads to a finish that delivers the most cost-effective result. If the finish is made finer, the cost escalates dramatically, while power may only change marginally-and it could go either up or down here. If the finish were made coarser, the price would drop only minimally, while the flow and power would drop measurably. But at the end of the day, finish is, at best, a second-order effect. The primary factor toward a functional head is port and chamber shape. Fail here and it matters little how good the surface finish is.

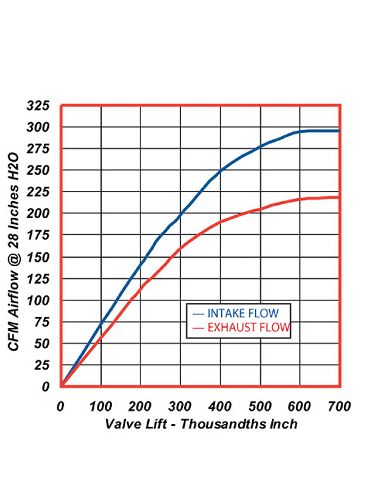

The reality is that shape dictates flow, swirl, port velocity, efficiency, wet-flow characteristics, and more. With any high-performance head, good airflow is essential, and though these AFR heads had that, there proved to be a lot more to their power producing capabilities than just airflow. That said, let's start by taking a look at the airflow as measured on T&L's freshly calibrated bench, and then move on to the other power producing assets.

The nearby graph (opposite page) shows the flow numbers we saw on the T&L bench. These, incidentally, were slightly higher than AFR advertises. Along with good peak flow numbers were fat curves, which were good from the seats all the way up. A point of note is that the bigger the displacement for a given intake valve, the more important low- and mid-lift flow becomes. With a 175-cfm intake flow at .250-inch lift, this AFR head is about 5 to 7 cfm more than we normally see at that lift station.

Along with good flow, the AFR intake ports also generated swirl numbers that typically deliver good results. Additional probing showed good port velocities and velocity distribution. All this adds up to promising results on the dyno.

The influence of Mahle F1 piston technology can be seen filtering down to their high-performance street offerings. Coatings, plus thinner and lighter lower-tension rings, along with strut and skirt technology inherited from F1, give them the advantage.

The influence of Mahle F1 piston technology can be seen filtering down to their high-performance street offerings. Coatings, plus thinner and lighter lower-tension rings, along with strut and skirt technology inherited from F1, give them the advantage.

As good as all the gas dynamics of these heads were, it was still short of the sum total. Other options could make a big difference, especially if you intend to use them with a hydraulic roller cam. The valves, springs, and retainers we used have been selected to enhance the rpm capability of the heads without going to a spring as heavy as would normally be used. For instance, the valves had an 8mm stem (a little under 5/16) with a lightweight head. This chops the weight of the intake valve from typically 129 grams to 105 grams with a commensurate save taking place on the exhaust. The valvesprings used for these heads are high-dollar items and also present a performance advantage. For our 408, we are going to need a lot of valve lift. To make a stable valvetrain, the spring must have low mass and a high natural resonant frequency. The AFR spring has both. It weighs a scant 92 grams (typical is 110) and delivers 160 lbs on the seat, and 424 lbs at .600-inch valve lift. Because it is a much smaller diameter than most springs, it needs only a small retainer. This weighs a slim 17.5 grams, as opposed to a typical retainer mass of 33.5 grams. All this attention to detail chops a worthwhile amount of mass out of one of the most mass-critical areas of the valvetrain. AFR's efforts in this direction mean the heads are ideally suited to hydraulic roller cams, and to high-lift solid street rollers-the latter is just what we are going to use.

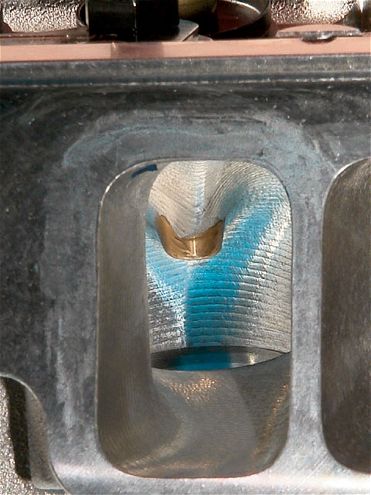

Note the finer-than-average finish in the combustion chamber of these AFR heads. This is the result of a CNC programming technique that is far from universal among entry-level CNC heads.

