Some hobbyists have no qualms pushing the envelope when attempting to maximize the performance of a combination, and that can include any component of the drivetrain. Without careful attention to detail, however, one can create a temperamental vehicle that's unhappy cruising at any speed and/or an engine unwilling to run on pump gas. Few can then blame such owners who are reluctant to venture far from home, fearing major malfunction or the inability to find quality fuel on the open road.

There are others, however, who wish to combine strong performance and a low-maintenance design. Though it may ultimately cost a few horsepower, the result is usually an engine that can be driven any distance or speed while happily operating on marginal-quality fuel. If this sounds desirable, then a powerplant like that featured here is for you. Follow along as we document the assembly of a 474ci engine that produces high horsepower on ordinary pump gas.

Buildup Basics

Dave Hall of Restore A Musclecar in Lincoln, Nebraska, explains to HPP his desire to boost the performance of his company's flagship show car. "Our '77 Trans Am gets driven long distances on events like the Bandit Run, and our technician, Gary Otto, rebuilt its T/A 6.6 engine during the total restoration a few years back. He mildly ported the original 6X-4 cylinder heads and added a Performer RPM intake manifold and Demon carburetor. The roller camshaft and rocker arms came from Butler Performance."

Of the combination, Dave states, "It runs pretty well, especially with headers, a five-speed manual transmission, and deep rear gears, but we kept the engine build somewhat mild because of its intended usage." The company went all out with the suspension and brakes, and the T/A's looks and sound seemed to draw attention, but it became quickly evident that its straight line performance prowess didn't match its heavily modified, corner-carving image.

Hall sought the expertise of Butler Performance in Leoma, Tennessee, and explained his goals to David Butler. "I wanted something that produced around 550-600 hp using a stock Pontiac block," he says. "I also told him that the combination needed to be suitable for in-town cruising or cross-country trips, and that meant that power brakes and air conditioning were a must.

"He laid out a 474ci combination that would suit our needs using a spare 455 block I had. He then provided us with virtually everything necessary to assemble the long-block, including a complete rotating assembly with forged components."

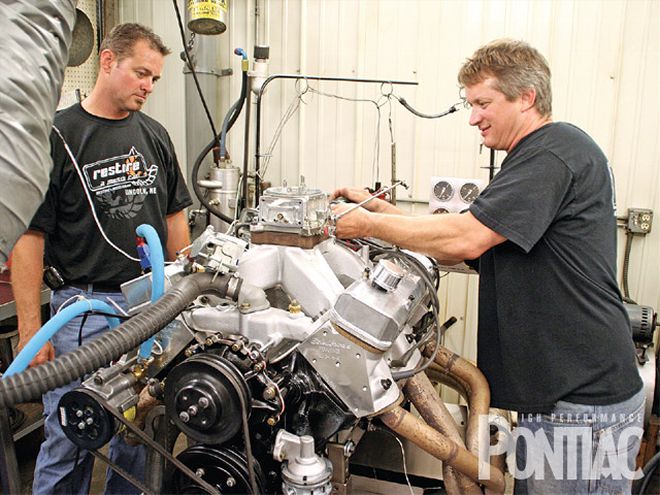

Starting with a two-bolt '71 455ci block and working with the measurements that Butler supplied, Hall had machinist Jon Wischmann prepare the block to accommodate the waiting internals. After complete machining, technician Gary Otto assembled the short-block with relative ease. "We checked all the clearances along the way, and everything was within the stated specifications," he adds. Once the 474ci was fully assembled, Hall and his crew gathered at Spanel Engines in Lincoln for dyno tuning.

A series of eight pulls were made on the Superflow SF-901 dyno, and most consisted of unique timing and/or carburetor settings. All numbers were corrected to standard conditions, and at the end of the session, the mill had peaked at an astounding 578 hp and 588 lb-ft of torque using 92-octane fuel-well within Hall's request of Butler.

Analyzing The Results

After digesting the results, David Butler comments, "The numbers look very good. We've seen 600 hp and 600 lb-ft of torque, sometimes slightly more from this combination with compression toward 11.5:1, which should operate suitably on 92- to 93-octane fuel with the aluminum heads. This wasn't a 'dyno' combo, however, which might typically include borderline compression, a huge camshaft, and a large carburetor. Instead, we took a conservative approach based on the vehicle's intended use."

He continues, "We knew the engine would operate on 89-octane at times, so we limited its compression ratio to just under 10:1. Wisely, 92-octane was used during the dyno session, and this is likely why it peaked with 42 degrees of total timing instead of the normal 36-38 we see when combining Edelbrock heads with 92-octane fuel. I'm confident it will produce similar peak power numbers with less timing when running on 89-octane; I suggest that timing be set to 38 degrees in those conditions."

Butler says he's pleased to see horsepower peak at 5,500 rpm-a relatively low number for a combination such as this. "It carried over 530 lb-ft of torque for nearly the entire pull, and that should make for a great street engine that can be driven in any situation with little to no maintenance. I think the team at Restore A Muscle Car will be very happy with this combination."

Hall contends, "I really didn't know what to expect going into the dyno session. There are countless factors that can affect the outcome, but we've always had great support from the team at Butler Performance, and David was there to assist every step of the way. I'm very pleased with the results, especially knowing that I can pull into any gas station, fill the tank with 89-octane fuel, and still produce that much horsepower. It's certainly a combination we'll offer to our customers."