Note the finer-than-average finish in the combustion chamber of these AFR heads. This is the result of a CNC programming technique that is far from universal among entry-level CNC heads.

Cam Selection

Probably the two top reasons why street engines use a hydraulic roller are the zero-service factor and the quiet operation. What this has done for many hot rodders is exclude the solid street roller from consideration. We have run COMP's solid street rollers for many years; our longest one in service has over 80,000 miles on it, and has yet to need a lash adjustment. Also, by making the lash adjustments with care, the valvetrain is far from noisy. The sound is more like a purr, and is far from objectionable. This is being brought up because a solid street roller was a more appropriate choice; let's look at this 408's requirement. First, it has a lot of inches, so it will need to have a high-lift valvetrain. Secondly, there is enough airflow through the heads to make power up to 7,000 rpm. This means we have to deal with two contradictory situations: high lift and high rpm. Added to that, we needed a long and reliable service life. A COMP Xtreme Energy street roller takes care of that. The profiles chosen were 286XSR for the intake, and 292XSR for the exhaust. These profiles are 248 degrees and 254 degrees for the intake and exhaust respectively. With COMP's 1.65:1 rocker (PN 1006) on the intake and 1.5:1 (PN 1004) on the exhaust, net valve lift after lash was .620-inch and .588-inch.

While the coarse stepped finish in the intake runner has almost no effect on airflow compared to a fine finish, the coarse finish does help break up fuel rivulets for a more combustible mixture.

While the coarse stepped finish in the intake runner has almost no effect on airflow compared to a fine finish, the coarse finish does help break up fuel rivulets for a more combustible mixture.

Induction

The intent is to test two intakes. First, we wanted to see how well an Edelbrock Air-Gap Performer RPM fared on an engine with a projected output of over 520 hp. Experience has shown that on engines in the 300 to 500hp range, this manifold really delivers. Some of our previous testing has also shown that at about 530 hp, it appears to be approaching a limit. But testing on our 408 should better define its already well-appreciated attributes for producing a really strong low end with what is, for a two-plane intake, a very creditable top end. Next on the list to test is a Holley Strip Dominator. This is a manifold which seems to be short on credit for its good power capabilities. On engines capable of 500 or more horsepower, our previous experience has shown it gets the job done in style. With the hot spec of this 408, it seemed like a good idea to reacquaint ourselves with the Strip Dominator's power potential. Both manifolds were checked for a port match. Both aligned pretty well, so it was decided that we would run both intakes in out-of-the-box form.

For carburetion, we had three custom-built Holley carbs. These were carbs that had calibrations specifically for a big-cam 400ci engine. T&L has these built and calibrated for their engines by a Cup Car carburetion specialist. When checked on the flow bench, these carbs (a 750 HP series, a 750 HP with an 850 baseplate, and an 850 with a milled choke horn and some airflow work) delivered 803, 901, and 932 cfm respectively.

Some subtle port relocation and less than subtle port bias toward the cylinder wall side has resulted in a strong flow from the AFR Eliminator exhaust ports.

Some subtle port relocation and less than subtle port bias toward the cylinder wall side has resulted in a strong flow from the AFR Eliminator exhaust ports.

Spark Generation

For ignition, we used a Pertronix HEI-style distributor with vacuum advance. This was equipped with the lightest springs for the mechanical advance and fed the spark to the plugs via ACCEL 8.8mm plug cables. So why the vacuum advance? With this coupled to manifold vacuum (not the ported vacuum source) we were able to get the motor much more street friendly. Not only did the vacuum advance allow us to get a better and smoother idle, but also it consumed less fuel at idle and part throttle cruise.

Dyno Time

As is often the case, our project engine was run on T&L's dyno in Stanfield, North Carolina. After a one-hour break-in, the oil filter was removed and cut open for a particulate examination. This delivered a clean bill of health, so a new filter was installed and oil was added. The valve lash was given a final check and we were ready to go.

Our main push was to see if we could make 600 hp, and with only 6 hours of dyno time available to us, we did not spend too much time with the Edelbrock Air-Gap Performer RPM tests. The point was more to see what the "bulk" difference might be between the two-plane Performer and the single-plane Holley Strip Dominator. Going in, it was already known that this combination would need a large cfm of carburetion. At the same time, we did not want to compromise driveability, so we chose to run the Holley 750 equipped with the 850 baseplate. With its measured 900-cfm capability, this looked to be a good compromise on what had to be a one-shot deal.