Conclusion

While additional compression and extended camshaft duration and valve lift might yield greater output from the 474ci, few will argue that 578 hp and 588 lb-ft of torque aren't impressive, particularly when considering the parameters set forth. Once installed, it should perform admirably in virtually any condition while maintaining excellent drivability at all speeds, and that's exactly what this customer ordered.

A point to keep in mind about our feature build is that not only does it highlight the power a moderately built Pontiac produces, it also proves that hobbyists needn't be professional engine builders to achieve such results. With precise block machining, any technician or competent hobbyist can assemble a large-cube mill like this with minimal effort-and seeing it generate 578 hp makes that effort worthwhile.

Engine Buildup WorksheetEngineEngine Displacement473.5 ciPeak Horsepower578 at 5,500 rpmPeak Torque588 lb-ft at 4,700 rpmBore/Stroke4.212x4.25-inBore/Stroke Ratio0.991:1Rod/Stroke Ratio1.60:1 Bottom EndBlock DescriptionYC-code No. 485428Year’71Block PreparationBored 0.060-inDeck HeightZeroCrankshaftButler Performance, forged-steel, 4.25-in stroke, 3.25-in main journal, 2.20-in rod journalCrank PreparationNormal Main CapsPro-Gram Engineering, No. PRO-P455F front, No. PRO-P455C center three, No. PRO-P455R rearMain Bearing Clearance0.003 inBalancerPerformance Street Balancer No. PBO-PB1056STRodsEagle Specialty Products, forged-steel, H-beam, 6.800-in length, 7/16-in ARP boltsBearingsFederal Mogul No. 151M-STD main journal, Federal Mogul 8-7200CH-STD rod journalPistonRoss custom, forged-aluminum, 4.211-in diameter, flat-top, 439.5 grams, 8.5cc reliefsPiston to Deck HeightZeroPiston PinsFerrea No. P70028-8, forged-alloy, 0.990-in diameter, 138 grams Piston RingsTotal Seal No. CR3455-65, plasma-moly, file-fit, 0.018-in gapFastenersARP 194-5601 four-bolt main-stud kitBalancedYes Oiling SystemNoNoCanton No. 15-450, road-raceMelling M54FShell Rotella 30W HeadsCasting NumberEdelbrock No. 60569-2ChamberOpen, hand-smoothedCombustion Chamber Volume90 cc’sCompression Ratio9.95:1Head ModsFully ported intake and exhaust portsIntake Port VolumeApprox. 220 cc’sIntake/Exhaust Flow Ratio75 percent Intake/Exhaust Flow at 28-in:0.200 140/86 cfm0.300201/173 cfm0.400258/199 cfm0.500292/217 cfm0.600312/230 cfm0.700316/236 cfmIntake ValveFerrea No. 5073, stainless steel, 2.11-in, 5.100-in lengthExhaust ValveFerrea No. 5144, stainless steel, 1.77-in, 5.100-in lengthAnglesMulti-angle with 45-deg seatsRetainersComp Cams No. 740-16, 10 degLocksComp Cams No. 611-16, 10 deg ValvespringsLunati No. 73100-16 Install Height1.79 inSeat Pressure137 psiOpen Pressure338 psiValveguidesBronze, 0.530-in diameterValve SealsVitonRocker StudsARP No. 100-7101, 7/16-inRocker ArmsComp Cams No. 19060, full rollerRocker Ratio1.5:1 PushrodsButler Performance No. SBR-581-R-16, 5/16-in diameter, 8.80-in length, chrome-molyFastenersARP No. 190-3605 head-bolt kit CamBrandComp Cams custom Butler grindTypeHydraulic rollerDuration at 0.050242/248-degLift0.540/0.562-in with 1.5:1 rockers Intake CenterlineInstalled at 106.5 degLobe Separation Angle110 degLiftersComp Cams No. 857-16Timing SetButler Performance No. JPP-5614LB-5, 0.005-in undersized, nine-way adjustableTiming Chain TypeBillet-steel roller Distributor Driven GearBOP No. PDG38, polymer, for MSD distributor InductionCarbBarry Grant DemonSize850 cfmModsNoneJets Front/RearNo. 81/89Fuel PumpRobbMc No. 1006Intake ManifoldEdelbrock Victor No. 2957, modified by Butler PerformanceSpacer1-in phenolic, open designFuel Used for Test92-octane BP IgnitionDistributorMSD Billet HEICoilMSD in-cap WiresMSD 8mmTotal Timing40 degSpark PlugsNGK No. R5671A-7, gapped at 0.050 in ExhaustHeadersDoug’s four-tubePrimary Diameter1.75-inCollector3.00-in GasketsBrandNo. SPM-KSX703-74, complete Pontiac overhaul At The DynoConditionsActual Air temp 74 deg F; Baro: 28.59-in of Hg; Humidity: 45 percentCorrected ToAir temp: 60 deg F; Baro: 29.92-in of Hg; Humidity: dryWater Temp195-degOil Temp195-deg Corrected Dyno ResultsRPMHPTorque3,1003155333,2003265353,3003365353,4003435303,5003525283,6003615273,7003725283,8003855323,9004115544,0004345704,1004465724,2004595754,3004785834,4004895844,5004975804,6005135864,7005275884,8005355854,9005475875,0005545825,1005615785,2005665725,3005745695,4005755595,5005785525,6005715355,700572527Pull Log

Average Horsepower/Torque from 3,200 to 5,600 rpm