A section through the AFR intake port reveals the floor has a lot less of a "ski jump" than most of its contemporaries.

A section through the AFR intake port reveals the floor has a lot less of a "ski jump" than most of its contemporaries.

The custom calibration on the carb proved to be right on the money, as any jet change up or down lost output. The results are in the chart on p. 92. Unless you are familiar with this sort of result, these numbers are going to take a little explaining for the true picture to be more clearly seen. First, note that the numbers are all rounded to the nearest whole lb-ft or hp. The reality is that this engine missed the 550hp mark by just 1.4 hp. That's a very creditable number for a two-plane intake. But look at the peak torque. That is only about 510 lb-ft. Normally, this would be somewhat higher, but because the peak torque is at relatively high rpm, the manifold is already pushed near its limit in terms of best airflow per revolution of the engine. At the peak torque figures, this combo is already well over the 500hp mark that Edelbrock envisaged would be about the limit of its use. What we have here is an example of a subtle parts mismatch. The demand from big cubes and high rpm is being effectively communicated, via a set of highly effective heads, to the intake manifold and carb. But as the big demand from the cubes/rpm/heads combo is increasing, the flow capability of the intake/carb combo is close to being maxed out, even at 5,000 rpm. Result: Because peak torque wants to occur so far up the rpm range on this big-inch motor, the peak torque value is being compromised by lack of sufficient airflow. Don't get me wrong here, the Edelbrock Air-Gap Performer is a great manifold. If, twenty years ago, you had asked a pro engine builder whether a two-plane intake could be made to support even 500 hp, the answer would have been, "not a chance." If we want to see that 5 to 10 lb-ft of increase, then it's a case of using a cam about 10-degrees shorter to move the powerband down into a range more suited to the intake.

So, as good as the Edelbrock two-plane may be, our next tests will show if there is any substance to our theory that this engine just needs more induction capacity.

Single-Plane Test

The first move was to swap out the two-plane intake for the single-plane Holley Dominator. On top of this went the basic mildly-modified 750 with calibrations deemed necessary for the single-plane setup. Although output below 4,500 rpm dropped, this 408 came on strong from there on up. Peak torque went up to 516 lb-ft, and peak hp to 572. That was good, but the carb capacity still looked a little on the weak side for this deep-breathing 408. To check and see if this was so, the 900-cfm 750 (with the 850 baseplate) was installed. Presto! 526 lb-ft and 579 hp. We are starting to look good here. Now working on the assumption that if some is good, and more is better, the 930-cfm (modified 850) might be just right, so it was installed. Result: 534 lb-ft and 587 hp.

At this point, you can see we are closely approaching our target 600 hp. The problem is, we have now used our biggest carb, but as often as not, a 2-inch spacer on an engine of this size can make the carb look bigger, so that was the next move. This resulted in a best of 541 lb-ft and 595.4 hp. Seeing as our 600hp target was so close, our next move would have been to do a little stagger jetting and change the oil for a good synthetic. That would have almost certainly given us the 600 hp we were looking for, but time was against us.

It's worth looking at our graph comparing the output with the two-plane against the output with the single-plane. In round terms, the Air-Gap Performer produced 45 lb-ft more down low, whereas the Strip Dominator produced 45 hp more at the top end. As can be seen from the graph, the crossover point was a shade over 4,500 rpm. As far as the valvetrain went, this COMP solid street roller ran like a 595hp Swiss watch at 6,800 rpm, and valvetrain noise at idle for our diligently lashed system was barely any more than a typical high-performance hydraulic. As for the AFR heads, they proved to be capable of feeding the 408 inches produced by the K1 crank and rods, and Mahle pistons.

At the end of the day, it has to be said that over 540 lb-ft and nearly 600 hp from a bolt-together engine running on pump gas is nothing to sneeze at. Of course, all these great results are academic if the cost of producing them is out of sight. All this comes in at a reasonable budget: T&L offers a turnkey replica of this engine complete with dyno sheet for less than $6,750, and that's well short of the big-block territory that a 600hp pump-gas friendly engine normally requires.